Technical Contents

Engineering Guide: Custom Cnc Machined Parts

Engineering Insight: The Critical Role of Precision in Custom CNC Machined Parts

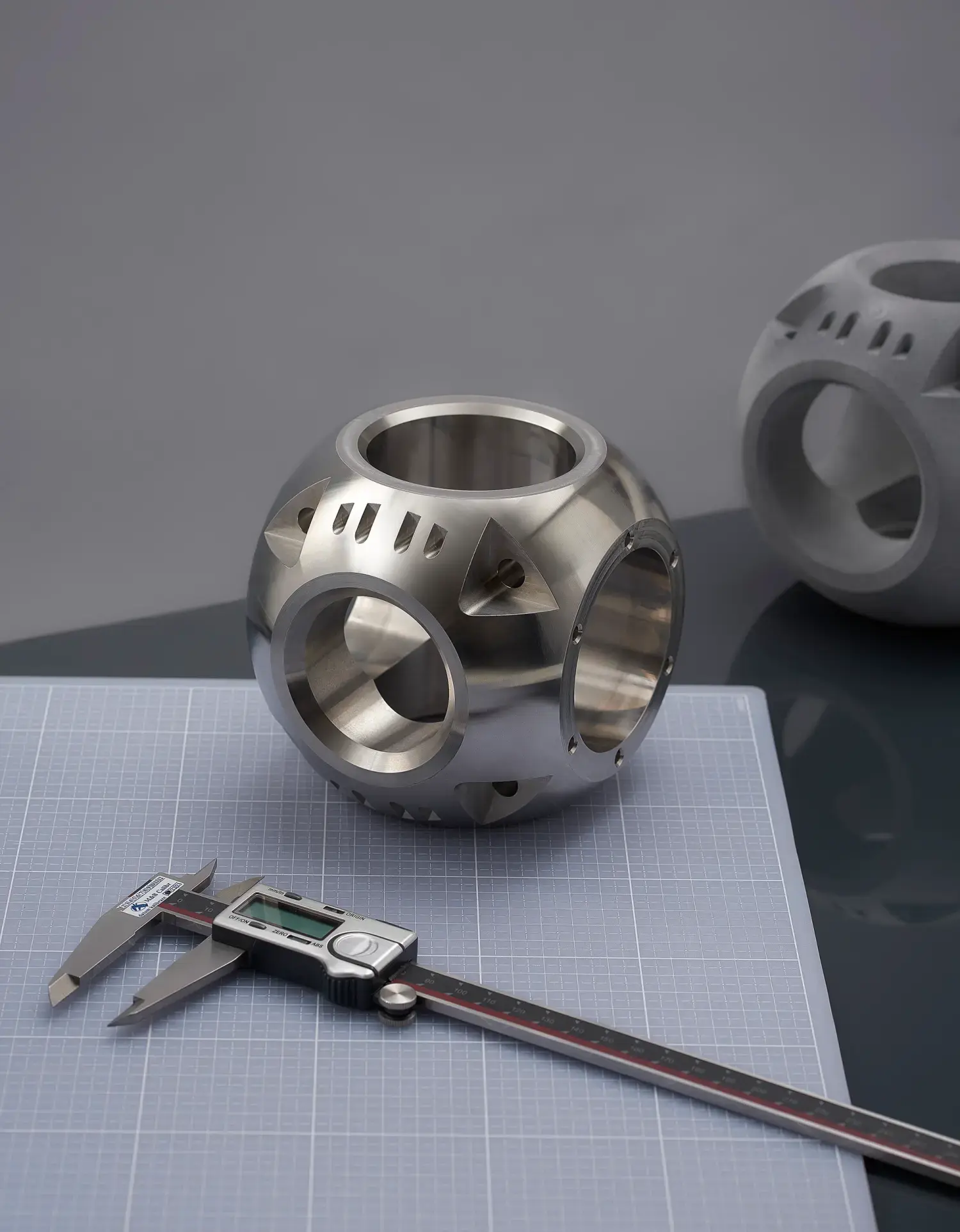

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and safety are built. Custom CNC machined parts serve as the backbone of countless high-performance systems, from aerospace propulsion to medical diagnostics, where even micron-level deviations can lead to catastrophic failure. At Wuxi Lead Precision Machinery, we recognize that achieving true precision demands more than advanced equipment; it requires engineering mastery, rigorous process control, and an unwavering commitment to excellence.

