Technical Contents

Engineering Guide: Custom Metal Molds

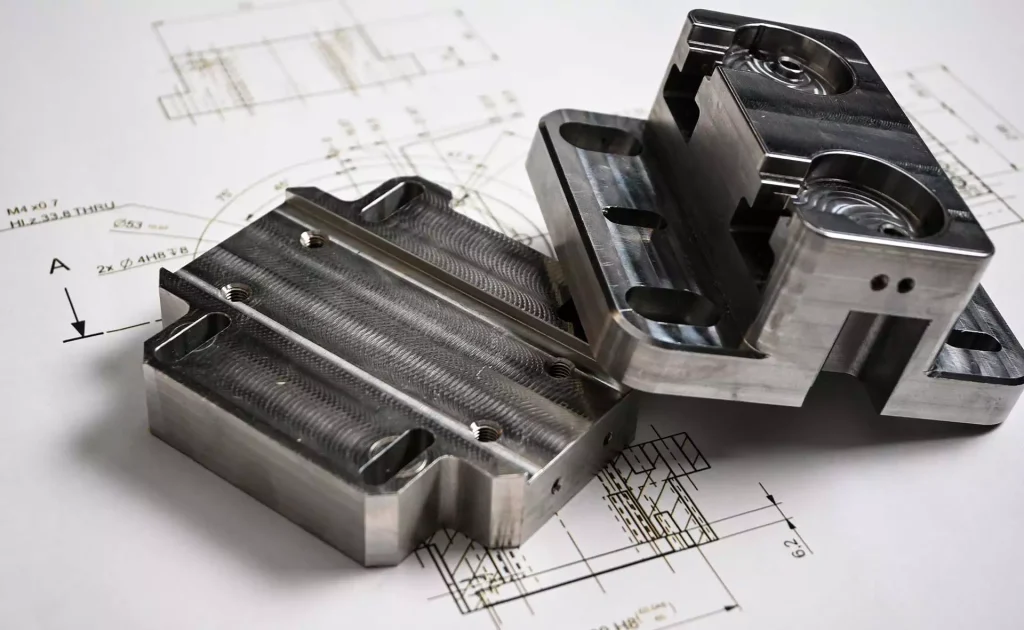

Engineering Insight Precision as the Non-Negotiable Foundation of Custom Metal Molds

In the realm of custom metal manufacturing, particularly for mission-critical applications, the precision of the mold is not merely a desirable attribute—it is the absolute bedrock of component integrity, performance, and longevity. Sub-micron deviations during the molding process propagate through every subsequent stage, ultimately compromising the final part’s dimensional accuracy, structural soundness, and functional reliability. For industries like aerospace, defense, and high-performance infrastructure, where failure is not an option, the mold itself must be engineered to exacting standards that transcend conventional manufacturing tolerances. This level of precision demands not only advanced CNC capabilities but also deep metallurgical understanding and rigorous process validation protocols applied from the initial design phase through final inspection.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering. Our experience forging components for Olympic venue structural systems and classified defense programs instills a unique discipline in our mold development process. These projects demanded zero-defect outcomes under extreme scrutiny, where material behavior under stress, thermal stability during production cycles, and micron-level geometric fidelity were non-negotiable. We translate this high-stakes experience directly into every custom metal mold we produce, implementing multi-axis CNC machining centers with sub-micron positioning accuracy, coupled with in-process metrology and comprehensive material certification. Our engineers treat mold steel selection, heat treatment sequencing, and surface finishing as integrated scientific processes, not isolated steps, ensuring the mold performs consistently across thousands of cycles while maintaining critical part specifications.

The tangible output of this rigorous approach is reflected in the measurable specifications achievable for custom metal molds. Below are typical performance parameters consistently delivered for high-integrity applications:

| Critical Specification | Standard Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | ISO 4287 |

| Geometric Accuracy (Flatness) | 0.01 mm/m² | 0.003 mm/m² | ASME Y14.5 |

| Material Hardness Control | ±3 HRC | ±1.5 HRC | ASTM E18 |

| Thermal Stability (Δ Dimension) | < 0.005 mm @ 200°C | < 0.002 mm @ 200°C | Internal Protocol |

This precision engineering directly translates to client success. When a mold consistently holds tolerances within 2 microns, it eliminates costly secondary operations, reduces scrap rates to near-zero, and ensures every cast or forged part meets the stringent assembly and performance requirements of the end application. For our clients in defense and critical infrastructure, this reliability is not just about cost savings—it is about ensuring operational readiness and safety where consequences of failure are severe. At Wuxi Lead Precision Machinery, we engineer molds not just to form metal, but to guarantee the performance and trustworthiness of the systems they enable. Precision is our standard, not our promise.

