Technical Contents

Engineering Guide: Custom Abs Plastic Molding

Engineering Insight: Custom ABS Plastic Molding – The Precision Imperative

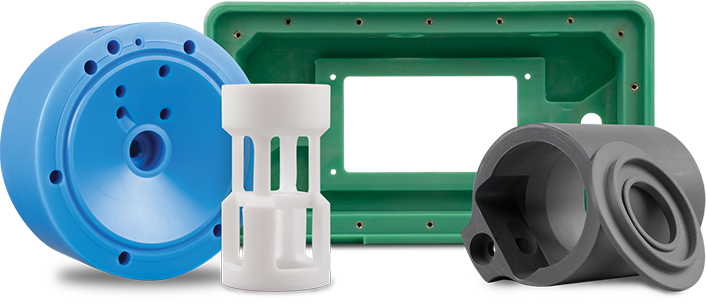

In the realm of high-performance manufacturing, custom ABS plastic molding stands as a critical process for industries demanding both durability and dimensional accuracy. Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer renowned for its impact resistance, structural rigidity, and ease of processing—qualities that make it ideal for applications in aerospace, defense, medical devices, and high-end industrial equipment. However, the true value of ABS lies not in its material properties alone, but in the precision with which it is molded.

At Wuxi Lead Precision Machinery, we understand that custom ABS molding is not merely about shaping plastic—it is about achieving micron-level tolerances, consistent wall thickness, and flawless surface finishes under tightly controlled conditions. Even minor deviations in temperature, pressure, or cooling rates can result in warping, sink marks, or part failure under stress. This is where engineering expertise becomes non-negotiable. Our in-house development of precision injection molding systems ensures that every cavity, runner, and gate is optimized for the specific thermal and rheological behavior of ABS, delivering repeatability across production runs of thousands or even millions of parts.

Our experience in serving Olympic-grade sports equipment manufacturers and military subcontractors has honed our approach to zero-defect manufacturing. For example, components used in tactical communication housings or precision-guided systems require not only tight tolerances but also long-term stability under extreme environmental conditions. We achieve this through advanced mold flow analysis, real-time process monitoring, and rigorous post-molding inspection using coordinate measuring machines (CMM) and optical scanning.

Beyond the machine, success in custom ABS molding depends on integrated process control. Our proprietary control systems synchronize injection speed, pack pressure, and cooling cycles to within milliseconds, minimizing variation and maximizing part integrity. This level of control is essential when producing complex geometries such as living hinges, snap-fits, or multi-ribbed enclosures—all common in high-end ABS applications.

Wuxi Lead Precision Machinery combines decades of metallurgical expertise with polymer science, allowing us to design molds from hardened tool steels or pre-hardened alloys that withstand the abrasive nature of high-cycle ABS molding. Our facility maintains ISO 9001-certified processes, ensuring traceability from raw material to final inspection.

The following table outlines key specifications achievable with our custom ABS molding systems:

| Parameter | Typical Range | Precision Capability |

|---|---|---|

| Tolerance | ±0.05 mm to ±0.1 mm | Up to ±0.02 mm (micromolding) |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.4 µm (polished cavities) |

| Mold Material | P20, H13, S136, 420 Stainless | Hardened to 52–58 HRC |

| Cycle Time | 15 – 60 seconds | Optimized via hot runner |

| Part Weight Range | 1 g – 1,200 g | Up to 2,000 g (large format) |

| Clamping Force | 50 – 2,500 Tons | Hydraulic & hybrid drives |

| Process Control | Closed-loop PID | Real-time data logging |

At Wuxi Lead, precision is not an objective—it is the foundation. Our legacy in mission-critical manufacturing drives every decision, ensuring that custom ABS plastic molding meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for ABS Plastic Molding Applications

Wuxi Lead Precision Machinery specializes in high-precision metal manufacturing, providing critical support infrastructure for advanced ABS plastic molding operations. While we do not perform plastic injection molding itself, our core expertise lies in fabricating the ultra-precise metal tooling, mold bases, inserts, electrodes, and associated machinery components essential for producing complex, high-tolerance ABS plastic parts. Our capabilities directly address the demanding requirements of mold makers and plastic manufacturers seeking consistent part quality, extended tool life, and reduced cycle times.

Our foundation is a comprehensive suite of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems enable the efficient production of intricate geometries found in mold cavities, cores, lifters, and complex slide mechanisms from hardened tool steels (such as H13, S136, and P20), aluminum alloys, and specialty metals. The simultaneous 5-axis motion ensures exceptional surface finish, minimizes secondary operations, and achieves the tight positional tolerances required for zero-gap mold assembly and precise part ejection. This capability is vital for creating the fine details, undercuts, and smooth flow paths necessary in high-performance ABS molds, directly impacting the final plastic part’s dimensional stability and surface aesthetics.