Our experience in delivering custom CNC machined components for mission-critical applications—including projects tied to Olympic-standard equipment and military-grade systems—underscores our capability to meet the most stringent tolerances and quality standards. These applications demand not only dimensional accuracy but also material integrity, surface finish consistency, and long-term durability under extreme conditions. The machining processes employed must be repeatable, traceable, and fully aligned with international quality benchmarks such as ISO 9001 and AS9100.

Precision begins at the design phase. Our engineering team collaborates closely with clients to optimize part geometry, material selection, and manufacturability—ensuring that every component is not only accurate but also cost-effective to produce at scale. Utilizing state-of-the-art 5-axis CNC machining centers, multi-spindle lathes, and advanced CMM inspection systems, we maintain tolerances as tight as ±0.002 mm. This level of control enables seamless integration of our parts into complex assemblies where alignment, fit, and function are non-negotiable.

Beyond equipment, our process discipline sets us apart. Every custom machined part undergoes a comprehensive quality verification protocol, including first-article inspection, in-process checks, and final certification. Materials are sourced from certified suppliers and documented for full traceability—a requirement in defense and aerospace sectors. Our facility’s integration of lean manufacturing principles ensures minimal variability and maximum throughput without compromising accuracy.

The following table outlines key performance specifications achievable at Wuxi Lead Precision Machinery for custom CNC machined parts:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Maximum Part Size | 1200 × 800 × 600 mm |

| Minimum Feature Size | 0.1 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (compliant) |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Surface Profilometers |

Precision in custom CNC machining is not an isolated attribute—it is the result of integrated engineering, advanced technology, and domain expertise. With proven performance in Olympic and military projects, Wuxi Lead Precision Machinery stands as a trusted partner for industries where failure is not an option.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered to Exacting Standards

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to transform complex conceptual designs into mission-critical components with unwavering accuracy. We specialize in high-mix, low-volume production of custom CNC machined parts for aerospace, medical, and semiconductor industries where failure is not an option. Our foundation rests on a modern fleet of 5-axis CNC machining centers, enabling the production of intricate geometries in a single setup. This eliminates cumulative error from multiple fixturing stages, ensuring dimensional integrity across complex contours, deep cavities, and undercuts that challenge conventional 3-axis systems. All machines operate under strict environmental controls with temperature-stabilized workshops to mitigate thermal drift, a critical factor for micron-level repeatability.

Process stability is non-negotiable. Our engineers deploy advanced simulation software to validate toolpaths and prevent collisions before metal cutting begins. This proactive approach minimizes machine downtime and guarantees first-article success. Material versatility spans aerospace-grade aluminum alloys, medical titanium, stainless steel 316L, Inconel 718, and high-performance polymers like PEEK, all processed using optimized cutting strategies to maintain material integrity and surface quality. Rigorous in-process inspections occur at defined checkpoints, with real-time data fed back to our central manufacturing execution system for immediate corrective action.

Quality assurance is embedded at every phase. Final verification is performed exclusively on calibrated Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), providing traceable, NIST-certified dimensional reports. Our CMM protocols exceed ISO 10360-2 standards, capturing full 3D point clouds to validate GD&T callouts, profile tolerances, and critical feature relationships. Every component receives a comprehensive inspection dossier, including first-article reports and batch-level SPC data, ensuring full compliance with AS9100 and ISO 13485 requirements. This end-to-end scrutiny guarantees that parts not only meet but consistently exceed client specifications.

The following table details our standard achievable tolerances across common material categories, reflecting real-world production capability under controlled conditions:

| Material Category | Tolerance Range | Surface Finish Ra (µm) |

|---|---|---|

| Aluminum Alloys (e.g., 7075-T6) | ±0.005 mm | 0.8 – 1.6 |

| Stainless Steel (e.g., 316L) | ±0.008 mm | 0.4 – 0.8 |

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.010 mm | 0.8 – 1.6 |

| Engineering Plastics (e.g., PEEK) | ±0.015 mm | 1.6 – 3.2 |

These specifications represent routinely maintained production standards, not theoretical limits. For applications demanding even tighter control—such as optical mounts or fluidic manifolds—we implement specialized metrology protocols and micro-machining techniques to achieve ±0.002 mm tolerances. Wuxi Lead Precision Machinery delivers more than machining; we provide certified precision that integrates seamlessly into your most demanding assemblies. Partner with us to convert engineering intent into flawless physical reality.

