Technical Contents

Engineering Guide: Custom 3D Print Service

Engineering Insight: Custom 3D Print Service – Where Precision Defines Performance

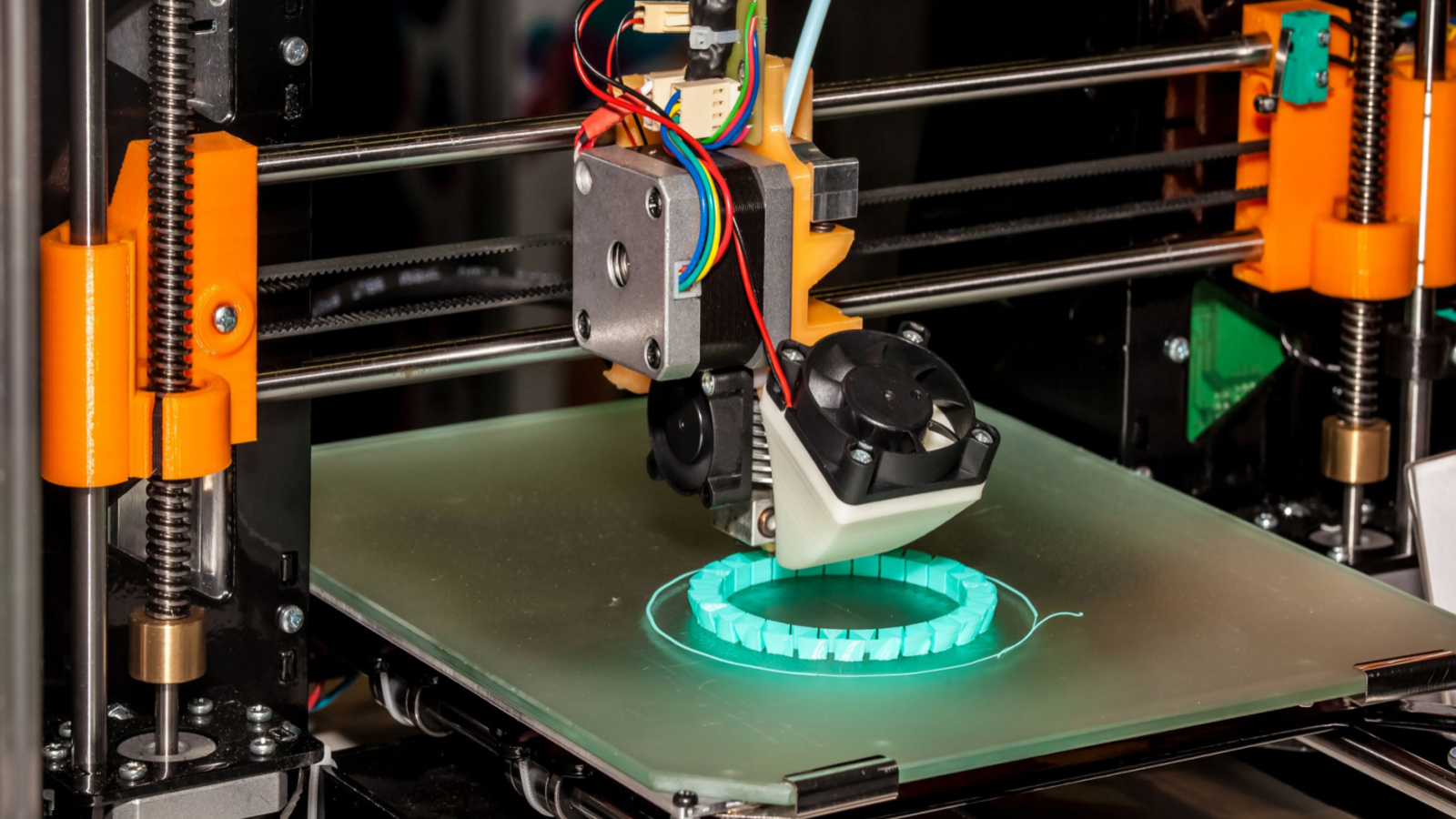

In the realm of advanced manufacturing, custom 3D printing is no longer a prototyping novelty—it has evolved into a mission-critical production method for high-performance industries. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not in speed or flexibility alone, but in precision. When components operate under extreme conditions—whether in aerospace, defense, or high-stakes industrial applications—micro-level deviations can lead to macro-level failures. This is why our custom 3D print service is engineered from the ground up to deliver micron-level accuracy, repeatability, and material integrity.

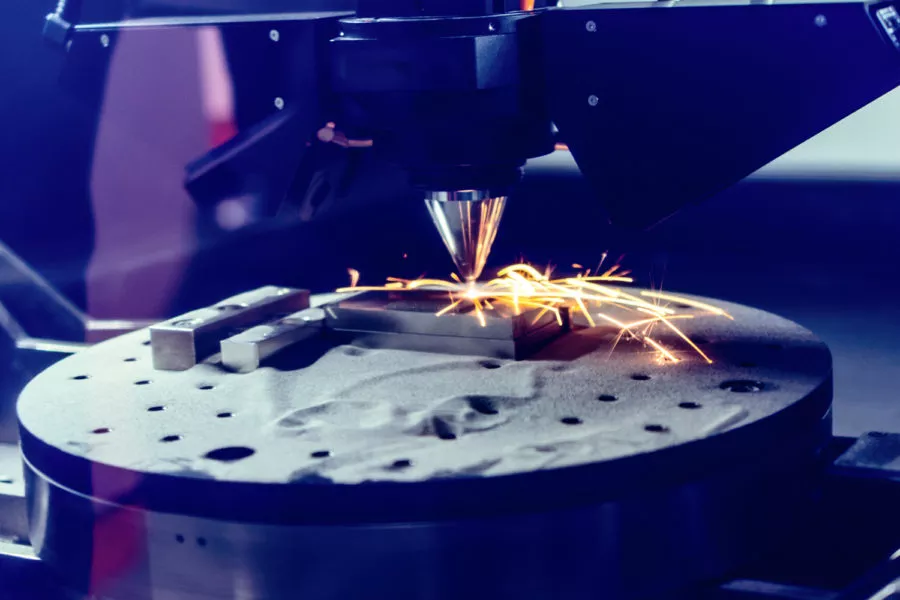

Precision in metal 3D printing is not simply about achieving tight tolerances. It encompasses thermal management during build, powder quality control, layer adhesion consistency, and post-processing calibration. At Lead Precision, we leverage industrial-grade laser powder bed fusion (LPBF) systems with in-situ monitoring and closed-loop feedback mechanisms to ensure dimensional stability across every build. Our engineering team applies decades of metallurgical expertise to optimize scan strategies, support structures, and build orientation—tailoring each parameter to the functional demands of the final part.

Our commitment to precision is validated through real-world performance. Lead Precision has delivered mission-critical components for Olympic-level sports technology, where marginal gains are measured in milliseconds. We have also supplied certified metal 3D printed parts for defense applications, meeting stringent MIL-STD requirements for durability, fatigue resistance, and geometric accuracy. These projects demand not only technical excellence but full traceability, from raw material certification to final inspection reports.

Every custom 3D printed component we produce undergoes rigorous quality assurance, including coordinate measuring machine (CMM) inspection, metallographic analysis, and, when required, computed tomography (CT) scanning for internal defect detection. This end-to-end control ensures that our customers receive parts that are not just dimensionally accurate but functionally reliable.

