Technical Contents

Engineering Guide: Custom Laser Cut Steel

Engineering Insight: Custom Laser Cut Steel

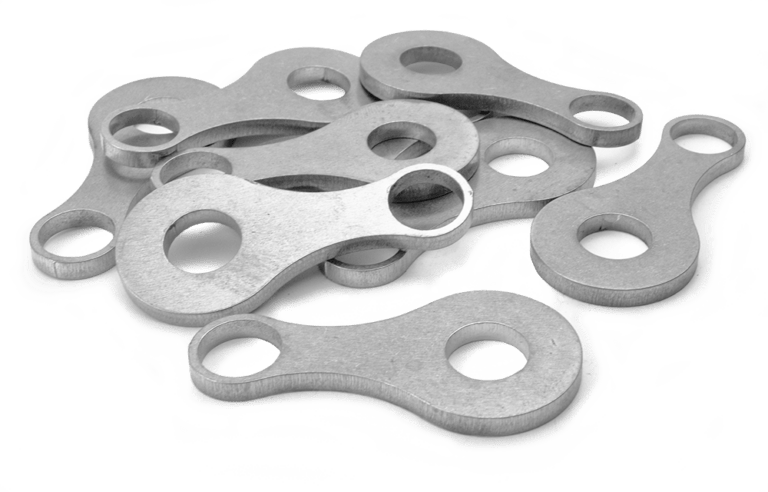

In high-performance manufacturing, precision is not merely a target—it is a requirement. Custom laser cut steel stands at the forefront of modern fabrication, where dimensional accuracy, edge quality, and repeatability define the success of a component. At Wuxi Lead Precision Machinery, we understand that even a tolerance deviation of ±0.1 mm can compromise the structural integrity or assembly function in critical applications. This level of exactness is why laser cutting has become the preferred method for producing complex steel parts across aerospace, defense, energy, and precision equipment sectors.

Our engineering team leverages state-of-the-art fiber laser technology to deliver clean, burr-free cuts with minimal heat-affected zones. This ensures that the metallurgical properties of the steel remain intact, preserving strength and durability. Whether processing mild steel, stainless steel, or high-strength low-alloy (HSLA) grades, our systems are calibrated to adapt to material thickness and design complexity, achieving intricate geometries that traditional methods cannot replicate.

Precision begins with control. Our CNC-guided laser platforms operate under strict environmental and calibration protocols, ensuring consistent performance across production runs. Every cut path is optimized using advanced nesting software, which maximizes material utilization and reduces waste—critical factors in high-volume or high-cost material applications. Moreover, real-time monitoring systems detect variances during operation, enabling immediate corrective action and ensuring compliance with ISO 9001 standards.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in custom laser cutting for mission-critical industries. Our work has contributed to infrastructure projects tied to Olympic venues, where architectural steel components demanded flawless dimensional harmony and surface finish. Additionally, we have supported defense contractors in producing ruggedized enclosures and mounting systems that meet stringent MIL-STD vibration and shock requirements. These projects underscore our capability to deliver not just parts, but engineered solutions where failure is not an option.

Our commitment extends beyond equipment. Every project undergoes rigorous design for manufacturability (DFM) analysis, where our engineers collaborate with clients to optimize part geometry, reduce assembly steps, and improve overall cost efficiency—without sacrificing precision.

The following table outlines the technical capabilities of our laser cutting systems:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Max Power | 12,000 W |

| Material Thickness Range | 0.5 mm – 25 mm (steel) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Cutting Speed (max) | Up to 100 m/min (thin sheet, <3 mm) |

| Supported File Formats | DXF, DWG, STEP, IGES |

| Quality Standard | ISO 9001:2015, ISO 39075 (laser cutting) |

At Wuxi Lead Precision Machinery, custom laser cut steel is more than a service—it is an engineering discipline. We combine advanced technology, strict process control, and deep industry experience to deliver components that meet the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting for Demanding Steel Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in custom laser cutting for steel, engineered specifically for high-integrity industrial components. Our advanced manufacturing cell centers on state-of-the-art 5-axis CNC laser systems, enabling complex geometries and intricate features impossible with conventional 2D or 3D platforms. This capability is critical for aerospace brackets, medical device housings, and energy sector components requiring precise bevel cuts, undercuts, and multi-faceted contours directly from the flat sheet. Our lasers utilize high-power fiber technology with intelligent power modulation and nitrogen assist gas for superior edge quality, minimal dross, and exceptional kerf width control across carbon steel, stainless steel, and tool steel alloys. Material handling is fully integrated with automated loading/unloading systems, ensuring consistent throughput for both prototyping and high-volume production runs up to 25mm thickness.

