Technical Contents

Engineering Guide: Custom Insert Molding

Engineering Insight Precision in Custom Insert Molding

Achieving flawless integration between metal inserts and molded components demands uncompromising precision at every stage. Custom insert molding is not merely an assembly process; it is a critical engineering challenge where microscopic misalignment or thermal mismatch can lead to catastrophic failure in high-stress applications. The core challenge lies in managing the fundamental material differences: metal inserts possess vastly different thermal expansion coefficients and surface energy characteristics compared to polymers. Without exacting control over insert placement, mold cavity geometry, and thermal profiles, results include compromised structural integrity, internal stresses causing premature part failure, flash, or incomplete encapsulation. These defects are unacceptable in sectors where component reliability is paramount.

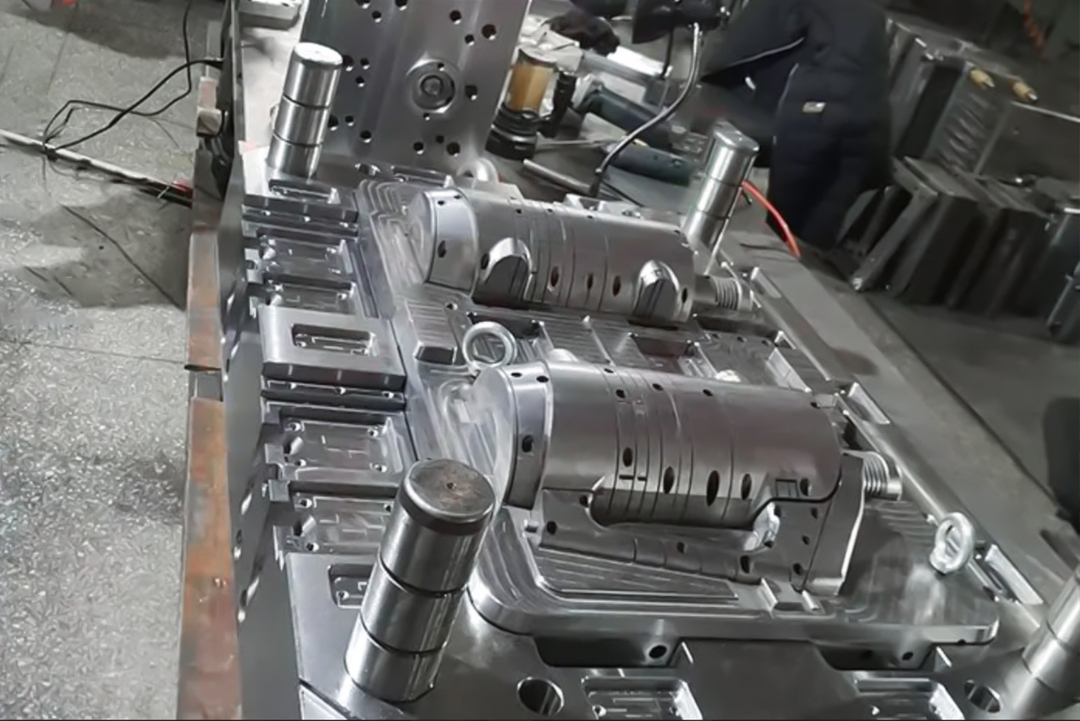

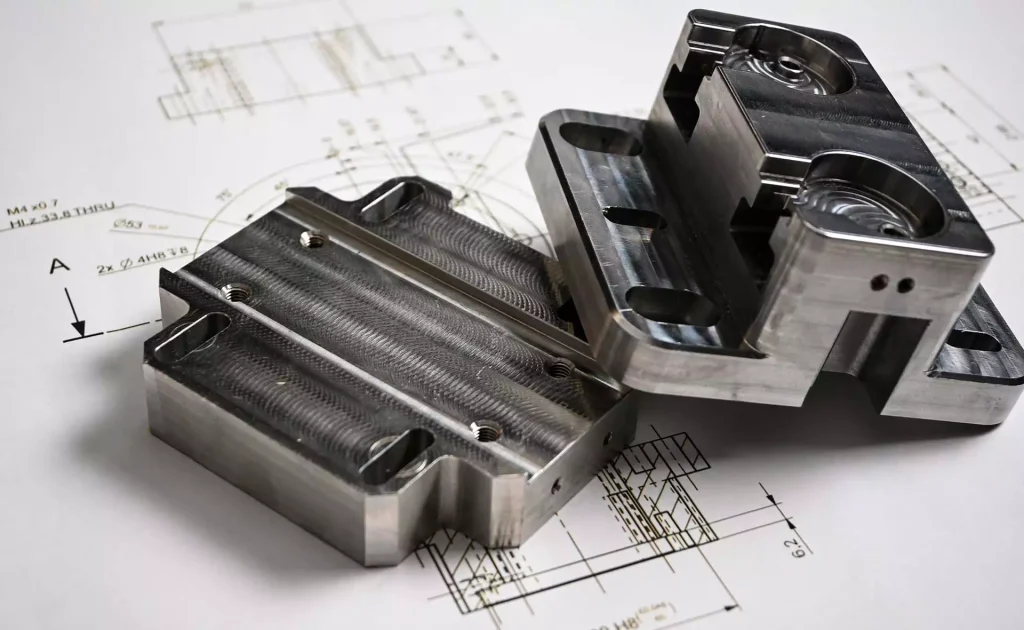

Precision begins with the metal insert itself. Its dimensional accuracy, surface finish, and consistency directly dictate the quality of the polymer-metal bond and the final part’s geometry. Our CNC machining processes at Wuxi Lead Precision Machinery ensure inserts meet stringent tolerances before they even reach the molding press. We then meticulously control the molding phase, focusing on critical parameters like cavity pressure uniformity, precise insert positioning within the mold (often requiring micron-level accuracy), and synchronized thermal management to minimize stress during cooling. This synchronization prevents warpage and ensures the polymer fully wets the insert surface, creating a robust mechanical and chemical bond. The consequences of imprecision are severe: in aerospace hydraulic manifolds, a slight misalignment can cause seal failure under pressure; in medical device housings, internal stresses can lead to cracking during sterilization cycles.

Wuxi Lead Precision Machinery leverages deep expertise forged in the most demanding environments. Our processes are proven in environments where failure is not an option, having supplied mission-critical insert molded components for Olympic-grade timing systems requiring nanosecond synchronization and specialized military equipment subjected to extreme vibration and temperature fluctuations. This experience translates directly to our commercial and industrial clients, ensuring their custom insert molded parts meet the highest reliability standards. We understand that precision is not an optional add-on; it is the foundational requirement for functional, durable, and safe integrated components.

The table below outlines key precision parameters essential for successful high-integrity custom insert molding:

| Parameter | Critical Range | Impact of Deviation |

|---|---|---|

| Insert Dimensional Tolerance | ±0.005 mm to ±0.02 mm | Misalignment, flash, bond failure |

| Cavity Placement Accuracy | ±0.01 mm to ±0.05 mm | Uneven wall thickness, stress points |

