Technical Contents

Engineering Guide: Custom Metal Components

Engineering Insight: The Critical Role of Precision in Custom Metal Components

In the realm of advanced manufacturing, custom metal components serve as the backbone of innovation across aerospace, defense, medical technology, and high-performance industrial systems. At Wuxi Lead Precision Machinery, we understand that the functionality, safety, and longevity of these systems hinge on one non-negotiable factor: precision. The difference between success and failure in mission-critical applications often lies in tolerances measured in microns, where even the slightest deviation can lead to system failure, regulatory non-compliance, or operational inefficiency.

Precision engineering is not merely about tight tolerances—it is a holistic approach encompassing material selection, process control, metrology, and design for manufacturability. At Lead Precision, our engineering philosophy centers on achieving repeatability, consistency, and traceability across every production run. This commitment is grounded in over a decade of experience delivering components for elite applications, including systems used in Olympic-level sporting equipment and certified military-grade hardware. These sectors demand absolute reliability under extreme conditions, and our track record reflects our ability to meet and exceed those expectations.

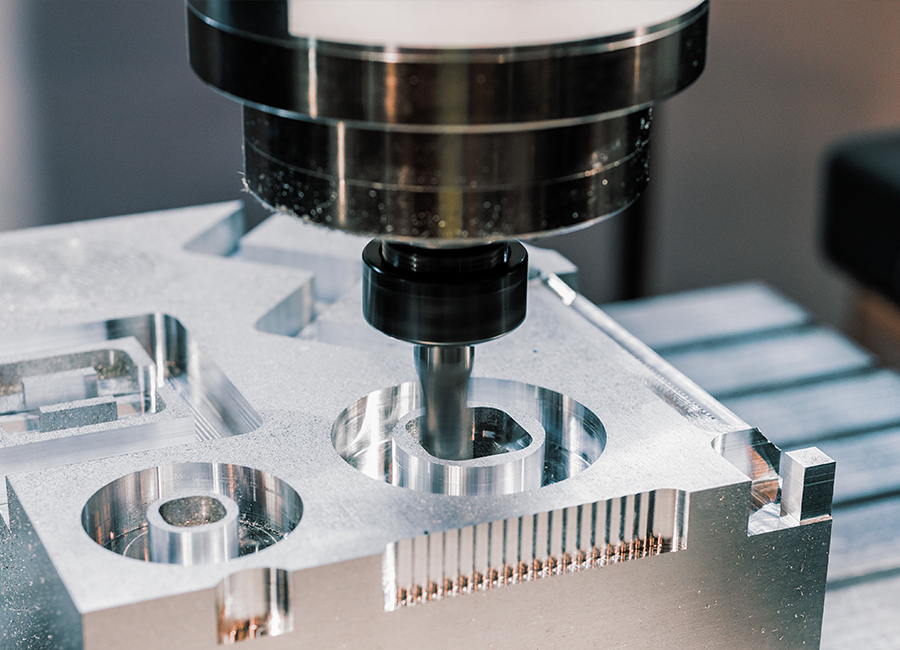

Our facility in Wuxi integrates state-of-the-art CNC machining centers, multi-axis milling and turning systems, and in-house quality assurance laboratories equipped with coordinate measuring machines (CMM) and optical inspection systems. This infrastructure enables us to maintain tolerances as tight as ±0.002 mm, ensuring that every component conforms precisely to design specifications. Furthermore, our engineers collaborate closely with clients during the design phase to optimize geometries, minimize stress concentrations, and select appropriate alloys—whether titanium for aerospace applications or hardened stainless steel for medical devices.

Beyond equipment and expertise, precision is sustained through rigorous process validation and documentation. Every batch undergoes full material traceability, first-article inspection, and final quality audits. This level of control is essential not only for compliance with ISO 9001 and AS9100 standards but also for building trust with partners who depend on flawless performance.

The following table outlines key precision capabilities at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 1.6 µm (customizable) |

| Maximum Part Size | 800 × 600 × 500 mm |

| Minimum Feature Size | 0.3 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (compliant) |

| Inspection Equipment | CMM, Optical Comparator, Surface Profilometer, Hardness Tester |

Precision in custom metal components is not an optional upgrade—it is the foundation of performance, safety, and innovation. At Wuxi Lead Precision Machinery, we bring proven expertise from the most demanding industries to every project, ensuring that our clients receive components engineered to perform without compromise.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal component manufacturing through advanced technical capabilities centered on state-of-the-art 5-axis CNC machining and rigorous quality control. Our engineering expertise and equipment portfolio are specifically designed to meet the stringent geometric and tolerance requirements of aerospace, medical, energy, and high-performance industrial sectors. We transform complex CAD models into mission-critical parts with exceptional surface finish and dimensional accuracy, handling materials ranging from aluminum and titanium alloys to hardened steels and exotic superalloys.