Below are key technical specifications that define the capabilities of our metal 3D printing service:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.05 mm / 100 mm |

| Surface Roughness (as-built) | Ra 10–15 μm; down to Ra 0.8 μm post-polished |

| Materials | Stainless Steel 316L, Inconel 718, Ti-6Al-4V, AlSi10Mg, Tool Steel (Maraging) |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting, Material Traceability (MTR) |

At Wuxi Lead Precision Machinery, we treat every custom 3D print project as an engineering partnership. Whether supporting rapid iteration for R&D or scaling into low-volume production, our focus remains constant: precision that performs, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Additive Manufacturing & Post-Processing

At Wuxi Lead Precision Machinery, our custom metal 3D printing service transcends rapid prototyping to deliver production-ready components meeting the most stringent aerospace, medical, and energy sector requirements. We integrate advanced metal additive manufacturing with proprietary post-processing protocols, ensuring geometric complexity never compromises dimensional integrity or material performance. Our facility operates exclusively with industrial-grade Directed Energy Deposition (DED) and Powder Bed Fusion (PBF) systems, processing Inconel 718, Ti-6Al-4V, 316L stainless steel, and aluminum alloys under ISO 13485 and AS9100 certified workflows. Critical to our value proposition is the seamless transition from additive build to precision finishing. Every component undergoes mandatory thermal stress relief and HIP (Hot Isostatic Pressing) where specified, eliminating internal voids and anisotropy before entering our CNC ecosystem.

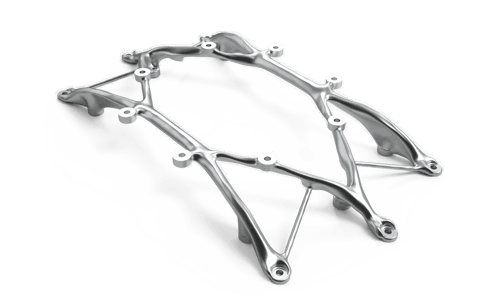

Our 5-axis CNC machining centers—equipped with high-resolution probing and adaptive toolpathing software—perform precision contouring, micro-milling, and bore finishing on near-net-shape AM parts. This hybrid approach achieves surface finishes down to Ra 0.4 µm and corrects layer-induced stair-stepping on complex organic geometries. Unlike standalone 3D printing vendors, we control the entire value stream: from initial topology optimization support to final functional testing. This eliminates tolerance stack-up risks inherent in multi-vendor supply chains. All machining operations leverage Renishaw touch-probe systems for real-time in-process verification, compensating for thermal drift and material spring-back during high-precision feature creation.

Quality assurance is non-negotiable. Every shipment includes full FAI (First Article Inspection) reports generated via our Zeiss CONTURA G3 CMM, programmed to ASME Y14.5-2018 standards. Critical dimensions undergo 100% inspection against customer CAD models, with point-cloud analysis validating form, position, and profile tolerances. Our metrology lab maintains NIST-traceable calibration and operates under ISO/IEC 17025 protocols, providing accredited measurement uncertainty data for all certified reports. Statistical process control (SPC) charts track capability indices (Cp/Cpk) for recurring production runs, ensuring sustained conformance to ±0.025 mm tolerances on critical features.

The following table defines achievable tolerance ranges for key material-process combinations after full post-processing:

| Material | Process Sequence | Tolerance Range (Linear) | Critical Feature Capability |

|---|---|---|---|

| Ti-6Al-4V | PBF + Stress Relief + 5AX | ±0.025 mm | Thin walls (0.5 mm), internal channels (Ø1.2 mm) |

| Inconel 718 | DED + HIP + 5AX | ±0.030 mm | Turbine blade airfoils (profile ±0.05 mm) |

| 316L Stainless | PBF + 5AX Finishing | ±0.020 mm | Sealing surfaces (flatness 0.01 mm) |

| AlSi10Mg | PBF + Precision Milling | ±0.015 mm | Optical mounting interfaces (angularity 0.005°) |

This capability suite enables clients to consolidate multi-part assemblies into single printed structures while meeting end-use functional requirements. We do not treat 3D printing as an isolated process but as the foundational step in a rigorously controlled precision manufacturing continuum. Partner with Wuxi Lead to transform complex metal components from design concept to precision-engineered reality.

