Technical Contents

Engineering Guide: Custom Plastic Molded Parts

Engineering Insight Precision Imperatives in Custom Plastic Molded Parts

In custom plastic molding, precision transcends aesthetics or basic functionality it directly determines part performance lifecycle and integration success within complex assemblies. Dimensional instability caused by inconsistent material flow cooling rates or mold deflection leads to critical failures: assemblies that won’t align seals that leak or components that fatigue prematurely. Achieving micron-level tolerances across high-volume production requires mastering the interplay between polymer science mold engineering and process control. Shrinkage warpage and sink marks are not mere cosmetic concerns but indicators of underlying process instability that compromise structural integrity and fit. The cost of imprecision manifests not only in scrap rates but in downstream assembly delays field failures and reputational damage for end products. True precision demands predictive modeling of material behavior under thermal stress and relentless validation against real-world operating conditions.

At Wuxi Lead Precision Machinery we apply the uncompromising standards honed through decades of aerospace defense and Olympic-grade metal component manufacturing to the plastic molding domain. Our engineering philosophy treats plastic not as a commodity material but as a precision engineering medium requiring the same rigor applied to titanium or Inconel. The metrology protocols process validation frameworks and failure mode analysis we developed for mission-critical military hardware and Olympic timing systems directly inform our approach to plastic molding. This cross-material discipline ensures every cavity in a multi-cavity mold performs identically across thousands of cycles. We leverage in-mold pressure sensors real-time thermal imaging and AI-driven process correction to maintain tolerances where competitors see only acceptable variation. Our experience proves that the mindset for zero-defect metal fabrication—rooted in traceability and physics-based process design—is equally vital for high-performance plastics.

The following table outlines critical precision parameters we rigorously control for demanding plastic molded applications:

| Parameter | Standard Tolerance | High-Precision Target | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.1 mm | ±0.025 mm | CMM with Temperature Compensation |

| Flatness | 0.15 mm | 0.05 mm | Optical Profilometry |

| Hole Position | ±0.08 mm | ±0.02 mm | Vision System with GD&T |

| Wall Thickness Variation | ±5% | ±1.5% | Ultrasonic Thickness Gauge |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Stylus Profilometer |

This precision foundation enables clients to achieve first-article acceptance reduce secondary operations and eliminate assembly line bottlenecks. For medical device housings automotive sensors or robotics components—even minute deviations cascade into system-wide failures. Wuxi Lead’s integrated approach combines polymer-specific simulation with manufacturing execution systems tested in environments where failure is not an option. We translate military-grade discipline into repeatable plastic molding excellence ensuring your components meet not just specifications but the unspoken demands of real-world performance. Partner with us to transform plastic from a cost-driven choice into a precision-engineered asset.

