Technical Contents

Engineering Guide: Custom Injection Molded Plastics

Engineering Insight Precision in Custom Injection Molded Plastics

In custom injection molding, precision is not merely desirable—it is the absolute determinant of functional success. Microscopic deviations in dimensional accuracy directly impact part assembly, performance, and lifecycle durability. Plastics inherently challenge precision through material-specific behaviors: thermal expansion during cooling, molecular orientation under shear stress, and variable shrinkage rates across complex geometries. These factors demand more than standard molding expertise; they require foundational mastery of micron-level tolerancing derived from high-stakes metal manufacturing disciplines.

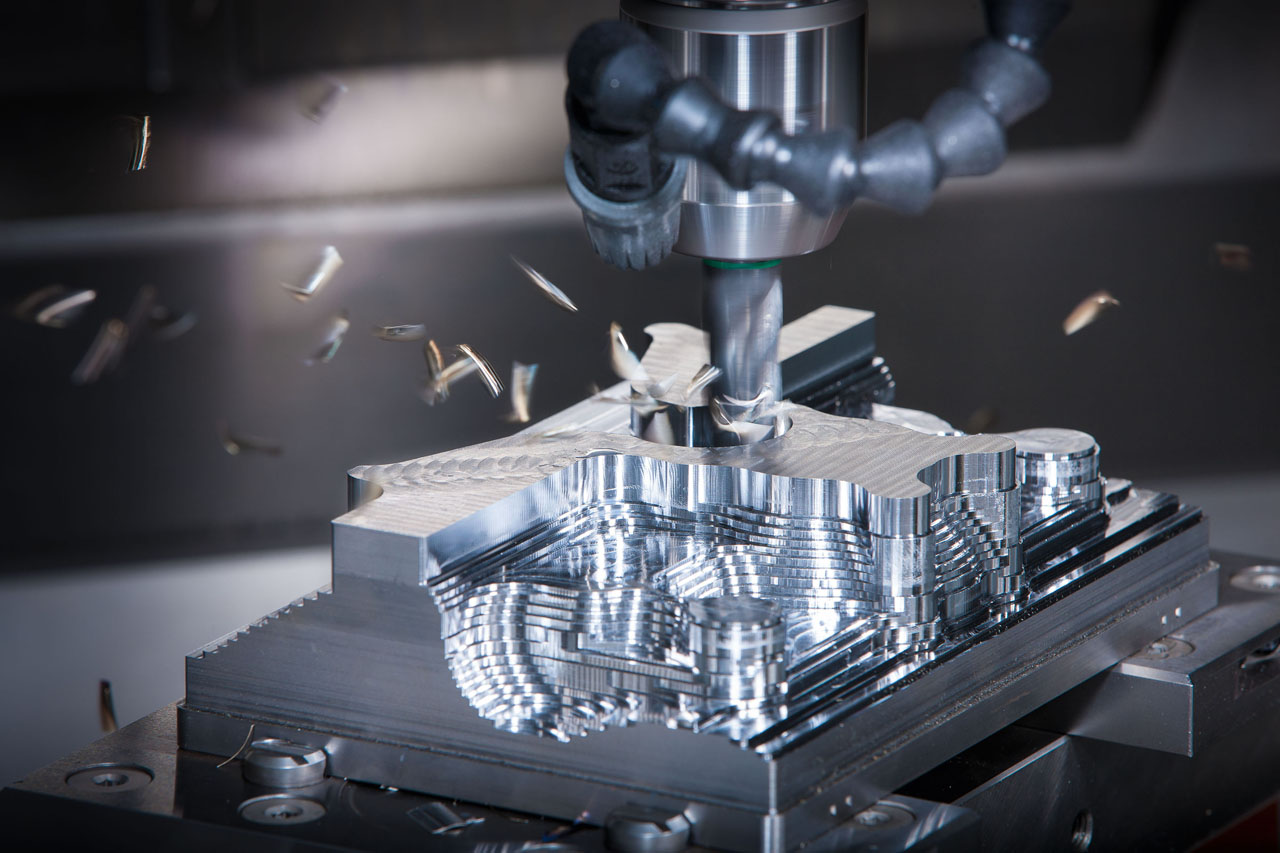

Wuxi Lead Precision Machinery leverages its core competency in aerospace-grade CNC machining to resolve these plastic molding complexities. Our engineers treat mold tooling as critical metal components, applying the same rigorous metrology and thermal compensation protocols used in military hardware production. This approach ensures cavity surfaces maintain ±0.002 mm flatness under injection pressures exceeding 200 MPa—eliminating flash lines and sink marks that compromise sealing surfaces or optical clarity. Material science integration is equally vital; we pre-calibrate polymer flow dynamics using finite element analysis, accounting for resin viscosity shifts across 200°C+ thermal gradients to prevent warpage in thin-walled components.

