Technical Contents

Engineering Guide: Custom Aerospace Machining

Engineering Insight: Precision as the Non-Negotiable Foundation of Aerospace Machining

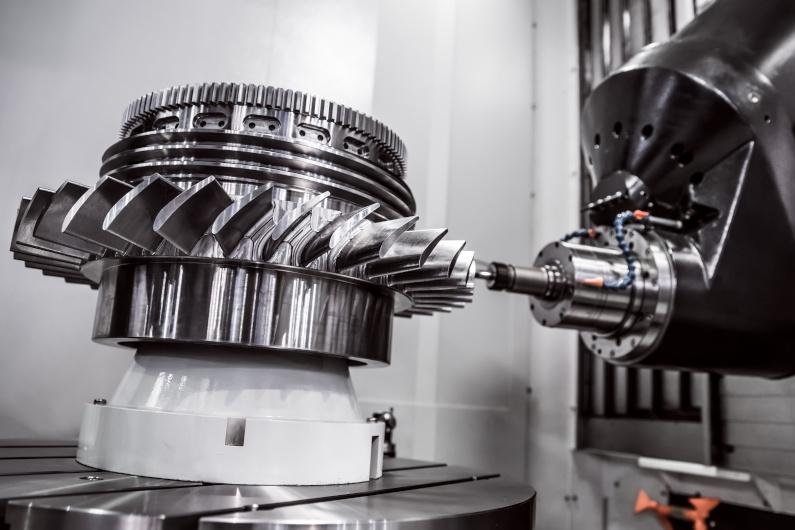

In aerospace manufacturing, precision transcends mere specification; it is the absolute bedrock of flight safety, component reliability, and regulatory compliance. The operational environments aerospace components endure—extreme temperatures, intense vibrations, and colossal structural loads—demand tolerances measured in microns. A deviation of even 0.01 millimeters in a turbine blade airfoil or a critical fastening interface can cascade into catastrophic fatigue failure, imbalance, or system malfunction. This inherent zero-defect requirement elevates precision machining from a technical capability to a fundamental engineering imperative. Achieving such levels consistently requires far more than advanced CNC equipment; it demands a holistic ecosystem encompassing thermal-stable manufacturing environments, rigorously calibrated metrology, deeply ingrained process discipline, and engineering expertise honed by real-world, mission-critical applications.

The consequences of inadequate precision are not theoretical. Sub-micron variations in bearing races accelerate wear exponentially. Imperceptible surface imperfections become initiation points for cracks under cyclic stress. Dimensional drift in structural fittings compromises assembly integrity and aerodynamic performance. Therefore, aerospace machining protocols mandate capabilities far exceeding standard industrial practices. This necessitates mastery across the entire value chain, from material certification and strategic fixturing to in-process probing and final validation against stringent aerospace standards like AS9100. The process window is exceptionally narrow, requiring constant vigilance and predictive process control.

Wuxi Lead Precision Machinery operates within this uncompromising realm daily. Our engineering team leverages decades of specialized experience, forged not only in commercial aerospace but also through demanding projects for Olympic timing systems and military defense programs. These sectors share aerospace’s relentless focus on absolute accuracy and failure-proof performance under pressure. Our facility is engineered for this challenge, featuring temperature-controlled machining cells and multi-sensor CMMs capable of nanometer-level verification. The table below outlines the core precision capabilities we routinely deploy for aerospace clients:

| Specification Category | Capability Range | Aerospace Standard Context |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) standard | Exceeds typical AS9100 requirements |

| Down to ±0.001 mm (±0.00004″) | Critical rotating/structural parts | |

| Surface Roughness (Ra) | 0.4 µm (16 µin) standard | General aerospace surfaces |

| Down to 0.05 µm (2 µin) achievable | High-performance seals/bearings | |

| Geometric Accuracy (GD&T) | Full ISO 1101 compliance | Critical for fit/function |

