Technical Contents

Engineering Guide: Custom Molding Services

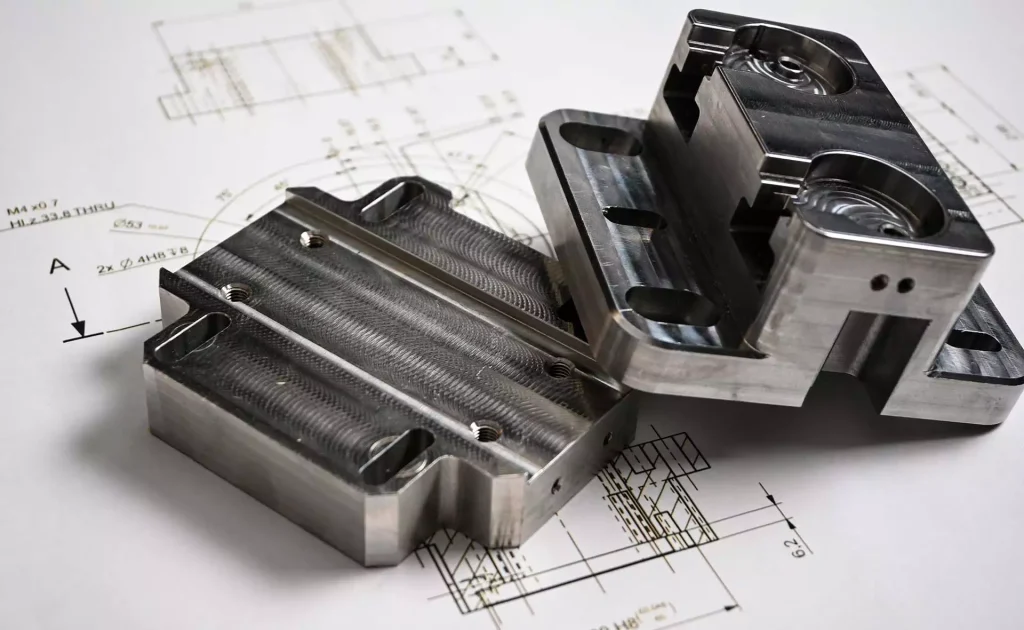

Engineering Insight Precision in Custom Molding Services

Precision is the non-negotiable cornerstone of advanced custom molding services, especially within mission-critical sectors like aerospace defense and high-performance industrial systems. In these applications, dimensional deviations measured in microns directly impact functionality safety and lifecycle durability. A tolerance error of ±0.01mm in a hydraulic manifold for military aircraft can cause catastrophic seal failure under extreme pressure. Similarly sub-micron surface finishes are essential for Olympic-grade timing system components where friction variance alters split-second accuracy. At Wuxi Lead Precision Machinery we treat precision not as a target but as a systemic engineering discipline embedded in every process from material selection to final inspection.

Our approach integrates multi-axis CNC milling wire EDM and precision grinding with real-time metrology. Closed-loop feedback systems continuously adjust machining parameters against CMM and optical comparator data ensuring parts conform to GD&T specifications before leaving the shop floor. This methodology evolved through demanding projects including components for China’s national defense systems and timing infrastructure for the Beijing Winter Olympics. These programs required zero-defect delivery under stringent regulatory audits proving our capability to meet ITAR and AS9100 standards consistently.

Material science expertise further elevates precision outcomes. We match exotic alloys like Inconel 718 and titanium Grade 5 to specific molding applications considering thermal expansion coefficients and stress-relief behaviors during post-processing. For instance military-grade actuators demand stress-relieved machining sequences to prevent warpage after 500+ thermal cycles. Our in-house metallurgical lab validates material properties pre- and post-fabrication eliminating guesswork in performance-critical environments.

The table below summarizes core precision capabilities enabling complex custom molding solutions

| Specification Category | Capability Range | Application Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001mm | Hydraulic manifolds aerospace brackets |

| Surface Finish (Ra) | 0.05µm – 1.6µm | Sealing surfaces optical components |

| Geometric Accuracy | <0.002mm flatness | Sensor mounts optical platforms |

| Material Complexity | Titanium Inconel Kovar | Defense cryogenic systems |

| Max Part Weight | 5000kg | Industrial molding bases |

Beyond technical execution precision engineering demands proactive collaboration. We engage clients during DFM stages to identify tolerance stack-up risks or manufacturability constraints early avoiding costly rework. This consultative model reduced scrap rates by 32% for a leading satellite manufacturer redesigning antenna housings. For custom molding services precision is the language of reliability. Wuxi Lead Precision Machinery delivers it through documented processes proven under the highest-stakes conditions ensuring your components perform exactly as engineered when performance cannot be compromised.

