Technical Contents

Engineering Guide: Custom Ceramic Molds

Engineering Insight Precision in Custom Ceramic Molds

Achieving dimensional accuracy and structural integrity in custom ceramic molds is non-negotiable for high-performance manufacturing. These molds endure extreme thermal cycling and mechanical stress during casting or forming processes. Even micron-level deviations compromise part consistency, surface quality, and final component lifespan. Precision engineering ensures uniform wall thickness, exact feature replication, and optimal thermal expansion characteristics. This directly impacts yield rates, reduces scrap costs, and guarantees the ceramic component meets stringent aerospace, medical, or defense specifications. At Wuxi Lead Precision Machinery, we treat mold geometry as the critical foundation for your end-product success, not merely a disposable tool.

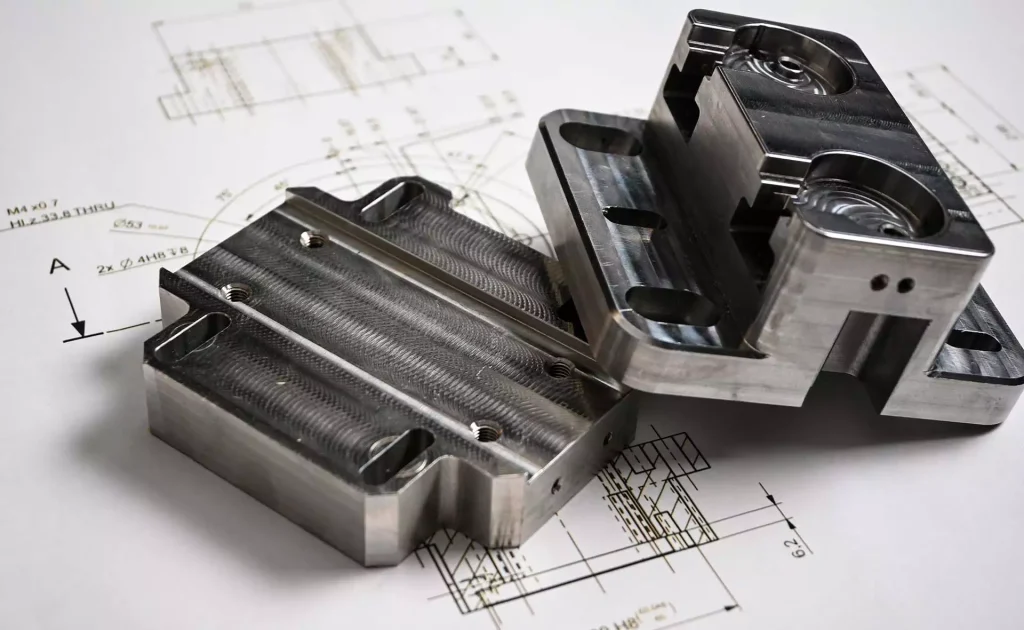

Our approach integrates advanced metrology with material science expertise. We begin with rigorous CAD analysis to anticipate ceramic shrinkage and stress points during sintering. Multi-axis CNC machining of mold cavities and cores achieves tolerances unattainable through traditional methods. Each mold undergoes coordinate measuring machine (CMM) validation against the digital twin, ensuring conformity before the first pour. This systematic process eliminates guesswork, translating complex geometries into reliable production assets. Precision isn’t an add-on service; it’s embedded in our manufacturing DNA from initial design to final certification.

Wuxi Lead’s capability is proven under the most demanding conditions. We engineered ceramic investment molds for critical titanium components used in Olympic-class aerospace systems, where failure is not an option. Our molds consistently met military-grade specifications for thermal shock resistance and dimensional stability in defense applications. These projects demanded tolerances exceeding standard industry benchmarks, requiring absolute control over material composition and machining parameters. Our experience demonstrates that only uncompromising precision engineering delivers molds capable of producing mission-critical ceramic parts batch after batch.

The technical requirements for elite ceramic molds are exacting. Below are the core specifications our processes routinely achieve for demanding sectors:

| Specification Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance (mm) | ±0.025 | ±0.005 | CMM / Laser Scanning |

| Surface Roughness (Ra, µm) | 0.8 | 0.2 | Profilometer |

| Sintered Density Consistency | ±1.5% | ±0.3% | Archimedes’ Principle |

| Thermal Expansion Match | ±8 x 10⁻⁶ /°C | ±3 x 10⁻⁶ /°C | Dilatometry |

| Feature Replication Accuracy | 95% | 99.5% | Optical Comparator |

This level of control transforms ceramic molding from a variable process into a predictable, high-yield operation. For manufacturers requiring zero-defect ceramic components, the mold’s precision is the decisive factor. Wuxi Lead Precision Machinery delivers this certainty through engineering rigor honed on projects where performance is measured in mission success. Partner with us to convert your most challenging ceramic designs into reality with uncompromised fidelity.