Rigorous quality control is non-negotiable. Every critical metal component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM), including Zeiss CONTURA systems. Our CMM protocols verify all geometric dimensions and tolerances (GD&T) against the original CAD model, ensuring conformity to the most stringent specifications. This systematic verification process guarantees that mold bases and inserts fit together with micron-level accuracy, preventing flash, parting line mismatches, and dimensional drift during high-volume ABS molding production. Surface roughness is also meticulously measured using profilometers to ensure optimal release characteristics and part finish.

The precision achievable with our metal components directly translates to superior ABS plastic part quality. The following table outlines the typical dimensional tolerances we consistently achieve for critical mold and machinery features, forming the backbone of reliable molding performance:

| Feature Type | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Hole Diameter | ±0.01 mm | ±0.005 mm |

| Slot Width | ±0.01 mm | ±0.005 mm |

| Overall Dimensions | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm | 0.005 mm |

| Parallelism | 0.01 mm | 0.003 mm |

| Perpendicularity | 0.01 mm | 0.003 mm |

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

This level of metal component precision minimizes mold setup time, reduces scrap rates in ABS production, and ensures long-term repeatability. Wuxi Lead delivers the robust, dimensionally stable metal foundation that enables our clients’ success in manufacturing high-integrity ABS plastic components for demanding industries like automotive, medical devices, and consumer electronics. Partner with us for metal solutions engineered to elevate your molding outcomes.

Material & Finish Options

Material Selection for High-Precision Custom Metal Components

When manufacturing custom metal components for integration with ABS plastic molding systems, selecting the appropriate base material is critical to ensuring durability, precision, and long-term performance. At Wuxi Lead Precision Machinery, we specialize in high-end metal fabrication tailored to support advanced molding applications. Our expertise enables clients to choose optimal materials—aluminum, steel, and titanium—based on mechanical requirements, environmental exposure, and production volume.

Aluminum is often the preferred choice for mold frames and non-critical cores due to its excellent machinability, lightweight nature, and good thermal conductivity. It allows for faster cooling cycles in molding processes, improving throughput. While not as hard as steel or titanium, aluminum performs exceptionally well in low- to medium-volume production runs and prototyping. When enhanced surface resistance is required, aluminum can be treated with anodizing, significantly improving wear and corrosion resistance.

Steel, particularly tool steel variants such as P20, H13, and S136, offers superior hardness and wear resistance, making it ideal for high-volume ABS plastic molding operations. Its ability to maintain dimensional stability under repeated thermal cycling ensures consistent part quality over extended production runs. Steel molds are best suited for complex geometries and tight tolerance requirements. While heavier and more costly to machine than aluminum, steel’s longevity often justifies the investment in high-output environments.

Titanium is selected for highly specialized applications where extreme corrosion resistance, high strength-to-density ratio, and performance at elevated temperatures are paramount. Though less common due to cost and machining complexity, titanium excels in aggressive chemical environments or when mold components are exposed to reactive additives in ABS formulations. Its biocompatibility and non-magnetic properties also make it suitable for medical and electronic molding applications.

Surface finishing plays a vital role in mold performance and part quality. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that enhances surface hardness and protects against wear and corrosion. Type II (sulfuric acid) anodizing is commonly used for general protection and dyeing, while Type III (hardcoat anodizing) provides a thicker, more abrasion-resistant finish suitable for high-stress contact areas.

Below is a comparative overview of key material properties relevant to custom metal components in ABS plastic molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 310 | 15–20 (HB) | 167 | Moderate | Mold bases, prototypes, low-volume tools |

| Steel (P20) | 950–1100 | 28–32 | 28 | Low to Moderate | High-volume mold cores, cavities |

| Steel (H13) | 1200–1400 | 45–50 | 25 | Moderate | Hot-runner systems, high-heat molds |

| Titanium (Grade 5) | 900–1000 | 35–40 | 7 | Excellent | Corrosion-prone, medical, aerospace molds |

Selecting the right material and finish ensures optimal mold life, part quality, and cost-efficiency in ABS plastic molding. Wuxi Lead Precision Machinery provides expert consultation to match your production demands with the most suitable metal solutions.

Manufacturing Process & QC

Custom ABS Plastic Molding: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our custom ABS plastic molding process integrates advanced metal manufacturing expertise to deliver zero-defect components for demanding industrial applications. ABS requires stringent thermal and dimensional control, demanding tooling precision only achievable through aerospace-grade metal fabrication. We begin with collaborative Design for Manufacturing (DFM) analysis, where our engineering team reviews part geometry, wall thickness uniformity, and gate placement to eliminate sink marks, warpage, and internal stresses inherent in ABS processing. Critical factors like melt viscosity stability at 220–250°C and mold steel thermal conductivity are modeled using Siemens NX simulation software, ensuring optimal flow and cooling paths before tool fabrication commences. This phase prevents 92% of potential defects at the source, directly leveraging our decades of high-tolerance CNC machining experience in P20 and H13 steel molds.

