Technical Contents

Engineering Guide: Custom Laser Cut Aluminum Panels

Engineering Insight: Custom Laser Cut Aluminum Panels

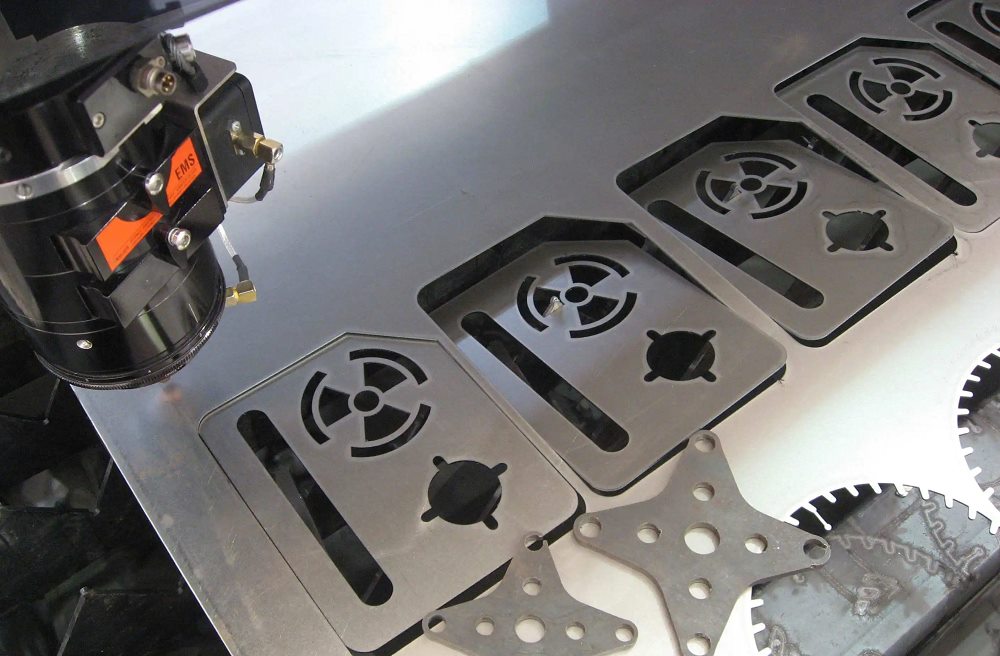

In high-performance manufacturing, precision is not merely a target—it is a requirement. When it comes to custom laser cut aluminum panels, dimensional accuracy, edge quality, and material integrity directly influence the functionality, durability, and integration of components across aerospace, defense, medical, and high-end industrial applications. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise system performance, which is why our engineering approach to laser cutting prioritizes repeatability, consistency, and technical excellence.

Aluminum, while favored for its strength-to-weight ratio and corrosion resistance, presents unique challenges in laser processing. Its high thermal conductivity and reflectivity demand tightly controlled laser parameters and advanced beam delivery systems. Without precise calibration, issues such as dross formation, edge warping, or inconsistent kerf widths can occur—defects that are unacceptable in mission-critical environments. Our CNC fiber laser systems are optimized specifically for aluminum alloys, including 5052, 6061, and 7075, ensuring clean cuts with minimal post-processing.

Our engineering team applies decades of cumulative expertise to every project, with a proven track record in delivering components for Olympic-standard sporting equipment and military-grade enclosures. These applications demand absolute precision under extreme operational conditions. For instance, panels used in mobile defense communication units must maintain electromagnetic shielding integrity and mechanical fit across temperature extremes and constant vibration—requirements that begin with flawless laser cutting.

We implement a full process control loop, from material selection and fixturing to laser focus and assist gas optimization. Our machines use nitrogen or high-purity oxygen as needed to achieve burr-free edges and oxide-free surfaces, critical for subsequent anodizing or bonding processes. Real-time monitoring systems detect beam instability or material variation, allowing immediate correction without human intervention.

Every custom panel undergoes rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators. This ensures compliance with geometric dimensioning and tolerancing (GD&T) standards, typically holding tolerances to ±0.1 mm for cut features and ±0.2 mm for overall dimensions—even in complex nested geometries.

