Technical Contents

Engineering Guide: Custom Machining Centers

Engineering Insight The Non-Negotiable Imperative of Precision in Custom Machining Centers

In high-stakes custom metal manufacturing, the term “precision” transcends mere specification; it represents the fundamental engineering constraint dictating component functionality, assembly integrity, and ultimately, the success of the end product. Custom machining centers are not generic tools but meticulously engineered systems where micron-level deviations directly impact performance, safety, and lifecycle costs. Achieving true precision demands an integrated approach far beyond basic machine capability. It requires harmonizing advanced motion control, thermal stability management, robust structural dynamics, and sophisticated process monitoring into a single, cohesive system. Compromising on any element introduces cumulative error chains, leading to scrap, rework, delayed time-to-market, and potential field failures – costs that dwarf initial machine investment. The engineering challenge lies not just in meeting nominal tolerances, but in guaranteeing consistent, repeatable precision under real-world production variables like tool wear, material batch variations, and ambient fluctuations.

At Wuxi Lead Precision Machinery, our engineering philosophy centers on embedding precision into the core architecture of every custom machining center we design and build. This is not theoretical; it is proven through rigorous application in the world’s most demanding sectors. Our systems form the backbone of critical component production for major international sporting events, including precision parts for Olympic timing and scoring infrastructure where absolute reliability is non-negotiable. Furthermore, we hold certifications and deliver solutions meeting stringent military and aerospace standards, where dimensional accuracy directly correlates to operational safety and mission success. This experience forges our understanding that precision engineering is a holistic discipline encompassing material science, control theory, metrology integration, and process validation.

The foundation of this capability is evident in the engineered specifications of our custom platforms. We prioritize features that actively combat the primary enemies of precision: thermal drift, vibration, and mechanical deflection. This commitment translates into tangible machine performance metrics designed for uncompromised output.

| Key Precision Engineering Specification | Typical Performance Range | Engineering Significance |

|---|---|---|

| Linear Axis Positioning Accuracy (ISO 230-2) | ≤ ±1.5 µm over 300mm travel | Ensures dimensional fidelity of complex geometries across the entire work envelope |

| Repeatability (3σ) | ≤ 0.8 µm | Guarantees consistent part-to-part quality essential for high-volume production |

| Spindle Radial Thermal Growth Compensation | ≤ 2.0 µm @ 15,000 RPM | Actively counters heat-induced growth to maintain bore tolerances and surface finish |

| Machine Base Material & Damping | Polymer Concrete Composite | Provides superior vibration absorption and long-term stability versus standard cast iron |

| Real-Time Thermal Compensation System | Multi-sensor, closed-loop | Continuously adjusts for ambient and process-induced thermal effects |

This level of engineered precision delivers direct client value: minimized scrap rates, elimination of secondary operations, accelerated qualification cycles, and components that perform flawlessly in their final assembly. For industries where failure is not an option, partnering with an engineering team possessing proven, certified precision execution – demonstrated on global stages from the Olympics to defense applications – is not a luxury, but a critical strategic requirement. Wuxi Lead Precision Machinery engineers custom machining centers where precision is the baseline, not the aspiration.

