Technical Contents

Engineering Guide: Custom Molded Plastics

Engineering Insight: The Critical Role of Precision in Custom Molded Plastics

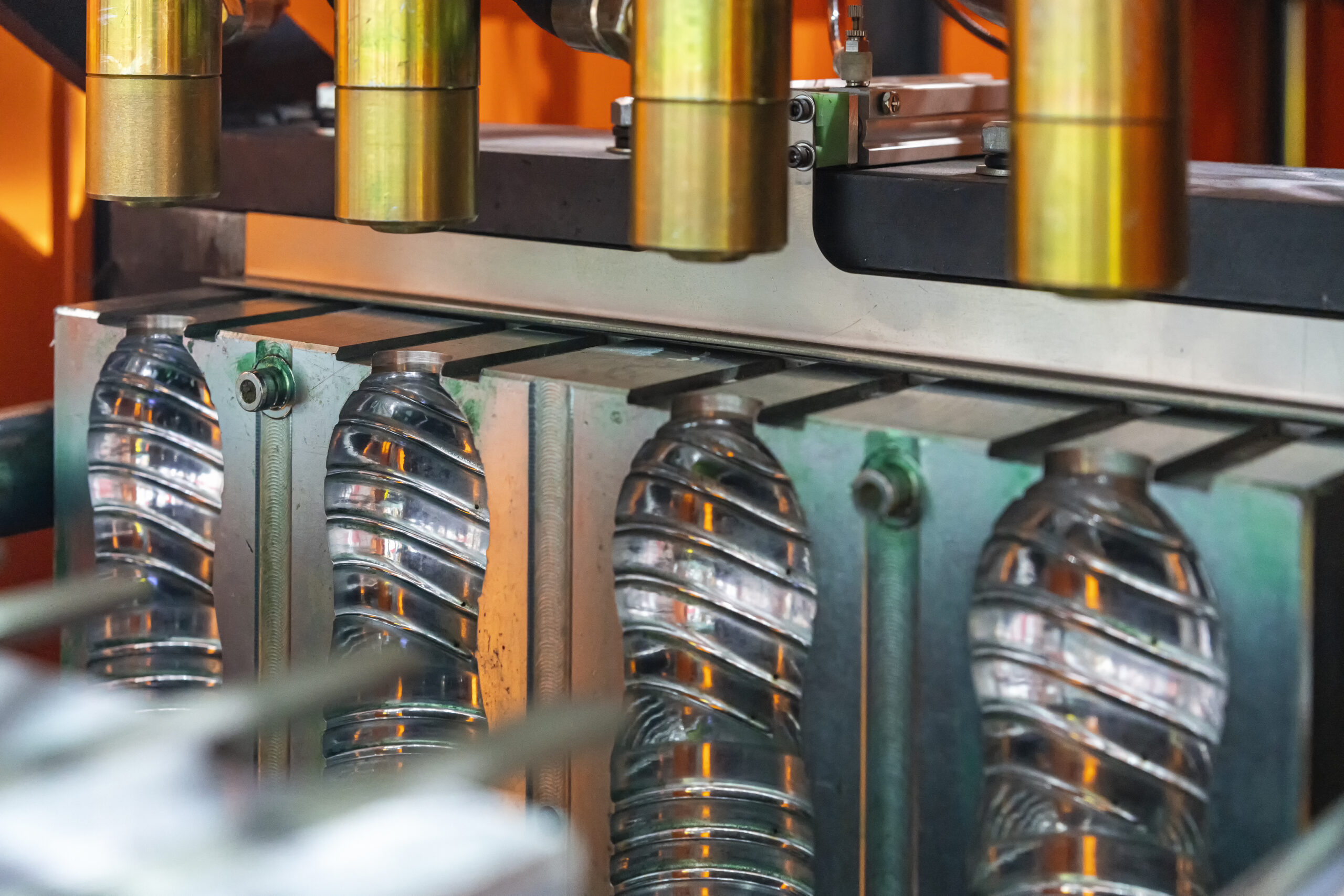

In the realm of high-performance manufacturing, custom molded plastics are no longer just components—they are engineered solutions that demand exacting standards, particularly when integrated into mission-critical systems. At Wuxi Lead Precision Machinery, we approach custom molded plastics not as a standalone process, but as a precision-driven extension of advanced metal manufacturing. Our decades of experience in aerospace, defense, and Olympic-grade equipment development have instilled a culture where tolerances are not negotiated, and consistency is non-negotiable.