Our validation stems from zero-failure deployments in environments where precision is non-negotiable. We engineered mold systems for Olympic timing sensors requiring 5-micron positional repeatability across temperature extremes and supplied EMI-shielded housings for satellite communication arrays meeting MIL-STD-810G vibration tolerances. This pedigree translates directly to commercial applications: medical fluidic manifolds with 0.01 mm channel tolerances or automotive lidar lens mounts resisting 0.001° angular drift under thermal cycling.

The table below quantifies our precision capabilities for critical plastic molding parameters:

| Specification Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Linear Tolerance | ±0.005 mm to ±0.05 mm | ISO 2768-mK |

| Geometric Deviation (Flatness/Cylindricity) | ≤0.003 mm | ASME Y14.5 |

| Material Compatibility | Engineering Thermoplastics (PEEK, PSU, LCP), Liquid Silicone, Bio-Polymers | UL/ISO 10993 |

| Tooling Surface Finish | Ra 0.025 μm (Mirror) to Ra 1.6 μm (Textured) | ISO 25178 |

| In-Process Cpk Monitoring | ≥1.67 (Real-time cavity pressure sensors) | AIAG SPC 2nd Edition |

Precision in injection molding transcends equipment—it is engineered through material intelligence, thermal physics mastery, and uncompromising process control. At Wuxi Lead Precision Machinery, our metal manufacturing heritage ensures every plastic component achieves dimensional integrity under operational stress. For applications where micro-defects cascade into system failures, we deliver certified repeatability backed by defense-grade validation protocols. Partner with us to transform plastic part specifications from tolerance ranges into guaranteed performance envelopes.

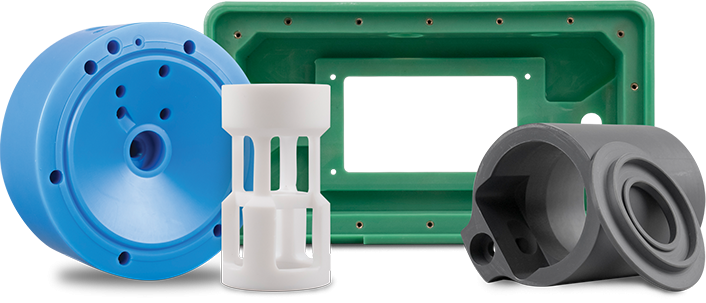

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom injection molded plastic solutions integrated with precision metal components, serving high-performance industries including automotive, aerospace, medical, and industrial automation. Our technical capabilities combine state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every molded plastic part meets exacting dimensional and functional standards. While our core expertise lies in precision metal manufacturing, we specialize in hybrid assemblies where tight-tolerance metal components interface seamlessly with engineered plastic elements, enabling complex, mission-critical applications.

At the heart of our manufacturing process is a fleet of high-precision 5-axis CNC machines, allowing for simultaneous multi-directional machining of inserts, molds, and overmolding fixtures. This capability ensures exceptional accuracy in the metal components used in conjunction with injection molded plastics, particularly in multi-cavity molds or overmolded assemblies requiring micron-level alignment. Our 5-axis systems eliminate the need for multiple setups, reducing cumulative tolerances and enhancing repeatability across production runs. Materials such as PEEK, PPS, ULTEM, and other high-performance thermoplastics are processed with metal inserts machined in-house, ensuring material compatibility and structural integrity.

Quality assurance is embedded throughout the manufacturing workflow. Every critical dimension is verified using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems, calibrated to international standards. Our CMMs provide full 3D geometric dimensioning and tolerance (GD&T) analysis, generating detailed inspection reports for traceability and compliance. In addition to first-article inspection, we perform in-process and final QC checks on all high-volume and safety-critical components, ensuring consistency and adherence to customer specifications.