| Mold Temperature Control | ±0.5°C to ±2.0°C | Inconsistent flow, warpage, poor bond |

| Polymer Melt Temperature | ±3°C to ±5°C | Viscosity variation, incomplete fill |

| Clamping Force Stability | ±1% of setpoint | Flash, parting line mismatch |

| Material Compatibility | Verified adhesion data | Delamination under thermal/mechanical load |

This level of control requires integrated expertise spanning ultra-precision metal fabrication, advanced mold design, and deep polymer processing knowledge. At Lead Precision, we engineer solutions where the metal insert and polymer function as a single, reliable unit, delivering performance that meets the exacting demands of modern high-end manufacturing. Precision is not just our standard; it is the guarantee we provide.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom insert molding solutions tailored for high-performance industries including aerospace, medical devices, automotive, and industrial automation. Our technical capabilities are built around precision engineering, advanced CNC technology, and rigorous quality assurance protocols, ensuring that every component meets the most demanding application requirements.

At the core of our manufacturing process is our 5-axis CNC machining platform. This state-of-the-art equipment enables us to produce complex geometries with exceptional accuracy and surface finish, critical for successful insert molding integration. The simultaneous movement across five axes allows for single-setup machining of intricate metal inserts, minimizing human error, reducing cycle times, and ensuring dimensional consistency across high-volume production runs. Our machines are maintained to OEM standards and operated by certified CNC programmers and machinists with over a decade of experience in tight-tolerance metal fabrication.

All custom insert molding components undergo comprehensive quality control, beginning with raw material verification and continuing through final inspection. Our dedicated metrology lab is equipped with a Zeiss DuraMax Coordinate Measuring Machine (CMM), enabling non-contact and tactile 3D measurement with micron-level precision. Each part is inspected against the client’s CAD model using GD&T analysis, ensuring full compliance with design specifications. We maintain full traceability for every batch, including material certifications, process parameters, and inspection reports, all stored securely for audit and recall readiness.

Our insert molding process supports a wide range of metals, including stainless steel (304, 316), aluminum alloys (6061, 7075), titanium, and brass. These inserts are precisely machined to interface seamlessly with overmolded thermoplastics such as PEEK, PPS, and liquid silicone rubber (LSR), ensuring strong mechanical bonds and long-term reliability under thermal, chemical, and mechanical stress. Secondary operations—including passivation, anodizing, plating, and laser marking—are available to meet functional and regulatory requirements.

