Technical Contents

Engineering Guide: Custom Automotive Fabrication

Engineering Insight: Precision in Custom Automotive Fabrication

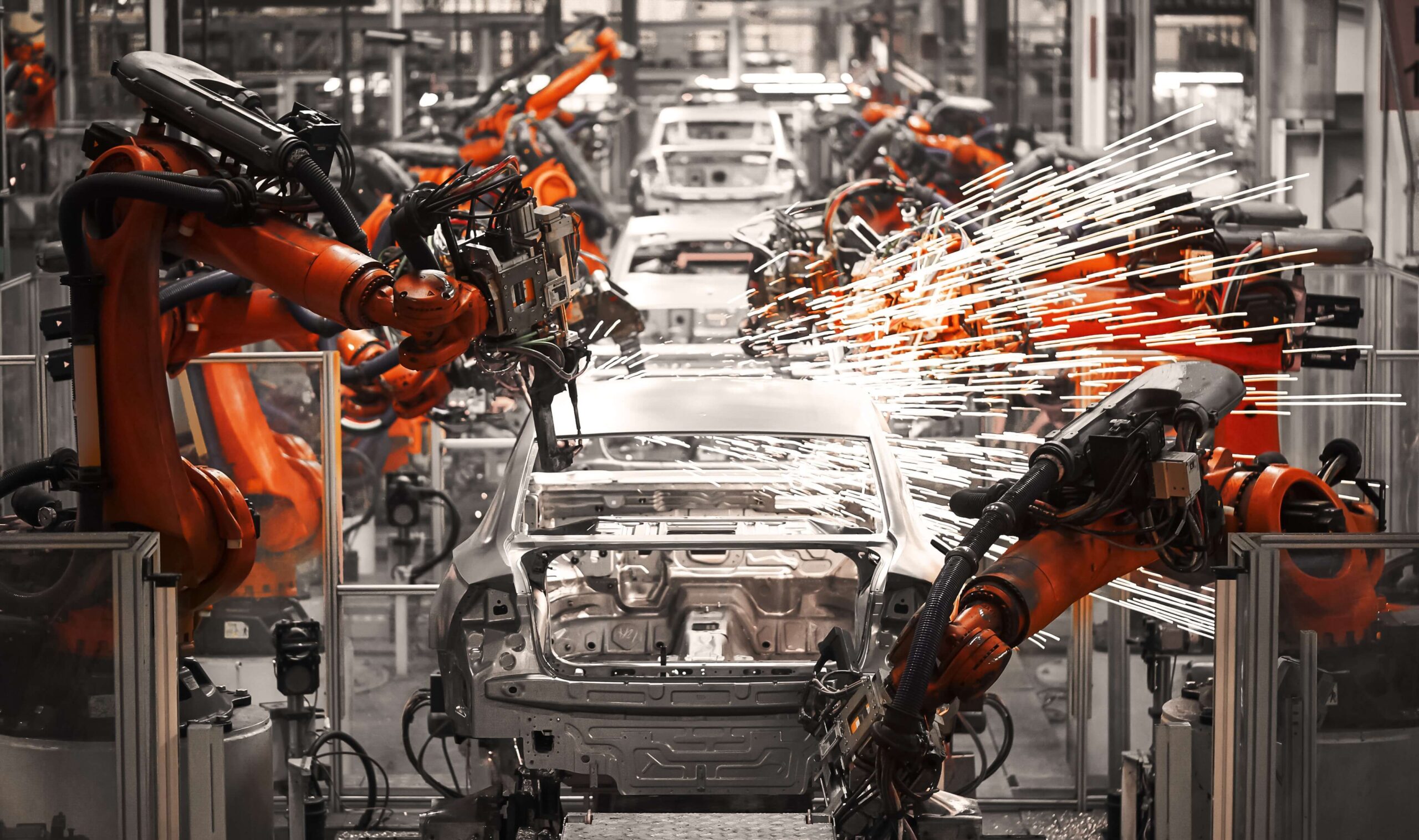

In the realm of custom automotive fabrication, precision is not merely a performance metric—it is the foundation of function, safety, and innovation. As vehicles evolve toward lightweight architectures, electrification, and advanced aerodynamics, the demand for tightly toleranced, repeatable sheet metal components has never been greater. At Wuxi Lead Precision Machinery, we understand that even a tolerance deviation of ±0.05 mm can compromise structural integrity, fitment, or performance in high-stakes automotive applications.