Rigorous quality assurance is embedded within our process flow, not merely a final checkpoint. Every critical dimension undergoes verification via coordinate measuring machine (CMM) inspection, providing full traceability and certified reports compliant with AS9100 and ISO 9001 standards. Our metrology lab utilizes calibrated Zeiss CONTURA systems, capable of sub-micron measurement resolution on complex 3D parts derived from laser-cut blanks. This systematic approach ensures dimensional conformity from the first article through full production, significantly reducing client scrap rates and assembly rework. Material certification and batch traceability are standard, providing complete confidence in the integrity of every steel component we produce.

The following table details our achievable geometric tolerances for custom laser cut steel parts, reflecting typical performance under controlled production conditions with appropriate material and design considerations:

| Parameter | Material Range | Typical Tolerance | Notes |

|---|---|---|---|

| Positional Accuracy | Carbon Steel (0.5-25mm) | ±0.05 mm | Across full sheet (up to 3000x1500mm) |

| Linear Dimension | Stainless Steel (1-20mm) | ±0.10 mm | For features > 50mm |

| Hole Diameter | Tool Steel (1-15mm) | +0.00 / -0.05 mm | Nitrogen cut, no secondary operation |

| Edge Perpendicularity | All Steels | ≤ 0.15° | Measured over 10mm height |

| Bevel Angle Accuracy | 5-Axis Cuts | ±0.5° | For weld prep & complex contours |

This precision foundation directly translates to client value: reduced assembly time, elimination of secondary machining for many features, and guaranteed fit for mission-critical assemblies. Our engineering team collaborates early in the design phase to optimize manufacturability, leveraging the full potential of 5-axis laser processing to achieve your exact functional requirements while minimizing cost and lead time. Wuxi Lead provides not just cut parts, but certified, ready-to-assemble components meeting the most stringent global industry demands. Partner with us for laser cutting where dimensional integrity is non-negotiable.

Material & Finish Options

Material Selection for Custom Laser Cut Steel and Advanced Sheet Metal Fabrication

Selecting the appropriate material is a critical step in achieving optimal performance, durability, and cost-efficiency in custom laser cutting applications. At Wuxi Lead Precision Machinery, we specialize in high-precision sheet metal fabrication, with expertise in processing aluminum, steel, and titanium—three of the most widely used metals in industrial manufacturing. Each material offers unique mechanical properties, making it suitable for specific operational environments, from aerospace to heavy machinery and electronics enclosures.

Steel remains the most common choice for laser cutting due to its strength, affordability, and broad availability. Mild steel (low-carbon steel) is ideal for structural components and general fabrication, offering excellent weldability and machinability. For applications requiring enhanced corrosion resistance, stainless steel grades such as 304 and 316 are preferred. These alloys contain chromium, which forms a passive oxide layer, protecting the material from rust and chemical degradation. Stainless steel is frequently used in food processing, medical devices, and outdoor installations where hygiene and longevity are paramount.

Aluminum is favored in applications where weight reduction is essential without sacrificing strength. Its high strength-to-weight ratio, excellent thermal and electrical conductivity, and natural corrosion resistance make it a top choice for aerospace, automotive, and electronic heat sink applications. Aluminum is also highly reflective, which requires specialized laser parameters during cutting to ensure clean, burr-free edges. Post-processing treatments such as anodizing further enhance aluminum’s surface properties.

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on aluminum, significantly improving wear resistance, corrosion protection, and aesthetic appeal. It also allows for color customization, which is valuable for branding or identification purposes. While anodizing is specific to aluminum, steel and titanium can undergo alternative surface treatments such as powder coating, passivation, or plating depending on environmental exposure and functional requirements.

Titanium, though more costly and challenging to process, delivers exceptional strength-to-density ratios and unparalleled resistance to extreme temperatures and corrosive environments. It is commonly used in aerospace, marine, and medical implant industries. Laser cutting titanium requires precise control of heat input to prevent oxidation and maintain material integrity.

Understanding the interplay between material properties and fabrication techniques ensures optimal component performance. Below is a comparative overview of key physical and mechanical properties.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Grades |

|---|---|---|---|---|---|

| Mild Steel | 7.85 | 370–500 | Low | Structural frames, machinery | Q235, S235 |

| Stainless Steel | 7.90 | 500–700 | High | Medical, food processing, marine | 304, 316 |

| Aluminum | 2.70 | 110–350 | Medium to High | Aerospace, electronics, transport | 5052, 6061, 7075 |

| Titanium | 4.51 | 900–1,200 | Very High | Aviation, medical, chemical plants | Gr2, Gr5 (Ti-6Al-4V) |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on design specifications, environmental conditions, and lifecycle requirements. Our advanced laser cutting systems ensure precision down to ±0.1 mm, while our engineering team provides full consultation on material compatibility and post-processing options.

