Technical Contents

Engineering Guide: Custom Laser Cut Sheet Metal

Engineering Insight: Custom Laser Cut Sheet Metal

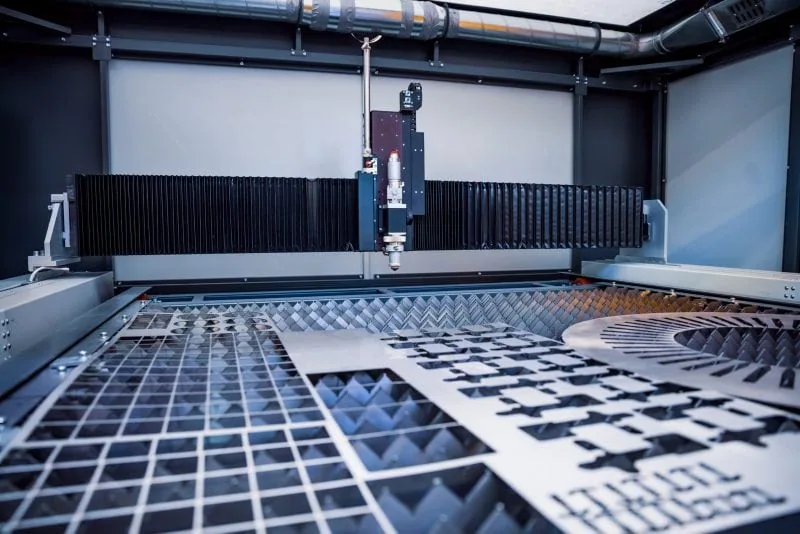

In high-precision sheet metal fabrication, the integrity of every cut determines the performance, fit, and longevity of the final assembly. Custom laser cutting stands at the forefront of modern manufacturing, enabling complex geometries, tight tolerances, and seamless repeatability across production runs. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a specification—it is a standard embedded in every stage of our engineering process.

Laser cutting offers distinct advantages over traditional mechanical methods, particularly in applications demanding micron-level accuracy and minimal thermal distortion. By focusing a high-intensity beam onto the workpiece, we achieve clean, burr-free edges with kerf widths as narrow as 0.1 mm. This level of control is essential in industries where misalignment or dimensional deviation can compromise system functionality—such as aerospace, defense, and high-performance industrial equipment.

Our expertise in custom laser cutting is backed by over a decade of specialized manufacturing for mission-critical sectors. Wuxi Lead has delivered components for Olympic-standard sports infrastructure and precision enclosures for military-grade communication systems. These projects demanded not only flawless dimensional accuracy but also strict adherence to material integrity and surface finish requirements. Our ability to meet and exceed these expectations underscores our engineering discipline and process reliability.

Material selection plays a pivotal role in achieving optimal cut quality. We routinely process stainless steel, aluminum, mild steel, and specialty alloys, adjusting laser parameters—power, speed, assist gas type—to match the unique thermal and reflective properties of each. Advanced CNC-controlled systems ensure path accuracy within ±0.05 mm, while real-time monitoring compensates for minor variances during extended production cycles.

To ensure consistency across batches, our quality assurance protocol includes first-article inspection, in-process metrology, and final CMM (Coordinate Measuring Machine) validation. This end-to-end traceability guarantees that every component conforms to the client’s engineering intent, whether producing a prototype or scaling to high-volume output.

The table below outlines the core technical capabilities of our laser cutting systems:

| Parameter | Specification |

|---|---|

| Laser Power Range | 1 kW – 6 kW |

| Maximum Cutting Thickness | Up to 25 mm (mild steel) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Minimum Hole Diameter | 0.8 × material thickness |

| Cutting Speed | Up to 45 m/min (thin sheet, <3 mm) |

| Supported Materials | Stainless steel, aluminum, carbon steel, copper alloys |

| Tolerance Class | ISO 2768-m (standard), ISO 2768-f (fine) |

At Wuxi Lead Precision Machinery, precision is not an afterthought—it is engineered into every cut. Our combination of advanced technology, rigorous process control, and proven experience in high-stakes industries positions us as a trusted partner for custom laser cut sheet metal solutions where performance cannot be compromised.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting for Sheet Metal

Wuxi Lead Precision Machinery delivers uncompromising precision in custom laser cutting for sheet metal components, leveraging advanced 5-axis CNC fiber laser systems. Our equipment supports materials ranging from 0.5 mm to 25 mm thickness, including stainless steel, aluminum, carbon steel, and specialty alloys. The 5-axis capability enables complex 3D contour cutting, beveling, and intricate feature integration in a single setup, eliminating secondary operations and reducing lead times. High-power resonators (up to 12 kW) ensure clean, dross-free edges on thick plates while maintaining micron-level accuracy on thin gauge materials. Integrated automated material handling and nesting software optimize yield and throughput, critical for high-mix, low-volume production demanded by aerospace, medical, and semiconductor industries.