Material & Finish Options

Material selection is a critical step in custom metal 3D printing, directly influencing the performance, durability, and cost-efficiency of end-use components. At Wuxi Lead Precision Machinery, we specialize in high-precision metal additive manufacturing using premium-grade aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties and thermal characteristics, making them suitable for specific industrial applications ranging from aerospace and automotive to medical and energy sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring high strength-to-density ratios and excellent thermal conductivity. This material is ideal for complex geometries in heat exchangers, engine parts, and drone components. Its low weight reduces inertia in moving parts, while its corrosion resistance ensures long-term reliability in harsh environments. Aluminum is also highly weldable and recyclable, aligning with sustainable manufacturing goals.

Stainless steel, especially 316L and 17-4 PH, delivers superior strength, wear resistance, and corrosion protection. These grades are commonly selected for demanding applications in marine, chemical processing, and food-grade equipment. 316L stainless steel exhibits excellent resistance to chloride-induced pitting, making it suitable for offshore and subsea components. In contrast, 17-4 PH offers high tensile strength and can be precipitation-hardened post-printing, enabling its use in high-stress mechanical systems such as valves, pumps, and tooling inserts.

Titanium alloys, primarily Ti6Al4V (Grade 5), represent the pinnacle of performance in high-stress, high-temperature environments. With exceptional strength-to-weight ratio, biocompatibility, and resistance to oxidation and fatigue, titanium is the material of choice for aerospace structural parts, medical implants, and motorsport components. Its ability to maintain integrity under extreme conditions ensures reliability in mission-critical applications where failure is not an option.

Post-processing surface finishes further enhance material performance. Anodizing, particularly for aluminum, improves surface hardness, wear resistance, and corrosion protection. Type II and Type III (hard coat) anodizing are available depending on the required thickness and functional demands. Anodized layers also provide excellent adhesion for paint and primers, enabling both functional and aesthetic customization.

Below is a comparative overview of key material properties used in our custom 3D printing service.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 8–12 | 2.67 | Heat exchangers, lightweight structures |

| 316L Stainless Steel | 550–600 | 300–350 | 35–45 | 8.00 | Marine components, chemical valves |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 10–15 | 7.80 | Tooling, aerospace actuators |

| Ti6Al4V | 900–950 | 800–850 | 10–12 | 4.43 | Aircraft parts, medical implants |

At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to match material and finish options to application-specific requirements, ensuring optimal performance and cost-effectiveness in every custom 3D-printed component.

Manufacturing Process & QC

Custom Metal 3D Printing Production Process: Precision from Concept to Volume

At Wuxi Lead Precision Machinery, our custom metal 3D printing service delivers uncompromising quality for demanding industrial applications. We execute a rigorously controlled three-phase production process—Design, Prototyping, and Mass Production—engineered to achieve Zero Defects outcomes. This systematic approach ensures your complex metal components meet exacting aerospace, medical, and energy sector requirements from initial concept through high-volume fulfillment.

Design Phase: Engineering for Manufacturability

Our process begins with deep collaboration. Our engineering team conducts rigorous Design for Metal Additive Manufacturing (DfM) analysis on your CAD files. We assess geometric complexity, support structure necessity, thermal stress risks, and optimal build orientation specific to your chosen alloy—whether Inconel 718, Ti-6Al-4V, or custom tool steels. Material certification documentation and AS9100-compliant traceability protocols are established upfront. This phase eliminates fundamental design flaws, ensuring the digital model is fully optimized for successful physical realization and inherent defect prevention.

Prototyping Phase: Validation and Process Lockdown

Critical design iterations occur here under controlled conditions. Using identical industrial-grade EOS M 400-4 or SLM Solutions S500 systems as mass production, we build functional prototypes. Each prototype undergoes comprehensive metrology via Zeiss CONTURA CMM systems and optional industrial CT scanning for internal defect detection. Mechanical testing per ASTM E8 and microstructure analysis validate material properties. Only when prototypes consistently meet all dimensional, mechanical, and metallurgical specifications do we finalize the production build file and parameters. This phase is non-negotiable for Zero Defects; it proves the process before scaling.