| Complex profile tolerancing | Airfoils, contoured structures | |

| Material Certification | Full traceability to AMS/ASTM specs | Mandatory for airworthiness |

| Process Validation | PPAP Level 3 standard | Customer approval requirement |

This precision capability is not an abstract claim but a proven reality, validated through our rigorous participation in projects where failure is not an option. Our work supporting precision timing for Olympic Games demanded microsecond synchronization—paralleling the nanometer tolerances vital in flight control systems. Similarly, military contracts instilled protocols for absolute reliability under the most severe conditions, directly transferable to aerospace’s unforgiving operational envelope. At Wuxi Lead, we understand that every micron machined contributes directly to the safety of those who fly. We engineer precision not as a target, but as the essential condition for aerospace excellence.

Precision Specs & Tolerances

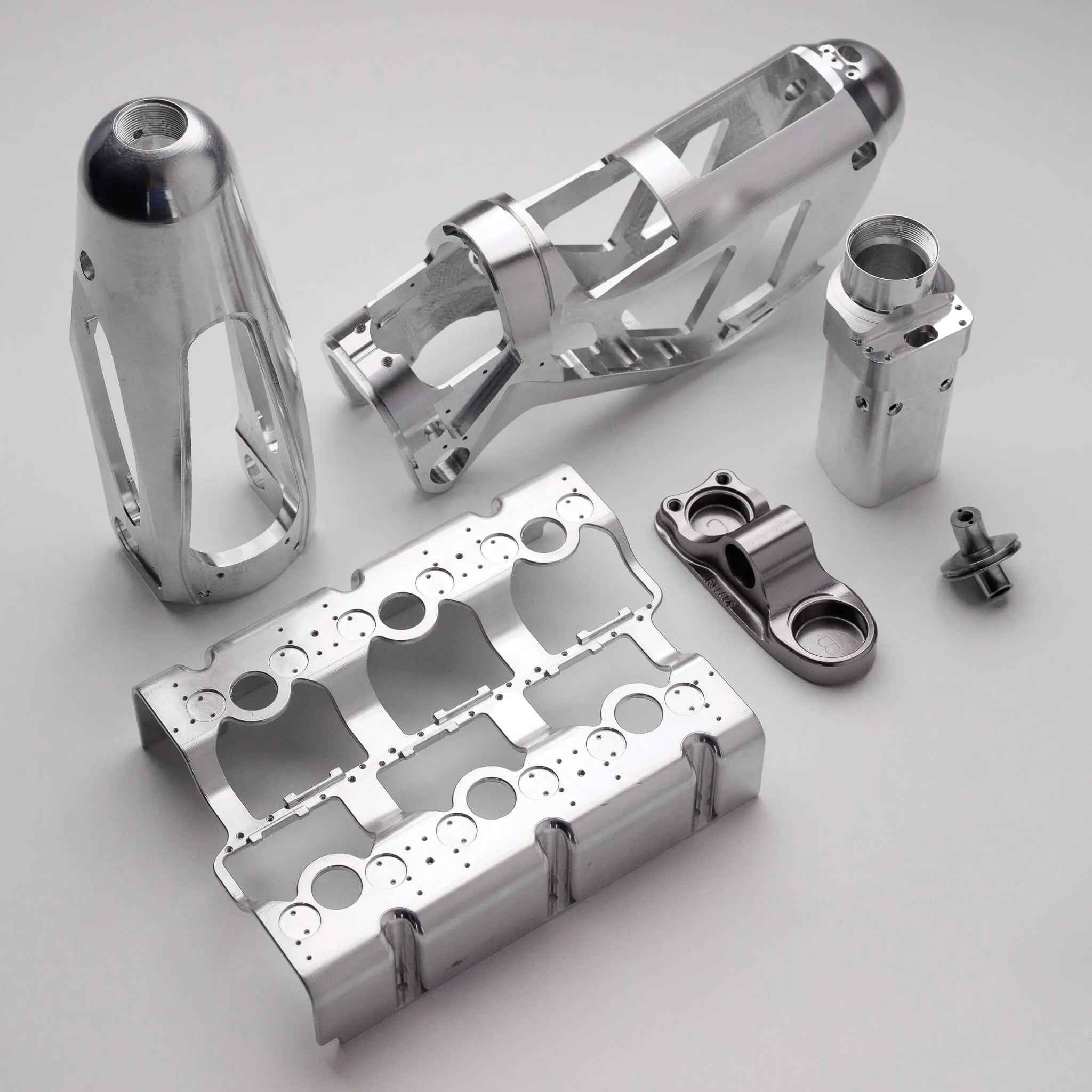

Wuxi Lead Precision Machinery delivers advanced custom aerospace machining solutions tailored to the rigorous demands of the global aerospace industry. Our technical capabilities are built around precision, repeatability, and compliance with the highest quality standards required for mission-critical components. At the core of our production floor are state-of-the-art 5-axis CNC machining centers, enabling us to manufacture complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow for simultaneous motion across all five axes, reducing setup times and eliminating the need for multiple fixtures, which in turn enhances dimensional consistency and part-to-part uniformity.

Our 5-axis machining platforms support a wide range of aerospace-grade materials, including titanium alloys (such as Ti-6Al-4V), Inconel 718 and 625, aluminum 7075 and 2024, and high-strength stainless steels. This versatility ensures compatibility with structural airframe components, engine housings, actuation systems, and landing gear assemblies. The integration of high-speed machining techniques and adaptive toolpath strategies further optimizes material removal rates while maintaining tight tolerances and minimizing thermal distortion.

Quality assurance is embedded at every stage of production. All machined components undergo comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), ensuring full traceability and compliance with AS9100 and ISO 9001 standards. Our metrology lab is climate-controlled to maintain measurement stability, and inspection reports are generated in alignment with customer-specific requirements, including First Article Inspection (FAI) documentation per AS9102.

