Technical Contents

Engineering Guide: Custom Injection Molders

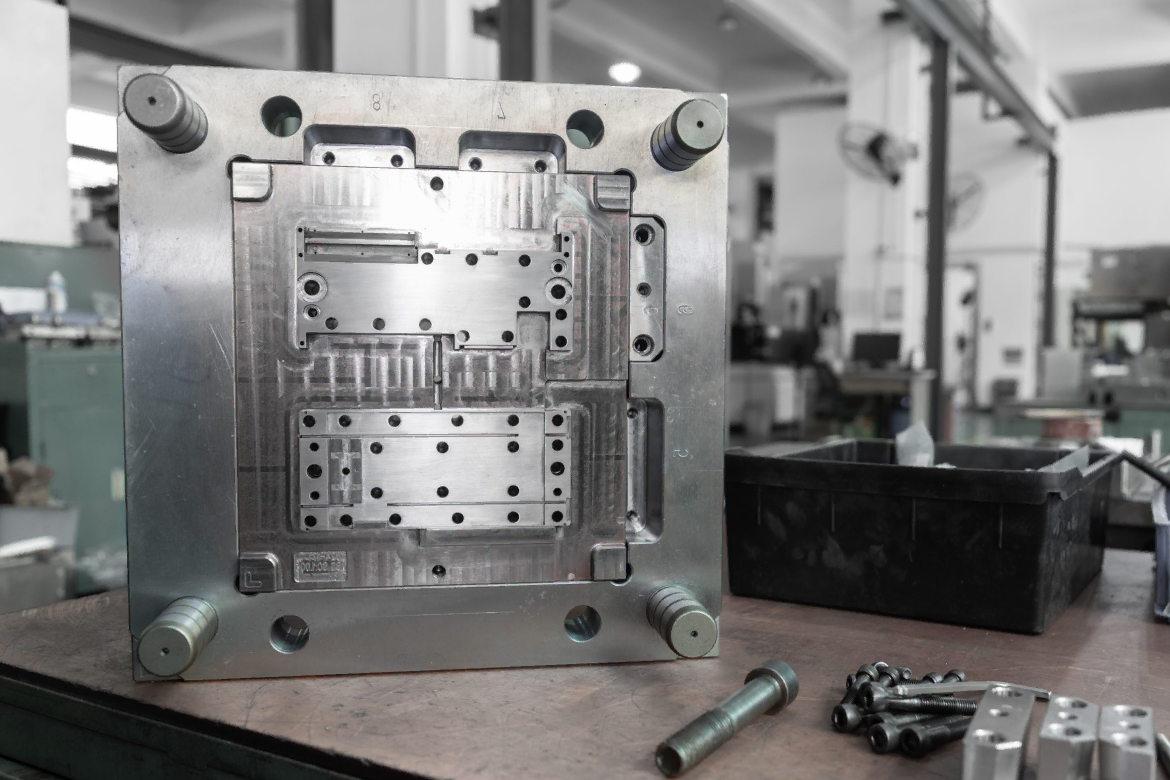

Engineering Insight: The Critical Role of Precision in Custom Injection Molding

In the realm of custom injection molding, precision is not merely a performance metric—it is the foundation of reliability, repeatability, and long-term success. For industries where component failure is not an option—such as aerospace, defense, and high-performance medical devices—the integrity of every molded part hinges on exacting tolerances, consistent material behavior, and flawless process control. At Wuxi Lead Precision Machinery, we understand that precision begins long before the first pellet is melted. It starts with engineering insight, material science expertise, and a commitment to manufacturing excellence that has been proven in the most demanding applications.

Our experience supplying mission-critical components for Olympic-grade equipment and military-grade systems underscores our capability in high-stakes manufacturing environments. These projects demanded more than just precision—they required zero-defect performance under extreme conditions, where even micron-level deviations could compromise system integrity. This level of accountability shapes our approach to every custom injection molding project, ensuring that our clients receive not just parts, but engineered solutions built to perform.