Manufacturing Process & QC

Custom Laser Cut Steel: Precision Production Process

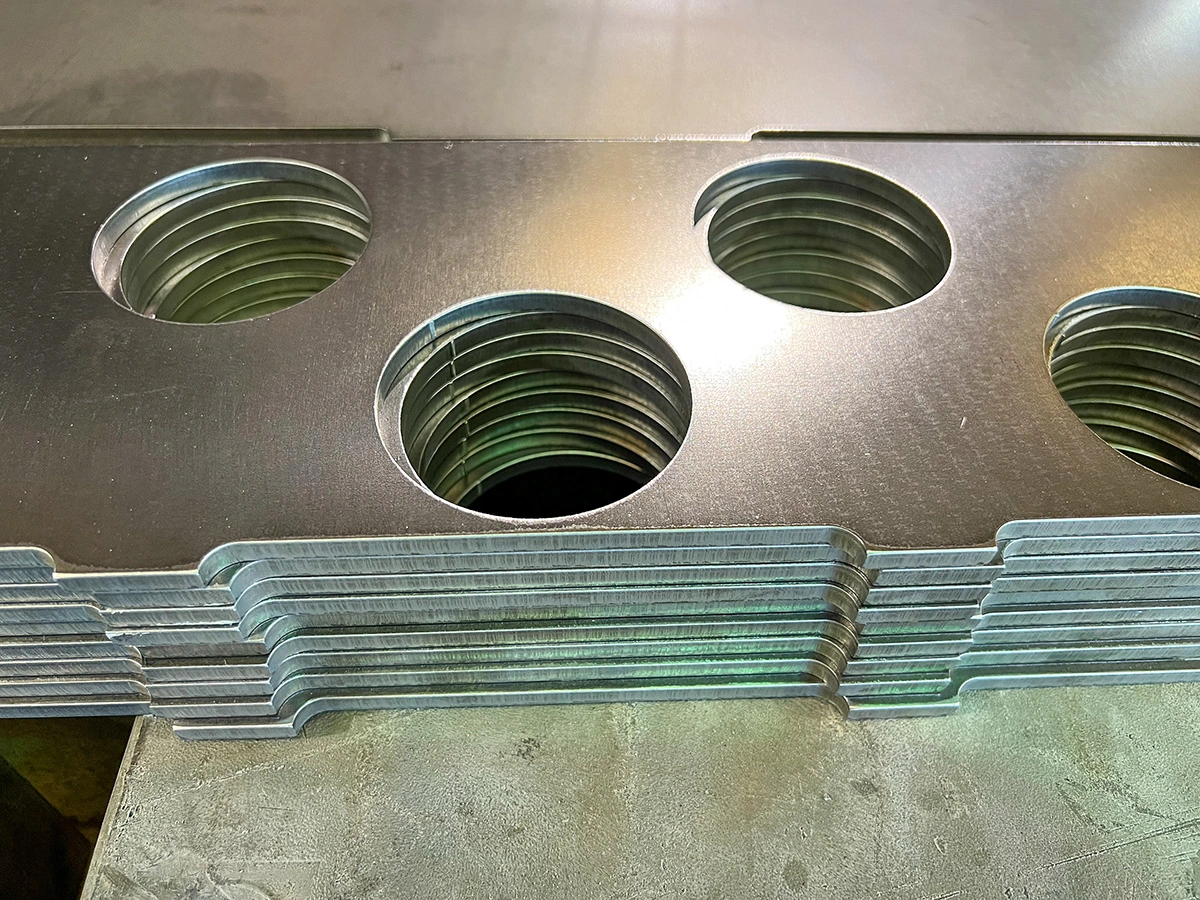

At Wuxi Lead Precision Machinery, our custom laser cutting process for steel sheet metal is engineered for uncompromising quality and repeatability. We implement a rigorously controlled workflow spanning design validation through mass production, underpinned by our Zero Defects philosophy. This systematic approach ensures every component meets exacting engineering specifications while optimizing material yield and throughput for high-volume requirements.

The process initiates with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with client CAD data, scrutinizing geometries, material selections, and tolerance stacks. We identify potential thermal distortion risks, nesting inefficiencies, or feature limitations inherent to laser processing early. This phase leverages advanced simulation software to predict kerf behavior and heat-affected zones, ensuring the design is inherently producible to specification before any metal is cut. Material certification and grade verification are mandatory prerequisites, confirming compliance with ASTM, EN, or client-specific standards.