We support low to medium volume production runs with rapid prototyping capabilities, making us a preferred partner for aerospace OEMs and Tier-1 suppliers requiring agile, responsive manufacturing. Our engineering team collaborates directly with clients during the Design for Manufacturability (DFM) phase to optimize part geometry, reduce lead times, and eliminate unnecessary costs without compromising performance.

The following table outlines the standard machining tolerances we consistently achieve across our production environment. These specifications reflect our commitment to precision and our ability to meet the exacting demands of aerospace applications.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Up to 800 mm length |

| Hole Diameter | +0.010 / -0.000 mm | +0.005 / -0.000 mm | Reamed and honed |

| Positional Tolerance | ±0.010 mm | ±0.005 mm | Relative to datum |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | As machined or polished |

| Angular Tolerance | ±0.005° | ±0.002° | Between features |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Critical sealing surfaces |

All tolerances are verified using calibrated CMM equipment with full GD&T analysis. Wuxi Lead Precision Machinery remains committed to advancing precision manufacturing through continuous investment in technology, personnel training, and process innovation—ensuring every aerospace component we produce meets the highest benchmarks for reliability and performance.

Material & Finish Options

Material Selection for Precision Aerospace Components

Material selection directly impacts flight safety, component longevity, and regulatory compliance in aerospace manufacturing. At Wuxi Lead Precision Machinery, we prioritize materials meeting stringent AMS and ASTM standards. Aluminum alloys dominate structural airframe components due to their exceptional strength-to-weight ratio and machinability. 7075-T6 aluminum is the aerospace workhorse for highly stressed parts like wing spars and landing gear components, offering high fatigue resistance. 2024-T3 provides superior fracture toughness for fuselage skins and stringers. While lighter than steel, aluminum requires protective finishes like anodizing to combat corrosion in demanding environments.