Precision Specs & Tolerances

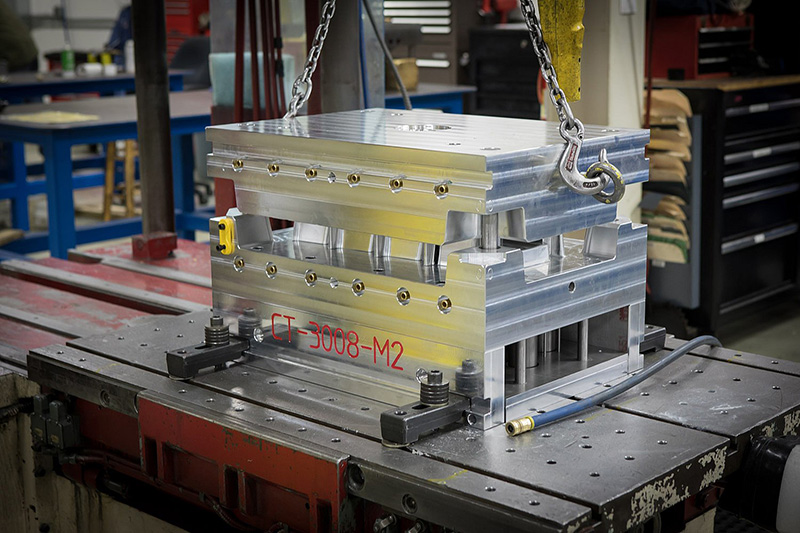

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industries such as aerospace, medical devices, energy, and advanced ceramics. At the core of our production workflow is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring intricate features that are often required in custom ceramic mold fabrication. The integration of high-speed machining with dynamic toolpath strategies ensures minimal material waste, reduced cycle times, and superior part consistency.

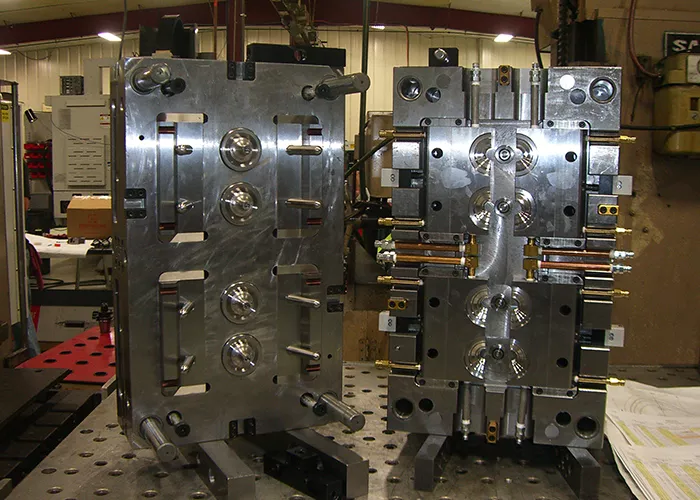

Our 5-axis CNC platforms are equipped with automated tool changers, high-resolution probing systems, and real-time spindle monitoring, ensuring continuous operation under tight tolerances. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize tool engagement, cutting parameters, and workpiece fixturing. This digital-first approach enables us to handle both prototyping and high-volume production runs with equal precision, supporting clients from initial design validation through full-scale manufacturing.

Quality control is embedded at every stage of the process. All critical dimensions on custom ceramic molds are verified using Coordinate Measuring Machine (CMM) inspection, performed on a Zeiss CONTURA G2 or equivalent metrology-grade system. These CMMs provide micron-level measurement accuracy in a temperature-controlled environment, ensuring repeatability and compliance with international standards such as ISO 9001 and AS9100. Our inspection protocols include first-article reporting (FAI), in-process checks, and final certification, with full traceability of materials, tooling, and measurement data.

We specialize in machining mold components from a range of high-performance materials, including hardened tool steels, stainless alloys, and specialty composites compatible with ceramic forming processes such as dry pressing, isostatic pressing, and injection molding. Surface finishes are precisely controlled to meet functional requirements, with options ranging from fine ground textures to mirror-polished cavities. All molds are designed to withstand repeated thermal cycling and mechanical stress, ensuring long service life in industrial ceramic production environments.