Precision in injection molding is influenced by multiple interdependent factors: mold design accuracy, thermal management, injection pressure control, and real-time process monitoring. At Lead Precision, we integrate advanced simulation software with high-resolution metrology systems to validate designs before production begins. Our in-house tooling department utilizes hardened, corrosion-resistant steels and multi-axis CNC machining to produce molds with tolerances as tight as ±0.002 mm. This ensures dimensional stability across thousands—or millions—of cycles.

We also prioritize material consistency, working with certified resins and conducting rigorous batch testing to ensure mechanical properties meet or exceed specifications. Our molding platforms are equipped with closed-loop control systems that adjust injection speed, pressure, and cooling rates in real time, minimizing variance and eliminating common defects such as warpage, sink marks, or short shots.

For clients in regulated or high-reliability sectors, traceability is equally critical. Every production run at Lead Precision is documented with full process data, including cavity pressure curves, temperature profiles, and first-article inspection reports. This level of transparency supports compliance with ISO 13485, AS9100, and MIL-STD standards.

The following table outlines key precision capabilities at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.025 mm (depending on part size) |

| Mold Steel Types | H13, S136, 2738, 718H, 420SS |

| Maximum Injection Pressure | 2,500 bar |

| Process Control System | Closed-loop with real-time monitoring |

| Material Drying Accuracy | ±1°C temperature control |

| Surface Finish Range | SPI A1 (mirror) to SPI C3 (textured) |

| First Article Inspection | Full CMM, optical, and GD&T reporting |

| Production Environment | ISO 9001-certified cleanroom options |

At Wuxi Lead Precision Machinery, we do not manufacture generic molded parts—we engineer precision solutions for clients who demand performance under pressure. Whether supporting defense logistics or enabling next-generation medical devices, our commitment to accuracy, repeatability, and technical excellence remains unwavering.

