Technical Contents

Engineering Guide: Custom Molders

Engineering Insight: The Critical Role of Precision in Custom Molding

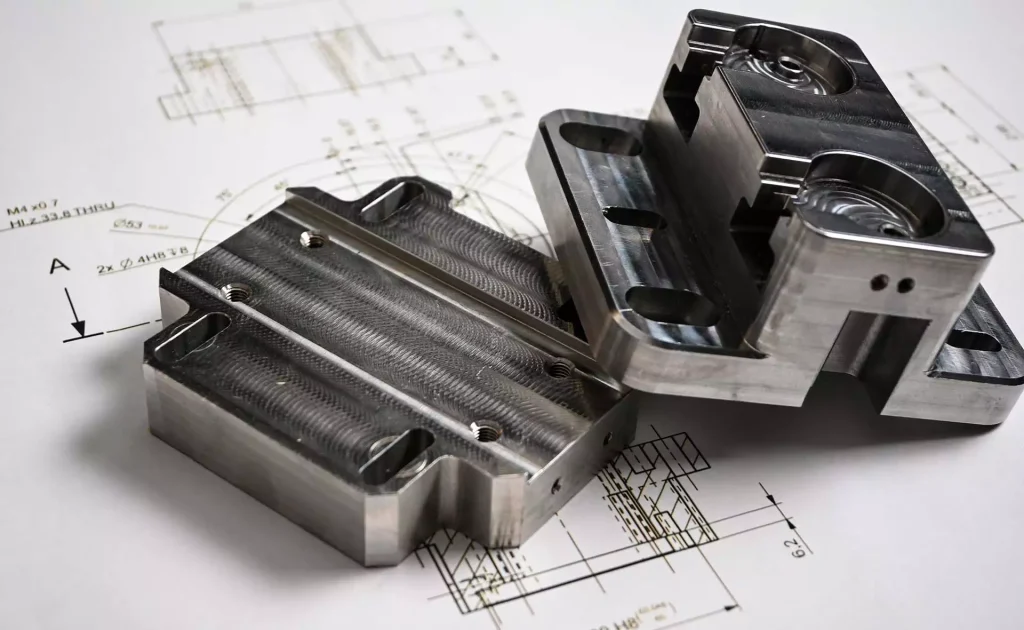

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation of reliability, safety, and long-term value. For custom molders serving high-stakes industries such as aerospace, defense, and advanced industrial equipment, even micron-level deviations can compromise structural integrity, operational efficiency, and regulatory compliance. At Wuxi Lead Precision Machinery, we understand that precision engineering is inseparable from process integrity, material science, and advanced CNC capabilities.

Our experience in delivering mission-critical components for Olympic-grade sports infrastructure and military-grade equipment underscores the uncompromising standards required in precision molding. These projects demanded not only adherence to tight tolerances but also rigorous validation under extreme environmental and mechanical stress. The molds we developed were engineered to maintain dimensional stability across thousands of cycles, ensuring repeatability and consistency in every output.

Custom molders must account for a range of variables—thermal expansion, material flow dynamics, ejection forces, and surface finish requirements. At Lead Precision, we integrate finite element analysis (FEA) and 3D simulation tools at the design stage to predict and mitigate potential defects such as warping, sink marks, or residual stress. This proactive engineering approach reduces trial-and-error iterations, accelerates time-to-market, and enhances overall part quality.

Moreover, the selection of tooling materials and surface treatments plays a decisive role in mold longevity and performance. We utilize high-grade tool steels, including H13 and S136, combined with advanced coatings such as TiN and DLC (Diamond-Like Carbon), to resist wear, corrosion, and thermal fatigue. Our in-house metrology lab, equipped with coordinate measuring machines (CMM) and laser scanning systems, ensures every mold conforms to ISO 2768 and customer-specific inspection criteria before deployment.

The integration of automation and real-time monitoring further elevates precision in production. Closed-loop control systems adjust injection parameters dynamically, compensating for material batch variations and environmental fluctuations. This level of control is essential when producing components for applications where failure is not an option.

