Technical Contents

Engineering Guide: Custom Aluminum Parts

Engineering Insight Precision in Custom Aluminum Parts Manufacturing

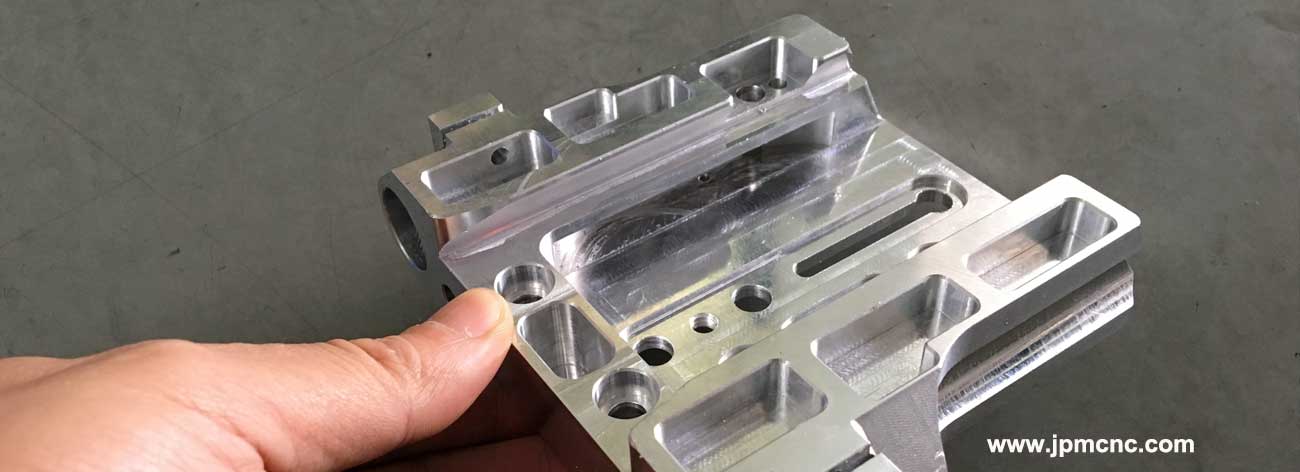

Achieving true precision in custom aluminum parts transcends mere dimensional accuracy; it is the cornerstone of functional reliability, performance longevity, and seamless integration within complex assemblies. Aluminum alloys, while prized for their strength-to-weight ratio and corrosion resistance, present unique machining challenges. Their relative softness compared to steel increases susceptibility to tool chatter, burring, and thermal deformation during high-speed CNC operations. Furthermore, aluminum’s high thermal conductivity demands meticulous thermal management strategies to prevent workpiece distortion as heat dissipates unevenly. Neglecting these factors results in parts that may measure within nominal tolerance on a CMM but fail catastrophically under operational stress due to residual stresses, compromised surface integrity, or subtle geometric deviations invisible to basic inspection. Precision engineering for aluminum requires anticipating material behavior, not just controlling machine movements.

At Wuxi Lead Precision Machinery, our approach integrates deep material science understanding with advanced CNC process engineering. We recognize that tolerances like ±0.005mm are meaningless without context; the critical factor is how that precision is achieved and sustained across the entire production lifecycle. Our protocols include rigorous pre-machining material certification, adaptive cutting parameter optimization based on real-time tool load monitoring, and specialized fixturing designed to minimize clamping-induced distortion inherent in aluminum. We implement multi-stage stress-relief cycles and utilize non-contact measurement techniques during intermediate stages to ensure geometric stability before final finishing. This systematic methodology prevents the common pitfalls of aluminum machining: thermal warpage, poor surface finish affecting fatigue life, and inconsistent hole perpendicularity critical for fluid dynamics or structural interfaces.

The consequences of imprecise aluminum components are severe in mission-critical applications. A micron-level deviation in an aerospace hydraulic manifold can cause catastrophic seal failure. Inconsistent wall thickness in a medical device housing may lead to thermal runaway. Surface roughness exceeding specifications on a satellite optical mount introduces vibration modes that blur imaging systems. Precision isn’t an optional premium; it is the non-negotiable baseline for performance.