Precision Specs & Tolerances

Advanced Technical Capabilities in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, our custom molding services are engineered to meet the most demanding specifications in high-performance industries such as aerospace, medical devices, automotive, and industrial automation. Central to our manufacturing excellence is our investment in advanced 5-axis CNC machining technology. This state-of-the-art equipment enables us to produce highly complex geometries with exceptional precision, efficiency, and repeatability. Unlike traditional 3-axis systems, our 5-axis CNC centers allow simultaneous movement across five planes, reducing setup times, minimizing human error, and ensuring superior surface finishes. This capability is particularly critical when manufacturing intricate molds, dies, and precision components where tight tolerances and consistent quality are non-negotiable.

Our 5-axis machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain optimal cutting conditions throughout production. This ensures minimal thermal distortion and maximum dimensional accuracy across both prototyping and high-volume production runs. We work with a wide range of metals, including aluminum alloys, stainless steel, titanium, and hardened tool steels, tailoring machining strategies to the material properties and end-use requirements of each component.

To guarantee that every part meets exacting standards, we implement a rigorous quality control process anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide metrology-grade verification of geometric dimensions, positional accuracy, and surface profiles. Each custom molding component undergoes comprehensive inspection protocols, with full traceability and detailed inspection reports provided to clients. This data-driven approach ensures compliance with international standards such as ISO 9001 and AS9100, especially critical in regulated sectors.

We maintain strict environmental controls in our metrology lab to eliminate thermal and vibrational interference during inspection, ensuring measurement repeatability down to the micron level. In addition to CMM, we utilize optical comparators, surface roughness testers, and hardness gauges to validate material and dimensional integrity at every stage of production.

The following table outlines the standard technical specifications and tolerances achievable through our custom molding and precision machining processes

| Parameter | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and geometry |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Verified via CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achievable with fine finishing passes |

| Angular Accuracy | ±0.05° | ±0.02° | Full 5-axis synchronization |

| Feature Repeatability | ±0.01 mm | ±0.008 mm | Over batch sizes up to 10,000 units |

Our technical capabilities are designed not only to meet but exceed the expectations of global OEMs and engineering partners who demand reliability, precision, and consistency in every component produced.

Material & Finish Options

Material Selection for Precision Custom Molding: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material for custom metal molding is critical to achieving performance, longevity, and cost efficiency. At Wuxi Lead Precision Machinery, our engineering team evaluates your application’s mechanical stress, environmental exposure, weight constraints, and functional requirements to prescribe the ideal material solution. This ensures your components meet exacting industry standards while minimizing total production costs.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics molding for their exceptional strength-to-weight ratio and thermal conductivity. These alloys machine cleanly, enabling complex geometries with tight tolerances. While inherently corrosion-resistant, aluminum benefits significantly from anodizing to enhance surface hardness and wear resistance. Steel remains indispensable for high-stress applications like tooling, machinery frames, and hydraulic components. Grades such as 4140 and 17-4 PH offer superior tensile strength and fatigue resistance, especially when heat-treated. Stainless variants (e.g., 304, 316) provide essential corrosion immunity for medical or marine environments but require precise machining parameters to avoid work hardening. Titanium Grade 5 (Ti-6Al-4V) is the premier choice for extreme conditions—think aerospace actuators or biomedical implants—where unparalleled corrosion resistance, biocompatibility, and strength at elevated temperatures are non-negotiable. Its low density reduces weight without sacrificing integrity, though it demands specialized tooling and slower machining cycles due to low thermal conductivity.

The following table summarizes key properties for common molding materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Enclosures, brackets, heat sinks |

| Steel 4140 | 7.85 | 655 | Moderate | Shafts, gears, tooling |

| Stainless 316 | 8.0 | 570 | Excellent | Marine hardware, medical devices |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional | Aircraft components, implants |

Anodizing is a vital finishing process for aluminum components, transforming the surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dye compatibility for color coding. For mission-critical parts, Type III (hardcoat) anodizing delivers thicker coatings (25–50 µm) with Rockwell hardness exceeding 60 HRC, ideal for hydraulic pistons or military hardware exposed to abrasion. Wuxi Lead Precision Machinery controls every parameter—bath chemistry, temperature, voltage, and sealing—to ensure uniform thickness, adhesion, and dimensional stability per ASTM B580 and MIL-A-8625 standards.

Material and finish selection directly impacts yield rates, lifecycle costs, and regulatory compliance. Our engineers collaborate early in your design phase to model material behavior under load, anticipate thermal expansion variances, and validate finish suitability. This proactive approach prevents costly redesigns and accelerates time-to-market. Partner with Wuxi Lead to transform material science into precision-engineered reality.