Our engineering philosophy centers on dimensional accuracy, material integrity, and process consistency. Whether producing custom chassis brackets, battery enclosures for electric vehicles, or aerodynamic body panels, every component undergoes rigorous design validation and in-process inspection. We utilize state-of-the-art CNC turret presses, fiber laser cutting systems, and automated bending cells, all calibrated to maintain micron-level repeatability across production runs.

Precision in fabrication directly influences downstream assembly efficiency, minimizing rework and ensuring seamless integration with composite or powertrain systems. For example, misaligned mounting points in a custom subframe can lead to drivetrain vibration, compromised handling, or accelerated wear. In electric vehicle builds, poorly formed battery housings may fail to meet IP67 sealing requirements or thermal management specifications. These risks are mitigated through our closed-loop quality control system, which includes real-time laser measurement and first-article inspection protocols.

Wuxi Lead Precision Machinery brings over 15 years of high-compliance manufacturing experience to the automotive sector. Our expertise is validated not only through ISO 9001 certification but also through our proven track record in mission-critical industries. We have supplied components for Olympic-level competition vehicles, where performance margins are measured in milliseconds, and for defense-grade tactical automotive platforms, where reliability under extreme conditions is non-negotiable. This cross-domain experience enables us to apply aerospace-grade discipline to custom automotive builds, ensuring that every part meets or exceeds functional and safety benchmarks.

Our commitment to precision extends beyond machinery—it is embedded in our engineering collaboration. We work closely with design teams to optimize manufacturability, suggest material substitutions for weight or strength improvements, and validate prototypes through rapid iteration. This proactive approach reduces time-to-market while enhancing end-product performance.

The following table outlines key fabrication capabilities that support high-precision custom automotive projects:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1° / ±0.2 mm |

| Maximum Part Size | 3000 mm × 1500 mm |

| Laser Cutting Power | Up to 12 kW Fiber |

| CNC Press Brake Tooling | Automatic crown compensation |

| Surface Treatment Options | Anodizing, Powder Coating, Passivation, Zinc Plating |

At Wuxi Lead, we recognize that custom automotive fabrication is as much about trust as it is about technology. Our clients rely on us to transform innovative designs into high-precision, real-world solutions—components that perform under pressure, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication for Automotive Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for custom automotive fabrication, leveraging advanced 5-axis CNC machining centers to meet the stringent demands of modern vehicle systems. Our HAAS UMC-750 and DMG MORI CTX beta 1250 platforms feature 762 mm x 508 mm x 508 mm travel, 15,000 RPM spindles, and integrated probing systems. This enables single-setup machining of complex geometries—including structural brackets, transmission housings, and EV battery enclosures—from monolithic billet or fabricated assemblies. The elimination of secondary operations reduces cumulative error while achieving critical features like compound angles, deep cavities, and integrated cooling channels within ±0.025 mm positional accuracy. Material versatility spans automotive-grade aluminum alloys (6061-T6, 7075-T6), high-strength steel (HSLA 590), and stainless steel (304/316), with thickness capabilities from 0.5 mm to 25 mm.

Rigorous metrology protocols underpin every component. Our Zeiss CONTURA G3 CMMs, certified to ISO 10360-2:2009 standards, perform full 3D scanning with 1.9 + L/300 µm volumetric accuracy. Each part undergoes first-article inspection per AIAG PPAP requirements, generating AS9102-compliant reports with GD&T analysis. Automated optical comparators verify edge radii, hole patterns, and surface finishes down to Ra 0.8 µm. This closed-loop quality system ensures conformance to automotive OEM specifications, including Ford WSS-M99P1111-A2, GM GMW3043, and Tesla Drawing Standards.