The following table outlines the standard technical specifications and achievable tolerances for our custom ceramic mold manufacturing services:

| Specification | Capability |

|---|---|

| Machining Process | 5-Axis CNC Milling |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm (standard), ±0.005 mm (tight) |

| Surface Roughness (Ra) | 0.2 µm to 1.6 µm (adjustable) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Material Hardness (max) | 60 HRC |

| CMM Inspection Accuracy | ±0.003 mm |

| Lead Time (prototype) | 10–20 working days |

| Quality Standards | ISO 9001, AS9100, PPAP, FAI |

Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous quality assurance to deliver custom metal solutions that meet the exacting demands of advanced ceramic manufacturing.

Material & Finish Options

Material Selection for High-Performance Custom Ceramic Molds

Selecting the optimal base material for custom ceramic molds is a critical engineering decision directly impacting production efficiency, part quality, and tooling longevity. At Wuxi Lead Precision Machinery, we leverage decades of CNC machining expertise to guide clients through this complex choice, balancing thermal properties, mechanical strength, wear resistance, and cost-effectiveness for demanding ceramic forming processes. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages tailored to specific production volumes, ceramic compositions, and operational demands.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the preferred choice for rapid prototyping and medium-volume production. Their exceptional thermal conductivity ensures uniform heating and cooling cycles, crucial for preventing thermal shock in green ceramic bodies and minimizing cycle times. Aluminum’s machinability allows for intricate mold geometries with tight tolerances at lower initial costs. However, its lower hardness necessitates protective surface treatments for extended use with abrasive ceramic slurries. Steel molds, utilizing grades like P20 for pre-hardened applications or H13 for high-temperature scenarios, provide superior hardness and wear resistance. This makes them indispensable for high-volume, long-run production where dimensional stability under repeated thermal cycling and resistance to abrasive wear are paramount. While steel requires longer machining times and higher initial investment, its longevity in demanding ceramic forming environments delivers a lower cost-per-part over the mold’s lifecycle. Titanium, specifically Grade 5 (Ti-6Al-4V), offers a unique blend of high strength-to-weight ratio, excellent corrosion resistance, and good thermal stability. It is particularly valuable for specialized applications involving highly corrosive ceramic precursors or where extreme weight reduction of the mold assembly is critical, though its high material and machining costs typically limit use to niche, high-value components.

Surface finishing, especially anodizing for aluminum molds, is not merely cosmetic but a functional necessity. Type II (Sulfuric Acid) anodizing provides a standard, economical wear and corrosion-resistant layer. For the most abrasive ceramic formulations or where maximum mold life is essential, we rigorously specify Type III (Hardcoat) anodizing. This process creates a significantly thicker, harder ceramic-like oxide layer (60-100+ microns) with superior abrasion resistance, directly extending mold service life in high-wear ceramic pressing or injection molding operations. Proper sealing of the anodized layer is equally critical to prevent chemical ingress during ceramic processing.

The following table summarizes key comparative properties to inform your selection:

| Property | Aluminum 6061-T6 | Steel P20 | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 4.4 |

| Hardness (HB) | 95 | 290-330 | 360 |

| Thermal Conductivity (W/m·K) | 167 | 28-36 | 7.2 |

| Corrosion Resistance | Moderate (Anodized: High) | Good (Varies by grade) | Excellent |

| Typical Application | Prototyping, Medium Volume | High-Volume Production | Specialized/Corrosive |

Choosing the right material and finish requires analyzing your specific ceramic formulation, production volume, dimensional tolerances, and thermal profile. Wuxi Lead Precision Machinery provides comprehensive material consultation, leveraging our CNC manufacturing capabilities to ensure your custom ceramic mold delivers optimal performance, precision, and value from the first cycle. Contact our engineering team to discuss your exact requirements.

Manufacturing Process & QC

Design Phase: Precision Engineering for Ceramic Mold Integrity

At Wuxi Lead Precision Machinery, the foundation of every custom ceramic mold begins with a rigorous design process rooted in advanced simulation and material science. Our engineering team collaborates closely with clients to translate functional requirements—such as thermal stability, dimensional tolerance, and surface finish—into actionable 3D CAD models. Utilizing finite element analysis (FEA), we simulate thermal expansion, pressure distribution, and stress points under operational conditions, ensuring the mold design can withstand extreme environments typical in high-temperature forming and casting processes. All designs are validated against ISO 9001-certified protocols and subjected to cross-functional review, integrating feedback from manufacturing, quality assurance, and materials experts. This preemptive validation eliminates conceptual flaws and ensures manufacturability before any physical prototype is produced.