Precision in custom molded plastics begins with material science and extends through mold design, tooling integrity, and process control. Even micron-level deviations can compromise part functionality, especially in applications involving sealing, load-bearing, or dynamic movement. For instance, in military-grade enclosures or hydraulic systems used in Olympic training equipment, thermal stability, dimensional accuracy, and repeatability are paramount. A seemingly minor warpage or flash can lead to system failure under operational stress.

Our engineering team leverages closed-loop injection molding systems, in-cavity pressure sensors, and real-time monitoring to maintain tolerances within ±0.005 mm. This level of control is achieved through proprietary mold flow analysis and finite element modeling, ensuring that every cavity fills uniformly and cools predictably. We specialize in high-temperature thermoplastics such as PEEK, PEI, and PPS, as well as reinforced composites, which demand not only precision tooling but also deep material expertise.

What sets Wuxi Lead apart is our integration of metal and plastic manufacturing under one quality umbrella. Many of our custom molded plastic components are designed to interface directly with precision-machined metal parts—actuators, sensors, or structural frames—requiring perfect alignment and thermal compatibility. Our dual competency allows for holistic design optimization, reducing assembly complexity and enhancing long-term reliability.

We have supplied components for Olympic timing systems where microsecond accuracy depends on flawless plastic housings, and for military communication modules where environmental resilience is tested under extreme conditions. These applications demand more than capability—they demand provenance.

The table below outlines key performance specifications achievable through our custom molded plastics process:

| Parameter | Capability | Testing Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.02 mm | ISO 2768-1 |

| Surface Finish (Ra) | 0.1 µm to 1.6 µm | ISO 4287 |

| Material Range | PEEK, PEI, PPS, PPSU, Nylon (GF) | UL94, FDA, RoHS Compliant |

| Mold Accuracy (Cavity-to-Core) | ±0.003 mm | ASME Y14.5 GD&T |

| Production Repeatability (CpK) | ≥1.67 | SPC, IATF 16949 |

| Environmental Resistance | -70°C to +260°C operational range | MIL-STD-810, IP68 |

At Wuxi Lead Precision Machinery, we treat every molded component as a precision system. Our legacy in high-stakes manufacturing drives our commitment to excellence—where every part is engineered to perform, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Component Manufacturing

Wuxi Lead Precision Machinery specializes in high-integrity custom metal component manufacturing, leveraging advanced CNC technology to deliver complex geometries with exceptional repeatability. Contrary to common industry confusion, our core expertise lies in precision metal machining—not plastic molding. We address critical applications where metal’s thermal stability, strength, and conductivity are non-negotiable, such as aerospace actuators, medical surgical tools, and semiconductor tooling. Our facility integrates multi-axis CNC systems with stringent metrology protocols to transform raw billets into mission-critical parts meeting the most demanding specifications.

