Technical Contents

Engineering Guide: Custom Plastic Molding Company

Engineering Insight Precision as the Non-Negotiable Foundation in Custom Plastic Molding

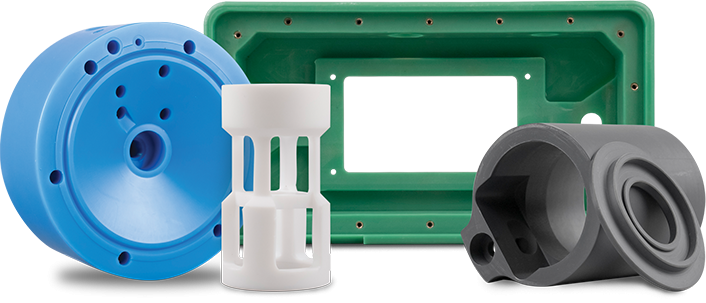

In custom plastic molding, achieving dimensional accuracy and part consistency is not merely desirable; it is an absolute prerequisite for functional reliability and cost-effective production. Minute deviations in mold geometry or process control directly translate to defective parts, assembly failures, compromised product lifespans, and significant waste. The complexity of modern plastic components—featuring micro-features, thin walls, and stringent surface finishes—demands metal tooling and machinery operating at the very edge of manufacturing capability. Tolerances measured in microns are standard, not exceptional. Any instability in the metal components forming the mold cavity, core, or critical machine elements like platens and tie bars cascades into part variation, undermining the entire molding process. This reality places immense responsibility on the precision engineering and fabrication of the metal systems enabling plastic molding.

Wuxi Lead Precision Machinery operates at this critical intersection. While we specialize in custom metal manufacturing, our expertise is fundamental to the success of high-end plastic molding operations globally. We engineer and produce the ultra-precise metal components—mold bases, inserts, precision-guided ejector systems, and custom machine elements—that form the rigid, stable foundation upon which consistent plastic molding depends. Our commitment to micron-level accuracy is proven in applications where failure is not an option. We have supplied mission-critical metal components for timing systems in Olympic events, demanding absolute repeatability under intense scrutiny, and for specialized military equipment, where environmental extremes and zero-failure requirements dictate uncompromising precision standards. This heritage directly informs our approach to supporting plastic molding partners: we understand that the metal backbone must be flawless.

The performance of plastic molding machinery hinges on the precision of its core metal structures. Below are key specifications we consistently achieve for critical components, directly impacting mold stability and part quality:

| Specification Parameter | Typical Capability | Relevance to Plastic Molding |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Ensures mold cavity/core alignment, preventing flash and dimensional drift in parts |

| Surface Flatness | ≤ 0.001 mm per 100 mm | Critical for mold parting lines and sealing surfaces, eliminating leaks and flash |

| Thermal Stability (ΔL/L) | ≤ 5 ppm/°C | Minimizes thermal growth effects during molding cycles, maintaining consistent cavity dimensions |

| Repeatability (Positioning) | ±0.001 mm | Guarantees consistent mold closing force and part ejection, vital for high-cavity molds |

| Material Hardness (HRC) | 50-60 (Custom Alloy Steels) | Provides wear resistance for long mold life under high pressure and abrasive materials |

Partnering with a metal manufacturer possessing deep precision engineering discipline and proven experience in the most demanding sectors is essential. At Wuxi Lead Precision Machinery, we translate our expertise in Olympic and military-grade metal fabrication into the reliable, high-performance tooling components that enable custom plastic molding companies to achieve true consistency, reduce scrap, and deliver parts meeting the most rigorous specifications. Precision in the metal foundation is the silent guarantee of success in the plastic molding process.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

Wuxi Lead Precision Machinery delivers exceptional technical expertise in custom metal manufacturing, serving high-performance industries including aerospace, medical, automotive, and industrial automation. Our core strength lies in the integration of advanced 5-axis CNC machining technology with rigorous quality control protocols, enabling the production of complex, high-precision components to exacting client specifications. With a focus on repeatability, accuracy, and material efficiency, our manufacturing processes are engineered to meet the most demanding engineering challenges.

Our 5-axis CNC machining centers provide unparalleled flexibility in component geometry, allowing for simultaneous multi-directional cutting. This eliminates the need for multiple setups, reducing cumulative error and significantly improving dimensional accuracy. The ability to approach a workpiece from virtually any angle ensures superior surface finish and the capacity to machine intricate contours, undercuts, and deep cavities—features often required in mission-critical applications. We work with a wide range of engineering metals, including aluminum alloys, stainless steel, titanium, tool steels, and specialty alloys such as Inconel and brass, supporting both prototyping and high-volume production runs.