Mass Production Phase: Controlled Volume Execution

Volume manufacturing leverages the validated process window. Builds occur within ISO Class 8 cleanrooms using inert argon atmospheres. Real-time in-situ monitoring tracks melt pool dynamics, layer adherence, and thermal profiles via integrated sensors. Automated powder sieving and recycling ensure consistent material flow. Every part batch undergoes 100% first-article inspection and statistical process control (SPC) sampling. Final components receive mandatory post-processing—stress relieving, HIP, precision machining, and surface finishing—per ISO 13485 standards. Comprehensive material test reports and dimensional certificates accompany every shipment.

Key Process Specifications Comparison

| Parameter | Prototyping Stage | Mass Production Stage |

|---|---|---|

| Build Volume | Up to 500 x 400 x 400 mm | Up to 500 x 400 x 400 mm |

| Layer Thickness | 20-50 μm | 20-30 μm (optimized) |

| Material Options | Full alloy range | Pre-qualified alloys only |

| Metrology Coverage | 100% critical features | 100% FAI + SPC sampling |

| Post-Processing | Customer-specified | Fully standardized |

| Lead Time Focus | Speed to validation | Consistent throughput |

This integrated workflow—where prototyping rigor directly enables production stability—is the cornerstone of our Zero Defects commitment. By eliminating variability at each transition point, Wuxi Lead delivers custom metal AM parts with the reliability your mission-critical applications demand, reducing your time-to-market while ensuring absolute conformity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom 3D Printing Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions tailored to the exact demands of high-performance industries. As a leading provider of custom metal manufacturing in China, we specialize in advanced metal 3D printing services that combine cutting-edge technology, rigorous quality control, and deep engineering expertise. Whether you’re developing prototypes for aerospace systems, producing end-use components for medical devices, or scaling production for industrial automation, partnering with us means gaining a reliable, responsive, and technically superior manufacturing ally.

Our state-of-the-art facility is equipped with a full suite of metal additive manufacturing systems, including selective laser melting (SLM) and direct metal laser sintering (DMLS) platforms. These technologies enable us to produce complex geometries, lightweight structures, and internal features that are impossible with traditional machining. Every build is supported by in-house design validation, topology optimization, and post-processing capabilities such as heat treatment, CNC finishing, and surface polishing—ensuring your parts meet exact mechanical, thermal, and dimensional requirements.

We understand that in mission-critical applications, consistency and compliance are non-negotiable. That’s why our quality management system is ISO 9001:2015 certified, and we maintain full traceability from raw material sourcing to final inspection. Our engineering team works closely with clients throughout the product lifecycle, offering design-for-additive-manufacturing (DfAM) guidance to reduce weight, consolidate assemblies, and improve performance—ultimately lowering total cost of ownership.

When you choose Lead Precision, you gain more than a supplier—you gain a strategic partner committed to innovation, speed, and precision. Our global logistics network ensures on-time delivery to clients across North America, Europe, and Asia, while our responsive communication model keeps you informed at every stage of production.

Below are key technical capabilities of our custom 3D printing service:

| Specification | Detail |

|---|---|

| Build Envelope (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20–50 μm |

| Materials Available | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel (625, 718), Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 μm (can be reduced to Ra <1 μm with finishing) |

| Post-Processing | Heat treatment, HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001:2015, Full material certification, First article inspection (FAI), CMM reporting |

To begin your next project with confidence, contact us today at [email protected]. Our engineering team is ready to review your CAD files, provide rapid prototyping quotes, and support high-mix, low-volume or scalable production runs. At Wuxi Lead Precision Machinery, we turn your most demanding designs into high-performance realities—faster, smarter, and with uncompromising precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.