Precision Specs & Tolerances

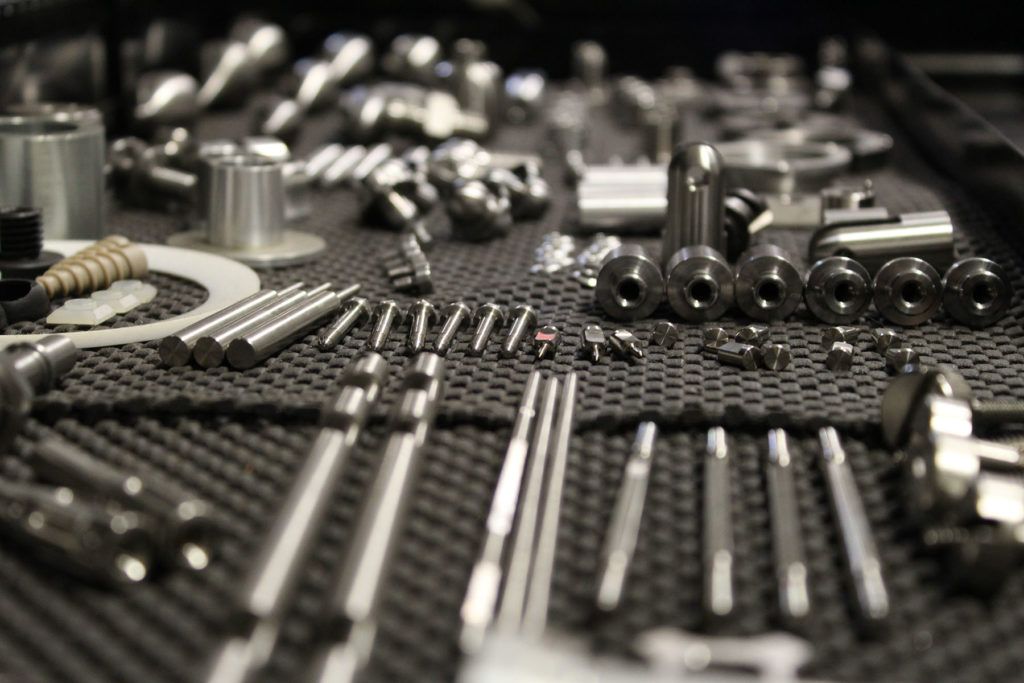

At Wuxi Lead Precision Machinery, our technical capabilities in custom metal mold manufacturing are anchored in advanced engineering infrastructure and precision-driven processes. We specialize in delivering high-integrity molds tailored to the exacting demands of aerospace, automotive, medical, and industrial equipment sectors. Central to our production excellence is our fleet of 5-axis CNC machining centers, which enable us to execute complex geometries with superior accuracy and surface finish. These machines allow simultaneous multi-directional cutting, reducing setup times and part handling while maintaining tight alignment and consistency across intricate mold cavities and core structures.

Our 5-axis CNC systems are operated by certified machinists with extensive experience in high-tolerance mold fabrication. Equipped with high-speed spindles and dynamic tool path optimization software, the machines support a wide range of materials including hardened steels, aluminum alloys, titanium, and specialty tooling grades. This flexibility ensures that each custom mold meets both functional performance and longevity requirements under demanding production cycles.

Quality control is fully integrated into every phase of manufacturing. All molds undergo rigorous inspection using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy. Our CMM systems are programmed to validate critical features such as draft angles, radii, parting lines, and cooling channel positioning with micron-level precision. Data from each inspection is compiled into comprehensive reports, traceable to individual work orders, ensuring full compliance with ISO 9001 standards and customer-specific quality protocols.

In addition to CMM inspection, we employ surface roughness testers, hardness gauges, and optical comparators to verify finish quality and material properties. Every mold is subjected to a final assembly and fit check, simulating real-world operational conditions to confirm alignment, ejection mechanisms, and thermal performance.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and repeatability:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.008 mm |

| Positional Tolerance | ±0.015 mm | ±0.01 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities are supported by robust CAD/CAM integration using Siemens NX and Mastercam, enabling seamless translation from design to production. We maintain full digital traceability, allowing rapid iteration and documentation for audits or design validation. At Wuxi Lead Precision Machinery, our technical infrastructure ensures that every custom metal mold is manufactured to the highest standards of precision, durability, and performance.