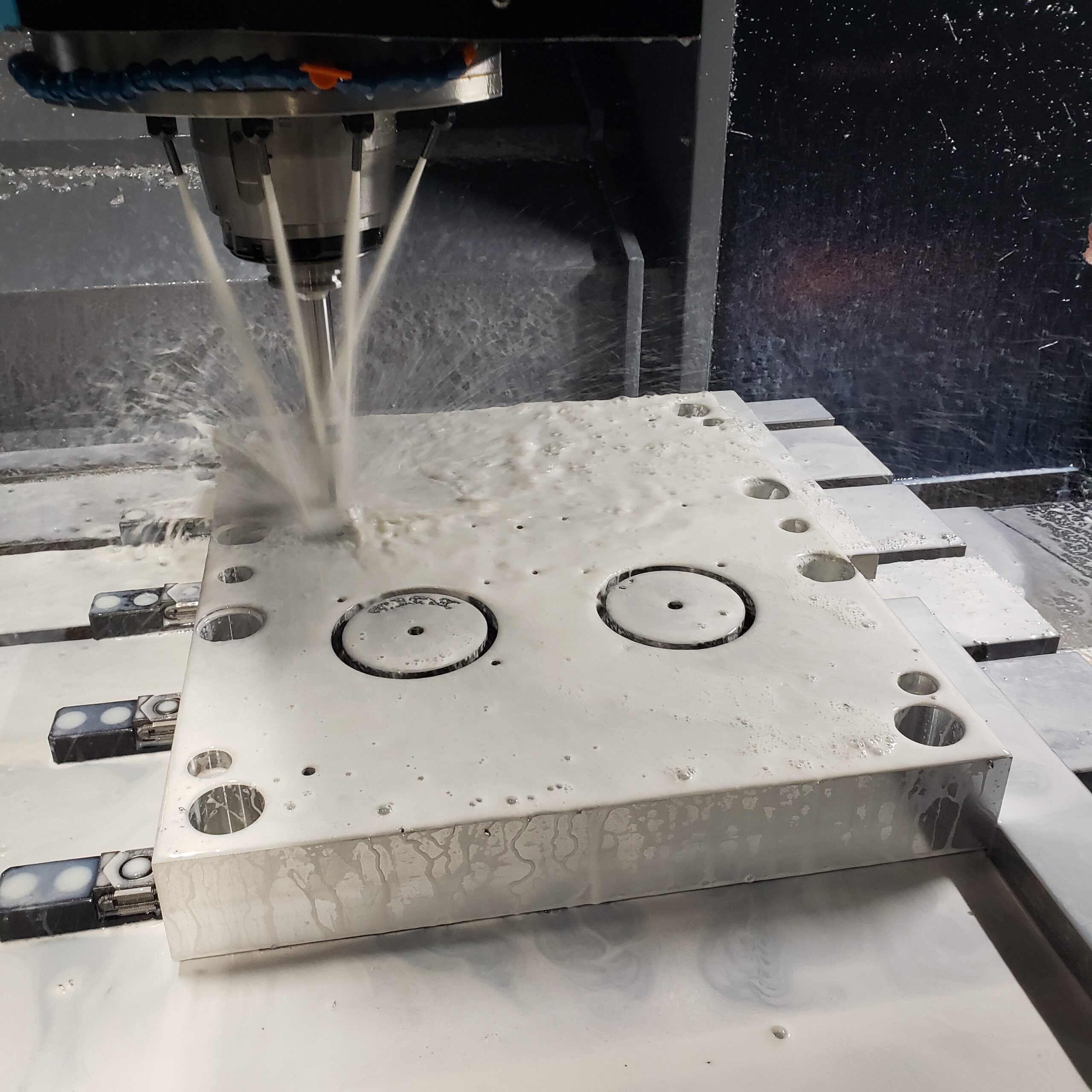

Our technical foundation centers on 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Haas UMC-750 models. These platforms enable single-setup machining of intricate contours, deep cavities, and undercuts, eliminating cumulative error from multiple fixturing stages. Key capabilities include:

Milling and turning of aluminum alloys, titanium, stainless steel, and Inconel up to Ø600 mm diameter and 1,200 mm height. High-speed spindles (12,000–24,000 RPM) ensure fine surface finishes (Ra 0.4 µm standard) while maintaining structural integrity. Advanced toolpath optimization reduces cycle times by 30% compared to conventional 3-axis methods, without compromising dimensional stability.

Quality assurance is non-negotiable. Every production run undergoes full CMM inspection using Zeiss CONTURA and Hexagon GLOBAL S systems, calibrated to ISO 17025 standards. Our quality engineers perform first-article inspections against GD&T callouts per ASME Y14.5, with real-time SPC data tracking for critical features. This closed-loop process ensures batch-to-batch consistency and immediate deviation correction.

Tolerance performance reflects our engineering rigor. The table below details achievable specifications across common materials and feature types:

| Feature Type | Standard Capability | Precision Capability | Verification Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm | CMM, Optical Comparator |

| Geometric Tolerances | ±0.015 mm | ±0.003 mm | CMM (GD&T Analysis) |

| Surface Roughness | Ra 0.8 µm | Ra 0.2 µm | Profilometer |

| Hole Concentricity | Ø0.020 mm | Ø0.005 mm | CMM, Ball Bar |

Material traceability is maintained from raw stock certification through final inspection, with full documentation packages including heat numbers, process sheets, and 3D deviation maps. For extreme applications—such as satellite components requiring ±0.001 mm tolerances—we deploy in-process laser probing and thermal compensation systems to counter environmental variables.