We specialize in low to mid-volume production with scalability for high-volume needs, offering rapid prototyping, design for manufacturability (DFM) reviews, and full project lifecycle support. Our engineering team collaborates directly with clients to optimize part design, material selection, and molding parameters, reducing risk and accelerating time to market.

The following table outlines our standard technical specifications and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling & Turning |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm (standard), ±0.002 mm (tight) |

| Surface Roughness (Ra) | 0.4 μm to 1.6 μm (machined), down to 0.1 μm (polished) |

| Feature Repeatability | ±0.003 mm (CpK ≥ 1.67) |

| Maximum Work Envelope | 800 x 500 x 400 mm |

| CMM Measurement Accuracy | ±0.0015 mm |

| Materials | Stainless Steel, Aluminum, Titanium, Brass, PEEK, PPS, LSR |

| Secondary Operations | Passivation, Anodizing, Plating, Laser Marking |

Wuxi Lead Precision Machinery combines engineering excellence with disciplined process control to deliver custom insert molding solutions that perform under the most demanding conditions.

Material & Finish Options

Material Selection for Precision Insert Molding Applications

Material selection critically impacts the performance, durability, and manufacturability of custom insert molded components. At Wuxi Lead Precision Machinery, our engineering team emphasizes matching substrate properties to the operational environment and molding process parameters. Key considerations include thermal expansion compatibility with the overmolded polymer, mechanical strength requirements, corrosion resistance, weight constraints, and secondary finishing needs. Aluminum, steel, and titanium represent the primary metallic substrates for demanding applications, each offering distinct advantages.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are widely favored for lightweight structural components requiring good machinability and thermal conductivity. They provide an excellent balance of strength-to-weight ratio and cost-effectiveness for aerospace brackets, automotive sensors, and consumer electronics housings. Steel, especially stainless grades like 304 and 17-4 PH, delivers superior strength, wear resistance, and dimensional stability under high loads or elevated temperatures. It is the standard choice for medical instrument components, hydraulic fittings, and industrial tooling inserts where longevity is paramount. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), offer exceptional strength-to-weight ratio, outstanding corrosion resistance in harsh environments (e.g., marine, chemical), and biocompatibility. While commanding a higher material and processing cost, titanium is indispensable for critical aerospace fasteners, surgical implants, and downhole oilfield equipment.

Surface preparation is equally vital. Anodizing is the predominant finishing process for aluminum substrates in insert molding. This electrochemical treatment creates a dense, porous aluminum oxide layer that significantly enhances corrosion resistance, wear properties, and provides an ideal mechanical key for polymer adhesion. Type II (sulfuric acid) anodizing offers good general protection and dyeing capability, while harder Type III (hardcoat) anodizing is specified for severe abrasion resistance. Proper sealing of the anodized layer post-molding is essential to maintain integrity and prevent fluid ingress. Steel and titanium typically utilize alternative finishes like passivation, electropolishing, or specialized coatings depending on the application, as anodizing is specific to aluminum.

Selecting the optimal material and finish requires analyzing the entire part lifecycle. Our precision CNC machining capabilities ensure tight tolerances on the metal insert, directly influencing the bond quality and final part performance during the molding cycle. Consult our engineering team early in the design phase to evaluate material suitability against your specific functional requirements and production volumes.

Key Material Properties Comparison for Insert Molding

| Property | Aluminum 6061-T6 | Stainless Steel 304 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Tensile Strength (MPa) | 310 | 515 | 900 |

| Yield Strength (MPa) | 275 | 205 | 830 |

| Thermal Conductivity (W/m·K) | 167 | 16 | 7.2 |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 23.6 | 17.3 | 8.6 |

| Primary Insert Molding Advantages | Lightweight, good thermal match with many polymers, cost-effective | High strength, wear resistance, temperature stability | Highest strength-to-weight, extreme corrosion resistance, biocompatible |

| Typical Anodizing Finish | Type II or Type III | Not Applicable (Passivation/EP typical) | Not Applicable (Specialty coatings typical) |

Manufacturing Process & QC

Custom insert molding at Wuxi Lead Precision Machinery integrates precision metal components with engineered thermoplastics to deliver high-strength, functionally optimized parts for demanding industrial applications. Our end-to-end production process is engineered for zero defects, ensuring reliability, repeatability, and compliance with the strictest quality standards in aerospace, medical, and automation sectors.

The process begins with collaborative design engineering. Our team works closely with clients to analyze component functionality, material compatibility, and structural requirements. Using advanced 3D CAD and finite element analysis (FEA), we simulate thermal expansion, stress distribution, and mold flow dynamics to optimize part geometry and insert placement. Design for manufacturability (DFM) reviews are conducted to preempt potential defects such as warpage, voids, or insert misalignment. This phase ensures that every design is not only functional but also inherently robust for high-volume production.