Precision Specs & Tolerances

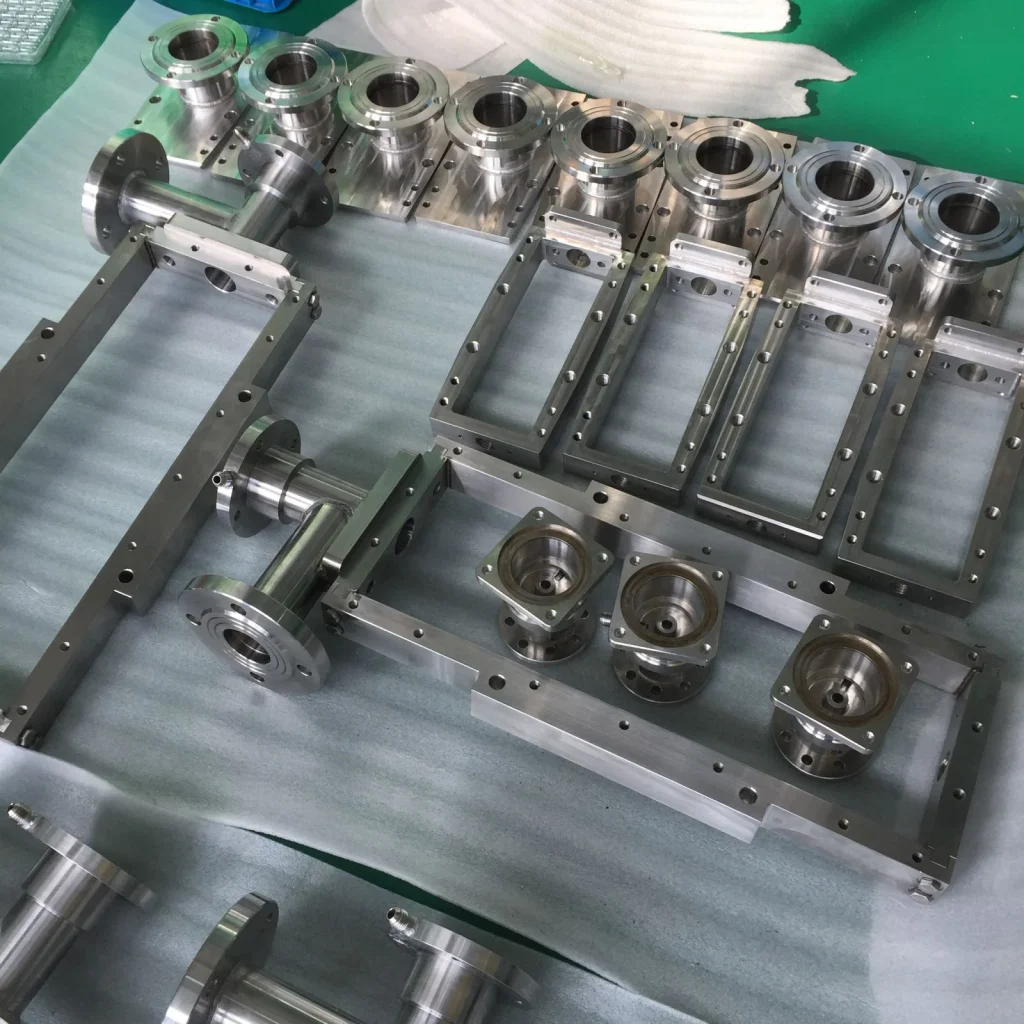

Technical Capabilities: Precision Metal Components for Injection Molding

Wuxi Lead Precision Machinery delivers engineered metal solutions meeting the exacting demands of high-performance injection molding applications. Our core strength lies in advanced multi-axis machining and rigorous quality validation, ensuring components perform reliably under high pressure and cyclic stress. We specialize in producing critical mold elements including cavities, cores, inserts, lifters, and precision bushings where dimensional stability and surface integrity are non-negotiable.

Our manufacturing foundation is built upon state-of-the-art 5-axis CNC machining centers. These systems provide exceptional geometric flexibility, enabling the production of complex organic shapes and deep cavities inherent in modern mold design without requiring multiple setups. This capability significantly reduces cumulative error, improves part consistency, and accelerates lead times. Machines feature high-speed spindles (up to 24,000 RPM), rigid construction for minimal vibration, and large working envelopes accommodating substantial mold bases. The integrated 5-axis simultaneous interpolation ensures smooth contouring and superior surface finishes directly off the machine, minimizing subsequent hand polishing requirements for critical cavity surfaces. This precision machining is essential for achieving the tight tolerances required for part sealing, venting, and ejection functionality within the mold.

Quality assurance is not a final step but an integrated process. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs provide traceable, micron-level measurement accuracy across complex 3D geometries. We perform comprehensive first-article inspections (FAI) per AS9102 standards and implement in-process checks for high-volume runs. This systematic approach validates conformance to print specifications, ensures geometric dimensioning and tolerancing (GD&T) compliance, and guarantees the erosion-resistant surfaces and precise fit necessary for extended mold life and consistent plastic part quality. Material certifications and full inspection reports are standard deliverables.

The following table represents our standard achievable tolerance capabilities for machined steel and aluminum mold components under controlled production conditions. Actual tolerances for specific features are determined during engineering review based on geometry, material, and functional requirements.

| Feature Type | Material (Typical) | Standard Capability | Tight Capability (Requires Review) |

|---|---|---|---|

| Linear Dimensions | P20 Steel | ±0.010 mm | ±0.005 mm |

| Linear Dimensions | Aluminum 7075 | ±0.008 mm | ±0.003 mm |

| Linear Dimensions | Copper Alloys | ±0.012 mm | ±0.006 mm |

| Flatness | Cavity/Core Plate | 0.015 mm / 100 mm | 0.008 mm / 100 mm |

| Positional Accuracy | Core Pins / Holes | ±0.010 mm | ±0.005 mm |

| Profile / Contour | Complex Surface | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | Critical Surfaces | 0.8 µm | 0.4 µm |

These capabilities, combined with our deep understanding of mold functionality and material behavior, allow Wuxi Lead to consistently produce metal components that directly contribute to mold longevity, reduced downtime, and superior plastic part quality for our injection molding partners. We collaborate closely from design review through final inspection to ensure manufacturability and performance.