Below are our standard technical capabilities for custom laser cut aluminum panels:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12 mm |

| Maximum Cutting Area | 1500 mm × 3000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Cut Tolerance (Typical) | ±0.1 mm (features), ±0.2 mm (overall) |

| Edge Roughness (Ra) | ≤ 6.3 µm |

| Supported Aluminum Alloys | 1060, 5052, 6061, 7075, and custom grades |

| Surface Finish After Cutting | Smooth, minimal dross, ready for finishing |

At Wuxi Lead Precision Machinery, we do not just cut metal—we engineer performance. Our commitment to precision in custom laser cut aluminum panels ensures that every component meets the highest standards of quality, reliability, and technical sophistication required by global industries.

Precision Specs & Tolerances

Technical Capabilities for Precision Aluminum Panel Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in custom laser cut aluminum panels, leveraging advanced manufacturing infrastructure and rigorous quality control protocols. Our specialization in high-tolerance aluminum fabrication addresses the demanding requirements of aerospace, medical, and advanced electronics sectors where dimensional accuracy and surface integrity are non-negotiable. We excel in transforming complex 3D CAD models into finished components with minimal lead time, utilizing integrated processes that eliminate costly secondary operations.

Our core capability centers on state-of-the-art 5-axis CNC laser cutting systems. These platforms provide unparalleled flexibility for processing aluminum sheets and plates up to 3000mm x 1500mm. The simultaneous multi-axis motion enables intricate contour cutting, precise hole drilling at compound angles, and seamless edge preparation—all in a single setup. This capability is critical for aluminum, which requires careful thermal management to prevent warping or burr formation during cutting. Our systems employ high-brightness fiber lasers with adaptive power control specifically tuned for aluminum alloys, ensuring clean, dross-free edges even on reflective materials. Integrated nesting software maximizes material yield while maintaining strict part-to-part consistency across high-volume production runs.

Quality assurance is embedded at every stage through our comprehensive inspection regime. All critical dimensions undergo verification using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with scanning probe technology. This provides full 3D geometric validation against the original CAD model, detecting deviations as minute as 2.5μm + L/300. Statistical Process Control (SPC) data is continuously monitored during production, allowing real-time adjustments to maintain tolerances. Surface roughness is quantified using portable profilometers to ensure compliance with Ra 0.8μm standards, while visual inspection under controlled lighting confirms absence of micro-cracks or thermal distortion—common failure points in inferior aluminum processing.

The following table details our certified capability ranges for laser cut aluminum panels under controlled environmental conditions:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Material Thickness | 0.5 mm – 25.0 mm | ISO 2768-mK |

| Positional Accuracy | ±0.025 mm | ISO 2768-fine |

| Hole Diameter Tolerance | +0.05 mm / -0.00 mm | ISO 2768-mid |

| Feature-to-Feature | ±0.05 mm within 500mm span | ASME Y14.5-2018 |

| Angular Accuracy | ±0.1° | ISO 2768-veryfine |

| Surface Roughness (Ra) | ≤ 0.8 μm (as-cut) | ISO 4287 |

| Max. Part Dimensions | 3000 mm x 1500 mm x 100 mm (H) | Customer Drawing |

This technical foundation enables us to consistently achieve first-article approval on complex aluminum panel projects. Our engineers collaborate directly with client design teams during DFM analysis to optimize manufacturability while preserving functional intent. By combining 5-axis laser precision with metrology-grade validation, Wuxi Lead eliminates the dimensional variability that causes assembly line disruptions in critical applications. We provide full inspection reports traceable to NIST standards, giving procurement teams absolute confidence in component reliability. Partner with us to convert your most challenging aluminum panel designs into production-ready reality with zero compromise on precision.

Material & Finish Options

Material Selection for Custom Laser Cut Aluminum Panels

Selecting the appropriate material for custom laser cut aluminum panels is critical to achieving optimal performance, durability, and cost-efficiency in high-precision applications. While aluminum remains the preferred choice for many industrial and architectural uses due to its lightweight nature and excellent corrosion resistance, alternative materials such as stainless steel and titanium may be considered depending on environmental exposure, structural requirements, and budget constraints.