This integrated approach to precision metal manufacturing ensures your components perform reliably in high-stress environments. Wuxi Lead does not outsource critical processes; all machining, finishing, and inspection occur within our ISO 9001:2015-certified facility under direct engineering oversight. Contact our applications team to discuss how our technical capabilities align with your metal component requirements.

Material & Finish Options

Material Selection for Custom Molded Plastics in Precision Metal Manufacturing

When producing custom molded plastics, the selection of mold materials is critical to achieving high repeatability, dimensional accuracy, and extended service life. At Wuxi Lead Precision Machinery, we specialize in precision metal manufacturing for injection molds used in high-volume and mission-critical plastic components. The performance of the mold directly impacts the quality of the final plastic part, making the choice of aluminum, steel, or titanium a strategic decision based on production volume, part complexity, and environmental exposure.

Aluminum is often selected for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. It allows for faster cycle times and reduced wear on CNC tooling during mold fabrication. While not as durable as steel, modern high-grade aluminum alloys—such as 7075 and 6061—offer sufficient strength and wear resistance for thousands of cycles, especially when used with engineering-grade thermoplastics. Aluminum is also ideal for applications requiring rapid turnaround and design validation.

For high-volume production, tool steel—particularly P20, H13, and S136—is the preferred choice. These steels provide superior hardness, wear resistance, and longevity, capable of withstanding millions of injection cycles. P20 steel is commonly used for general-purpose molds with moderate wear requirements, while H13 offers excellent thermal fatigue resistance for hot-runner systems. Stainless tool steels like S136 are corrosion-resistant and ideal for molding halogen-free or medical-grade plastics where surface purity is essential.

Titanium, though less common in standard mold construction, is gaining traction in specialized applications requiring extreme strength-to-weight ratio and corrosion resistance. Its use is typically limited to mold inserts or cores exposed to aggressive environments or where weight reduction in large molds improves handling and automation efficiency. While costly and challenging to machine, titanium offers unparalleled durability in niche industrial and aerospace molding operations.

Surface finish plays a pivotal role in part ejection, surface quality, and mold maintenance. Anodizing is a widely used finish for aluminum molds, enhancing surface hardness and corrosion resistance. Hard anodizing, in particular, creates a durable ceramic-like layer that significantly improves wear performance. For steel molds, options include polishing, texturing, and nitriding, but anodizing is not applicable due to material composition.

Below is a comparative overview of key mold materials used in custom molded plastics manufacturing.

| Material | Hardness (HRC) | Typical Use Case | Thermal Conductivity (W/m·K) | Corrosion Resistance | Max Cycle Life |

|---|---|---|---|---|---|

| Aluminum 6061 | 30–35 | Prototyping, low volume | 167 | Low (improved with anodizing) | 10,000–50,000 cycles |

| Aluminum 7075 | 36–40 | Medium volume, complex parts | 130 | Moderate | 50,000–100,000 cycles |

| P20 Steel | 28–32 | High volume, general use | 36 | Low | 500,000+ cycles |

| H13 Steel | 48–52 | Hot-runner, high stress | 30 | Moderate | 1,000,000+ cycles |

| S136 Steel | 50–54 | Corrosive environments | 28 | High | 1,000,000+ cycles |

| Titanium (Grade 5) | 36–41 | Specialized inserts | 7.6 | Very High | 500,000+ cycles |

Selecting the right material and finish ensures optimal performance, cost-efficiency, and part consistency in custom molded plastic production. At Wuxi Lead Precision Machinery, we support clients in matching material properties to application demands, ensuring precision and reliability at every stage.

Manufacturing Process & QC

Precision Metal Tooling for Zero-Defect Custom Molded Plastics Production

At Wuxi Lead Precision Machinery, we engineer the metal tooling backbone for flawless custom molded plastics. Our process transcends standard injection molding by embedding zero-defect assurance into every phase—from initial design through mass production. This rigor ensures your plastic components meet aerospace, medical, and automotive specifications where failure is not an option.