Below are key specifications reflecting our precision molding capabilities:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Maximum Mold Weight | 25,000 kg |

| Maximum Shot Weight | 5,000 g |

| Tool Steel Options | H13, S136, 2344, 2714 |

| Surface Finishes | Mirror polish (SPI A1), textured (VDI 3400), matte, etched |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), AS9100 (aerospace) |

| Lead Time (Average) | 6–10 weeks, depending on complexity |

Precision in custom molding is not achieved through machinery alone—it is the result of decades of engineering refinement, disciplined process control, and a deep understanding of application demands. At Wuxi Lead Precision Machinery, our legacy in supporting Olympic and military projects reflects our capacity to deliver under the most stringent requirements. For custom molders seeking a partner committed to excellence, we offer not just manufacturing, but engineered assurance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Molding Applications

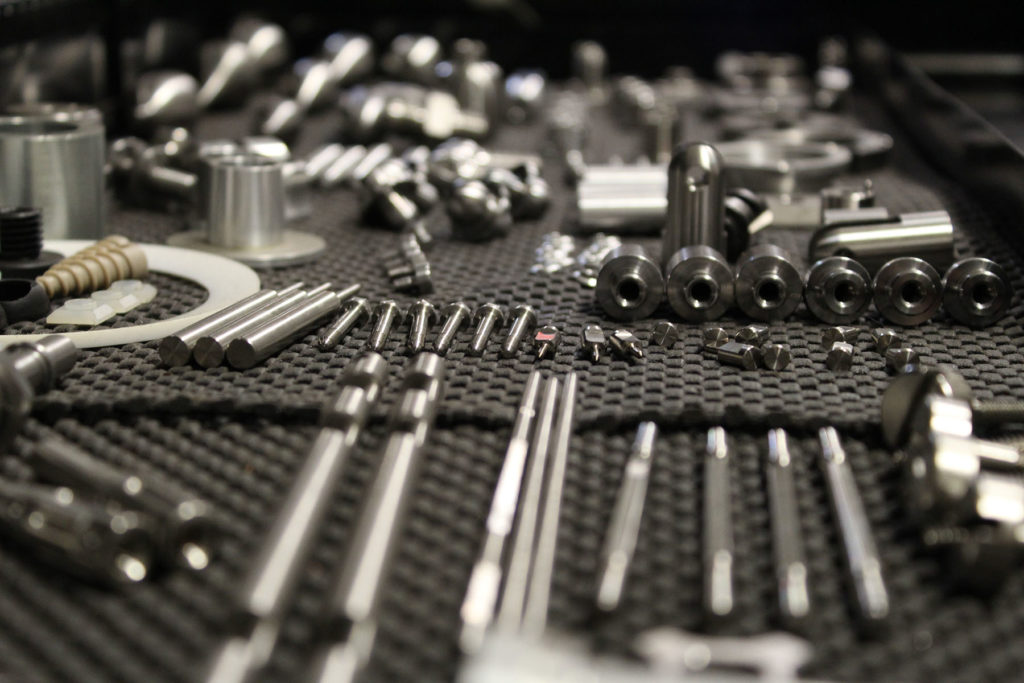

At Wuxi Lead Precision Machinery, we deliver uncompromising precision for custom molders requiring complex metal components. Our integrated technical capabilities center on advanced 5-axis CNC machining and metrology-grade inspection, ensuring every part meets the stringent geometric and dimensional demands of high-performance molding systems. This foundation enables us to produce intricate cores, cavities, inserts, and structural components with exceptional accuracy, surface integrity, and material consistency—critical for mold longevity and part quality in injection, blow, and die-casting processes.

Our 5-axis CNC machining centers (DMG MORI, Makino, and Hermle platforms) provide simultaneous multi-directional toolpath control, eliminating secondary setups and minimizing cumulative error. This capability is essential for molding applications requiring undercuts, organic contours, or deep cavities—such as multi-gate runner systems, textured surfaces, or conformal cooling channels. We machine aerospace-grade aluminum alloys, tool steels (H13, S7, 420SS), and exotic materials like beryllium copper with sub-micron repeatability. Integrated high-speed spindles (up to 30,000 RPM) and rigid toolholding systems ensure optimal surface finishes (Ra ≤ 0.4 µm) directly from the machine, reducing secondary polishing time and preserving critical thermal management geometries.