Our commitment to this standard is proven through demanding real-world validation. We consistently deliver components meeting the exacting requirements of defense contractors for unmanned aerial vehicle structural elements and precision-guided munition subsystems, where failure is not an option. Similarly, our partnership in supplying critical track cycling components for Olympic athletes demanded unprecedented consistency in weight distribution and aerodynamic surface finish, directly impacting world-record performances. This experience shapes our standard operating procedures for every client.

The following table outlines our core precision capabilities for custom aluminum parts, reflecting the standards applied across commercial and high-stakes projects:

| Parameter | Standard Capability | Olympic/Military Projects |

|---|---|---|

| Dimensional Tolerance | ±0.010 mm | ±0.002 mm |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Feature Repeatability | ±0.008 mm | ±0.0015 mm |

| Material Certification | Mill Cert Required | Full AMS/ASTM Traceability |

Wuxi Lead Precision Machinery leverages this hard-won expertise to transform aluminum’s challenges into engineered advantages. We ensure your custom parts perform exactly as designed, every time, because in high-stakes manufacturing, precision is the only acceptable margin. Partner with us for components where measurement is merely the starting point of quality assurance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom aluminum part manufacturing, serving high-performance industries including aerospace, medical, automation, and precision instrumentation. Our facility is equipped with state-of-the-art 5-axis CNC machining centers, enabling the production of complex geometries with superior accuracy and surface finish. These multi-axis systems allow for simultaneous movement across five planes, reducing the need for part repositioning and minimizing cumulative error. This results in tighter tolerances, improved consistency, and faster turnaround times compared to conventional 3-axis methods.

Our 5-axis CNC platforms are optimized for aluminum alloys commonly used in demanding applications, such as 6061, 7075, and 2024. These machines feature high-speed spindles, automated tool changers, and real-time tool wear compensation, ensuring dimensional stability across both prototyping and high-volume production runs. In addition, our programming team employs advanced CAM software to generate optimized toolpaths, reducing cycle times while maintaining material integrity and feature precision.

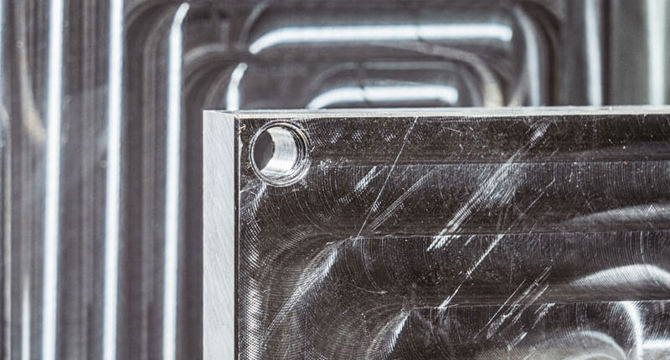

Quality control is fully integrated into our manufacturing workflow. Every custom aluminum component undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This metrology-grade system provides non-contact and tactile probing capabilities, enabling precise verification of critical dimensions, geometric tolerances, and surface profiles. All inspection data is documented in detailed first-article inspection reports (FAIR) and available upon request, ensuring full traceability and compliance with ISO 9001 standards.

We maintain strict environmental controls within the metrology lab to eliminate thermal drift, ensuring measurement accuracy down to ±0.0001 inches (2.5 µm). In-process inspections are conducted at key stages of production, allowing for immediate correction and minimizing rework. Our quality engineers are trained in GD&T (Geometric Dimensioning and Tolerancing) and work closely with clients to interpret drawing requirements and ensure compliance with functional specifications.