Critical Tolerances for Automotive Components

| Feature Type | Material Range | Standard Tolerance | Tight Tolerance Capability | Process |

|---|---|---|---|---|

| Hole Diameter | Aluminum/Steel/SS | ±0.05 mm | ±0.012 mm | 5-Axis Drilling |

| Flatness | ≤1000 x 500 mm | 0.1 mm | 0.025 mm | CNC Milling |

| Positional Accuracy | All Critical Features | ±0.1 mm | ±0.025 mm | 5-Axis Machining |

| Thread Fit | M3 – M24 | 6H/6g | 4H/4g | Tapping/Milling |

| Edge Break | All Sheet Metal | 0.2 x 45° | 0.05 x 45° | Deburring |

Our integrated workflow—from CAD/CAM programming in Siemens NX to in-process gauge validation—ensures repeatability across volumes from prototypes to 50,000+ annual units. Surface treatments including anodizing (Type II/III), powder coating (AAMA 2604), and robotic welding (ISO 15614-1 certified) are executed within controlled cleanrooms to prevent particulate contamination. For electric vehicle clients, we specialize in EMI-shielded enclosures with ≤0.05 mm gap tolerances on mating surfaces, validated through MIL-STD-461G testing protocols. This technical rigor positions Wuxi Lead as a strategic partner for Tier 1 suppliers requiring zero-defect delivery in powertrain, chassis, and ADAS subsystems.

Material & Finish Options

Material selection is a foundational decision in custom automotive fabrication, directly influencing performance, durability, weight, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in precision sheet metal fabrication for high-end automotive applications, where material properties and surface finishes are optimized for both function and aesthetics. Aluminum, steel, and titanium represent the core materials used in this sector, each offering distinct advantages depending on the application requirements.

Aluminum is widely favored in automotive fabrication for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suited for body panels, structural components, and heat exchangers where weight reduction is critical without sacrificing structural integrity. Grade 6061-T6 is commonly used for its weldability and moderate strength, while 7075-T6 offers higher strength for performance-critical parts. Aluminum’s natural oxide layer provides inherent corrosion protection, but for enhanced durability and visual appeal, anodizing is frequently applied.

Steel remains the backbone of automotive structural design due to its high tensile strength, impact resistance, and cost-effectiveness. Mild steel (A36, Q235) is often used for chassis and frame components, while high-strength low-alloy (HSLA) steels offer improved strength and fatigue resistance for safety-critical systems. Stainless steel grades such as 304 and 316 are selected when corrosion resistance and aesthetic finish are paramount, commonly used in exhaust systems and trim components. While heavier than aluminum, steel’s formability and weldability make it indispensable in complex fabrication workflows.

Titanium, though more expensive and challenging to process, is increasingly used in high-performance and luxury automotive applications. Its exceptional strength-to-density ratio, resistance to extreme temperatures, and corrosion resistance make it ideal for exhaust systems, suspension components, and aerospace-inspired structural elements. Grade 5 (Ti-6Al-4V) is the most common titanium alloy in automotive use, offering a balance of strength, toughness, and weldability.

Anodizing is a key surface treatment for aluminum components, enhancing wear resistance, corrosion protection, and aesthetic versatility. The electrochemical process thickens the natural oxide layer, allowing for color integration through dyeing—commonly black, red, or gold—while maintaining precise dimensional control. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) is used for high-wear applications requiring superior surface hardness.

Below is a comparative overview of key material properties for selection guidance.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | High | 6061-T6, 7075-T6 | Body panels, heat sinks, frames |

| Steel (Mild) | 7.8 | 400–550 | Low (uncoated) | Q235, A36 | Chassis, brackets, structural parts |

| Stainless Steel | 8.0 | 505–860 | Very High | 304, 316 | Exhausts, trim, fasteners |

| Titanium | 4.5 | 900–1000 | Exceptional | Ti-6Al-4V (Grade 5) | High-performance exhausts, mounts |

Selecting the right material and finish requires a balance of engineering requirements, environmental exposure, and design intent. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through material testing, prototyping, and precision fabrication tailored to the demands of modern automotive innovation.

Manufacturing Process & QC

Custom Automotive Sheet Metal Fabrication: Precision Production Process

At Wuxi Lead Precision Machinery, our zero-defect philosophy drives every phase of custom automotive sheet metal fabrication. We integrate stringent quality controls from initial design through mass production, ensuring components meet IATF 16949 standards and OEM-specific requirements. This systematic approach eliminates rework, reduces time-to-market, and guarantees dimensional accuracy critical for vehicle safety and assembly.

The process begins with collaborative engineering design. Our team conducts thorough Design for Manufacturability (DFM) analysis using Siemens NX software, identifying potential weaknesses in material flow, weld accessibility, and tolerance stack-ups. Finite Element Analysis (FEA) validates structural integrity under real-world loads, while Geometric Dimensioning and Tolerancing (GD&T) callouts are optimized for producibility. Client sign-off on these digital models prevents downstream errors, ensuring designs translate flawlessly to physical parts.