Our core strength lies in multi-axis simultaneous machining. Utilizing high-torque, high-speed 5-axis CNC machining centers from industry leaders, we achieve intricate geometries impossible with 3-axis systems. This capability eliminates the need for multiple setups and secondary operations, significantly reducing part handling errors, improving feature-to-feature relationships, and accelerating time-to-market. Complex contours, deep cavities, undercuts, and organic shapes are produced in a single, highly controlled operation, ensuring superior surface integrity and repeatability. Machine tool calibration and thermal stability protocols are strictly maintained to guarantee consistent performance across extended production runs.

Quality assurance is integrated at every stage, not merely a final checkpoint. All critical dimensions undergo comprehensive verification using calibrated Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs provide micron-level accuracy for first-article inspection (FAI) and ongoing in-process checks, generating detailed, traceable inspection reports compliant with AS9102 or customer-specific formats. This systematic approach, combined with operator expertise and statistical process control (SPC), ensures dimensional integrity from prototype to full production, mitigating risk and guaranteeing components perform reliably in their end application.

The following table details our standard and achievable tolerance capabilities across common feature types, reflecting the precision attainable with our optimized processes and equipment:

| Feature Type | Standard Tolerance | Achievable Tolerance |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Diameter | ±0.008 mm | ±0.003 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Profile of a Surface | ±0.012 mm | ±0.006 mm |

| Flatness | 0.010 mm | 0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver custom metal components where precision is non-negotiable. Our technical capabilities provide the foundation for solving your most challenging manufacturing problems, ensuring parts meet exact specifications with documented quality and on-time delivery. Partner with us for components engineered to perform under the most demanding conditions.

Material & Finish Options

Material Selection for High-Performance Custom Metal Components

Selecting the appropriate material is a foundational decision in the production of custom metal components, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing using advanced CNC technologies, enabling us to work with a range of high-grade metals including aluminum, steel, and titanium. Each material offers distinct mechanical and chemical properties suited to specific industrial applications, from aerospace and medical devices to automotive and energy systems.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is critical without compromising structural integrity. Grade 6061-T6 is commonly used for general engineering components, while 7075-T6 offers higher strength for more demanding environments. Aluminum’s natural oxide layer provides inherent protection, but for enhanced surface performance, anodizing is recommended.

Steel remains the material of choice for components requiring high tensile strength, wear resistance, and dimensional stability under load. We utilize both carbon steel (e.g., 1045) and alloy steels (e.g., 4140) depending on the application. Stainless steel grades such as 304 and 316 are selected when corrosion resistance and hygiene are paramount, making them ideal for food processing, medical, and marine environments. While steel components typically do not undergo anodizing, they can be treated with coatings such as zinc plating, passivation, or powder coating for added protection.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. It is frequently specified in aerospace, defense, and biomedical applications where long-term reliability under stress and exposure is non-negotiable. Although more challenging to machine than aluminum or steel, our advanced CNC processes ensure tight tolerances and high surface quality in titanium components.

Anodizing is a key surface treatment for aluminum parts, enhancing wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) provides a thicker, harder surface layer for industrial and military-grade components. Anodized finishes also allow for color coding, improving part identification in complex assemblies.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310–570 | High (with anodizing) | 6061-T6, 7075-T6 | Aerospace, electronics, transport |

| Steel (Carbon) | 7.8 | 500–700 | Moderate | 1045, 4140 | Industrial machinery, tooling |

| Stainless Steel | 7.9 | 505–900 | Very High | 304, 316 | Medical, marine, food processing |

| Titanium | 4.5 | 900–1,170 | Excellent | Ti-6Al-4V (Gr 5) | Aerospace, defense, implants |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle expectations. Our engineering team at Wuxi Lead Precision Machinery supports clients through this decision process, ensuring optimal performance and cost-effectiveness in every custom component we produce.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our process begins with rigorous collaborative design engineering. Clients submit CAD models or sketches which our team analyzes for manufacturability using advanced simulation software. We identify potential tolerance stacking issues thermal deformation risks and material suitability early. Our engineers provide actionable Design for Manufacturing feedback ensuring optimal geometry for CNC machining casting or forming. This phase includes material certification verification and fixture planning to eliminate downstream errors. Every design undergoes cross-departmental review validating feasibility against our machine capabilities and quality protocols before progression.