Prototyping serves as the critical validation step. Using the exact production laser systems and parameters planned for the final run, we fabricate functional prototypes. This eliminates tooling variance, providing true representation of mass production output. Each prototype undergoes first-article inspection against all critical dimensions using calibrated CMMs and optical comparators. Dimensional reports and material test certificates are provided for client approval, confirming the process capability meets the target ±0.1mm tolerance envelope before committing to volume.

Mass production integrates real-time quality control at every stage. Our automated fiber laser systems feature integrated process monitoring, tracking power, gas pressure, and beam focus to maintain cut consistency. Statistical Process Control (SPC) charts govern critical parameters, with automatic machine adjustment if trends approach control limits. Every 50th part undergoes 100% dimensional verification via inline vision systems, while full material traceability is maintained from coil to shipment. Final inspection includes rigorous flatness checks and surface finish validation against agreed Ra values, ensuring components arrive ready for immediate assembly with zero rework.

This closed-loop methodology, combining advanced technology with disciplined process control, delivers the dimensional accuracy and surface integrity demanded by aerospace, medical, and high-end industrial applications. Wuxi Lead’s commitment to Zero Defects is not aspirational—it is engineered into every phase of production.

Key Laser Cutting Specifications

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Material Thickness | Mild Steel: 0.5mm – 30mm | ±0.1mm (≤10mm) |

| Stainless Steel: 0.5mm – 25mm | ±0.2mm (>10mm) | |

| Aluminum: 0.5mm – 20mm | ||

| Laser Power | 1kW – 20kW Fiber | Optimized per material/thickness |

| Tolerance | Standard: ±0.1mm | Tight: ±0.05mm (DFM dependent) |

| Surface Roughness | Ra ≤ 3.2μm (typical) | Ra ≤ 1.6μm (fine cut) |

| Production Speed | Up to 45m/min (thin gauge) | Optimized for quality & yield |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Laser Cut Steel Fabrication

When precision, consistency, and reliability define your manufacturing standards, partnering with Wuxi Lead Precision Machinery ensures your sheet metal components meet the highest global benchmarks. As a leading provider of custom laser cut steel solutions in China, we specialize in delivering high-tolerance, repeatable fabrication services tailored to the exacting demands of aerospace, automotive, energy, medical, and industrial equipment sectors. Our advanced fiber laser technology, combined with rigorous quality control and engineering expertise, enables us to transform your designs into precision-engineered steel components—on time and to specification.

At Lead Precision, we understand that your success depends on more than just cutting steel. It’s about precision, scalability, and supply chain confidence. Our ISO 9001-certified manufacturing facility is equipped with state-of-the-art laser cutting systems capable of handling complex geometries and tight tolerances down to ±0.05 mm. Whether you require low-volume prototypes or high-volume production runs, our agile production lines and expert team ensure seamless execution from concept to delivery.

We work with a wide range of steel materials, including mild steel, stainless steel, and high-strength low-alloy (HSLA) grades, supporting thicknesses from 0.5 mm up to 25 mm. Our laser systems deliver clean, burr-free edges that minimize secondary processing, reducing lead times and overall production costs. Every part undergoes in-process inspection and final quality verification to ensure dimensional accuracy, material integrity, and surface finish consistency.

Our engineering team collaborates directly with your design and manufacturing staff to optimize part layouts, reduce material waste, and improve manufacturability—delivering not just parts, but value-added solutions. With automated material handling, real-time production monitoring, and global logistics support, we ensure your supply chain remains agile and responsive.

Choose a partner who combines technical excellence with operational reliability. At Wuxi Lead Precision Machinery, we are committed to being an extension of your manufacturing capability—delivering precision, transparency, and performance on every order.

Contact us today at [email protected] to discuss your custom laser cut steel requirements. Let our team provide a detailed quotation, material recommendations, and engineering support tailored to your project. We respond to all inquiries within 12 business hours and offer sample parts upon request to demonstrate our capabilities.

| Specification | Detail |

|---|---|

| Material Types | Mild Steel, Stainless Steel (304, 316), HSLA Steel |

| Thickness Range | 0.5 mm – 25 mm |

| Tolerance | ±0.05 mm |

| Laser Power | Up to 12 kW Fiber Laser |

| Max Cutting Area | 1500 mm × 3000 mm |

| Edge Quality | Burr-free, minimal dross |

| Certifications | ISO 9001:2015 |

| Lead Time | From 5 days (prototype), scalable for volume |

Start your next project with confidence. Reach out to [email protected] and experience the Lead Precision advantage in custom laser cut steel fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.