Precision is at the heart of our operations. Every component undergoes comprehensive dimensional verification using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems. These systems provide micron-level accuracy in measuring geometric features, ensuring full compliance with GD&T (Geometric Dimensioning and Tolerancing) standards. Our CMMs are integrated into the production workflow, enabling real-time quality feedback and process adjustments. All inspection reports are documented and traceable, meeting ISO 9001 standards and customer-specific quality requirements.

To maintain consistency and performance across all production batches, we enforce strict environmental controls in our machining and inspection areas, minimizing thermal drift and external variables. Our skilled engineers and machinists are trained in advanced CNC programming, toolpath optimization, and metrology, ensuring every part meets the highest benchmarks for quality and performance.

The table below outlines the standard capabilities and achievable tolerances across our production platform.

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Positional Accuracy | ±0.005 mm |

| Linear Tolerance | ±0.01 mm (typical), down to ±0.002 mm (tight) |

| Geometric Tolerance (GD&T) | ±0.01 mm (form and position) |

| Surface Roughness (Ra) | 0.8 µm (standard), down to 0.2 µm (polished) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Minimum Feature Size | 0.5 mm (internal radii, slots) |

| Material Compatibility | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, etc. |

| Inspection Equipment | Zeiss and Mitutoyo CMM Systems |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP support |

Wuxi Lead Precision Machinery combines cutting-edge technology with disciplined engineering practices to deliver custom metal components that meet the highest performance standards. Our technical capabilities are designed to support innovation, reduce lead times, and ensure long-term reliability in the most challenging applications.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, our engineering team evaluates mechanical properties, environmental exposure, and functional requirements to match your application with the ideal metal substrate. This ensures components meet stringent aerospace, medical, and industrial tolerances while minimizing lifecycle costs. Below we detail critical considerations for aluminum, steel, and titanium alloys, alongside essential finishing protocols.

Aluminum Alloys dominate lightweight structural applications requiring high strength-to-weight ratios and thermal conductivity. Series 6000 alloys like 6061-T6 offer excellent machinability and weldability for enclosures and brackets, while 7075-T6 provides superior strength for aerospace fittings. Aluminum’s natural corrosion resistance is significantly enhanced through anodizing, making it ideal for outdoor or marine environments.

Stainless Steel is indispensable for applications demanding extreme corrosion resistance and high-temperature stability. Austenitic grades 304 and 316 excel in medical and food processing equipment due to non-reactive surfaces, while 17-4 PH precipitation-hardening steel delivers exceptional strength for hydraulic manifolds and valve bodies. Proper passivation is mandatory to maximize corrosion resistance in critical environments.

Titanium Alloys such as Grade 5 (Ti-6Al-4V) are reserved for mission-critical components where unparalleled strength, biocompatibility, and resistance to extreme temperatures are non-negotiable. Common in aerospace landing gear and surgical implants, titanium requires specialized machining parameters due to its low thermal conductivity and high reactivity during cutting.

Anodizing: The Critical Finishing Process

Anodizing is non-negotiable for aluminum components exposed to wear or corrosive elements. This electrochemical process thickens the natural oxide layer, creating a durable, non-conductive surface. Type II (sulfuric acid) anodizing provides standard corrosion resistance and dye acceptance for aesthetic or identification purposes. For severe industrial use, Type III (hardcoat) anodizing delivers abrasion resistance exceeding 60 HRC, essential for hydraulic pistons or aerospace bushings. All anodized parts at Wuxi Lead undergo rigorous ASTM B137 sealant verification to ensure pore closure and longevity.

Material performance specifications are summarized below for rapid comparison:

| Material | Key Properties | Common Grades | Primary Applications |

|---|---|---|---|

| Aluminum Alloys | Lightweight, high thermal conductivity | 6061-T6, 7075-T6 | Enclosures, brackets, heat sinks |

| Stainless Steel | Corrosion resistance, high strength | 304, 316, 17-4 PH | Medical devices, valves, pumps |

| Titanium Alloys | Extreme strength-to-weight, biocompatible | Grade 2, Grade 5 | Aerospace fittings, surgical implants |

Material selection directly impacts manufacturability, total cost of ownership, and field performance. Wuxi Lead’s engineering team collaborates early in your design phase to validate material suitability against operational stresses, ensuring your components exceed performance expectations while optimizing production efficiency. Contact our specialists to discuss alloy-specific tolerancing and finishing protocols for your next precision project.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every custom metal manufacturing project begins with meticulous design engineering. Our team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models and technical drawings. Utilizing advanced simulation software, we conduct structural, thermal, and flow analysis to validate performance under real-world conditions. This phase ensures dimensional accuracy, material suitability, and manufacturability long before any physical prototype is produced. Design for Manufacturability (DFM) reviews are standard, minimizing complexity while maximizing functionality and cost-efficiency. All designs comply with international standards including ISO 9001 and AS9100, ensuring traceability and consistency across industries such as aerospace, medical, and high-end automation.