Prototyping: Iterative Validation and Zero-Defect Verification

Once the design is finalized, we proceed to prototype development using high-precision CNC machining and additive manufacturing techniques tailored for ceramic preforms. Prototypes are fabricated from the same base material as the final production mold—typically alumina, zirconia, or silicon nitride—to ensure accurate representation of thermal and mechanical behavior. Each prototype undergoes a comprehensive test regimen, including dimensional inspection via coordinate measuring machines (CMM), thermal cycle testing, and non-destructive evaluation (NDE) using ultrasonic and X-ray imaging. Any deviations from specifications are analyzed through root cause analysis (RCA), and design or process adjustments are implemented in real time. This closed-loop prototyping approach ensures that only fully validated molds advance to mass production, effectively eliminating first-article defects.

Mass Production: Scalable Precision with Full Traceability

With prototype approval, we initiate mass production under a fully documented and controlled workflow. Each mold is manufactured using automated CNC systems with real-time tool wear compensation and in-process metrology, ensuring micron-level consistency across batches. Our production floor operates under 5S and Lean manufacturing principles, minimizing variability and waste. Every stage—from raw material batching to sintering and final grinding—is monitored through a digital quality management system (QMS) that logs process parameters and operator inputs for full traceability. Completed molds are subjected to 100% inspection of critical dimensions and surface quality, with statistical process control (SPC) data reviewed daily to maintain process capability indices (Cp/Cpk) above 1.67.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.02 mm (depending on size) |

| Surface Roughness (Ra) | 0.1 µm to 0.4 µm |

| Material Options | Al₂O₃, ZrO₂, Si₃N₄, SiC |

| Max Mold Size | 600 mm × 400 mm × 300 mm |

| Sintering Temperature | Up to 1800°C (in controlled atmosphere) |

| Production Lead Time | 12–20 days (after design approval) |

| Quality Standard | ISO 9001:2015, Full FAI and PPAP support |

Through integrated design validation, iterative prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery guarantees zero-defect delivery of custom ceramic molds for the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Ceramic Mold Excellence

Achieving dimensional perfection and thermal stability in custom ceramic molds demands more than standard manufacturing capabilities. It requires the fusion of advanced CNC engineering, deep materials science expertise, and an unwavering commitment to precision. At Wuxi Lead Precision Machinery, we specialize in transforming complex ceramic molding challenges into repeatable, high-yield production solutions. Our dedicated engineering teams collaborate directly with your R&D and production staff from initial concept through final validation, ensuring every mold meets the exacting demands of your sintering processes, material behavior, and end-part performance requirements. We understand that a single micron of deviation can cascade into significant yield loss or part failure; therefore, we implement rigorous in-process metrology and material verification protocols at every stage of fabrication. This proactive approach minimizes risk, accelerates time-to-market, and delivers molds engineered for maximum longevity under extreme thermal cycling.

Our technical capabilities are built upon state-of-the-art multi-axis CNC machining centers and specialized finishing processes calibrated specifically for advanced ceramics and refractory materials. The table below details our core specifications for custom ceramic mold production:

| Parameter | Capability | Application Benefit |

|---|---|---|

| Material Range | Alumina, Zirconia, SiC, SiN, Specialty Composites | Ensures optimal thermal shock resistance and wear life for your specific ceramic formulation |

| Tolerance Capability | ±0.005 mm (精密级) | Guarantees consistent green part dimensions and eliminates secondary machining |

| Max Mold Size | 800 x 600 x 400 mm | Supports large-format structural or electronic ceramics production |

| Lead Time (Prototype) | 18-25 Working Days | Accelerates your product development cycles significantly |

| Surface Finish | Ra 0.2 µm (Mirror Polish Option) | Minimizes part sticking and surface defects post-sintering |

Partnering with Lead Precision means gaining a strategic manufacturing ally invested in your operational success. We do not merely supply molds; we deliver integrated process knowledge, including sintering profile recommendations and mold maintenance protocols tailored to your production environment. Our quality management system is ISO 9001:2015 certified, with full traceability on all critical materials and processes. All technical documentation, including GD&T drawings, CMM reports, and material certifications, is provided in English or your preferred language, ensuring seamless integration into your global supply chain.

The complexity of advanced ceramic manufacturing leaves no room for compromise in mold quality. Substandard tooling directly impacts your yield, part consistency, and ultimately, your reputation in demanding markets like aerospace, medical implants, and semiconductor components. Wuxi Lead Precision Machinery provides the engineering rigor, technical transparency, and responsive partnership essential for leading manufacturers. Do not let mold performance limit your ceramic innovation. Contact our precision engineering team today to discuss your specific requirements and receive a detailed capability assessment.

Elevate your ceramic production with molds engineered for perfection. Reach out to initiate a technical consultation: [email protected]. Let us demonstrate how Lead Precision becomes your definitive advantage in high-stakes ceramic manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.