Prototyping follows with rapid validation. Utilizing 5-axis CNC laser cutting and precision press brakes, we produce 1–5 functional prototypes within 72 hours. Each prototype undergoes rigorous CMM inspection against 3D CAD data, verifying critical features to ±0.05 mm. Dimensional reports and material certifications are provided for client approval. This phase confirms tooling feasibility, surface finish compliance, and assembly fitment—addressing 95% of potential defects before tooling investment.

Mass production leverages closed-loop automation for zero-defect output. Stamping, bending, and welding occur on Mazak and Amada equipment with integrated in-process sensors. Real-time SPC (Statistical Process Control) monitors key parameters like bend angle deviation and weld penetration depth, auto-correcting deviations before non-conformances occur. Every component is traceable via laser-etched QR codes, linking material certs, machine logs, and final inspection data. Final validation includes 100% first-article inspection and AQL 0.65 random sampling, with full reports delivered per shipment.

Key Production Specifications

| Parameter | Capability | Standard Tolerance | Validation Method |

|---|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ISO 2768-mK | Ultrasonic Thickness Gauge |

| Dimensional Accuracy | Up to 2000 x 3000 mm | ±0.1 mm | CMM / Laser Tracker |

| Bend Angle | 0° – 180° | ±0.5° | Optical Angle Sensor |

| Weld Penetration | TIG/MIG Robotic | 100% of base material | Destructive Test Reports |

| Surface Finish | Brushed, Anodized, Powder-Coated | Ra ≤ 0.8 µm | Spectrophotometer |

| Production Volume | 1 – 500,000+ units | N/A | Real-time SPC Dashboard |

This end-to-end discipline—where design foresight, prototype rigor, and intelligent production converge—ensures every component exits our facility with zero escapes. For automotive Tier 1 suppliers demanding flawless integration, Wuxi Lead delivers precision-engineered solutions backed by full process transparency and on-time delivery. Contact our engineering team to initiate a defect-proof fabrication workflow for your next program.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Automotive Fabrication

At Wuxi Lead Precision Machinery, we understand that in the world of high-performance automotive manufacturing, precision isn’t just a goal—it’s a requirement. As a trusted leader in sheet metal fabrication based in China, we specialize in delivering custom automotive components that meet the exacting standards of global OEMs and Tier-1 suppliers. Our advanced manufacturing capabilities, rigorous quality assurance protocols, and deep engineering expertise ensure that every part we produce contributes directly to the performance, safety, and innovation of modern vehicles.

When you choose to partner with Lead Precision, you’re not just outsourcing production—you’re gaining a strategic manufacturing ally. Our facility is equipped with state-of-the-art CNC punching, laser cutting, bending, and robotic welding systems, enabling us to handle complex geometries and tight tolerances with unwavering consistency. From prototype development to full-scale production runs, we maintain full traceability and process control, ensuring every component meets international standards such as ISO 9001 and IATF 16949.

Our engineering team works collaboratively with your design and R&D departments to optimize manufacturability, reduce material waste, and accelerate time-to-market. Whether you require lightweight structural components, custom chassis elements, or precision enclosures for electric vehicle systems, we bring your vision to life with exceptional accuracy and repeatability.

We serve a global clientele with seamless communication, on-time delivery, and a commitment to continuous improvement. Our logistics network ensures reliable shipment to North America, Europe, and Asia, backed by real-time project tracking and responsive customer support. At Lead Precision, we don’t just meet expectations—we exceed them.

To learn how we can support your next custom automotive fabrication project, contact us today. Our team is ready to review your technical drawings, provide detailed quotations, and guide you through our end-to-end manufacturing process.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Material Types | Cold-rolled steel, stainless steel, aluminum, galvanized steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.1 mm (standard), tighter upon request |

| Max Part Size | 3000 mm × 1500 mm |

| Processes | Laser cutting, CNC punching, precision bending, robotic welding, assembly |

| Finishing Options | Powder coating, anodizing, passivation, plating |

| Certifications | ISO 9001, IATF 16949, RoHS compliant |

| Lead Time | 15–25 days (varies by complexity and volume) |

For immediate assistance, email us at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision automotive fabrication—where engineering excellence drives every outcome.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.