Technical Contents

Engineering Guide: Custom Metal Casting Molds

Engineering Insight: The Non-Negotiable Role of Precision in Custom Metal Casting Molds

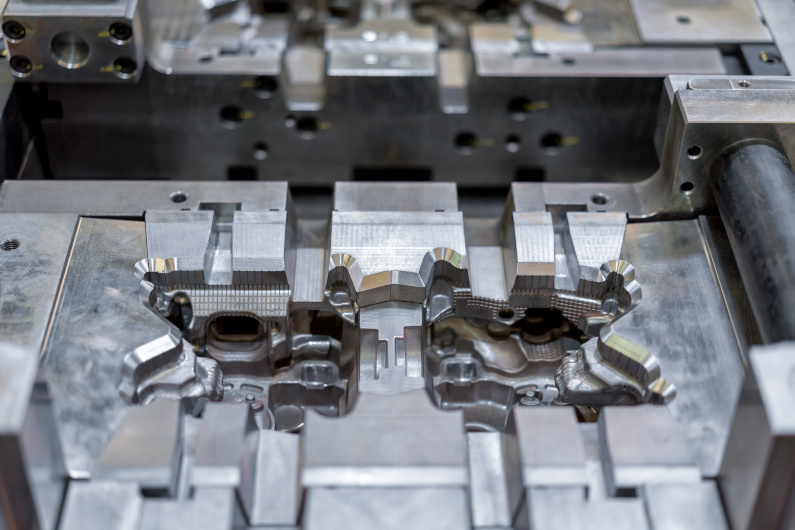

In custom metal casting, the mold is not merely a container; it is the definitive blueprint for the final component’s dimensional accuracy, structural integrity, and functional performance. Minute deviations in mold geometry translate directly into costly defects, material waste, and compromised part functionality. Achieving true precision in mold manufacturing demands far more than standard machining capabilities—it requires an integrated understanding of metallurgy, thermal dynamics, and the specific stresses inherent in the casting process itself. At Wuxi Lead Precision Machinery, we recognize that tolerance control at the micron level is the foundation upon which successful, high-value castings are built. This precision eliminates secondary machining, ensures seamless assembly, and guarantees the component performs reliably under extreme operational conditions, whether in aerospace turbines or deep-sea hydraulic systems.

Our engineering process begins with rigorous material selection and advanced simulation. We utilize proprietary thermal modeling software to predict and compensate for metal shrinkage and distortion during solidification, ensuring the as-cast part meets exact specifications without iterative corrections. This predictive capability, combined with our 5-axis CNC machining centers operating under strict environmental controls, delivers mold cavities and cores with exceptional repeatability. The table below outlines the core specifications achievable through our integrated process:

| Specification Category | Capability Range | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm to ±0.05 mm | CMM (ZEISS CONTURA) |

| Surface Finish (Cavity) | Ra 0.4 µm to Ra 1.6 µm | Profilometer (Mitutoyo SJ-410) |

| Material Grades | H13, 420SS, Tool Steel, Inconel 718 | Spectrographic Analysis |

| Thermal Stability Testing | Validated up to 1200°C cycling | In-house Thermal Simulation Rig |

| Lead Time (Complex Molds) | 8-12 weeks (incl. validation) | Project Management System |

This level of control is not theoretical. It is proven daily in mission-critical applications. Wuxi Lead Precision Machinery has engineered molds for components used in Olympic-level sporting equipment, where aerodynamic perfection and weight distribution are measured in grams and microns. More significantly, our molds meet stringent military-grade specifications, producing castings for defense systems where failure is not an option. These projects demand absolute adherence to AS9100 and NADCAP standards, requiring traceable material certifications, 100% dimensional inspection, and zero-defect validation protocols. The experience gained from these ultra-high-stakes environments directly informs our approach to every custom mold project, regardless of industry.

Precision in mold manufacturing is an investment that pays dividends across the entire production lifecycle. It minimizes scrap rates, accelerates time-to-market, and delivers cast parts ready for immediate integration. For engineers specifying custom metal castings, the mold maker’s capability is the critical variable determining project success. Wuxi Lead Precision Machinery provides the engineering rigor, advanced technology, and proven track record to transform complex casting requirements into reality, with precision you can measure and reliability you can trust.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the design and production of custom metal casting molds, serving high-performance industries such as aerospace, automotive, energy, and industrial equipment. Our integrated manufacturing platform combines precision engineering with state-of-the-art CNC technology to ensure molds meet the most stringent dimensional and functional requirements.

At the core of our production workflow is our 5-axis CNC machining center, which enables complex geometries and tight tolerances unachievable with conventional 3-axis systems. The simultaneous multi-axis movement allows for continuous tool engagement and optimal toolpath control, significantly reducing cycle times while enhancing surface finish and part accuracy. This capability is particularly critical in the fabrication of intricate mold cavities, undercuts, and organic shapes commonly required in investment, die, and sand casting applications. Our machines are maintained to OEM specifications and operated by certified CNC programmers with over a decade of experience in mold-specific machining strategies.