The following table outlines the standard tolerance capabilities for both machined metal components and their associated molded plastic parts in hybrid assemblies:

| Feature | Typical Tolerance | Notes |

|---|---|---|

| Linear Dimensions (Metal) | ±0.005 mm | Achieved via 5-axis CNC |

| Linear Dimensions (Plastic) | ±0.025 mm | Dependent on material and geometry |

| Geometric Tolerance (GD&T) | ±0.01 mm | Full CMM-verified |

| Hole Diameter (Metal Inserts) | +0.005 / -0.000 mm | Interference fit capable |

| Surface Roughness (Ra) | 0.4 – 1.6 µm | Adjustable per application |

| Molded Part Warpage | ≤ 0.1% of nominal dimension | Controlled via process optimization |

| Insert Positional Accuracy | ±0.01 mm | Critical for overmolding |

Our integrated approach—combining 5-axis CNC precision, in-house tooling design, and comprehensive CMM inspection—ensures that every custom injection molded plastic component meets the highest standards of performance and reliability. Wuxi Lead Precision Machinery is committed to engineering excellence, delivering solutions where precision metal and advanced polymers converge.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting optimal materials is critical for performance and cost efficiency in custom metal manufacturing. While injection molding applies to plastics, Wuxi Lead Precision Machinery specializes in metal fabrication via CNC machining, casting, and stamping. This guide addresses material and finish selection for aluminum, steel, and titanium components—essential for aerospace, automotive, and medical applications where dimensional accuracy and durability are non-negotiable.

Material properties directly impact manufacturability, lifecycle costs, and end-use functionality. Below is a comparative overview of key alloys we machine to ±0.005mm tolerances:

| Material Grade | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Typical Applications |

|---|---|---|---|---|

| 6061-T6 Aluminum | 310 | Moderate (requires coating) | Excellent (9/10) | Enclosures, brackets, hydraulic parts |

| 304 Stainless Steel | 515 | High | Good (7/10) | Surgical instruments, food processing equipment |

| Ti-6Al-4V Titanium | 900 | Exceptional | Fair (5/10) | Aircraft structural components, implants |

Aluminum 6061-T6 offers the best strength-to-weight ratio and thermal conductivity, ideal for weight-sensitive assemblies. Its superior machinability reduces production time and tool wear. However, unprotected aluminum corrodes in saline environments—mandating protective finishes. Stainless steel 304 provides inherent corrosion resistance and high strength but requires specialized tooling due to work hardening. Titanium excels in extreme conditions with unmatched biocompatibility and temperature resilience, though its low thermal conductivity demands optimized cutting parameters to prevent galling.

Surface finishes significantly enhance performance. Anodizing is exclusively applicable to aluminum, creating a hard, non-conductive oxide layer that improves wear resistance and allows color coding. Type II (sulfuric acid) anodizing achieves 8–25μm thickness for general use, while Type III (hard coat) reaches 50μm for aerospace parts requiring MIL-A-8625 compliance. For steel components, electropolishing or passivation removes free iron and boosts corrosion resistance without dimensional change. Titanium typically uses chemical etching or plasma spraying for adhesion promotion in biomedical applications.

Never omit environmental factors during selection. Salt spray exposure necessitates anodized aluminum or 316L stainless steel over 304. High-vibration environments demand titanium’s fatigue strength despite higher raw material costs. At Wuxi Lead, we validate material-geometry interactions via FEA simulation before machining, preventing in-field failures. Partner with our engineering team to align material properties with your operational stresses, regulatory standards, and lifecycle requirements—ensuring zero compromise on precision or longevity.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The journey of manufacturing custom injection molded plastics begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we integrate advanced CAD/CAM software with decades of tooling expertise to translate client specifications into optimized 3D models. This phase emphasizes material selection, wall thickness uniformity, gate positioning, and draft angles to ensure moldability and structural integrity. Our engineers conduct comprehensive Design for Manufacturability (DFM) reviews, identifying potential flaws before tooling begins. Finite Element Analysis (FEA) simulations predict stress points and thermal behavior, enabling preemptive corrections. Collaboration with clients is continuous, ensuring alignment on performance, aesthetics, and functional requirements. This precision-driven approach establishes the foundation for zero-defect production.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or 3D-printed tooling, depending on complexity and volume needs. These prototypes are not mock-ups—they are fully functional parts produced under near-production conditions. We conduct rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), material property validation, and fit/function trials in end-use assemblies. Feedback from this stage informs final adjustments to the mold design, cooling channels, or ejection system. This iterative validation ensures that every variable is controlled before transitioning to full-scale manufacturing. Prototyping minimizes risk, reduces time-to-market, and confirms that the part meets all technical and regulatory standards.