Material & Finish Options

Material selection is a critical step in custom injection molding, especially when developing high-performance tooling or precision metal components. At Wuxi Lead Precision Machinery, we specialize in advanced metal manufacturing solutions, supporting clients in choosing optimal materials based on application requirements, production volume, environmental exposure, and cost efficiency. The most commonly used metals in custom injection mold tooling and related components are aluminum, steel, and titanium. Each offers distinct mechanical properties, machinability, and longevity characteristics.

Aluminum is widely favored for prototype molds and low-volume production due to its excellent thermal conductivity and ease of machining. It enables faster cooling cycles, reducing part cycle times during injection molding. While not as durable as steel, aluminum provides a cost-effective solution for initial design validation and short production runs. It is particularly suitable for resins with low abrasive content and applications where rapid turnaround is essential.

Steel, particularly tool steel grades such as P20, H13, and S136, remains the standard for high-volume production molds. These steels offer superior hardness, wear resistance, and longevity, capable of withstanding tens of thousands to millions of cycles. P20 is commonly used for general-purpose molds, while H13 excels in applications involving high thermal stress. Stainless tool steels like S136 provide excellent corrosion resistance, making them ideal for medical, food-grade, or optical applications where surface purity is paramount.

Titanium is less common in mold construction but plays a vital role in specialized components such as inserts, cores, or wear-prone areas. Its high strength-to-density ratio, corrosion resistance, and performance at elevated temperatures make it suitable for aerospace and medical applications. Though more expensive and challenging to machine, titanium offers unparalleled durability in aggressive environments.

Surface finishing further enhances material performance. Anodizing is a widely adopted electrochemical process, primarily for aluminum components. It increases surface hardness, improves wear and corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are the most common, with Type III offering thicker, denser oxide layers for severe service conditions. While anodizing does not apply to steel or titanium in the same way, these metals can be treated with alternatives such as nitriding, chrome plating, or passivation.

Understanding the interplay between material and finish ensures optimal mold performance, part quality, and production efficiency. The table below summarizes key properties of the three primary materials used in custom metal manufacturing for injection molding applications.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use Case | Machinability |

|---|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 500–570 | 130 | Prototypes, low-volume molds | Excellent |

| Steel (P20) | 28–32 | 900–1100 | 30 | Medium to high-volume production | Good |

| Steel (H13) | 45–50 | 1300–1600 | 28 | High-temperature, high-stress molds | Moderate |

| Steel (S136) | 48–52 | 1400–1700 | 25 | Corrosion-resistant, optical molds | Moderate |

| Titanium (Ti-6Al-4V) | 35–40 | 900–1000 | 7 | Aerospace, medical inserts | Poor |

At Wuxi Lead Precision Machinery, we guide clients through every stage of material and finish selection, ensuring alignment with technical and economic objectives.