Quality assurance is embedded at every stage of production. All custom metal casting molds undergo comprehensive dimensional verification using a coordinate measuring machine (CMM) with sub-micron resolution. This metrology-grade inspection ensures conformity to design specifications and provides full traceability for compliance with ISO 9001 and customer-specific quality standards. Our CMM system supports both contact and non-contact probing methods, enabling precise measurement of internal features, draft angles, radii, and surface profiles—even on highly complex mold surfaces.

We support a wide range of mold materials, including tool steels (H13, P20, S7), stainless steels, aluminum alloys, and high-strength bronzes, tailored to application demands such as thermal cycling resistance, wear performance, and casting cycle life. Mold designs are optimized using advanced simulation software to predict mold fill, solidification, and potential defect zones, thereby minimizing trial iterations and accelerating time to production.

The following table outlines our standard technical specifications and achievable tolerances for custom metal casting molds:

| Parameter | Specification |

|---|---|

| Machining Accuracy | ±0.005 mm |

| Surface Finish (typical) | Ra 0.4 – 1.6 µm |

| Maximum Work Envelope | 1200 x 800 x 750 mm (X-Y-Z) |

| Positional Tolerance | ±0.01 mm over full travel |

| Angular Tolerance (5-axis) | ±0.02° |

| Feature Repeatability | ±0.008 mm |

| Minimum Internal Radius | 0.2 mm (with micro-tooling) |

| CMM Measurement Uncertainty | < 2.5 + L/300 µm (L in mm) |

| Lead Time (average) | 15–25 days, depending on complexity |

All molds are delivered with full inspection reports, material certifications, and optional first-article inspection (FAI) documentation. Wuxi Lead Precision Machinery remains committed to technical excellence, ensuring every custom casting mold meets the highest benchmarks in precision, durability, and performance.

Material & Finish Options

Material Selection for High-Performance Custom Metal Casting Molds

Selecting the optimal material for custom metal casting molds is fundamental to achieving part quality, production efficiency, and cost-effectiveness. At Wuxi Lead Precision Machinery, our engineering team rigorously evaluates project requirements to match the mold material to your specific application, balancing factors like casting alloy, production volume, dimensional precision needs, and thermal management. The primary contenders—Aluminum, Tool Steel, and Titanium—each offer distinct advantages and limitations critical to long-term mold performance.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production of non-ferrous castings like aluminum or zinc. Their high thermal conductivity significantly reduces cycle times, while inherent machinability allows for complex geometries and faster lead times. However, aluminum’s lower hardness and wear resistance limit its suitability for high-volume runs or casting harder alloys like brass or bronze, where erosion becomes a concern. Tool steels, such as H13 or S7, are the industry standard for high-volume ferrous and demanding non-ferrous casting applications. Offering exceptional hardness, thermal fatigue resistance, and wear properties, they withstand the intense thermal cycling and abrasive forces encountered with iron, steel, or copper-based alloys. While requiring more complex heat treatment and machining, their extended service life and ability to maintain tight tolerances over millions of cycles deliver superior long-term value for high-production scenarios. Titanium alloys, while significantly more expensive and challenging to machine, provide unparalleled strength-to-weight ratio and corrosion resistance. They are reserved for highly specialized applications involving extremely corrosive casting materials or where extreme weight reduction of the mold itself is critical, such as in aerospace component production. Their use is less common due to cost and processing complexity but represents the pinnacle for niche, high-stress environments.

Surface finishing, particularly anodizing for aluminum molds, is a critical enhancement. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer that dramatically improves surface hardness, reduces galling, and enhances release properties for cast parts. This treatment is essential for maximizing the lifespan of aluminum molds in production environments, directly impacting part quality and reducing maintenance downtime. For steel molds, nitriding or specialized PVD coatings are typically employed to achieve similar surface durability goals.

Wuxi Lead Precision Machinery leverages decades of foundry experience to guide your material and finish selection. We understand that the right choice minimizes total cost of ownership, not just initial mold cost. Consult our engineering team early in your design phase to optimize your casting process.

| Material | Hardness (HRC) | Melting Point (°C) | Key Applications | Best For |

|---|---|---|---|---|

| Aluminum Alloys | 15-30 | 580-650 | Prototyping, Low/Med volume Al/Zn | Fast cycles, Complex geometries, Cost-sensitive |

| Tool Steels | 45-55 | 1370-1530 | High-volume Ferrous, Brass, Bronze | Long life, Tight tolerances, Harsh conditions |

| Titanium Alloys | 30-40 | 1668 | Specialized Corrosive, Aerospace | Extreme corrosion resistance, Weight critical |

Manufacturing Process & QC

Design, precision, and consistency define the foundation of Wuxi Lead Precision Machinery’s custom metal casting mold production. Our end-to-end process is engineered to deliver zero-defect performance for high-volume industrial applications. Every phase—design, prototyping, and mass production—is governed by strict quality controls, advanced simulation tools, and decades of metallurgical expertise.