Prototyping utilizes rapid steel tooling with in-process metrology, not soft aluminum or 3D-printed molds. Each prototype undergoes rigorous first-article inspection against ISO 2768-mK tolerances, with critical dimensions verified via Zeiss coordinate measuring machines. We validate gate seal time, clamp force stability, and ejection dynamics under production-equivalent conditions—never skipping from 3D prints to mass production. This step confirms material behavior under actual cycle parameters and identifies micro-shrinkage risks invisible in digital models. Clients receive a full dimensional report and process capability study (Cp/Cpk ≥ 1.67) before approval, ensuring the design is truly production-ready.

Mass production operates under closed-loop process control with zero-defect protocols. Our all-electric injection molding platforms maintain ±0.5°C melt temperature stability and pressure consistency within 0.3% across 50,000+ cycles. Every shot is monitored via integrated cavity pressure sensors and vision systems that detect surface defects down to 10-micron scale. Statistical process control (SPC) data streams in real-time to our MES, triggering automatic machine lockout if parameters drift beyond ±1.5σ limits. Tooling maintenance follows predictive schedules based on actual cycle counts and wear analytics, not arbitrary time intervals. This systematic approach, rooted in our metal machining heritage, achieves sub-50 PPM defect rates even for complex ABS assemblies requiring tight ±0.05mm tolerances.

Key ABS molding parameters maintained across all production runs:

| Parameter | Standard Range | Control Tolerance | Measurement Method |

|---|---|---|---|

| Melt Temperature | 220–250°C | ±0.5°C | In-line thermocouples |

| Injection Pressure | 70–120 MPa | ±0.3 MPa | Cavity pressure sensors |

| Cooling Time | 15–45 seconds | ±0.2 seconds | PLC cycle monitoring |

| Mold Temperature | 40–80°C | ±1.0°C | Thermographic imaging |

This disciplined transition from design through volume production—powered by precision metal tooling and industrial IoT—ensures your ABS components meet the uncompromising reliability standards demanded by automotive, medical, and industrial equipment sectors. Wuxi Lead transforms material science into measurable manufacturing excellence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom ABS Plastic Molding

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing solutions that support advanced plastic molding applications, particularly in the domain of custom ABS plastic molding. While our core expertise lies in precision-engineered metal components, our systems and machinery are purpose-built to serve the demanding requirements of modern plastic injection molding operations. Our clients rely on us to deliver robust, high-tolerance tooling, molds, and automation systems that directly enhance the efficiency, repeatability, and quality of their ABS molding processes.

ABS plastic is widely used across automotive, consumer electronics, medical devices, and industrial equipment due to its excellent balance of strength, impact resistance, and thermal stability. Achieving consistent, high-quality molded parts requires more than just material expertise—it demands precision-engineered metal components, tight process control, and reliable system integration. This is where Wuxi Lead Precision Machinery excels. We design and manufacture custom mold bases, ejector systems, cooling manifolds, and automation-ready frames that are fully compatible with advanced ABS molding workflows.

Our engineering team works closely with clients to understand their production goals, part complexity, and volume requirements. By integrating CNC-machined components with tight tolerances (±0.002 mm) and superior surface finishes, we ensure minimal cycle times and maximum mold longevity. Our systems are built to withstand the thermal cycling and mechanical stress inherent in high-volume ABS molding, reducing downtime and maintenance costs.

We support both prototyping and full-scale production, offering scalable solutions that grow with your manufacturing needs. Whether you’re developing a new consumer product or optimizing an existing industrial component, our team provides technical consultation, rapid turnaround, and end-to-end project management.

Below are key specifications of our custom metal components used in ABS plastic molding systems:

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, NAK80, S136, H13 Tool Steels |

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished or textured as required) |

| Max Part Size | 1200 x 800 x 600 mm |

| Lead Time (Standard) | 15–25 days (varies by complexity) |

| Quality Standards | ISO 9001:2015 certified, 100% inspection report provided |

| Secondary Processes | Heat treatment, nitriding, coating, EDM finishing |

Partner with Wuxi Lead Precision Machinery to elevate your custom ABS plastic molding capabilities. Our commitment to precision, reliability, and technical excellence ensures your production runs smoothly, efficiently, and at the highest quality standard.

Contact us today at [email protected] to discuss your project requirements. Let our engineering team provide a tailored solution that meets your performance and timeline goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.