Design: Engineering Precision at the Foundation

We begin with collaborative digital engineering, translating your plastic part requirements into ultra-precise metal mold designs. Our engineers use advanced simulation software to model material flow, thermal dynamics, and stress points within the cavity and core tooling. Critical factors like gate placement, cooling channel geometry, and ejection mechanics are optimized to prevent sink marks, warpage, or knit lines in the final plastic part. Every micron of steel is calculated to counteract polymer shrinkage, ensuring dimensional stability down to ±0.005 mm tolerances. This phase eliminates 90% of potential defects before metal cutting begins.

Prototyping: Validating Perfection

Rapid prototyping on our 5-axis CNC machining centers transforms digital designs into physical mold inserts with micron-level accuracy. We produce functional steel molds—not soft aluminum prototypes—to validate true production conditions. Each prototype run undergoes rigorous metrology: CMM scans verify cavity conformity, while molded sample parts are stress-tested for mechanical integrity and surface finish. Clients receive full material traceability reports and defect root-cause analysis. If deviations occur, our engineers adjust the mold geometry digitally and re-machine inserts within 72 hours. This iterative validation guarantees the final tool will perform flawlessly at scale.

Mass Production: Sustaining Zero Defects

Our production cells integrate real-time monitoring with closed-loop process control. Hydraulic presses pair with sensors tracking cavity pressure, melt temperature, and clamp force 1,000 times per second. Any parameter drift triggers automatic correction before a single defective part is produced. Every mold undergoes preventive maintenance after 100,000 cycles, with critical wear surfaces re-measured via optical comparators. Final inspection employs AI-powered vision systems detecting sub-0.02 mm surface anomalies. The result: sustained CpK >1.67 across million-part runs.

Wuxi Lead Production Specifications

| Parameter | Capability | Industry Standard |

|---|---|---|

| Mold Steel Hardness | HRC 52-58 (Pre-hardened/D2/H13) | HRC 48-52 |

| Dimensional Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Finish (Cavity) | Ra 0.025 µm (Mirror Polish) | Ra 0.40 µm |

| Max Cavity Count | 64 | 32 |

| Cycle Time Validation | ±0.15 seconds (1M+ cycles) | ±0.5 seconds |

This integrated approach—where metal tooling precision enables plastic part perfection—makes Wuxi Lead the strategic partner for mission-critical molded components. We don’t just manufacture molds; we engineer defect elimination into your supply chain.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components that meet the rigorous demands of advanced manufacturing sectors. While our core focus remains on precision-engineered metal solutions, our capabilities frequently intersect with industries requiring integrated assemblies—where custom molded plastics play a supporting role in final product performance. Our engineering-first approach ensures that every component, whether metal or interface-compatible with plastic elements, is manufactured to exacting standards of tolerance, durability, and repeatability.

Choosing the right manufacturing partner is critical when developing complex, mission-critical parts. At Lead Precision, we combine state-of-the-art CNC machining, multi-axis turning, and automated production systems with decades of metallurgical expertise. This allows us to produce components used in aerospace, medical devices, automotive systems, and industrial automation—applications where failure is not an option. Our facility in Wuxi, China, operates under ISO 9001-certified processes, ensuring full traceability, consistent quality control, and compliance with international standards.

We understand that modern manufacturing often involves hybrid systems—where high-strength metal components interface seamlessly with custom molded plastic elements. While we do not produce plastic injection molds, our engineering team collaborates closely with your design and supply chain partners to ensure dimensional compatibility, thermal stability, and long-term mechanical integrity between metal and plastic subsystems. From prototype development to high-volume production, we offer rapid turnaround, competitive pricing, and full documentation packages, including GD&T drawings, material certifications, and inspection reports.

Our commitment to precision is matched only by our dedication to partnership. We work proactively with global clients to optimize part design for manufacturability, reduce assembly complexity, and lower total cost of ownership. Whether you’re integrating metal housings with plastic seals, producing threaded inserts, or developing overmolded metal components, our team provides actionable feedback early in the design phase to prevent costly revisions downstream.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (precision polishing) |

| Production Capacity | Up to 50,000 units/month (automated lines) |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, First Article Reporting |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 25–35 days after approval |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that values precision, reliability, and engineering excellence. If your project requires high-integrity metal components designed to interface with custom molded plastics or function independently in demanding environments, we are ready to support you.

Contact us today at [email protected] to discuss your application, request a quote, or receive design for manufacturability feedback. Let Lead Precision be your trusted partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.