Prototyping: Validating Performance with Zero Tolerance for Error

Once the design is finalized, we move to precision prototyping using CNC machining, wire EDM, and multi-axis milling technologies. These methods allow us to produce functional prototypes from the actual production-grade materials, enabling accurate testing of fit, form, and function. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. We perform first article inspections (FAI) and generate comprehensive reports detailing all critical-to-quality (CTQ) characteristics. Feedback from testing is integrated rapidly, allowing for iterative improvements within days—not weeks. This agile validation process ensures that design flaws are eliminated early, reducing risk during full-scale production.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into high-volume manufacturing. Our fully automated production lines are monitored in real time using IoT-enabled sensors and Statistical Process Control (SPC) systems. Every component is traceable through a digital twin system, logging process parameters, inspection data, and operator inputs. We employ in-line vision systems and automated gauging to detect deviations instantly, triggering corrective actions before non-conformances occur. Our zero-defect philosophy is enforced through layered quality audits, preventive maintenance schedules, and operator certification programs. Production outputs are regularly validated against initial prototypes to ensure consistency across batches.

Material & Process Specifications

| Parameter | Specification |

|---|---|

| Materials | Aluminum Alloys (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass |

| Tolerances | ±0.005 mm (standard), ±0.001 mm (tight-tolerance applications) |

| Surface Finish | Ra 0.2 µm to 3.2 µm (custom finishes available) |

| Max Part Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | Up to 500,000 units/month with multi-shift operations |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS, REACH compliant |

| Lead Time (Mass Prod) | 4–8 weeks, depending on complexity and volume |

Through integrated design, validated prototyping, and intelligent mass production, Wuxi Lead Precision Machinery delivers custom metal components with uncompromising quality—ensuring zero defects and total client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

In high-stakes custom plastic molding, the performance and longevity of your tooling and support components directly dictate output quality, production uptime, and total cost of ownership. Substandard metal parts introduce dimensional instability, thermal management failures, and premature wear—compromising every molded unit. Wuxi Lead Precision Machinery delivers the uncompromising metal manufacturing foundation your plastic molding operations demand. We engineer precision metal solutions where tolerances of ±0.001mm and material integrity are non-negotiable, ensuring your molds, inserts, and fixtures perform flawlessly under continuous industrial stress.

Our integrated approach combines advanced CNC milling, turning, and grinding capabilities with rigorous in-process metrology. Every component undergoes 100% inspection against your exact specifications using calibrated CMMs and optical comparators, eliminating guesswork and scrap. We specialize in challenging alloys including H13 tool steel, stainless 420, and beryllium copper—materials critical for thermal conductivity, corrosion resistance, and wear longevity in demanding molding environments. Our facility operates under ISO 9001:2015 protocols with real-time SPC data tracking, guaranteeing repeatable accuracy from prototype to high-volume production.

| Capability | Specification | Relevance to Plastic Molding |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Ensures perfect mold cavity alignment |

| Surface Finish | Ra 0.1 µm (4 µin) achievable | Prevents part sticking and surface defects |

| Max Work Envelope | 1200 x 800 x 650 mm (47 x 31 x 26″) | Supports large mold bases and frames |

| Material Expertise | Tool steels, stainless, aluminum alloys | Optimizes thermal cycling and durability |

| Lead Time (Typical) | 15-25 days for complex components | Reduces mold commissioning delays |

Choosing Wuxi Lead means partnering with engineers who speak the language of plastic molding. We collaborate early in your design phase to identify potential manufacturability issues, recommend material optimizations for specific resins, and validate thermal performance through simulation. Our clients report 30% fewer mold repairs and 22% longer service life on critical wear components—translating directly to lower cost per molded part. When dimensional precision impacts your yield rates and brand reputation, generic metal suppliers cannot deliver the accountability required.

Secure your competitive edge with manufacturing precision engineered for plastic molding excellence. Contact our engineering team directly to discuss your next mold base, insert, or support component. Submit your RFQ with detailed specifications to [email protected]. Our technical sales engineers will provide a feasibility assessment and timeline within 24 business hours. Let Wuxi Lead Precision Machinery become your trusted metal manufacturing partner—where exacting standards meet industrial reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.