Complementing our machining prowess is a dedicated Coordinate Measuring Machine (CMM) laboratory operating under ISO/IEC 17025 standards. All critical features undergo full 3D inspection using Zeiss and Hexagon CMMs with probe accuracies of ±1.5 + L/350 µm. Our inspection protocols validate not only dimensional conformance but also geometric tolerances—flatness, concentricity, and profile critical to mold assembly and part ejection. Real-time SPC data is shared with clients via secure portals, providing full traceability from raw material to final shipment. This closed-loop quality process ensures zero-defect delivery for molds operating under extreme thermal cycling and pressure conditions.

The following table details our standard and achievable tolerance capabilities, reflecting typical performance for features under 300 mm. Tighter tolerances are attainable with material-specific process validation and client collaboration.

| Feature Type | Standard Capability | Tight Capability (Consultation Required) |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm |

| Hole Diameter | ±0.008 mm | ±0.002 mm |

| Positional Tolerance | ±0.015 mm | ±0.005 mm |

| Flatness | 0.010 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Features | ±0.005° | ±0.001° |

These capabilities are not theoretical benchmarks but proven standards in our daily operations for mold components serving medical, automotive, and consumer electronics sectors. We partner with custom molders to translate design intent into manufacturable reality—optimizing toolpaths for thermal stability, minimizing residual stress, and ensuring interchangeability across mold sets. Contact our engineering team to discuss how our technical infrastructure resolves your most complex molding challenges.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, directly influencing performance, durability, cost, and manufacturability of end components. For precision molders and OEM partners, understanding the mechanical and chemical properties of aluminum, steel, and titanium ensures optimal part functionality across diverse industrial applications—from aerospace and medical devices to automotive and energy systems. At Wuxi Lead Precision Machinery, we support custom molders with advanced CNC machining and material expertise to deliver high-integrity components tailored to application demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suited for applications requiring lightweight structures without sacrificing structural integrity. The 6061 and 7075 aluminum alloys are commonly specified, with 6075 offering higher strength for demanding environments. Aluminum’s natural corrosion resistance can be significantly enhanced through anodizing, a process that creates a durable, non-conductive oxide layer on the surface. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with Type III providing superior wear and corrosion resistance for high-stress applications.

Steel remains the material of choice when high tensile strength, wear resistance, and dimensional stability are paramount. Tool steels such as H13 and P20 are frequently used in mold making due to their thermal stability and resistance to deformation under repeated cycling. Stainless steels like 304 and 17-4 PH offer excellent corrosion resistance and are ideal for medical and food-grade applications. While steel does not anodize, surface treatments such as nitriding, passivation, and coating (e.g., PVD or electroplating) are employed to enhance surface hardness and longevity.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an exceptional balance of high strength, low density, and outstanding corrosion resistance, especially in extreme environments. It is commonly used in aerospace, defense, and biomedical implants. However, titanium’s low thermal conductivity and high chemical reactivity require specialized machining techniques, including optimized cutting speeds and rigid tooling setups. Surface finishing for titanium typically involves acid etching, sandblasting, or thermal oxidation rather than anodizing, although certain voltage-controlled anodizing processes can yield decorative or mildly protective finishes.

Below is a comparative overview of key material properties and finishing capabilities relevant to custom molders:

| Material | Typical Alloys | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310–570 | 2.7 | Moderate to High | Anodizing (Type II/III), Powder Coat |

| Steel | H13, P20, 304, 17-4 PH | 500–1300 | 7.8–8.0 | Varies by alloy | Nitriding, Passivation, PVD Coating |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | Very High | Sandblasting, Thermal Oxidation |

Selecting the right material and finish requires a holistic assessment of operational environment, load conditions, regulatory requirements, and lifecycle costs. At Wuxi Lead Precision Machinery, we collaborate closely with custom molders to evaluate these factors and apply precision manufacturing techniques that ensure consistency, repeatability, and compliance with international quality standards.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our custom metal manufacturing process for molders is engineered for uncompromising quality and efficiency, ensuring zero defects reach your production line. We move seamlessly from initial concept through rigorous validation to flawless high-volume output, eliminating costly rework and delays inherent in less structured approaches. This disciplined workflow is fundamental to delivering components that meet the exacting demands of advanced molding applications.

The process begins with collaborative Design Engineering. Our team partners directly with your engineers to translate functional requirements into manufacturable designs. We apply advanced GD&T principles and perform comprehensive DFM analysis, identifying potential production vulnerabilities early. Finite element analysis (FEA) validates structural integrity under molding pressures and thermal cycles. This phase establishes the critical dimensional tolerances, material specifications, and surface finish requirements documented in the master manufacturing plan, forming the bedrock of our zero-defect commitment. Clear communication ensures alignment before any metal is cut.