Manufacturing Process & QC

Process Rigor: The Zero Defects Framework for Precision Metal Injection Molding

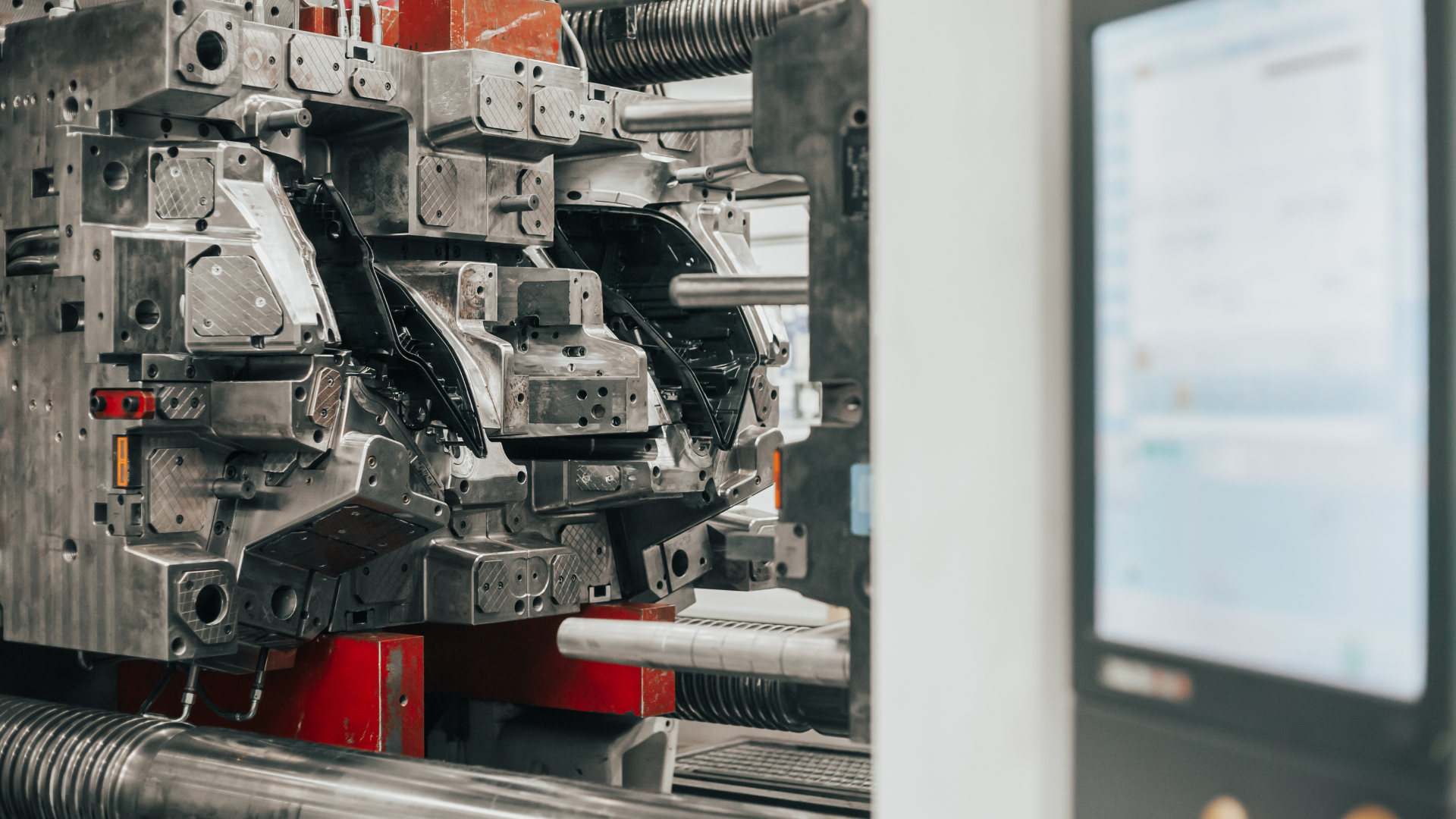

Achieving zero defects in custom metal injection molding demands an uncompromising, integrated process from initial concept to final shipment. At Wuxi Lead Precision Machinery, we enforce a closed-loop methodology where Design, Prototyping, and Mass Production function as interdependent stages, not isolated steps. This eliminates costly rework and ensures first-article compliance with aerospace, medical, and automotive specifications where tolerances as tight as ±0.005mm are non-negotiable.

Design initiates defect prevention through rigorous simulation and material science integration. Our engineers utilize Moldflow and proprietary thermal analysis software to model cavity filling, cooling dynamics, and residual stress before tooling begins. This phase includes collaborative Design for Manufacturability (DFM) reviews with clients, addressing potential porosity, warpage, or density variations in complex geometries. Material selection—whether 17-4PH stainless steel, titanium, or tungsten alloys—is validated against end-use environmental stresses, ensuring microstructure integrity under operational loads. Skipping this step risks latent defects only detectable post-production, escalating costs by 20x.

Prototyping transcends simple validation; it is a statistical process qualification gate. We produce 50–100 pre-series units under production-intent conditions, subjecting each to full metrological scrutiny via CMM, X-ray tomography, and mechanical testing. Critical dimensions, surface roughness (Ra ≤ 0.8µm), and material density are tracked against control charts. If CpK < 1.67 is observed in any parameter, the tooling design or process parameters are recalibrated immediately. This iterative loop continues until all outputs consistently meet ±3σ limits, proving process stability before scaling.