Precision Specs & Tolerances

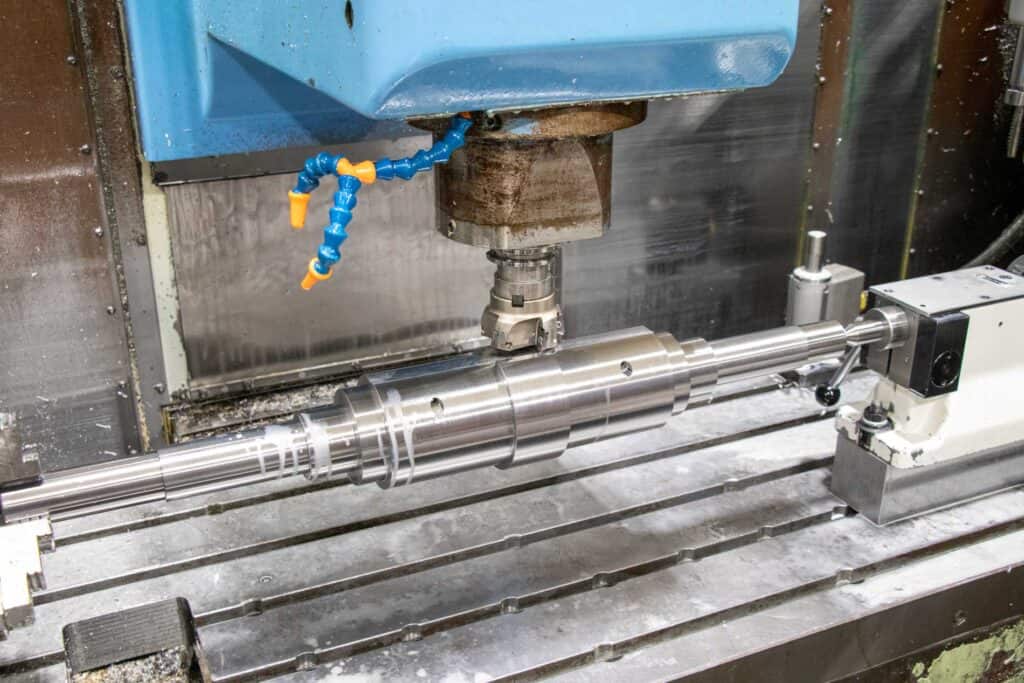

Wuxi Lead Precision Machinery delivers advanced custom machining center solutions engineered for high-precision metal manufacturing across aerospace, medical, energy, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with superior accuracy, surface finish, and dimensional consistency. These multi-axis systems allow simultaneous movement across X, Y, Z, and two rotational axes, facilitating single-setup machining of intricate parts that would otherwise require multiple operations or specialized tooling. This integration reduces lead times, minimizes human error, and ensures repeatable precision across both prototyping and high-volume production runs.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain optimal cutting conditions and prolong tool life. We process a wide range of materials, including aluminum alloys, stainless steel, titanium, Inconel, brass, and specialty composites, supporting diverse performance requirements such as high strength-to-weight ratios, corrosion resistance, and thermal stability. Each custom machining center is configured to meet the specific needs of the client’s application, including work envelope dimensions, load capacity, coolant delivery systems, and integration with automation or robotic loading.

Quality control is integral to our manufacturing process. Every component undergoes rigorous inspection using a calibrated Coordinate Measuring Machine (CMM), ensuring compliance with tight geometric and dimensional tolerances. Our CMM systems are programmed to perform full-spectrum metrology, including form analysis, positional verification, and surface profile evaluation, with digital reports provided for full traceability. This closed-loop inspection process supports AS9100 and ISO 9001 quality standards, delivering confidence in every machined part.

The following table outlines the standard precision tolerances achievable across common machining operations at Wuxi Lead Precision Machinery. These values reflect typical performance under controlled environmental conditions and may be further tightened based on part geometry, material, and customer specifications.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.012 mm | ±0.008 mm |

| Positional Tolerance | ±0.015 mm | ±0.007 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angular Accuracy | ±0.005° | ±0.002° |

| Repeatability (5-axis) | ±0.008 mm | ±0.003 mm |

All tolerances are verified under controlled temperature conditions using Zeiss or Mitutoyo CMM systems. Custom inspection plans are available upon request, including first-article inspection reports (FAIR) and PPAP documentation. Wuxi Lead Precision Machinery combines advanced equipment, material expertise, and metrology-grade validation to deliver custom machining centers that meet the most demanding technical requirements in modern manufacturing.

Material & Finish Options

Material Selection for Precision Machined Components

Material selection fundamentally determines the performance, longevity, and manufacturability of custom machined parts. At Wuxi Lead Precision Machinery, we emphasize that the optimal choice balances application requirements—such as strength, weight, corrosion resistance, thermal properties, and cost—with the realities of high-precision CNC machining. Understanding the core characteristics of common aerospace, medical, and industrial alloys is critical for successful project execution. Misalignment here leads to compromised part function, excessive production costs, or extended lead times. Our engineering team collaborates closely with clients during the design phase to ensure material suitability for both the end-use environment and our advanced machining processes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications demanding an exceptional strength-to-weight ratio and excellent machinability. Aluminum’s high thermal conductivity aids heat dissipation during high-speed machining, reducing tool wear. It is ideal for structural components, housings, and prototypes where weight savings are paramount. Stainless steels like 304 and 17-4 PH offer superior strength, hardness, and outstanding corrosion resistance, essential for medical implants, marine hardware, and high-wear tooling. Machining stainless steel requires precise toolpath strategies and coolant management to mitigate work hardening. Titanium alloys, primarily Ti-6Al-4V (Grade 5), deliver unparalleled strength-to-weight ratios and extreme corrosion resistance, making them indispensable in critical aerospace and biomedical applications. However, titanium’s low thermal conductivity and chemical reactivity necessitate specialized cutting parameters, rigid setups, and sharp tooling to prevent galling and excessive heat buildup.

Surface finishing, particularly anodizing for aluminum, enhances functional properties beyond aesthetics. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dyeability for consumer and industrial parts. Type III (Hardcoat) anodizing creates a significantly thicker, harder, wear-resistant ceramic layer essential for hydraulic components, gears, and high-friction surfaces. Anodizing thickness, hardness, and sealing method must be specified early, as they influence final dimensions and require precise machining allowances. Note that anodizing is specific to aluminum; steel and titanium require alternative finishes like passivation, plating, or specialized coatings.

The following table summarizes key mechanical properties and machining considerations for standard grades:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (Anodized Best) | Excellent (A) |

| Stainless 304 | 8.0 | 515 | Excellent | Fair (C) |

| Titanium Ti-6Al-4V | 4.4 | 900 | Exceptional | Poor (D) |

Selecting the right material is not merely a technical specification but a strategic decision impacting total project success. Wuxi Lead Precision Machinery leverages decades of CNC expertise to advise on material suitability, optimize machining parameters for each alloy, and integrate finishing requirements seamlessly into the manufacturing workflow, ensuring your custom components meet the highest standards of precision and performance.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom machining center production process is engineered for precision, repeatability, and zero-defect output. We serve high-performance industries including aerospace, medical, and advanced automation, where component integrity is non-negotiable. Our end-to-end workflow integrates Design, Prototyping, and Mass Production into a seamless pipeline governed by strict quality controls and advanced CNC technologies.