Following design validation, we proceed to prototyping using high-precision CNC-machined molds and production-intent materials. Prototypes are manufactured under controlled conditions that mirror full-scale production, enabling accurate performance assessment. Each prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and optical metrology systems. Functional testing, including tensile strength, thermal cycling, and electrical continuity checks, verifies performance under real-world conditions. Feedback from this stage is used to fine-tune mold parameters and process settings, ensuring a seamless transition to mass production.

Mass production is executed on automated, closed-loop injection molding platforms equipped with in-cavity pressure and temperature sensors. These systems enable real-time process monitoring and automatic correction of deviations, maintaining tight tolerances and consistent part quality. Inserts—typically machined from stainless steel, aluminum, or specialized alloys—are precisely placed using robotic loaders with micron-level accuracy. The molding process utilizes high-performance thermoplastics such as PEEK, PSU, or nylon, selected for chemical resistance, mechanical strength, and thermal stability.

Throughout production, statistical process control (SPC) is employed to monitor critical dimensions and process capability. Every batch is subjected to 100% visual inspection and抽样 testing per AQL standards. Our ISO 13485 and IATF 16949-certified facility ensures full traceability, from raw material lot numbers to mold cavity data.

| Specification | Detail |

|---|---|

| Insert Materials | Stainless Steel (304, 316), Aluminum (6061, 7075), Brass, Custom Alloys |

| Plastic Materials | PEEK, PSU, PPS, Nylon 6/6, PBT, LCP |

| Insert Tolerance | ±0.005 mm |

| Molded Part Tolerance | ±0.02 mm |

| Production Capacity | Up to 500,000 units/month |

| Quality Standards | ISO 13485, IATF 16949, AQL 1.0 |

| Secondary Operations | Ultrasonic welding, laser marking, heat treatment, plating |

Wuxi Lead Precision Machinery’s insert molding process is built on precision, control, and continuous improvement—delivering zero-defect components that perform reliably in the most critical applications.

Why Choose Wuxi Lead Precision

Elevate Your Insert Molding Projects with Lead Precision Engineering

Achieving flawless integration of metal components within precision plastic assemblies demands more than standard manufacturing. Custom insert molding requires exceptional dimensional control, material science expertise, and process stability to ensure structural integrity, electrical performance, and long-term reliability in demanding applications. At Wuxi Lead Precision Machinery, we specialize in transforming complex insert molding challenges into repeatable, high-yield manufacturing successes for the aerospace, medical device, and advanced electronics sectors. Our integrated engineering and production approach eliminates the communication gaps and quality inconsistencies common when sourcing inserts and molding separately.

Our dedicated team of CNC engineers and molding specialists collaborates from the initial design review through final validation. We leverage advanced multi-axis milling and turning centers, operating under strict environmental controls, to produce inserts with micron-level tolerances and superior surface finishes critical for optimal polymer adhesion and part function. This precision manufacturing foundation, combined with our deep understanding of polymer flow dynamics and thermal management during the molding cycle, ensures your inserts are perfectly positioned and encapsulated every time. We manage the entire critical path, from raw material certification to final dimensional and functional inspection, providing a single point of accountability for your most demanding projects.

Key capabilities enabling your insert molding success include:

| Specification Category | Lead Precision Capability |

|---|---|

| Insert Tolerance Range | ±0.005 mm to ±0.025 mm |

| Compatible Insert Materials | Stainless Steel (304, 316L, 17-4PH), Titanium, Inconel, Brass, Aluminum Alloys |

| Max Insert Part Size | 300 mm x 200 mm x 150 mm |

| Typical Lead Time (Prototype to Pilot) | 4-6 Weeks |

| Quality Certifications | ISO 9001:2015, IATF 16949, Full Traceability & PPAP Documentation |

Partnering with Lead Precision mitigates your project risks significantly. We proactively identify potential molding issues during the insert design phase, preventing costly tooling modifications and production delays downstream. Our rigorous first-article inspection protocols and in-process statistical process control guarantee consistency batch after batch, directly supporting your regulatory compliance and reducing scrap rates. You gain not just a supplier, but a strategic engineering resource committed to optimizing your total cost of ownership through design-for-manufacturability insights and robust process validation.

Do not compromise on the critical metal-to-plastic interface in your next high-value product. Wuxi Lead Precision Machinery delivers the engineering rigor and manufacturing excellence required for mission-critical insert molding applications. Initiate your project with confidence by contacting our technical sales team. Provide your design specifications and requirements to receive a comprehensive feasibility assessment and precision manufacturing proposal within 48 hours. Secure your competitive advantage through unparalleled component integration.

Contact Lead Precision today at [email protected] to discuss your custom insert molding requirements. Let our engineering expertise become your production advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.