Prototyping & Validation is where theoretical design meets physical reality under controlled conditions. Utilizing high-precision 5-axis CNC milling and wire EDM, we produce functional prototypes from your specified production-grade material. These prototypes undergo exhaustive metrology using calibrated CMMs, optical comparators, and surface profilometers, verifying every critical dimension against the master plan. Rigorous functional testing, including mold flow simulation correlation and pressure testing, confirms performance. This stage is non-negotiable; it validates the design, refines the process parameters, and provides tangible evidence of capability before significant tooling investment. Only prototypes meeting 100% of specifications advance.

Zero-Defect Mass Production leverages the validated process with unwavering discipline. Our ISO 9001-certified facility employs automated CNC cells with real-time in-process monitoring. Statistical Process Control (SPC) tracks key parameters like tool wear, temperature, and dimensional drift, triggering immediate corrective action if trends approach tolerance limits. Every component undergoes 100% automated optical inspection for surface defects and critical feature verification, supplemented by periodic CMM audits. This layered inspection strategy, combined with rigorous material traceability and operator certification, ensures consistent output meeting the highest standards. Defect prevention is systemic, not reactive.

The following table details the core process capabilities underpinning our zero-defect guarantee for custom metal mold components:

| Process Phase | Key Capability | Typical Specification Range | Verification Method |

|---|---|---|---|

| Design Engineering | Geometric Dimensioning & Tolerancing | ±0.005 mm to ±0.05 mm | GD&T Review, FEA Simulation |

| Prototyping | Dimensional Accuracy (CMM) | ±0.002 mm to ±0.01 mm | Zeiss CMM, Optical Comparator |

| Mass Production | Surface Roughness (Ra) | 0.2 µm to 1.6 µm | Surface Profilometer |

| Mass Production | In-Process Dimensional Control (SPC) | Real-time monitoring | Automated Gauging, SPC Charts |

| Final Inspection | 100% Critical Feature Verification | Per customer print | AOI, Manual CMM Spot Check |

This integrated approach—grounded in meticulous design, proven through rigorous prototyping, and executed with disciplined production controls—guarantees components that perform reliably in your molding operations. Wuxi Lead delivers not just parts, but confidence in every cycle.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Metal Manufacturing

When precision, reliability, and technical excellence define your production standards, your choice of manufacturing partner becomes critical. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal components tailored to the exacting demands of global industries including automotive, aerospace, medical devices, and industrial automation. With over 15 years of advanced CNC machining experience, we combine cutting-edge technology with rigorous quality control to ensure every part meets or exceeds your specifications.

Our facility in Wuxi, China, is equipped with state-of-the-art multi-axis CNC machines, Swiss lathes, and high-speed milling centers, enabling us to produce complex geometries with tolerances as tight as ±0.005 mm. We work with a broad range of materials, including aluminum alloys, stainless steel, titanium, brass, and specialty engineering plastics, ensuring compatibility with diverse application requirements. Every stage of production is monitored under ISO 9001-certified processes, with full traceability, in-process inspections, and final QA documentation provided upon request.

What sets us apart is our engineering-first approach. We don’t just manufacture parts—we collaborate. From initial design review to prototyping, material selection, and full-scale production, our team of experienced CNC engineers works closely with your design and manufacturing teams to optimize for performance, cost-efficiency, and manufacturability. Whether you require low-volume prototypes or high-volume production runs, we offer scalable solutions with rapid turnaround times and consistent quality.

We understand that custom molders and OEMs face intense pressure to reduce lead times, maintain compliance, and control costs without sacrificing precision. That’s why we’ve built a reputation for responsive service, transparent communication, and on-time delivery—backed by real-time project tracking and dedicated account support.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining Types | 3-axis to 5-axis milling, turning, milling-turning combo, Swiss machining |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Tolerance Capability | ±0.005 mm typical, up to ±0.002 mm with special processes |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass (C3604), PEEK, PTFE |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, CMM reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (depending on complexity and volume) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to your success. We are ready to support your next high-precision project with technical depth, operational agility, and unwavering quality.

Contact us today at [email protected] to discuss your custom metal manufacturing needs and receive a detailed quotation within 24 hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.