The following table outlines our standard machining capabilities and achievable tolerances for custom aluminum parts:

| Specification | Capability |

|---|---|

| Maximum Work Envelope (5-axis) | 800 mm × 600 mm × 500 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Linear Tolerance | ±0.025 mm (0.001″) |

| Tight Tolerance Machining | ±0.005 mm (0.0002″) |

| Geometric Tolerances (Flatness, Perpendicularity, etc.) | As per ISO 2768-mK or customer-specified GD&T |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin), achievable via fine finishing passes |

| CMM Measurement Accuracy | ±1.5 + L/300 µm (L = length in mm) |

At Wuxi Lead Precision Machinery, technical excellence is not only defined by equipment but by the integration of precision engineering, skilled programming, and uncompromising quality assurance. This holistic approach ensures that every custom aluminum component meets the highest standards of performance and reliability.

Material & Finish Options

Material Selection for High-Performance Custom Aluminum Parts

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in precision-critical components. At Wuxi Lead Precision Machinery, our engineering expertise ensures your custom aluminum parts leverage the ideal alloy and finish for demanding applications. While aluminum alloys dominate lightweight structural needs, understanding comparative properties against steel and titanium is essential for informed decision-making. Material choice directly impacts machinability, weight, strength-to-weight ratio, corrosion resistance, and final part cost. We rigorously evaluate your operational environment, load requirements, and lifecycle expectations to recommend the most suitable solution, prioritizing performance without unnecessary expense.

Aluminum alloys offer the best balance for most high-volume precision applications requiring light weight, good strength, and excellent thermal/electrical conductivity. Steel provides superior hardness and wear resistance for heavy-load scenarios but significantly increases weight. Titanium delivers exceptional strength-to-weight and corrosion resistance for extreme environments like aerospace or medical implants, though at a substantially higher material and machining cost. The following table outlines key comparative specifications to guide initial selection:

| Material Category | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Relative Cost (USD/kg) | Primary Applications |

|---|---|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6 | 310-570 | 2.7 | 3.5-6.0 | Aerospace frames, automotive brackets, consumer electronics housings |

| Carbon/Alloy Steel | 4140, 1018 | 415-1700 | 7.8 | 1.2-2.5 | Shafts, gears, high-wear tooling, structural supports |

| Titanium Alloys | Ti-6Al-4V | 900-1100 | 4.4 | 30-50 | Aircraft components, surgical implants, marine hardware |

For aluminum components, anodizing is the industry-standard electrochemical finish to enhance surface properties. This process creates a durable, corrosion-resistant oxide layer integral to the base metal. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dyeability for aesthetic or identification purposes, suitable for general industrial use. Type III (Hard Anodizing) delivers significantly thicker, harder coatings (60-80 Rockwell C) for extreme wear resistance, electrical insulation, and superior corrosion protection in harsh environments like aerospace or military applications. Our certified anodizing lines strictly adhere to MIL-A-8625 and ISO 10074 standards, ensuring consistent coating thickness, hardness, and sealing quality. We precisely control parameters like voltage, temperature, and electrolyte concentration to meet your exact dimensional and functional requirements, preventing part distortion or performance compromise.

Choosing aluminum with the correct alloy and anodizing specification minimizes total cost of ownership by extending service life and reducing maintenance. Wuxi Lead’s engineering team collaborates closely with your designers during the quotation phase to validate material suitability, optimize for manufacturability, and specify the precise anodizing class needed. Contact our technical sales department with your application details for a tailored material and finish recommendation backed by 15 years of precision CNC manufacturing excellence.

Manufacturing Process & QC

From Concept to Consistent Quality: The Custom Aluminum Parts Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we deliver high-precision custom aluminum parts through a rigorously controlled production workflow designed for performance, repeatability, and zero defects. Our process integrates advanced engineering with precision manufacturing, ensuring every component meets exact client specifications from first concept to full-scale delivery.

The journey begins with design collaboration. Our engineering team works closely with clients to review 3D CAD models, analyze structural integrity, thermal behavior, and manufacturability. We conduct Design for Manufacturing (DFM) assessments to optimize wall thickness, tolerances, and tooling access—ensuring the design is not only functional but also cost-efficient to produce. Material selection is confirmed at this stage, with aerospace-grade 6061-T6, 7075-T6, and other high-performance aluminum alloys available based on application requirements.