Steel alloys remain critical for ultra-high-strength applications where weight is secondary to absolute durability. 4340 alloy steel, vacuum melted and heat-treated, delivers exceptional toughness for critical rotating parts such as landing gear axles and engine mounts. Its high hardenability ensures consistent properties through thick sections. 17-4 PH stainless steel provides an optimal balance of corrosion resistance, strength, and weldability for hydraulic fittings, actuators, and fasteners exposed to fuels and hydraulic fluids. Steel components often require specialized coatings or plating alongside precision machining.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for high-temperature and extreme corrosion resistance requirements. This material excels in jet engine components (compressor blades, discs), critical fasteners, and airframe sections near engines. Its near-iron strength at half the density, combined with immunity to saltwater corrosion, justifies the higher material and machining costs. Titanium’s low thermal conductivity demands specialized CNC strategies to manage heat generation during cutting, a capability rigorously maintained on our production floor.

Anodizing is the aerospace-standard finish for aluminum, transforming the surface into a hard, corrosion-resistant aluminum oxide layer. Type II (sulfuric acid) anodizing provides essential base protection and paint adhesion. Type III (hardcoat) anodizing delivers significantly thicker, harder, and more wear-resistant surfaces for components subject to abrasion or requiring electrical insulation. Precise control of bath chemistry, voltage, and temperature is non-negotiable to meet AMS 2469 or AMS 2471 specifications. Incorrect anodizing parameters can induce hydrogen embrittlement in high-strength steels or compromise fatigue life.

Material choice must align with functional requirements, environmental exposure, weight targets, and regulatory mandates. Consult early with our engineering team to optimize material and finish selection for your specific aerospace application, ensuring manufacturability and compliance from prototype to volume production.

| Material | Key Aerospace Applications | Critical Properties | Common Standards | Primary Finish Requirement |

|---|---|---|---|---|

| Aluminum 7075-T6 | Wing spars, landing gear parts | High strength, fatigue resistance, good machinability | AMS 4121, QQ-A-250/12 | Type II or Type III Anodize |

| Steel 4340 VIM/VAR | Landing gear axles, engine mounts | Very high strength, toughness, hardenability | AMS 6414, AMS 6415 | Cadmium Plating, Passivation |

| Steel 17-4 PH | Hydraulic fittings, fasteners | Corrosion resistance, strength, weldability | AMS 5604, AMS 5884 | Passivation, Anodize (Al) |

| Titanium Ti-6Al-4V | Engine components, critical fasteners | High strength/weight, temp resistance, corrosion immunity | AMS 4928, AMS 4967 | Alodine, Anodize (special) |

Manufacturing Process & QC

Design Engineering: Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless aerospace component manufacturing begins with meticulous design engineering. Our design phase integrates advanced CAD/CAM software with deep domain expertise in aerospace material behavior and geometric dimensioning. Engineers collaborate directly with clients to interpret technical schematics, performance requirements, and regulatory standards such as AS9100 and NADCAP. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are employed to validate structural integrity, thermal resistance, and aerodynamic efficiency prior to physical development. This digital-first approach ensures that every design is optimized for manufacturability, minimizing risk and eliminating conceptual flaws before prototyping begins.

Prototyping: Validating Performance with Zero Tolerance for Error

Once the digital model is approved, we proceed to rapid prototyping using high-precision 5-axis CNC machining and wire EDM technologies. Prototypes are produced in the same aerospace-grade materials specified for final production—such as Inconel 718, Ti-6Al-4V, and 7075-T6 aluminum—to ensure accurate evaluation of mechanical properties and fit. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM), optical scanners, and surface roughness testers. Dimensional accuracy is verified to within ±0.002 mm, and material certifications are documented for full traceability. This stage is not merely a form check; it is a functional validation under simulated operational conditions, including thermal cycling and stress load testing. Client feedback is incorporated in real time, enabling rapid iteration until perfection is achieved.