Mass Production executes with embedded real-time controls. Each molding cycle is monitored for cavity pressure, temperature gradients, and ejection force deviations via IoT sensors. Automated vision systems inspect 100% of parts for surface defects, while in-line CMMs validate critical features at defined intervals. Our statistical process control (SPC) system triggers automatic machine lockouts if trends approach specification limits, preventing non-conforming batches. All data feeds into a centralized quality dashboard, enabling traceability from raw powder lot to finished component. This infrastructure sustains Six Sigma-level yields (DPMO < 3.4) even for annual volumes exceeding 500,000 units.

The following table outlines our non-negotiable process controls across stages:

| Process Stage | Control Parameter | Target Metric | Validation Method |

|---|---|---|---|

| Design | Simulation Accuracy | ±2% vs. physical outcome | Moldflow/thermal analysis correlation |

| Prototyping | Process Capability (CpK) | ≥1.67 for all critical features | SPC charting of 50+ sample units |

| Mass Production | Dimensional Stability | ±0.005mm tolerance band | In-line CMM + automated vision |

| Mass Production | Material Density | ≥99.8% theoretical | Archimedes testing + X-ray tomography |

This tri-phase discipline converts zero defects from an aspiration into a measurable outcome. By anchoring each stage in data-driven validation and cross-functional accountability, Wuxi Lead ensures your components perform flawlessly in mission-critical applications—eliminating scrap, accelerating time-to-market, and securing your competitive advantage. The cost of perfection is far lower than the cost of failure.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Injection Molding Excellence

When precision, reliability, and technical mastery define your manufacturing needs, partnering with Wuxi Lead Precision Machinery ensures your project is in expert hands. As a leading provider of custom metal manufacturing solutions based in China, we specialize in high-performance injection mold development and precision machining tailored to the exacting demands of global industries. From aerospace and medical devices to automotive and consumer electronics, our engineering team delivers mold solutions that combine advanced materials, cutting-edge CNC technology, and rigorous quality control.

Our commitment begins with deep collaboration. We work closely with your engineering and design teams to analyze part geometry, material selection, production volume, and lifecycle requirements. This consultative approach allows us to optimize mold design for manufacturability, durability, and cost-efficiency—ensuring faster time-to-market and reduced long-term maintenance. Whether you require single-cavity prototypes or high-volume multi-cavity production molds, our facility supports full turnkey services from concept to final inspection.

At Wuxi Lead, we invest in next-generation infrastructure to maintain a competitive edge. Our facility is equipped with high-speed CNC machining centers, wire and sinker EDM systems, precision grinders, and automated polishing stations. All processes are monitored under ISO 9001-certified quality management protocols, with full traceability and metrology validation using coordinate measuring machines (CMM) and 3D scanning. This ensures every mold meets micron-level tolerances and superior surface finishes, critical for complex injection applications.

We understand that today’s manufacturers demand more than just parts—they require a strategic partner capable of innovation, scalability, and responsive support. Our engineering team offers DFM (Design for Manufacturability) analysis, mold flow simulation, and rapid prototyping to de-risk development cycles. With in-house tooling design and experienced mold builders, we reduce lead times without compromising quality. Our international clients rely on us not only for technical excellence but for clear communication, on-time delivery, and continuous improvement throughout the partnership lifecycle.

Below are key technical capabilities that define our custom injection molding services

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 x 800 x 800 mm |

| Mold Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 1.6 µm (polished, textured, EDM) |

| Materials | P20, 718H, S136, H13, Stainless Steel, Aluminum, Hardened Steels |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| EDM Systems | Sinker and Wire EDM with ±0.002 mm accuracy |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) |

| Lead Time (Typical) | 4–8 weeks, based on complexity |

Your success is built on precision, consistency, and trust. At Wuxi Lead Precision Machinery, we are committed to being the partner who delivers on all three.

Contact us today at [email protected] to discuss your next custom injection molding project. Let our engineering expertise become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.