The process begins with Design, where our engineering team collaborates closely with the client to translate technical requirements into manufacturable solutions. Utilizing advanced CAD/CAM software, we develop 3D models, conduct tolerance analysis, and simulate machining paths to optimize tool life and dimensional accuracy. Material selection, surface finish requirements, and geometric dimensioning are all validated at this stage to ensure alignment with functional and regulatory standards.

Once the design is finalized, we proceed to Prototyping. A limited batch of components is produced using the same CNC machining centers intended for full-scale production. This ensures process consistency and allows for real-world validation of form, fit, and function. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Any deviations are traced to root causes—whether material, thermal, or tooling-related—and corrected before moving forward. This iterative validation phase is critical to achieving zero defects in serial production.

Mass Production is executed on our fleet of high-precision 5-axis machining centers, equipped with automated tool changers, in-process probing, and real-time spindle monitoring. Every machine is maintained to ISO 10791-2 standards and operates within a climate-controlled environment to minimize thermal drift. Production runs are managed under a full documentation trail, with First Article Inspection (FAI) reports and Process Failure Mode Effects Analysis (PFMEA) in place. Statistical Process Control (SPC) is applied to key dimensions, ensuring continuous compliance with ±0.002 mm tolerances.

Throughout all stages, our quality management system adheres to ISO 9001:2015 and IATF 16949 standards. Traceability is maintained via laser part marking and digital batch records, enabling full audit capability. Our zero-defect philosophy is enforced through preventive maintenance, operator certification, and multi-stage inspection checkpoints.

The following table summarizes key capabilities across our production process:

| Process Phase | Equipment Used | Tolerance Capability | Inspection Tools | Lead Time (Typical) |

|---|---|---|---|---|

| Design | Siemens NX, SolidWorks, CAM | N/A | GD&T Analysis, FEA Simulation | 3–7 days |

| Prototyping | 5-axis CNC, Turning Centers | ±0.005 mm | CMM, Optical Comparator, Roughness Tester | 10–15 days |

| Mass Production | Automated 5-axis Cells | ±0.002 mm | In-line CMM, SPC Monitoring | 4–6 weeks |

This structured, technology-driven approach ensures that every custom machining center we deliver meets the highest standards of performance, reliability, and precision.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Custom Machining Excellence

At Wuxi Lead Precision Machinery, we engineer custom machining centers not as commodities, but as strategic extensions of your manufacturing capability. Our partnership model begins with deep technical collaboration, ensuring every spindle, axis, and control system aligns precisely with your dimensional tolerances, material challenges, and production throughput demands. We integrate German-engineered components with ISO 9001-certified processes to deliver machines that sustain micron-level accuracy across 20,000+ operational hours. This is not standard equipment procurement; it is the deployment of a dedicated production asset engineered to eliminate your bottlenecks.

Our technical team engages at the blueprint stage, translating your most complex geometries—titanium aerospace brackets, medical implant arrays, or high-pressure hydraulic manifolds—into optimized machining sequences. We validate performance through rigorous in-house testing under simulated production loads, providing documented proof of capability before shipment. The table below outlines core specifications achievable across our custom VMC and 5-axis platforms:

| Machine Type | Travel Range (X/Y/Z) | Positioning Accuracy | Spindle Speed (RPM) | Max Workpiece Load |

|---|---|---|---|---|

| Custom 5-Axis VMC | 1200 x 800 x 750 mm | ±0.005 mm | 24,000 | 1,200 kg |

| Heavy-Duty Mill-Turn | Ø850 x 1500 mm | ±0.003 mm | 12,000 | 3,500 kg |

| Ultra-Precision VMC | 600 x 500 x 500 mm | ±0.002 mm | 30,000 | 500 kg |

These specifications reflect baseline capabilities; your project’s exact configuration will be refined through joint engineering analysis. We specialize in integrating specialized tooling systems, automated pallet changers, and coolant-through-spindle solutions for mission-critical applications where scrap rates or downtime carry unacceptable costs. Our commitment extends beyond delivery: Lead Precision provides onsite operator certification, real-time remote diagnostics, and lifecycle maintenance planning to ensure 95%+ machine uptime.

When your project demands more than off-the-shelf machinery, engage our engineering team for a capability assessment. Send your part drawings, material specifications, and target cycle times to [email protected]. Within 48 hours, you will receive a detailed technical proposal including process validation data, risk-mitigation protocols, and a timeline for prototype machining. Do not compromise on precision when your reputation depends on flawless execution. Partner with the engineers who build certainty into every micron. Let us validate your requirements and deliver the machining center that becomes the foundation of your competitive advantage. Contact us today to initiate your custom solution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.