Mass Production: Consistency at Scale with Zero Defects

With prototype approval, we transition seamlessly into high-volume production under a Zero Defects framework. Our manufacturing cells are equipped with automated tool monitoring, in-process gauging, and real-time data acquisition systems that feed into a centralized quality management platform. Every machining cycle is traceable, with parameters logged for spindle load, cutting temperature, and tool wear. Statistical process control (SPC) ensures deviations are detected and corrected before they impact output. Components are batch-inspected according to AQL 1.0 standards, with 100% critical dimension checks on safety-of-flight parts. Our cleanroom-compatible environment and strict adherence to ITAR and ISO 9001 protocols guarantee compliance across global aerospace supply chains.

Production Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | Ti-6Al-4V, Inconel 718, 7075-T6, 17-4 PH SS |

| Dimensional Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Max Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Production Capacity | 50,000+ units/month (modular cell scaling) |

| Quality Standards | AS9100, ISO 9001, NADCAP, ITAR Compliant |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 4–6 weeks (volume-dependent) |

Wuxi Lead Precision Machinery delivers aerospace components where precision is non-negotiable. From digital design to full-scale production, our process is engineered for perfection—ensuring reliability, repeatability, and zero defects.

Why Choose Wuxi Lead Precision

Elevate Your Aerospace Supply Chain with Lead Precision

Wuxi Lead Precision Machinery delivers mission-critical custom machining solutions engineered to the uncompromising standards of global aerospace. As an AS9100D-certified manufacturer, we operate under stringent quality management systems that align with FAA, EASA, and Nadcap requirements. Our facility integrates ISO Class 7 cleanrooms, redundant metrology labs, and closed-loop process controls to ensure every component meets the thermal, structural, and fatigue demands of flight-critical applications. When failure is not an option, our statistically insignificant scrap rates and 100% traceable material pedigrees provide the confidence your program demands.

Our technical capabilities span complex geometries in exotic alloys, supported by multi-axis milling, turning, and grinding platforms. We machine to micron-level tolerances while maintaining surface finishes essential for aerodynamic efficiency and fatigue resistance. Below details our core aerospace production parameters:

| Parameter | Capability | Industry Standard Reference |

|---|---|---|

| Material Range | Inconel 718/625, Ti-6Al-4V, Waspaloy, 17-4PH, 300M | AMS, ASTM, MIL-SPEC |

| Tolerance Control | ±0.0002″ (5µm) positional accuracy | AS9102 FAI Level 3 |

| Surface Finish | Ra 0.4µm to 0.8µm (critical sealing surfaces) | AMS 2404, AMS 2750F |

| Max Work Envelope | 1,200 x 800 x 650 mm (5-axis) | NASM-1312-10 |

| Documentation | Full PPAP, CofC, 3D scan reports | SAE ARP9006 Rev. B |

Partnering with Lead Precision mitigates supply chain volatility through dedicated engineering cells and dynamic capacity allocation. We deploy DFMA analysis during quoting to identify cost-saving opportunities without sacrificing integrity—reducing lead times by up to 30% versus conventional vendors. Our technical team collaborates from blueprint review through PPAP submission, providing real-time production visibility via encrypted dashboards. This proactive engagement ensures design intent translates flawlessly into manufactured reality, eliminating costly rework cycles.

For Tier 1 aerospace suppliers and OEMs, geographic proximity to Shanghai port infrastructure enables rapid global deployment while maintaining Chinese cost efficiency. We enforce dual-source material verification and implement first-article inspection protocols exceeding AS9102 requirements, ensuring zero non-conformances reach your assembly line. Our commitment extends beyond delivery: dedicated CMM technicians validate in-process measurements against your CAD models, with all data archived for 20+ years to support maintenance, repair, and overhaul (MRO) lifecycles.

Initiate your project with an engineering consultation that defines measurable quality gates and delivery milestones. Contact [email protected] to submit your RFQ with 3D model files. Our technical sales team will respond within 4 business hours with a feasibility assessment and timeline-optimized production plan. Trust Wuxi Lead Precision Machinery to transform your aerospace component challenges into certified, on-specification deliverables—where precision engineering meets absolute accountability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.