Prototyping: Validating Performance Before Scale

Prototyping transforms validated designs into physical test articles under controlled production conditions. We utilize the same CNC centers and inspection equipment planned for mass production ensuring prototype fidelity. Each prototype undergoes dimensional validation via CMM coordinate measuring machines and surface finish analysis per ISO 25178 standards. Functional testing including stress load cycles and assembly integration checks occurs in our metrology lab. Clients receive comprehensive reports detailing deviations from CAD nominal values allowing design refinement. Only when prototypes consistently meet all specifications do we approve the process for full production release. This iterative validation prevents costly errors at scale.

Mass Production: Institutionalizing Zero Defects

Zero Defects is not a goal but our operational baseline. Mass production leverages SPC statistical process control with real-time monitoring of critical parameters like tool wear coolant concentration and thermal drift. Every component undergoes in-process inspections at defined intervals using automated vision systems and laser micrometers. Final inspection mandates 100% dimensional verification against ASME Y14.5 GD&T standards alongside material traceability documentation. Our ERP system tracks every part from raw material batch to shipping manifest enabling full traceability. Non-conforming parts trigger immediate root cause analysis with corrective actions implemented within 4 hours. This closed-loop system ensures consistent conformance across production runs of any volume.

Key Production Capabilities Enabling Zero Defects

| Parameter | Capability | Standard Compliance |

|————————-|————————————-|————————–|

| Dimensional Accuracy | ±0.002 mm | ISO 2768-mK |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm | ISO 1302 |

| Material Range | Aluminum Steel Titanium Inconel | AMS QQ ASTM |

| Max Part Size | 1200 x 800 x 600 mm | Custom fixturing support |

| Inspection Coverage | 100% critical features | AS9102 PPAP Level 3 |

This integrated approach transforms design intent into flawless physical components. By embedding quality at every phase we eliminate scrap rework and supply chain disruptions delivering custom metal parts that perform predictably in your most demanding applications. Wuxi Lead’s process is your assurance of manufacturing integrity from prototype to millionth part.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Precision-Engineered Metal Components Tailored to Your Exact Requirements

In the world of high-performance manufacturing, the quality of your components directly influences the success of your final product. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components that meet the most rigorous industrial standards. With over 15 years of experience in precision CNC machining, sheet metal fabrication, and complex assembly solutions, we serve leading OEMs across aerospace, medical, automation, and energy sectors. Our commitment to engineering excellence, combined with advanced manufacturing capabilities, positions us as a trusted extension of your production team.

Our end-to-end service model begins with collaborative design consultation, where our engineering team works closely with yours to optimize manufacturability, reduce costs, and accelerate time to market. From prototyping to full-scale production, we maintain strict process controls and implement comprehensive quality assurance protocols, including ISO 9001-certified procedures and full traceability on every component. Whether you require tight tolerances of ±0.005 mm, complex geometries, or materials ranging from aluminum and stainless steel to titanium and exotic alloys, our facility in Wuxi, China, is equipped to deliver consistent, repeatable results.

We understand that global supply chains demand more than just precision — they require reliability, transparency, and responsive communication. That’s why we assign a dedicated project manager to every client, ensuring seamless coordination from order placement through final delivery. Our logistics network supports JIT (Just-in-Time) scheduling and export-ready packaging, with regular production updates and real-time reporting to keep you informed at every stage.

Below are key specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling; turning |

| Tolerance Control | ±0.005 mm |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Max Work Envelope | 1200 x 800 x 650 mm (milling); Ø500 x 1000 mm (turning) |

| Sheet Metal Fabrication | Laser cutting, bending, welding, stamping |

| Surface Treatments | Anodizing, powder coating, passivation, plating |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP |

| Production Volume | Prototypes to high-volume production runs |

| Lead Times | As fast as 7 days for prototypes |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier — you gain a strategic manufacturing ally focused on your long-term success. Our engineering-driven approach ensures that every component we produce not only meets your technical specifications but also enhances the performance and reliability of your end product.

To begin your next project with precision and confidence, contact us today at [email protected]. Let our team support your innovation with custom metal manufacturing you can trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.