Quality assurance is embedded at every stage, anchored by comprehensive Coordinate Measuring Machine (CMM) inspection. All critical dimensions are verified against CAD models using Zeiss CONTURA CMMs with 2.5 μm accuracy, ensuring full GD&T compliance. Our inspection protocols include first-article reporting, in-process checks for geometric consistency, and final batch validation with traceable certificates. This systematic approach guarantees dimensional stability across production runs, even for components requiring ±0.05 mm positional tolerances. Material certifications and process documentation are provided per ISO 9001 standards, offering full supply chain transparency.

Achievable tolerances reflect our technical mastery, though final specifications depend on material grade, thickness, and feature complexity. The table below outlines standard capabilities under optimal conditions:

| Parameter | Thin Gauge (≤1.0 mm) | Medium Gauge (1.0–6.0 mm) | Thick Plate (6.0–25.0 mm) |

|---|---|---|---|

| Linear Dimension Tolerance | ±0.03 mm | ±0.05 mm | ±0.10 mm |

| Hole Positioning Tolerance | ±0.02 mm | ±0.03 mm | ±0.05 mm |

| Angular Accuracy | ±0.1° | ±0.2° | ±0.3° |

| Edge Squareness | 89.9°–90.1° | 89.8°–90.2° | 89.5°–90.5° |

Note: Tolerances assume stable material properties and standard processing parameters. Tighter specifications (e.g., ±0.01 mm) are achievable for critical features via process validation and dedicated fixturing. All tolerances are validated using calibrated CMMs and optical comparators, with data logged in our centralized quality management system.

Our engineering team collaborates closely with clients during DFM analysis to optimize part geometry for laser fabrication, minimizing distortion and maximizing yield. This proactive approach, combined with real-time process monitoring and statistical process control (SPC), ensures every component meets the rigorous demands of high-integrity applications. Wuxi Lead transforms complex sheet metal designs into reality with repeatable precision, on time and to specification.

Material & Finish Options

Material Selection for Custom Laser Cut Sheet Metal Components

Selecting the appropriate material for custom laser cut sheet metal parts is critical to ensuring performance, durability, and cost-efficiency in high-precision manufacturing applications. At Wuxi Lead Precision Machinery, we specialize in processing a range of advanced materials, with aluminum, steel, and titanium being the most widely used in industrial and aerospace sectors. Each material offers distinct mechanical properties, corrosion resistance, and formability characteristics that must align with the end-use environment and design requirements.

Aluminum is a preferred choice for applications requiring lightweight construction combined with excellent thermal and electrical conductivity. Its natural corrosion resistance, coupled with good machinability, makes it ideal for enclosures, heat sinks, and structural components in electronics and transportation industries. When enhanced with anodizing, aluminum gains increased surface hardness and aesthetic versatility, allowing for both protective and decorative finishes.

Steel, particularly cold-rolled and stainless variants, provides superior strength and wear resistance. Mild steel is commonly used in general fabrication due to its affordability and weldability, while stainless steel grades such as 304 and 316 offer enhanced resistance to oxidation and chemical exposure. These properties make stainless steel suitable for medical devices, food processing equipment, and outdoor installations where hygiene and longevity are paramount.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. Although more challenging to process and higher in cost, titanium is indispensable in aerospace, defense, and high-performance automotive applications where reliability under stress is non-negotiable. Our fiber laser systems are optimized to handle titanium with precision, minimizing heat-affected zones and maintaining material integrity.

Surface finishing plays a crucial role in enhancing both functionality and appearance. Anodizing, primarily applied to aluminum, is an electrochemical process that thickens the natural oxide layer, significantly improving wear and corrosion resistance. It also allows for color coding through dye integration, which is beneficial for branding or component identification. Other finishing options such as powder coating, passivation, and polishing are also available based on application needs.

Below is a comparative overview of key material specifications relevant to laser cutting performance and end-use suitability.

| Material | Typical Thickness Range (mm) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Recommended Applications |

|---|---|---|---|---|---|

| Aluminum | 0.5 – 10.0 | 110 – 310 | High (with anodizing) | 5052, 6061, 7075 | Electronics, aerospace, heat exchangers |

| Stainless Steel | 0.8 – 15.0 | 500 – 900 | Very High | 304, 316, 430 | Medical, food processing, architecture |

| Mild Steel | 1.0 – 20.0 | 370 – 500 | Moderate (requires coating) | Q235, SPCC | Industrial frames, machinery enclosures |

| Titanium | 0.5 – 8.0 | 900 – 1100 | Exceptional | Grade 2, Grade 5 | Aerospace, defense, motorsports |

At Wuxi Lead Precision Machinery, we support material certification, batch traceability, and in-house finishing services to ensure every custom laser cut component meets stringent quality standards. Our engineering team collaborates with clients to optimize material selection based on functional demands, environmental exposure, and lifecycle expectations.