Wuxi Lead Precision Machinery

Where Precision Meets Reliability

Material & Finish Options

Material Selection for High-Performance CNC Machined Parts

Selecting the appropriate material is critical in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in manufacturing custom CNC machined parts using premium-grade aluminum, steel, and titanium—each offering distinct advantages depending on application requirements. Understanding the mechanical properties, machinability, and compatibility with finishing processes such as anodizing ensures optimal component functionality across aerospace, medical, automotive, and industrial sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Grade 6061-T6 is particularly popular in structural and enclosure applications due to its weldability and ease of machining. It responds exceptionally well to anodizing, a process that enhances surface hardness and wear resistance while allowing for color coding or branding. For high-speed machining and lightweight designs, aluminum delivers superior performance with reduced cycle times and material costs.

Steel, particularly alloy and stainless variants such as 4140, 17-4 PH, and 304/316, offers high tensile strength, durability, and resistance to deformation under load. These properties make steel ideal for components subjected to high stress, impact, or elevated temperatures. While heavier than aluminum, steel provides greater dimensional stability and wear resistance, especially in tooling, shafts, and hydraulic components. Stainless steels also exhibit excellent corrosion resistance, crucial for medical devices and marine environments. However, steel’s increased hardness can lead to higher tool wear and longer machining times, requiring advanced CNC strategies and tooling.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Renowned for its exceptional strength-to-density ratio and resistance to fatigue and corrosion—even in aggressive environments—titanium is extensively used in aerospace, defense, and biomedical implants. Despite its challenging machinability due to low thermal conductivity and high chemical reactivity, our precision CNC systems employ specialized cutting parameters and tooling to ensure tight tolerances and superior surface finish.

Surface treatment plays a vital role in extending part life and performance. Anodizing is most effective on aluminum, creating a controlled oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied based on functional or aesthetic needs. While steel and titanium do not anodize in the traditional sense, they benefit from alternative finishes such as passivation, plating, or coating.

Below is a comparative summary of key material properties for common alloys used in CNC machining.

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, brackets, heat sinks | Yes |

| Steel | 4140 | 655 | 7.85 | Shafts, tooling, structural parts | No |

| Stainless Steel | 304 | 505 | 8.0 | Medical, food processing, marine | No |

| Titanium | Ti-6Al-4V | 900 | 4.43 | Aerospace, implants, racing components | No (specialized oxide layers possible) |

Material selection must balance performance requirements, environmental exposure, and post-processing needs. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal material and finish to ensure reliability, precision, and value in every custom CNC machined component.

Manufacturing Process & QC

Precision CNC Production: From Design to Zero Defects Fulfillment

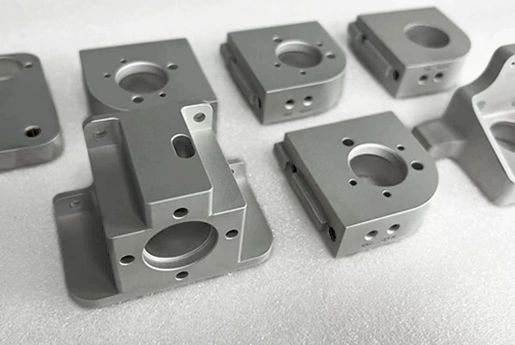

At Wuxi Lead Precision Machinery, our production process for custom CNC machined parts is engineered for uncompromising quality and repeatability, culminating in true Zero Defects delivery. We integrate advanced technology with rigorous process control across three critical phases, ensuring every component meets exacting specifications before reaching your production line.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with your design data, utilizing advanced CAD/CAM simulation software to identify potential machining challenges, material stresses, or tolerance conflicts before metal is cut. This proactive review optimizes toolpaths, selects the most suitable aerospace-grade alloys or engineered plastics, and confirms geometric feasibility, preventing costly errors downstream. We translate your vision into a manufacturable blueprint, validated through virtual machining to ensure dimensional stability and surface integrity.