Once the design is finalized, we move into precision prototyping. Using 5-axis CNC machining centers and advanced CAM programming, we produce functional prototypes that mirror the final product in both form and function. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We validate fit, function, and dimensional accuracy, providing clients with physical samples for testing and approval. This phase minimizes risk and accelerates time to market by identifying potential issues before mass production begins.

With prototype approval, we transition seamlessly into high-volume, zero-defect manufacturing. Our state-of-the-art facility in Wuxi operates under ISO 9001-certified quality management systems. Each production run is supported by Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. Automated tool monitoring, real-time dimensional checks, and in-process audits ensure consistency across thousands of parts. We utilize robotic part handling and closed-loop feedback systems to reduce human error and maintain micron-level precision.

Final inspection includes full-spectrum quality validation—dimensional accuracy, surface finish, material certification, and non-destructive testing if required. All parts are traceable through batch numbers and digital quality records. We support secondary operations including anodizing, powder coating, laser engraving, and precision welding, all performed in-house to maintain process control.

Our end-to-end process is engineered for reliability. By integrating design validation, iterative prototyping, and tightly monitored mass production, Wuxi Lead ensures every custom aluminum component meets the highest standards of quality and performance.

| Specification | Detail |

|---|---|

| Material Options | 6061-T6, 7075-T6, 5052, 2024, and custom alloys |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Surface Finish | As-machined, anodized (Type II & III), powder coated, polished |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 14001, RoHS compliant |

| Inspection Tools | CMM, optical comparator, profilometer, ultrasonic testing |

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Component Supply Chain Through Strategic Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical custom aluminum parts. We transcend conventional manufacturing by integrating deep technical expertise with agile, high-precision production capabilities. Our commitment is to become an extension of your engineering team, ensuring your complex aluminum components meet exacting performance, reliability, and delivery requirements from prototype through high-volume production. Partnering with Lead Precision means securing a supplier whose operational excellence directly enhances your product quality and market competitiveness.

Our core strength lies in advanced CNC machining centers and rigorous process controls, specifically optimized for aluminum alloys including 6061-T6, 7075-T6, and 2024-T3. The table below details our standard production capabilities for custom aluminum components:

| Specification | Capability | Material Applicability |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (Standard) | All aerospace & industrial |

| ±0.002 mm (Tight Tolerance) | Critical sealing surfaces | |

| Max Work Envelope | 2000 x 1500 x 800 mm | Large structural components |

| Surface Finish (Ra) | 0.8 µm (Standard Milling) | General applications |

| 0.4 µm (Precision Finish) | Hydraulic/pneumatic systems | |

| Material Removal Rate | Optimized 30% above industry avg | High-volume cost efficiency |

This precision foundation is amplified by proactive engineering collaboration. Our applications engineers engage during your design phase to identify manufacturability improvements, material selection guidance, and cost-saving opportunities without compromising performance. We implement Design for Manufacturability (DFM) analysis as standard practice, preventing costly iterations and accelerating time-to-market. This consultative approach ensures your aluminum parts are not only precisely made but inherently optimized for production efficiency and long-term reliability.

Quality is non-negotiable in critical aluminum applications. Our ISO 9001:2015 certified quality management system incorporates comprehensive in-process inspection protocols, full material traceability, and final verification using calibrated CMMs and surface profilometers. Every batch undergoes rigorous dimensional and metallurgical validation against your specifications, providing documented assurance for regulated industries including aerospace, medical, and advanced automation. We maintain full transparency through detailed First Article Inspection (FAI) reports and real-time production data access.

Secure your competitive advantage in aluminum component manufacturing. Contact our engineering team directly to discuss your specific requirements and receive a precision-focused quotation within 24 business hours. Initiate a partnership built on technical excellence and unwavering reliability. Email [email protected] with your part drawings or project specifications. Let Wuxi Lead Precision Machinery become your trusted source for custom aluminum parts where precision, quality, and partnership deliver measurable value to your supply chain. Your next-generation aluminum components demand nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.