Precision Specs & Tolerances

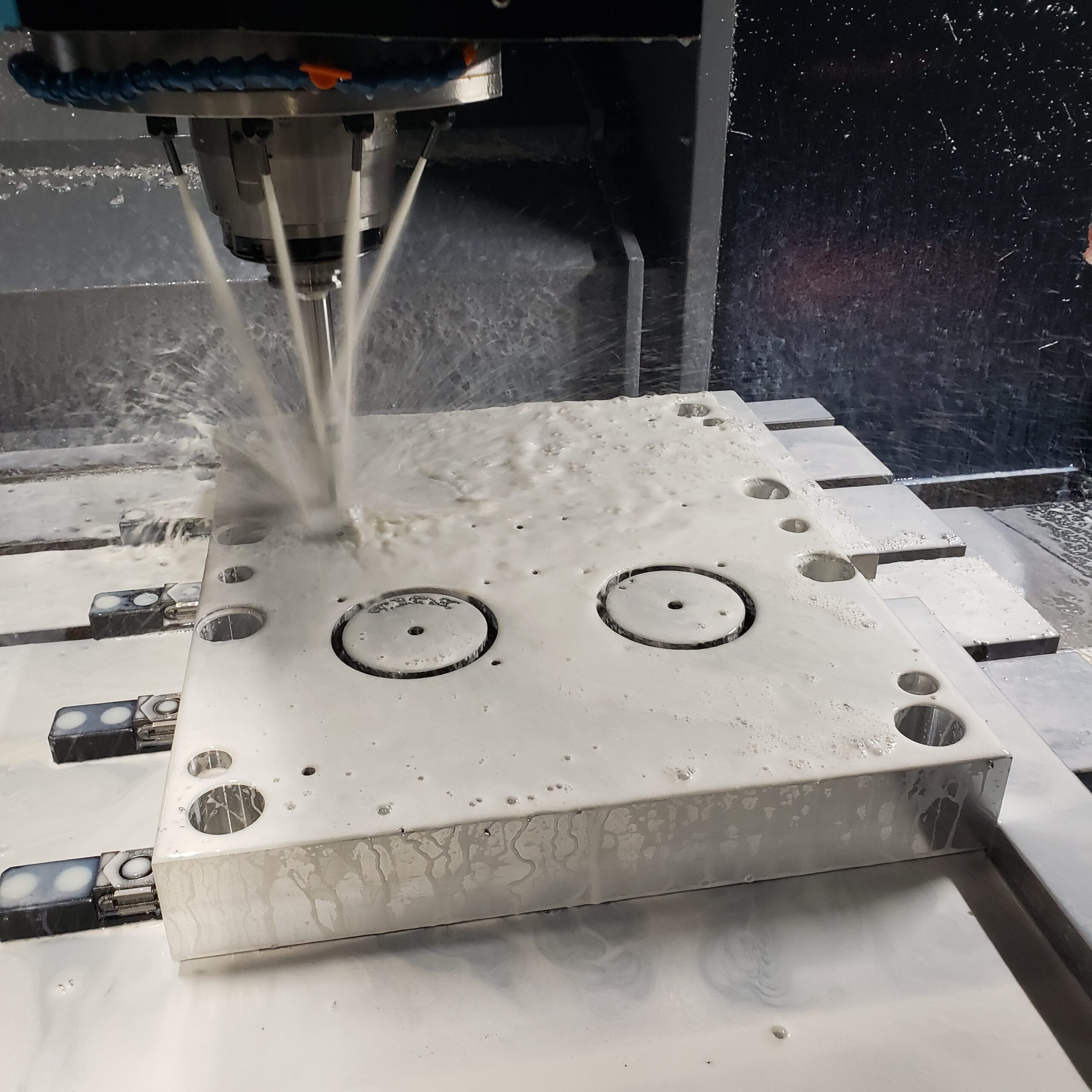

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications. Our expertise extends to the production of custom plastic molded parts through integrated hybrid manufacturing processes, where precision metal tooling and post-processing play a critical role in ensuring final part consistency and performance. Central to our operations is a modern fleet of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring and feature machining—particularly vital when creating molds, inserts, and precision housings used in injection molding of plastic components.

Our 5-axis CNC technology supports a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and tool steels, all commonly used in mold fabrication for plastic parts. This capability ensures that molds and tooling meet the stringent demands of high-volume plastic molding cycles while maintaining dimensional stability and thermal resistance. In addition to mold production, we offer secondary precision machining of metal components that interface directly with custom plastic molded parts, ensuring seamless integration in final assemblies.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes rigorous inspection using a Zeiss Coordinate Measuring Machine (CMM), providing traceable, high-resolution metrology data. The CMM system verifies geometric dimensions, positional tolerances, and surface relationships in full 3D space, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Our quality technicians generate detailed inspection reports for each production batch, offering full documentation for customer review and regulatory compliance.