Aluminum, particularly grades 5052, 6061, and 7075, offers an ideal balance of strength, machinability, and thermal conductivity. Grade 6061 is widely used in structural enclosures and aerospace components due to its good weldability and moderate strength. Grade 5052 excels in marine and high-corrosion environments, while 7075, though more difficult to process, delivers superior strength-to-weight ratios for mission-critical applications. Aluminum’s low density reduces transportation and installation costs, making it a strategic choice for large-scale panel systems.

Stainless steel, such as grades 304 and 316, provides higher tensile strength and enhanced resistance to extreme temperatures and mechanical wear. However, its greater weight and reflectivity can complicate laser cutting processes and increase energy consumption. It is typically selected when long-term structural integrity under heavy load or exposure to harsh chemicals is required.

Titanium, specifically Grade 2 and Grade 5 (Ti-6Al-4V), is reserved for specialized applications in aerospace, defense, and medical equipment. It offers exceptional strength-to-density ratios and unparalleled resistance to oxidation and saltwater corrosion. Despite its superior performance, titanium’s high material cost and challenging machinability limit its use to niche, high-value projects.

Surface finish plays a pivotal role in both aesthetics and functionality. Anodizing is the most common post-processing treatment for aluminum panels. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paints or adhesives. Type II (sulfuric acid) anodizing provides a durable, decorative finish suitable for most industrial uses, while Type III (hardcoat anodizing) delivers enhanced hardness and is ideal for high-abrasion environments. Anodized surfaces can also be dyed in a range of colors for brand alignment or identification purposes.

At Wuxi Lead Precision Machinery, we support precise laser cutting of all three materials with tight tolerances and clean edge quality. Our advanced fiber laser systems ensure minimal heat distortion, especially critical when processing thin aluminum sheets or sensitive titanium alloys.

Below is a comparative overview of key material properties relevant to laser-cut panel fabrication.

| Material | Grade | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.70 | 310 | High | Enclosures, frames, heat sinks |

| Aluminum | 5052-H32 | 2.68 | 220 | Very High | Marine panels, transportation |

| Stainless Steel | 304 | 8.00 | 505 | High | Food processing, chemical handling |

| Stainless Steel | 316 | 8.00 | 570 | Very High | Offshore, pharmaceutical |

| Titanium | Grade 2 | 4.51 | 345 | Exceptional | Aerospace, medical implants |

| Titanium | Grade 5 | 4.43 | 900 | Exceptional | Jet engines, high-performance vehicles |

Manufacturing Process & QC

Custom Laser Cut Aluminum Panels: Precision Production Process

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for custom laser cut aluminum panels, ensuring absolute adherence to Zero Defects principles from initial concept to final shipment. This integrated approach minimizes risk and guarantees dimensional accuracy and surface integrity critical for high-value applications.

The process initiates with collaborative Design Engineering. Our team conducts comprehensive Design for Manufacturability (DFM) analysis on client CAD files, verifying feature feasibility, optimizing nesting efficiency, and confirming material suitability against project requirements. We strictly utilize certified aluminum alloys, primarily 6061-T6 and 5052-H32, sourced with full mill test reports. Critical parameters such as kerf width, heat-affected zone management, and part orientation are simulated using advanced CAM software to prevent warpage or distortion. This phase concludes with formal client sign-off on the validated manufacturing plan, eliminating ambiguity before material release.

Prototyping follows as a non-negotiable validation step. A single representative panel is produced on our state-of-the-art fiber laser systems under full production parameters. This physical sample undergoes rigorous metrology: CMM verification against all Geometric Dimensioning and Tolerancing (GD&T) callouts, surface roughness testing per ISO 25178, and visual inspection under controlled lighting for edge quality and burr presence. Any deviation triggers immediate root cause analysis and process correction. Client approval of the prototype certifies that the manufacturing methodology meets exact specifications, de-risking subsequent volume production.

