Technical Contents

Engineering Guide: Custom Cnc Milling Georgia

Engineering Insight: The Critical Role of Precision in Custom CNC Milling for Georgia’s Advanced Manufacturing Sector

In the rapidly evolving landscape of advanced manufacturing, Georgia has emerged as a key hub for aerospace, defense, medical device, and industrial technology firms demanding the highest levels of component accuracy and repeatability. At the heart of this transformation lies custom CNC milling—a process where precision is not merely a performance metric but a foundational requirement for operational success, safety, and compliance.

Precision in CNC milling refers to the ability to consistently produce parts within tight tolerances, often as tight as ±0.0002 inches (±0.005 mm), with exacting surface finishes and geometric integrity. For industries such as aerospace and defense—sectors where Georgia-based contractors are heavily involved—such precision is non-negotiable. A single out-of-tolerance component in a flight control system or weapon assembly can compromise mission integrity and safety. This is where the engineering rigor and process discipline of an experienced partner become critical.

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in high-precision CNC milling, serving clients with mission-critical requirements on global stages. Our work has supported components used in Olympic-level sporting equipment, where performance margins are measured in milliseconds, and in military-grade subsystems, where environmental resilience and dimensional stability under stress are paramount. These applications demand more than advanced machinery—they require a culture of precision embedded in every phase of production, from material selection to final inspection.

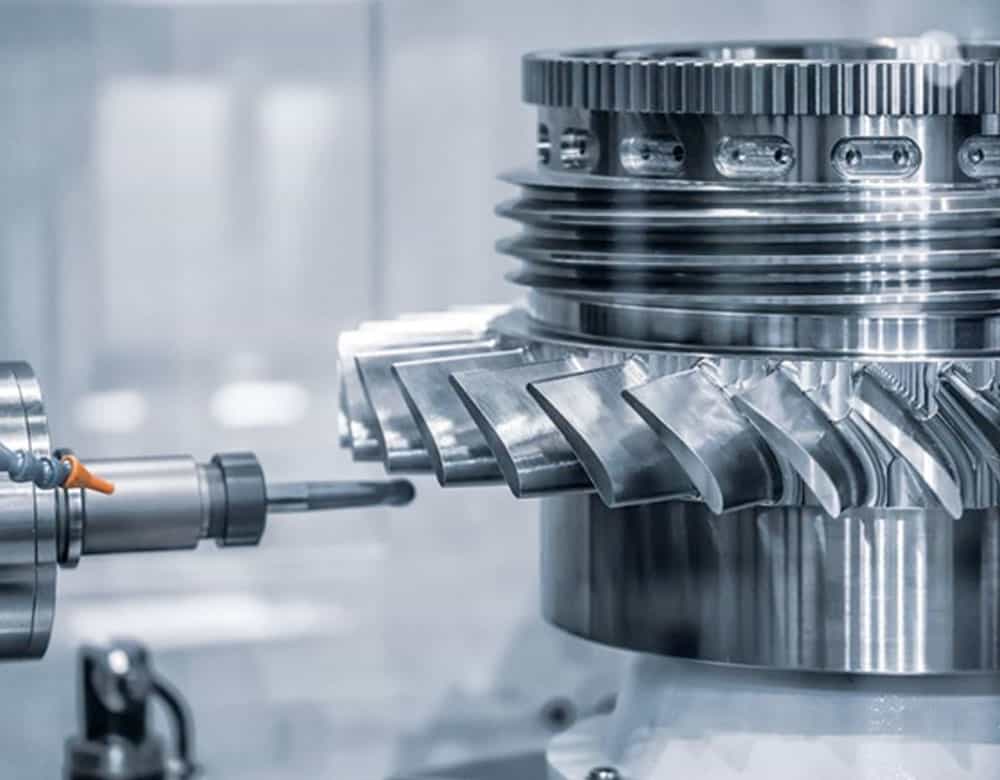

Our CNC milling capabilities are built on a foundation of state-of-the-art 3-, 4-, and 5-axis machining centers, integrated with automated tool measurement and in-process probing systems. These technologies, combined with ISO 9001-certified quality management, ensure that every custom-milled part meets or exceeds the most stringent specifications. Whether producing complex aluminum housings for unmanned aerial systems or titanium fixtures for medical robotics, our process control systems eliminate variability and ensure traceability.