To maintain consistent output quality, we follow a process-driven approach that includes first-article inspection, in-process checks, and final validation. Our facility operates under ISO 9001-certified quality management protocols, reinforcing our commitment to precision, repeatability, and continuous improvement.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | Precision Capability (Optional) |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Angular Dimensions | ±0.1° | ±0.05° |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Runout | 0.015 mm | 0.005 mm |

These specifications reflect our ability to support high-performance applications in aerospace, medical devices, automation, and advanced electronics—sectors where custom plastic molded parts must interface precisely with metal components. At Wuxi Lead Precision Machinery, we combine advanced CNC technology with metrology-grade quality control to deliver custom metal solutions that ensure the success of your plastic molding projects.

Material & Finish Options

Material Selection for High-Performance Metal Components

Selecting the optimal material is a critical engineering decision impacting component performance, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we guide clients through this process with data-driven insights, ensuring your custom CNC-machined parts meet exact functional and environmental demands. Aluminum, steel, and titanium represent the core material families for precision metal components, each offering distinct advantages for specific applications.

Aluminum alloys, particularly 6061-T6, provide an exceptional strength-to-weight ratio and excellent machinability, making them ideal for aerospace brackets, heat sinks, and consumer electronics housings where weight reduction is paramount. Steel variants like 304 stainless offer superior hardness, wear resistance, and structural integrity for hydraulic manifolds, medical instruments, and marine hardware requiring robust corrosion resistance. Titanium Grade 5 (Ti-6Al-4V) delivers unparalleled strength-to-weight performance and biocompatibility, essential for critical aerospace landing gear, surgical implants, and deep-sea exploration components exposed to extreme stress or corrosive environments. Material choice directly influences machining parameters, tool life, and secondary operations; our engineering team validates material suitability against your load, temperature, and lifecycle requirements before production begins.

The following table summarizes key mechanical properties for common high-end alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | Good (with treatment) | Aerospace, Automotive, Electronics |

| Steel 304 | 8.0 | 515 | 205 | Excellent | Medical, Marine, Food Processing |

| Titanium Grade 5 | 4.43 | 900 | 830 | Exceptional | Aerospace, Medical Implants, Oil & Gas |

Surface finishing is equally vital for performance and compliance. Anodizing is the industry-standard electrochemical process for aluminum, significantly enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides durable decorative and protective finishes for general industrial use, while Type III (hardcoat) anodizing delivers thicker, harder coatings (up to 100µm) for military, aerospace, and high-wear applications requiring extreme abrasion resistance. We strictly control anodizing parameters—including electrolyte concentration, temperature, and current density—to ensure uniform coating thickness, optimal adhesion, and precise color consistency per ASTM B580 and MIL-A-8625 standards. For steel components, passivation or electropolishing is recommended to maximize corrosion resistance, while titanium typically requires specialized chemical treatments like acid etching for biocompatibility.

Material and finish selection must align with your component’s operational environment, regulatory constraints, and lifecycle costs. Wuxi Lead Precision Machinery leverages 15+ years of CNC machining expertise to optimize this decision, preventing costly rework or premature failure. Our engineers collaborate early in your design phase to recommend the most efficient material-finish combination, ensuring your parts perform reliably under real-world conditions while minimizing total production costs. Contact our technical team for a material suitability assessment tailored to your project specifications.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, the production of custom plastic molded parts is executed with the precision and reliability expected in high-end industrial manufacturing. Our process is structured into three core phases: Design, Prototyping, and Mass Production. Each stage is engineered to ensure zero defects, consistent repeatability, and full compliance with international quality standards.

The process begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into manufacturable solutions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and mold flow dynamics. This phase includes comprehensive tolerance analysis, wall thickness evaluation, and gate positioning to prevent warping, sink marks, or voids. Design for manufacturability (DFM) reviews are conducted to eliminate potential production risks before tooling begins.

Next is Prototyping, a critical validation step that ensures design integrity under real-world conditions. We employ rapid tooling and CNC-machined prototype molds to produce functional samples within 10–15 days, depending on complexity. These prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), material performance validation, and fit/function checks in assembly environments. Any identified deviations are addressed through iterative refinement, ensuring the final design is both functional and scalable.