Wuxi Lead Precision Machinery

Engineered Precision, Delivered Globally

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful custom molding project begins with precision-driven design engineering. Our team collaborates closely with clients to translate initial concepts into technically sound, manufacturable designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we evaluate structural integrity, material behavior, and thermal dynamics to ensure optimal performance under real-world conditions. Design for manufacturability (DFM) principles are applied rigorously to eliminate inefficiencies before tooling begins. This phase includes comprehensive tolerance analysis, material selection guidance, and mold flow simulation for metal forming processes such as die casting, stamping, and precision forging. Our engineers ensure that every geometric feature supports both functional requirements and production scalability, setting the stage for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move into the prototyping phase—where theoretical models meet physical validation. Using CNC machining, rapid tooling, and additive manufacturing where applicable, we produce high-fidelity prototypes that mirror final production quality. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), mechanical stress testing, and surface finish analysis. The goal is not only to verify form, fit, and function but also to identify and resolve any potential production risks early. Clients receive detailed inspection reports and first article testing (FAI) documentation, enabling informed approval before mass production. This iterative validation process is critical to achieving zero defects, as it allows us to fine-tune tooling parameters, material inputs, and process controls under controlled conditions.

Mass Production: Scalable Excellence with Zero-Defect Assurance

With design and prototype approval secured, Wuxi Lead initiates full-scale production using automated, high-precision molding systems monitored by real-time quality control protocols. Our manufacturing floor integrates IoT-enabled machines, statistical process control (SPC), and 100% inline inspection for critical dimensions. Each batch is traceable through our ERP system, ensuring full transparency from raw material to finished component. We maintain strict adherence to ISO 9001 and IATF 16949 standards, with continuous audits and preventive maintenance schedules to minimize variability. Our zero-defect philosophy is enforced through multi-stage quality gates, including pre-production checks, in-process monitoring, and final outgoing inspection.

The following table outlines key production specifications and capabilities:

| Parameter | Capability |

|---|---|

| Tolerance Control | ±0.005 mm |

| Materials Supported | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass |

| Production Capacity | Up to 500,000 units/month |

| Lead Time (Mass Production) | 4–8 weeks (varies by complexity) |

| Quality Standards | ISO 9001, IATF 16949, RoHS, PPAP Level 3 |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, X-ray (for castings) |

Through seamless integration of design intelligence, prototyping rigor, and disciplined mass production, Wuxi Lead Precision Machinery delivers custom molding solutions that meet the highest standards of precision, reliability, and consistency—ensuring zero-defect performance for global industrial clients.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Molding Excellence

In the demanding landscape of precision metal manufacturing, your choice of partner directly impacts product integrity, time-to-market, and long-term operational success. Wuxi Lead Precision Machinery transcends the role of a standard supplier; we function as your dedicated engineering extension, committed to solving complex metal molding challenges with unwavering precision and reliability. Our foundation lies in advanced CNC technology, rigorous quality systems, and deep metallurgical expertise, specifically engineered for high-value, low-to-medium volume custom molding applications where tolerance and repeatability are non-negotiable.

We understand that critical components demand more than just fabrication; they require a partner who anticipates design constraints, material behavior, and production scalability from the earliest stages. Our engineering team collaborates closely with yours during the design for manufacturability (DFM) phase, identifying potential risks and optimizing geometries to ensure flawless execution. This proactive approach eliminates costly iterations and production bottlenecks, safeguarding your project timeline and budget. Our ISO 9001-certified processes, coupled with in-house material testing and real-time process monitoring, guarantee consistent adherence to the most stringent aerospace, medical, and industrial specifications. Intellectual property security is paramount, with all projects handled under strict NDA protocols and secure data management practices.

The technical capability underpinning our partnership is demonstrated through measurable performance metrics:

| Capability | Specification | Application Impact |

|---|---|---|

| Material Range | Aluminum Alloys, Stainless Steels (300/400 Series), Titanium, Inconel, Brass, Bronze | Supports demanding environments requiring corrosion resistance, high strength, or biocompatibility |

| Dimensional Tolerance | ±0.005 mm (0.0002″) standard; ±0.002 mm (0.00008″) achievable | Ensures perfect fit, function, and assembly of critical subcomponents |

| Surface Finish | Ra 0.4 µm (16 µin) standard; mirror finishes achievable | Meets stringent aesthetic and functional requirements for sealing or fluid dynamics |

| Maximum Work Envelope | 1200 x 800 x 650 mm | Accommodates complex, integrated mold components and larger assemblies |

| Core Technology | 5-Axis Milling, High-Speed Machining, Wire EDM | Enables intricate geometries, tight internal features, and superior surface integrity |

Transitioning from concept to certified production is seamless with Lead Precision. Our structured onboarding process begins with a detailed technical consultation to fully understand your application, performance criteria, and regulatory needs. We provide comprehensive project planning, including realistic lead time forecasting and transparent milestone updates. Throughout production, you receive full traceability documentation and have direct access to our engineering support team for any technical queries. We deliver not just parts, but zero-defect components backed by full material certifications and first-article inspection reports, ready for your assembly line.

Elevate your custom molding projects with a partner engineered for precision. Initiate your technical consultation today. Contact our engineering team directly at [email protected] to discuss your specific requirements and discover how Lead Precision ensures your metal components exceed expectations. Let us secure your supply chain with manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.