For Georgia’s engineering teams seeking reliable offshore manufacturing partners, Wuxi Lead offers not just capacity, but proven performance in high-stakes environments. Our ability to interpret complex GD&T callouts, manage challenging materials like Inconel and PEEK, and deliver full documentation packages makes us a strategic extension of your R&D and production teams.

Below are key specifications that define our custom CNC milling capabilities:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling |

| Tolerance Range | ±0.0002 in (±0.005 mm) |

| Maximum Work Envelope | 2000 x 1000 x 800 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass, Plastics |

| Surface Finish | As fine as Ra 0.4 μm (16 μin) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports, CMM validation |

| Lead Times | 10–25 days, based on complexity and volume |

In Georgia’s competitive manufacturing ecosystem, success hinges on partnerships that deliver precision without compromise. Wuxi Lead Precision Machinery stands ready to support your most demanding custom CNC milling requirements with engineering excellence and documented performance in the world’s most rigorous applications.

Precision Specs & Tolerances

Technical Capabilities for Precision CNC Milling

Wuxi Lead Precision Machinery delivers advanced custom CNC milling solutions meeting the stringent demands of aerospace, medical, and industrial sectors targeting the Georgia market. Our technical foundation integrates cutting-edge multi-axis machining with rigorous quality assurance to ensure dimensional accuracy and repeatability for complex geometries. Operating from our ISO 9001:2015-certified facility in Wuxi, China, we provide seamless global supply chain support for Georgia-based clients requiring high-integrity components.

Precision Equipment Platform

Our core capability centers on a modern fleet of 5-axis CNC milling centers including DMG MORI and Makino systems. These machines enable simultaneous 5-axis interpolation, eliminating secondary setups and reducing cumulative error for intricate parts such as turbine blades, surgical implants, and fluid manifold systems. High-speed spindles (up to 24,000 RPM) coupled with sub-micron linear encoders ensure surface finishes down to Ra 0.4 µm and contour accuracy within ±0.005 mm. Integrated probing systems perform in-process verification, automatically compensating for tool wear and thermal drift to maintain tolerances across production runs.

Quality Control Protocol

Every component undergoes a structured inspection regime anchored by Zeiss and Hexagon CMMs with nanometer-level resolution. Critical features are verified against CAD models using PC-DMIS software, generating AS9102-compliant first-article reports with full traceability. Statistical Process Control (SPC) data is monitored in real-time for high-volume orders, ensuring Cp/Cpk values consistently exceed 1.67. Dimensional validation is supplemented by surface roughness testers, optical comparators, and coordinate measuring arms for on-floor verification, guaranteeing compliance with GD&T callouts per ASME Y14.5 standards.

Achievable Tolerance Specifications

| Parameter | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Angular Features | ±0.1° | ±0.02° |

| Positional Tolerance | ±0.012 mm | ±0.003 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| True Position (Ø) | 0.025 mm | 0.008 mm |