The process begins with collaborative design engineering. Our team works directly with client specifications to develop optimized mold geometries that account for thermal expansion, material flow, and ejection dynamics. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate casting behavior under real-world conditions to preempt defects such as porosity, shrinkage, or warping. This digital validation ensures that the mold design achieves dimensional accuracy and longevity before any metal is cut.

Following design approval, we move into precision prototyping. A functional prototype is manufactured using CNC machining centers with tolerances held to ±0.005 mm. This prototype undergoes rigorous testing, including trial casting runs with the client’s specified alloy—aluminum, zinc, magnesium, or specialized ferrous materials. Data from these trials feed back into final design refinements, ensuring optimal fill rates, cooling uniformity, and part release. Only when the prototype meets all performance benchmarks do we proceed to full-scale production.

Mass production is executed on automated, high-pressure die casting lines integrated with real-time monitoring systems. Each mold is fabricated from premium-grade tool steel—typically H13 or 420 stainless—heat-treated to 48–52 HRC for wear resistance and thermal stability. Our production cells operate under ISO 9001-certified protocols, with in-process inspections at every critical stage. Automated vision systems, coordinate measuring machines (CMM), and ultrasonic testing ensure every mold surface and cavity conforms to specification.

Throughout the production cycle, we maintain full traceability. Each mold is serialized, and material certifications, heat treatment records, and inspection reports are archived for client access. This level of documentation supports industries where compliance and repeatability are non-negotiable—automotive, aerospace, and medical device manufacturing.

Below are key technical specifications for our custom casting molds:

| Parameter | Specification |

|---|---|

| Material Options | H13, 420 Stainless, SKD61, NAK80 |

| Hardness | 48–52 HRC (standard), up to 56 HRC (enhanced) |

| Tolerance | ±0.005 mm to ±0.02 mm (based on size) |

| Surface Finish | Ra 0.2–0.8 µm (polished or textured) |

| Mold Life | 100,000–1,000,000 cycles (alloy-dependent) |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days (depending on complexity) |

At Wuxi Lead Precision Machinery, we treat every custom mold as a mission-critical component. Our integrated process eliminates variability, delivering molds that perform reliably at scale—zero defects, every time.

Why Choose Wuxi Lead Precision

Precision Begins with Partnership

At Wuxi Lead Precision Machinery, we engineer custom metal casting molds that transform ambitious designs into production-ready reality. For over 15 years, global manufacturers have trusted us to solve their most demanding casting challenges—where micron-level tolerances, complex geometries, and material integrity are non-negotiable. Our integrated approach merges metallurgical science with advanced CNC manufacturing, ensuring molds deliver consistent repeatability across thousands of cycles. We don’t just fabricate tooling; we optimize your entire casting workflow to eliminate scrap, reduce cycle times, and guarantee first-article approval.

Our technical capabilities are rigorously validated against aerospace, automotive, and energy sector standards. Below are core specifications defining our mold production excellence:

| Parameter | Capability Range | Industry Benchmark |

|---|---|---|

| Material Options | H13, 420SS, P20, Inconel 718, Ductile Iron | Up to 1,200°C stability |

| Tolerance Control | ±0.02 mm to ±0.05 mm | ±0.1 mm (standard) |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm | Ra 3.2 µm |

| Max Mold Size | 2,500 x 1,800 x 1,200 mm | 2,000 mm diagonal |

| Lead Time | 15–30 days (complex molds) | 45+ days |

| Complexity Tier | Multi-cavity, thin-wall, undercuts | Single-cavity only |

What sets Lead Precision apart is our closed-loop engineering process. Every project starts with a DFM analysis where our metallurgists and CNC programmers collaborate with your team to preempt casting defects before steel is cut. We deploy 5-axis simultaneous machining for critical core inserts, paired with thermal simulation software to predict and correct distortion risks. Our in-house heat treatment facility ensures uniform hardness (48–52 HRC) across mold sections, while CMM validation tracks every tolerance stack to AS9100D standards. This eliminates the guesswork that plagues offshore suppliers—giving you documented process control from CAD to cast.

When your project demands zero-defect validation for mission-critical components, partnering with us mitigates risk at every phase. We provide real-time machining updates, material traceability reports, and post-casting support to refine your process parameters. Our molds consistently achieve 20% longer service life than industry averages, directly reducing your cost per casting.

Contact us today to accelerate your next metal casting initiative. Email [email protected] with your part drawings and requirements. Our engineering team will respond within 4 business hours with a feasibility assessment and actionable timeline. Don’t let substandard tooling compromise your production—demand molds engineered for uncompromising performance. Partner with Wuxi Lead Precision Machinery, where precision is manufactured, not promised.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.