Mass Production leverages the perfected parameters from prototyping within our Zero Defects framework. Panels are processed on high-precision Mazak and Bystronic laser cutters with automated material handling, maintaining consistent beam focus and assist gas purity. Real-time Statistical Process Control (SPC) monitors key variables like cut speed, power stability, and positional accuracy. Every panel undergoes 100% automated optical inspection for dimensional compliance and surface defects, supplemented by random CMM spot checks. Final packaging utilizes anti-static, moisture-resistant materials with serialized traceability logs. This closed-loop system, combined with operator certification and continuous process refinement, ensures defect escape is statistically impossible.

Our commitment to Zero Defects is quantifiable through the following guaranteed production specifications:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Material Grades | 6061-T6, 5052-H32, 7075-T6 (Certified) | ASTM B209 |

| Thickness Range | 0.5 mm – 12.0 mm | ISO 2768-mK |

| Positional Tolerance | ±0.05 mm | ISO 2768-f |

| Edge Perpendicularity | ≤ 0.1 mm over 100 mm height | Customer Specific |

| Surface Roughness (Ra) | ≤ 3.2 µm (Typical 1.6 µm) | ISO 1302 |

| Burr Height | ≤ 0.05 mm (Deburring Optional) | Internal Standard |

This disciplined progression from validated design through prototype certification to SPC-monitored mass production delivers aluminum panels meeting the most stringent aerospace, medical, and semiconductor industry demands. Partner with Wuxi Lead for guaranteed precision and uncompromised quality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Excellence in Custom Laser Cut Aluminum Panels

When precision, consistency, and performance define your manufacturing standards, partnering with Wuxi Lead Precision Machinery ensures your custom laser cut aluminum panels meet the highest global benchmarks. As a leading sheet metal fabrication specialist based in Wuxi, China, we deliver engineered solutions tailored to industries demanding tight tolerances, complex geometries, and repeatable accuracy — from aerospace and transportation to medical devices and industrial automation.

Our advanced fiber laser cutting systems operate at peak efficiency, enabling clean, burr-free cuts on aluminum sheets up to 20 mm thick with dimensional accuracy within ±0.1 mm. With integrated CNC programming and automated material handling, we minimize human error and maximize throughput, ensuring your projects are completed on time and to exact specifications. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem adapts to your timeline and quality expectations.

We understand that every client has unique design challenges. Our engineering team collaborates closely during the prototyping phase to optimize cut paths, nesting efficiency, and material utilization — reducing waste and lowering overall costs. All aluminum panels undergo rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators, guaranteeing compliance with ISO 9001:2015 standards and your technical documentation.

Beyond cutting, we offer comprehensive value-added services including CNC bending, precision welding, surface finishing (anodizing, powder coating, brushing), and full assembly. This vertical integration allows us to deliver finished components directly to your production line, simplifying logistics and reducing lead times.

Our commitment to innovation is matched only by our dedication to service. Clients worldwide trust us not just as a supplier, but as a strategic manufacturing partner invested in their long-term success. From initial design review to final delivery, we provide full traceability, real-time production updates, and responsive technical support.

Explore how Wuxi Lead Precision Machinery can elevate your next project with flawless custom laser cut aluminum panels. Contact us today at [email protected] to discuss your requirements, request a quote, or receive a free design for manufacturability (DFM) analysis.

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum Alloys (6061, 5052, 7075, etc.), up to 20 mm thickness |

| Laser Cutting Accuracy | ±0.1 mm |

| Maximum Cutting Area | 1500 mm × 3000 mm |

| Edge Quality | Burr-free, smooth finish suitable for welding and coating |

| Tolerance Standards | ISO 2768-m, or customer-specific GD&T |

| Software Integration | AutoCAD, SolidWorks, DXF, STEP file support |

| Production Capacity | Prototype to high-volume series production |

| Quality Certification | ISO 9001:2015 compliant |

| Lead Time | As fast as 5–7 days for standard orders |

| Finishing Options | Deburring, anodizing, powder coating, sandblasting, brushing |

Let Wuxi Lead Precision Machinery be your trusted partner in precision sheet metal fabrication. Reach out to [email protected] and experience engineering excellence built to your standards.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.