Material & Finish Options

Material Selection for Precision Metal Molds: Engineering Performance

Material selection directly impacts mold longevity, part quality, production efficiency, and total cost of ownership in custom metal mold manufacturing. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your specific application demands, production volume, and part geometry. Understanding the core characteristics of aluminum, steel, and titanium alloys, alongside critical finishing processes like anodizing, is fundamental to optimal mold performance.

Aluminum Alloys

Aluminum, particularly grades 6061-T6 and 7075-T6, offers exceptional machinability and superior thermal conductivity. This significantly reduces cycle times in high-volume plastic injection molding or low-pressure casting, as heat transfers rapidly from the mold cavity. Aluminum molds are ideal for prototyping, bridge tooling, and medium-volume production runs where rapid heat dissipation is critical. While less durable than steel under extreme wear conditions, modern aluminum alloys provide sufficient hardness for many applications. Anodizing is highly recommended to enhance surface hardness, wear resistance, and corrosion protection, extending mold life substantially.

Tool Steels

For high-volume production demanding maximum durability and wear resistance, tool steels are the industry standard. P20 offers a balanced combination of toughness, machinability, and moderate wear resistance for general-purpose molds. H13 excels in applications requiring high thermal stability (up to 500°C) and resistance to thermal fatigue, making it essential for die casting and high-temperature injection molding. S7 provides superior impact resistance for applications involving significant mechanical stress. Steel molds inherently offer higher hardness and dimensional stability under thermal cycling than aluminum but require longer machining times. Surface treatments like nitriding or specialized coatings are often applied alongside precision polishing.

Titanium Alloys

Titanium (primarily Grade 5, Ti-6Al-4V) is employed in highly specialized, demanding applications where its unique properties justify the cost. Its exceptional strength-to-weight ratio, corrosion resistance in aggressive environments, and biocompatibility are critical for aerospace components, medical implants, and specific chemical processing molds. Machining titanium requires specialized CNC processes due to its low thermal conductivity and tendency to gall. Anodizing titanium primarily serves decorative or specific biocompatibility purposes rather than significant wear enhancement.

Anodizing: Critical Surface Enhancement

Anodizing is a vital electrochemical finishing process, especially for aluminum molds. It creates a controlled, porous oxide layer that can be sealed or dyed. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and a base for coloring. Type III (Hard Anodizing) produces a much thicker, denser, and harder surface layer (typically 25-50 µm), dramatically improving wear resistance, lubricity, and release properties – directly extending mold life in abrasive polymer applications. The specific anodizing type and thickness must be precisely specified based on the polymer being molded and expected cycle count.

The following table summarizes key comparative properties for common mold materials:

| Material | Typical Hardness | Thermal Conductivity (W/m·K) | Primary Application Strengths | Key Limitation |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 HB | 167 | Rapid prototyping, medium volume, fast cycle times | Lower wear resistance |

| Aluminum 7075-T6 | 150 HB | 130 | Higher strength than 6061, better for wear areas | More expensive, harder to machine |

| Tool Steel P20 | 28-32 HRC | 28-36 | General purpose, good toughness, polishability | Moderate wear resistance |

| Tool Steel H13 | 48-52 HRC | 24-30 | High temp stability, thermal fatigue resistance | Higher cost, slower machining |

| Titanium Ti-6Al-4V | 36 HRC | 7.2 | Extreme corrosion resistance, high strength/weight | Very high cost, difficult machining |

Selecting the optimal material and finish requires balancing performance requirements with economic factors. Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients during the design phase to analyze your specific needs and recommend the most cost-effective, high-performance solution for your custom metal mold investment. Consult our specialists for detailed material and finishing specifications tailored to your project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, the production of custom metal molds follows a rigorously controlled workflow designed to ensure precision, repeatability, and zero-defect output. Our integrated process spans three core phases—Design, Prototyping, and Mass Production—each governed by advanced engineering standards and continuous quality validation.

The process begins with Design, where our engineering team collaborates closely with the client to translate functional requirements into detailed 3D CAD models. Using industry-leading software such as SolidWorks, AutoCAD, and Siemens NX, we simulate mold behavior under operational conditions, analyzing thermal distribution, stress points, and material flow. This virtual validation phase ensures optimal mold geometry and identifies potential failure modes before physical production begins. All designs are reviewed against ISO 9001:2015 standards and subjected to Design Failure Mode and Effects Analysis (DFMEA) to mitigate risks proactively.

Once the design is approved, we proceed to Prototyping. A single mold unit is fabricated using high-precision CNC machining, wire EDM, and surface grinding technologies, all operating within ±0.002 mm tolerances. The prototype is then subjected to a comprehensive test cycle, including mold flow analysis, first-article inspection (FAI), and functional trials on client-specified injection or die-casting equipment. Any deviations are corrected through iterative refinement, ensuring the mold meets all dimensional, surface finish, and performance criteria. This phase is critical for verifying manufacturability and serves as the benchmark for mass production.