Engineering Integration

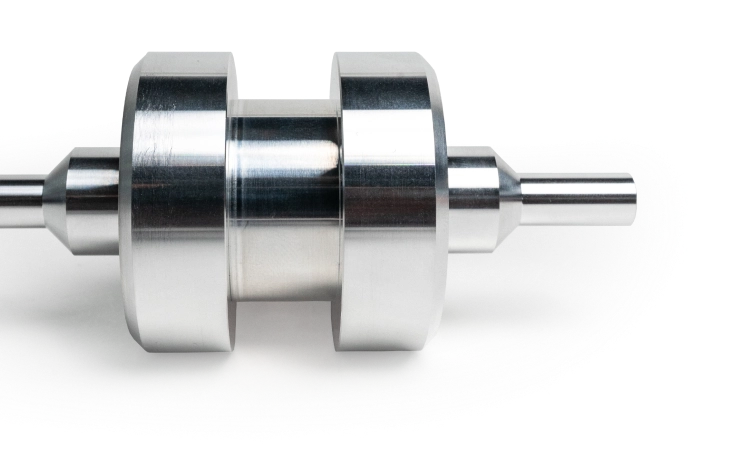

Our technical team collaborates with Georgia clients during Design for Manufacturability (DFM) stages to optimize part geometry for milling efficiency. We leverage Mastercam and Siemens NX to simulate toolpaths, preventing collisions and minimizing cycle times while preserving critical tolerances. Material expertise spans titanium alloys (Ti-6Al-4V), Inconel 718, aluminum 7075-T6, and engineered plastics like PEEK, with dedicated fixturing solutions for thin-walled components. All processes adhere to NIST-traceable calibration standards, providing documented evidence of conformance for regulated industries.

Wuxi Lead Precision Machinery ensures Georgia manufacturers receive components that exceed specification requirements through disciplined process control and advanced metrology. Contact our engineering team for a detailed capability review and DFM analysis tailored to your project.

Material & Finish Options

Material selection is a critical decision in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. For high-performance applications in industries such as aerospace, medical, and automotive—particularly in regions like Georgia where advanced manufacturing is expanding—the choice between aluminum, steel, and titanium must align with mechanical requirements, environmental exposure, and finishing needs. At Wuxi Lead Precision Machinery, we support global clients with expert guidance on material and surface treatment options to ensure optimal outcomes in custom CNC milling projects.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly used in structural and prototyping applications due to its weldability and corrosion resistance. For more demanding environments, 7075-T6 offers superior strength, making it ideal for aerospace components. Aluminum’s natural oxide layer provides some protection, but for enhanced surface durability and aesthetics, anodizing is recommended. Type II (sulfuric acid) anodizing improves corrosion and wear resistance, while Type III (hardcoat) anodizing delivers a thicker, harder surface suitable for high-wear applications.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, offers high tensile strength, excellent wear resistance, and superior performance in high-temperature or corrosive environments. 304 stainless steel is widely used in medical and food processing equipment due to its non-reactive properties and ease of sterilization. 17-4 PH, a precipitation-hardening stainless steel, can be heat-treated to achieve very high strength, making it suitable for critical aerospace and defense components. While steel does not anodize, it can be treated with passivation, electropolishing, or coatings such as zinc plating or black oxide to enhance surface properties.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice when extreme strength-to-density ratio, biocompatibility, and corrosion resistance are paramount. It is extensively used in aerospace, medical implants, and marine applications. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium delivers unmatched performance in harsh environments. Surface treatments such as anodizing can be applied for color coding or minor wear improvement, though its natural oxide layer provides excellent corrosion resistance.

The following table summarizes key mechanical and processing properties of these materials:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Typical Applications | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, automotive, enclosures | Type II/III Anodizing, powder coat |

| Stainless Steel | 304, 17-4 PH | 505–1310 | 7.9 | Medical, food processing, defense | Passivation, electropolishing, plating |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1,170 | 4.4 | Aerospace, implants, marine | Anodizing, laser marking |

Selecting the right material and finish ensures that CNC milled components meet both functional and regulatory standards. Wuxi Lead Precision Machinery leverages decades of experience in high-precision manufacturing to guide clients through these decisions, ensuring performance, reliability, and cost-effectiveness in every custom part produced.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero-Defect Delivery for Georgia Manufacturers

At Wuxi Lead Precision Machinery, our CNC milling process for Georgia-based clients integrates stringent quality protocols at every phase to ensure zero defects in high-precision components. We begin with collaborative Design Phase engineering, where our team conducts rigorous Design for Manufacturability (DFM) analysis. This step identifies potential machining constraints early, optimizing part geometry for Georgia’s demanding aerospace, medical, and industrial sectors. We utilize advanced CAD/CAM software to simulate toolpaths, material stress points, and tolerances, ensuring designs align with AS9100 and ISO 13485 standards before physical production commences.

The Prototyping Phase validates design integrity through iterative physical testing. Using 5-axis milling centers, we produce functional prototypes with tolerances as tight as ±0.0002″. Each prototype undergoes comprehensive metrology inspection via CMM and optical comparators, verifying critical dimensions against Georgia client specifications. This phase includes material certification review and stress testing, with data shared transparently via secure client portals. Only after formal sign-off—confirming form, fit, and function—do we transition to mass production.