Prototyping is not merely a sample phase; it is a critical validation checkpoint. Using the same high-precision CNC centers (5-axis machining centers, Swiss-type lathes) and materials designated for final production, we manufacture initial units. These prototypes undergo comprehensive First Article Inspection (FAI) per AS9102 standards, employing CMMs, optical comparators, and surface roughness testers. Every critical dimension, feature, and material property is verified against your engineering drawing. Any deviations trigger immediate process refinement and revalidation, ensuring the production-ready process is flawless. This iterative step eliminates assumptions and guarantees the prototype is the production part.

Mass production executes the perfected process under stringent statistical process control (SPC). Each CNC machine operates within tightly monitored parameters, with real-time data collection on tool wear, temperature, and positional accuracy. Our integrated quality management system mandates 100% critical feature inspection on initial runs and statistically significant sampling during extended runs, far exceeding standard AQL levels. Full material traceability, from certified mill certificates to individual part serialization, is maintained. Automated in-process gauging and final inspection against the original FAI report ensure absolute conformance. Defects are not merely caught; they are systematically prevented through predictive maintenance, operator certification, and continuous process monitoring, achieving our Zero Defects commitment.

Wuxi Lead Precision Production Capabilities

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (0.00004 inch) | CMM, High-Precision Micrometers, Optical CMM |

| Surface Roughness | Ra 0.1 µm (4 µin) achievable | Profilometer, Comparison Standards |

| Material Traceability | Full Lot-to-Part Traceability | Certified Mill Reports, Barcoding System |

| Critical Feature Inspection | 100% Initial Run, SPC Sampling | First Article Inspection (AS9102) |

| Process Control | Real-Time SPC, Automated Gauging | Statistical Process Control Charts |

This seamless integration of design validation, prototype rigor, and controlled mass production, underpinned by relentless data-driven quality assurance, defines Wuxi Lead’s commitment to delivering custom CNC machined parts that perform flawlessly in your most demanding applications. Zero Defects is not a target; it is our operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom CNC Machined Parts

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, precision is not a luxury—it’s a requirement. As a trusted leader in precision CNC machining based in China, we specialize in delivering custom CNC machined parts that meet the most demanding engineering standards. Whether you operate in aerospace, medical devices, automation, or advanced industrial equipment, our engineering-first approach ensures your components perform flawlessly in real-world applications.

Our advanced manufacturing capabilities are backed by decades of technical experience, state-of-the-art CNC equipment, and a relentless commitment to quality. We utilize multi-axis machining centers, high-precision turning, milling, and grinding technologies to produce parts with tolerances as tight as ±0.002 mm. Every component is manufactured under strict ISO 9001-certified processes, ensuring consistency, traceability, and compliance with international standards.

What sets us apart is our collaborative engineering model. We don’t just manufacture to print—we partner with your design and engineering teams from concept to completion. Our engineers provide Design for Manufacturability (DFM) analysis, material selection guidance, and rapid prototyping services to optimize performance, reduce lead times, and lower total production costs. This proactive collaboration ensures that your custom parts are not only precise but also cost-effective and production-ready.

We support a wide range of materials, including aerospace-grade aluminum, stainless steel, titanium, brass, copper, and high-performance engineering plastics such as PEEK and PTFE. With in-house capabilities in surface finishing, heat treatment, anodizing, plating, and precision inspection, we deliver fully finished components—ready for integration into your final assembly.

Our global clients rely on us for low to mid-volume production runs with exceptional repeatability and fast turnaround. With a responsive supply chain and dedicated project management, we ensure on-time delivery without compromising quality.

Technical Capabilities at a Glance

| Specification | Detail |

|---|---|

| Machining Processes | 3-axis to 5-axis milling, CNC turning, multi-spindle machining, precision grinding |

| Tolerances | ±0.002 mm (±0.00008″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 5), Brass, Copper, PEEK, PTFE, and more |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing, plating |

| Quality Standards | ISO 9001:2015 certified, full inspection reporting (CMM, optical comparators, surface testers) |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally. We are committed to supporting your innovation with responsive, reliable, and technically superior manufacturing solutions.

Contact us today at [email protected] to discuss your next project. Let us help you turn precision into performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.