Once the prototype is approved, we transition to Mass Production using high-precision injection molding machines with tight process control. Our facility operates 24/7 with real-time monitoring systems that track pressure, temperature, cycle time, and clamp force. Every production run is supported by Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. In-process quality checks occur at defined intervals, and final inspection includes 100% visual screening and automated metrology for critical dimensions. Our cleanroom molding cells are available for medical and optical-grade components requiring ISO Class 7 or better environments.

Wuxi Lead’s commitment to zero defects is reinforced through full traceability—each batch is logged with material lot numbers, machine parameters, and inspection data. We support annual production volumes from 10,000 to over 5 million units, with lead times as low as 4 weeks for full-scale output.

Key production specifications are summarized below:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on part size and material) |

| Material Compatibility | ABS, PC, POM, PP, PE, PA6/66, PBT, PPS, LCP, PEEK, and medical-grade resins |

| Mold Base Standards | HASCO, DME, or custom |

| Injection Press Capacity | 50–1,200 tons |

| Secondary Operations | Ultrasonic welding, insert molding, pad printing, laser marking, assembly |

| Quality Standards | ISO 9001:2015, IATF 16949, ISO 13485 (for medical) |

| Production Environment | Standard and cleanroom (ISO Class 7–8) options |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures that every custom plastic molded part meets the highest benchmarks in quality, consistency, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

Securing a manufacturing partner capable of delivering precision metal components under exacting global standards is non-negotiable for advanced industrial applications. Wuxi Lead Precision Machinery bridges the gap between complex engineering requirements and flawless execution. We specialize in tight-tolerance CNC machining, milling, and turning of custom metal parts for aerospace, medical, energy, and automation sectors. Our facility in Wuxi, China, operates under ISO 9001 and AS9100 certifications, ensuring every component meets stringent international quality benchmarks. Unlike generic suppliers, we integrate engineering collaboration from prototype to full-scale production, mitigating risks associated with offshore manufacturing through transparent communication and rigorous process validation.

Your project demands more than machinery—it requires expertise in material science, geometric dimensioning, and statistical process control. Our engineers analyze your CAD models to optimize manufacturability, reduce waste, and accelerate time-to-market without compromising integrity. We machine exotic alloys like Inconel 718, titanium Grade 5, and beryllium copper to tolerances unattainable with plastic molding processes, ensuring structural reliability in extreme environments. This precision is critical for hydraulic manifolds, surgical robotics components, and turbine assemblies where failure is not an option.

The following table outlines our core technical capabilities for custom metal components:

| Specification | Capability | Industry Standard | Critical Application Note |

|---|---|---|---|

| Tolerance Range | ±0.005 mm to ±0.05 mm | ISO 2768-mK | Aerospace fuel system interfaces |

| Max Work Envelope | 1200 x 800 x 650 mm | DIN 80601 | Industrial automation frames |

| Material Complexity | Titanium, Inconel, Hastelloy | AMS/ASTM | Chemical processing equipment |

| Surface Finish | Ra 0.2 µm to Ra 3.2 µm | ISO 1302 | Medical implant subassemblies |

| Batch Volume | 1–50,000 units | Lean Production | Prototype to serial production |

Partnering with Lead Precision eliminates supply chain fragmentation. We handle secondary operations in-house—including anodizing, passivation, and precision welding—reducing lead times by 30% compared to multi-vendor approaches. Our real-time quality reporting via cloud-based dashboards provides full traceability from raw bar stock to final inspection, with CMM reports and material certifications delivered electronically. This level of oversight is essential for compliance in regulated industries where audit trails determine market access.

Do not compromise on the foundation of your product’s performance. Contact our engineering team directly to discuss how our metal manufacturing expertise solves your most demanding challenges. Email [email protected] with your project specifications and volume requirements. Include “Custom Metal Components Inquiry” in the subject line for immediate technical review. Our engineers will respond within 4 business hours with a manufacturability assessment and timeline. For urgent RFQs, reference project code LEAD-METAL-2024 to prioritize your submission. Trust Lead Precision to transform precision metal requirements into certified, on-specification reality—where every micron matters.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.