Upon successful prototype validation, the project transitions to Mass Production. Our fully automated production lines, equipped with multi-axis CNC centers and robotic material handling, ensure consistent part quality across high-volume runs. Every mold undergoes 100% in-process inspection using coordinate measuring machines (CMM) and optical comparators. We implement Statistical Process Control (SPC) to monitor key parameters in real time, enabling immediate corrective action if trends approach tolerance limits. Final inspection includes hardness testing, surface roughness measurement, and assembly verification, all documented in a full First Article Inspection Report (FAIR).

Throughout the entire production lifecycle, Wuxi Lead enforces a Zero Defects philosophy. This is achieved through operator training, preventive maintenance of equipment, and a closed-loop corrective action (CAPA) system that logs and resolves any non-conformances. Our quality management system is certified to ISO 9001 and IATF 16949, ensuring compliance with automotive, medical, and industrial manufacturing standards.

Key production specifications are maintained across all projects:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.8 µm |

| Materials | H13, P20, S136, 718H, Stainless Steel |

| Machining Equipment | 5-axis CNC, Wire EDM, Surface Grinders |

| Inspection Tools | CMM, Optical Comparator, Hardness Tester |

| Quality Standards | ISO 9001, IATF 16949, FAI, SPC |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days (volume-dependent) |

This disciplined approach ensures that every custom metal mold delivered by Wuxi Lead Precision Machinery meets the highest standards of performance, durability, and precision.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Mold Excellence

In the demanding landscape of precision manufacturing, your custom metal mold is not merely a component—it is the foundational element determining product quality, production efficiency, and ultimately, your market competitiveness. Selecting a mold partner demands more than basic fabrication capability; it requires deep engineering insight, unwavering process control, and a commitment to solving the most complex challenges inherent in high-tolerance metal forming. At Wuxi Lead Precision Machinery, we engineer partnerships built on this exacting standard, transforming your most demanding mold specifications into reality with zero tolerance for compromise.

Our integrated approach merges decades of specialized mold-making expertise with cutting-edge CNC technology and rigorous quality management systems. We understand that dimensional stability under thermal cycling, surface finish perfection, and micron-level repeatability are non-negotiable for your success. This understanding drives every process, from initial material selection and heat treatment protocols to the final polishing stage. We eliminate guesswork through advanced simulation and meticulous first-article inspection, ensuring your mold performs flawlessly from the first shot, minimizing downtime and maximizing your production yield.

The technical capabilities underpinning our partnership are quantifiable and consistently delivered. Below represents our core manufacturing envelope for custom metal molds:

| Specification Category | Capability Detail |

|---|---|

| Material Capability | Tool Steels (H13, S7, D2, A2, P20), Stainless Steels (420, 17-4PH), Aluminum Alloys |

| Dimensional Tolerance | ±0.002 mm (±0.00008″) achievable on critical features |

| Surface Finish | Ra 0.05 µm (2 µin) mirror polish; specialized textures to customer specification |

| Maximum Mold Footprint | 1200 mm x 800 mm x 800 mm (47″ x 31.5″ x 31.5″) |

| Lead Time (Prototype) | 4-6 weeks for complex molds (dependent on design complexity & material) |

| Quality Certification | ISO 9001:2015 certified processes; full traceability; comprehensive CMM reporting |

Why partner with Lead Precision? We operate as an extension of your engineering team. Our senior CNC engineers engage proactively during the design phase, identifying potential manufacturability issues and optimizing for longevity and performance—saving you time and costly revisions. We invest in the latest multi-axis machining centers, EDM technology, and metrology equipment, ensuring absolute precision is maintained throughout the build. Crucially, our quality assurance is not a final checkpoint but an embedded discipline, with in-process inspections at every critical stage to guarantee conformity before assembly. This systematic rigor delivers molds renowned for exceptional durability, consistent output, and reduced total cost of ownership.

The cost of mold failure extends far beyond the tool itself—it halts production lines, delays shipments, and damages customer relationships. Partnering with Lead Precision mitigates this risk at its source. We provide the technical depth, process transparency, and responsive support necessary to bring your most ambitious metal forming projects to fruition, on time and to the highest global standards. Do not navigate the complexities of custom mold manufacturing alone. Contact our engineering team today to initiate your project with confidence.

Contact [email protected] to discuss your specific requirements and receive a detailed technical consultation. Let Lead Precision become your definitive partner for precision metal molds.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.