Mass Production Phase execution centers on our Zero-Defect Manufacturing System. Components are machined on dedicated production cells with real-time SPC monitoring. Every 15 minutes, automated probes verify critical dimensions, while in-process inspections catch deviations before they escalate. Our Georgia-focused production lines feature climate-controlled environments to mitigate thermal drift, essential for maintaining micron-level accuracy in Georgia’s variable humidity. Final inspection includes 100% first-article reporting and batch-level traceability, with all data archived for 10+ years per aerospace requirements.

This phased approach eliminates waste and rework, delivering Georgia clients on-time, defect-free parts certified to NADCAP standards. Our Atlanta-based logistics hub ensures seamless delivery within 72 hours of completion, supporting just-in-time manufacturing needs across Georgia’s industrial corridor.

Wuxi Lead Precision Machinery Production Specifications

| Parameter | Capability | Relevance for Georgia Clients |

|---|---|---|

| Machine Types | DMG MORI 5-axis, Makino A51nx, Okuma MU-5000 | Complex geometries for aerospace actuators and medical implants |

| Tolerance Range | ±0.0002″ (5µm) standard | Meets Lockheed Martin and Siemens Energy specs |

| Material Expertise | Titanium Ti-6Al-4V, Inconel 718, PEEK, 4140 Steel | Critical for Georgia’s defense and energy sectors |

| Lead Time | 10–15 days (prototype), 25 days (1,000 units) | Aligns with Georgia manufacturers’ accelerated production cycles |

| Quality Systems | AS9100 Rev D, ISO 13485, NADCAP | Ensures compliance with Georgia OEM supply chain mandates |

Our process transforms Georgia engineering concepts into flawless physical assets through uncompromising precision and proactive quality ownership. Every component ships with full documentation, ready for integration into your mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Expertise in Georgia and Beyond

When precision matters, Lead Precision delivers. As a leading provider of custom CNC milling services from China, Wuxi Lead Precision Machinery bridges the gap between global manufacturing demands and high-accuracy engineering solutions. Our advanced machining capabilities support clients across industries—including aerospace, medical devices, automotive, and industrial automation—ensuring every component meets the strictest standards for quality, repeatability, and performance. Whether you are based in Atlanta, Savannah, or any location throughout Georgia, partnering with us means gaining access to world-class CNC milling technology backed by decades of technical expertise.

Our facility in Wuxi integrates state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling centers, enabling us to produce complex geometries with micron-level precision. We specialize in low-volume prototyping to high-volume production runs, all executed under strict ISO 9001-certified quality management systems. With a focus on materials such as aluminum alloys, stainless steel, titanium, brass, and engineering plastics, we tailor our processes to meet your exact specifications—regardless of complexity.

One of the key advantages of working with Lead Precision is our seamless international collaboration model. We understand the challenges of sourcing from overseas, which is why we’ve built robust communication protocols, real-time project tracking, and rapid turnaround times into every phase of production. Our engineering team works directly with your design staff to review DFM (Design for Manufacturability), optimize toolpaths, and ensure first-time-right outcomes—minimizing delays and reducing total project costs.

We serve clients across North America with reliable logistics, consistent quality, and responsive customer service. By combining Chinese manufacturing efficiency with Western engineering standards, we deliver a competitive edge that local Georgia shops often cannot match—especially for high-mix, high-precision applications.

Below are key specifications that define our CNC milling capabilities:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm (47″ × 31.5″ × 23.6″) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Speed | Up to 24,000 RPM |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, PEEK, Delrin, and more |

| Tolerances Achieved | As tight as ±0.001 mm (±0.00004″) |

| Finishes Available | As-machined, bead blast, anodizing, passivation, plating, powder coating |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, Full CMM reporting |

Let us become your trusted partner for custom CNC milling in Georgia and beyond. Contact us today at [email protected] to discuss your next project. Our engineering team is ready to support you with fast quoting, DFM analysis, and scalable production solutions designed to meet your timeline and quality expectations. With Lead Precision, precision isn’t just a promise—it’s our standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.