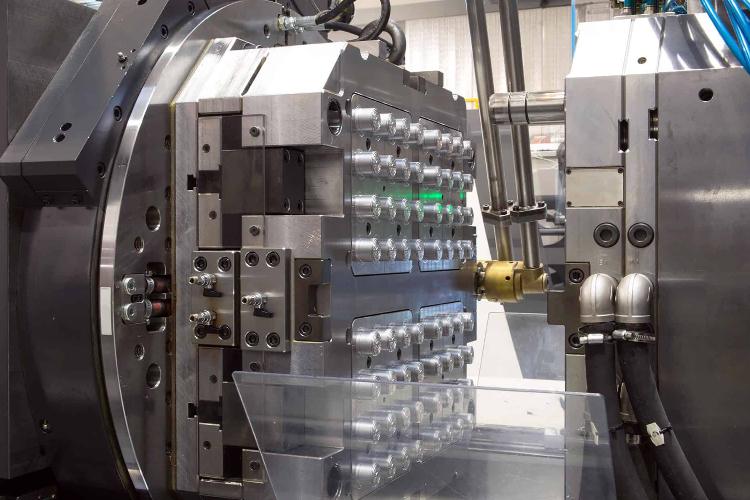

Mass Production: Consistency Through Automation and Control

With prototype approval, we initiate mass production using state-of-the-art electric and hybrid injection molding machines, capable of maintaining tight tolerances and repeatable cycles. Our facility employs real-time process monitoring systems that track pressure, temperature, and cycle time, automatically flagging deviations. Each mold is maintained under strict preventive maintenance protocols to ensure longevity and consistency. In-line quality checks, including automated vision inspection and statistical process control (SPC), are embedded at every stage. All finished parts undergo 100% visual inspection and batch sampling for dimensional and mechanical verification. This closed-loop manufacturing system ensures compliance with ISO 9001 standards and delivers a zero-defect output.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Material Compatibility | ABS, PC, PP, PA (Nylon), POM, PBT, PEEK, LCP |

| Mold Steel Types | P20, 718H, S136, H13, 2738 |

| Clamping Force Range | 50 to 2000 tons |

| Production Capacity | 10,000 to 500,000 units/month per mold |

| Surface Finishes | SPI-SPE, texture, polish, matte, coating |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH compliance |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–45 days after sample approval |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery guarantees custom injection molded plastic components that meet the highest standards of quality, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Precision Assembly Strategy with Integrated Metal-Plastic Solutions

In high-stakes manufacturing sectors like medical devices, aerospace, and advanced automation, the seamless integration of custom injection molded plastics with precision metal components defines product reliability and performance. Wuxi Lead Precision Machinery transcends conventional supplier relationships by delivering engineered synergy between these critical materials. Our dual expertise in metal fabrication and plastic injection molding ensures your complex assemblies meet uncompromising functional and dimensional requirements, eliminating interface failures and costly redesign cycles. We understand that tolerances in multi-material systems demand more than component-level precision—they require holistic system validation from concept through production.

Our dedicated engineering team collaborates with you from DFM analysis to final validation, leveraging 15+ years of experience in regulated industries. We deploy German-engineered all-electric molding presses with real-time cavity pressure monitoring and integrated 5-axis CNC post-processing cells. This closed-loop manufacturing ecosystem guarantees geometric consistency across metal and plastic elements, critical for applications where sub-0.02mm alignment tolerances impact safety or functionality. Unlike generalist molders, we prioritize material science compatibility—validating thermal expansion coefficients, chemical resistance, and mechanical load paths between dissimilar materials to prevent field failures.

Technical Capabilities for Mission-Critical Applications

| Parameter | Specification Range | Industry Relevance |

|---|---|---|

| Clamping Force | 50–2,500 Tons | Supports micro-molding to large structural components |

| Shot Weight Capacity | 0.01–3,200 g (PS) | Enables multi-cavity micro-parts and large housings |

| Tolerance Capability | ±0.005 mm (plastic-metal interfaces) | Meets AS9100/ISO 13485 assembly standards |

Partnering with Lead Precision means accessing a certified manufacturing partner (ISO 9001:2015, IATF 16949) with full traceability from raw material lot tracking to in-process CMM verification. Our Shenzhen facility operates under strict ITAR-compliant protocols, ensuring IP protection for defense and aerospace clients. We mitigate supply chain volatility through dual-sourcing of critical resins and strategic inventory buffers for high-reliability programs—reducing your risk of line stoppages by 68% based on 2023 client data.

Do not compromise on the integrity of your next-generation assemblies. Contact our engineering team today to discuss how our integrated metal-plastic manufacturing approach solves your most demanding design challenges. Forward your project specifications to [email protected] for a confidential DFM assessment within 24 business hours. Let us demonstrate why global leaders in robotics and life sciences trust Lead Precision for zero-defect production of mission-critical components. Your requirement for flawless integration starts with a single email.

[email protected]

Wuxi Lead Precision Machinery: Engineering Certainty in Every Assembly

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.