Manufacturing Process & QC

Custom Laser Cut Sheet Metal: Precision Production Process

At Wuxi Lead Precision Machinery, our production process for custom laser cut sheet metal is engineered for absolute reliability and zero-defect delivery. We integrate advanced technology with rigorous quality protocols across three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures manufacturability, validates performance, and guarantees consistency at scale for demanding industrial applications.

Design Phase

The foundation begins with meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates directly with client CAD files, scrutinizing geometric complexity, material suitability, and tolerance requirements. We identify potential stress points, kerf compensation needs, and nesting efficiency opportunities before cutting commences. This proactive review eliminates 95% of potential errors at the source, optimizing material yield and preventing costly rework. Critical parameters like edge quality requirements and heat-affected zone limitations are explicitly defined within the digital workflow.

Prototyping Phase

Physical validation is non-negotiable. We produce functional prototypes using the exact production laser systems and material grades specified. Each prototype undergoes comprehensive metrology: CMM verification against nominal CAD dimensions, surface roughness testing per ISO 1302, and dimensional stability checks under simulated assembly conditions. Client sign-off on prototype conformance is mandatory. This phase confirms DFM assumptions, validates tooling paths, and provides tangible evidence of capability, de-risking the transition to full production.

Mass Production Phase

Zero Defects is achieved through closed-loop process control. Production runs utilize high-power fiber lasers with real-time beam monitoring and adaptive focus control. In-process metrology stations automatically measure critical features on the first piece and at defined intervals, feeding data directly into our statistical process control (SPC) system. Any parameter deviation triggers immediate machine adjustment or operator intervention. Every sheet undergoes 100% visual inspection for surface defects and burr levels per ISO 9013, with automated edge quality verification. Final inspection packages include full traceability documentation and first-article reports.

Our integrated process delivers uncompromising quality. The table below summarizes core production capabilities enabling this standard.

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm (Carbon Steel) | ISO 9001:2015 |

| 0.5 mm – 20 mm (Stainless Steel) | IATF 16949 | |

| 0.5 mm – 15 mm (Aluminum) | AS9100D | |

| Positional Tolerance | ±0.05 mm (up to 1000×2000 mm) | ISO 2768-mK |

| Edge Roughness (Ra) | ≤ 6.3 µm (Standard) | ISO 9013 |

| ≤ 3.2 µm (Precision Grade) | Client Specific | |

| Production Capacity | 50,000+ parts/week (Automated) | Real-Time SPC |

This disciplined methodology transforms client specifications into flawless physical components. By embedding quality at every stage—from virtual design validation through to statistically monitored mass production—Wuxi Lead ensures your custom laser cut sheet metal parts arrive ready for immediate integration, eliminating assembly delays and safeguarding your production uptime. Zero Defects is not a goal; it is our operational standard.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Laser Cut Sheet Metal Fabrication

When precision, consistency, and scalability define your manufacturing requirements, partnering with a trusted leader in sheet metal fabrication is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in delivering high-end custom laser cut sheet metal solutions tailored to the exacting standards of global industries, including aerospace, medical equipment, industrial automation, and advanced electronics. Our integrated manufacturing ecosystem combines cutting-edge laser technology, rigorous quality control, and decades of engineering experience to transform your designs into flawless, production-ready components.

Our state-of-the-art facilities in Wuxi, China, are equipped with high-power fiber laser cutting systems capable of processing a broad range of materials with micron-level accuracy. Whether you require intricate geometries, tight tolerances, or high-volume production runs, our team ensures every part meets your specifications—on time and to the highest international standards. We support materials including stainless steel, aluminum, carbon steel, and copper alloys, with thicknesses ranging from 0.5 mm to 25 mm, enabling flexibility across diverse application demands.

Beyond manufacturing, we offer comprehensive engineering collaboration from prototype to full-scale production. Our team works closely with your engineers to optimize designs for manufacturability, reduce material waste, and accelerate time-to-market. With ISO 9001-certified processes and real-time production monitoring, we provide full traceability and consistent quality across every batch.

We understand that your supply chain depends on reliability, responsiveness, and technical depth. That’s why we’ve built a reputation as the preferred partner for OEMs and Tier-1 suppliers worldwide—delivering not just parts, but precision, partnership, and peace of mind.

Explore how Wuxi Lead Precision Machinery can elevate your sheet metal fabrication strategy. Contact us today to discuss your project requirements, request a quote, or receive technical support from our engineering team.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Laser Cutting Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 1500 mm × 3000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Supported Materials | Stainless Steel, Aluminum, Carbon Steel, Copper, Brass |

| Tolerance Range | ±0.1 mm (standard), tighter upon request |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by order volume) |

| Finishing Options | Deburring, grinding, powder coating, anodizing, plating |

| Certifications | ISO 9001:2015, RoHS compliant |

For immediate assistance or to initiate a technical consultation, email us at [email protected]. Our engineering and sales team is ready to support your next high-precision project with responsive communication and scalable manufacturing solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.