Technical Contents

Engineering Guide: Countersink For Steel

Engineering Insight: Countersink for Steel – The Critical Role of Precision in High-Performance Applications

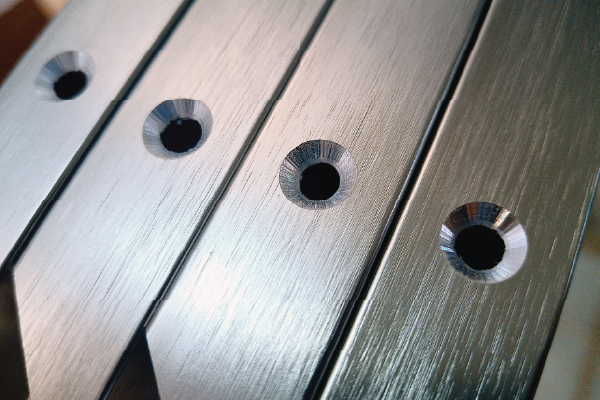

In high-end manufacturing, particularly within aerospace, defense, and precision engineering sectors, the countersink for steel is far more than a simple finishing operation—it is a critical determinant of structural integrity, assembly accuracy, and long-term reliability. At Wuxi Lead Precision Machinery, we understand that even the most robust steel components can fail prematurely if the countersink geometry does not meet exacting specifications. Precision in countersinking ensures optimal load distribution across fastener heads, minimizes stress concentrations, and maintains flush surface alignment—parameters that are non-negotiable in mission-critical applications.

Steel, due to its high strength and hardness, presents unique challenges during countersinking. Improper tool selection, incorrect feed rates, or inadequate tool geometry can lead to tool wear, burring, or even micro-cracking in the material. These defects, though seemingly minor, can propagate under cyclic loading, especially in environments such as military vehicles or aerospace structures where components are subjected to extreme vibration and thermal cycling. Our engineering team at Lead Precision employs advanced CNC machining centers with rigid spindle configurations and high-precision toolholding systems to maintain ±0.02 mm tolerance on countersink diameters and angles—ensuring repeatability across high-volume production runs.

Our experience in delivering components for Olympic-standard equipment and military-grade systems has reinforced the necessity of process control. For instance, in the assembly of high-stress steel joints used in armored vehicle chassis, a deviation of just 2° in countersink angle can compromise the clamping force of a fastener by up to 15%. This level of sensitivity demands not only advanced machinery but also deep metallurgical understanding and in-process inspection protocols. We utilize coordinate measuring machines (CMM) and optical comparators to validate each batch, ensuring compliance with ISO 2768 and AS9100 standards.

Wuxi Lead Precision Machinery combines decades of metallurgical expertise with state-of-the-art manufacturing capabilities to deliver countersunk steel components that meet the most stringent performance criteria. Whether working with hardened 4140 steel or corrosion-resistant 17-4PH stainless, our process is designed to achieve clean, burr-free, dimensionally accurate results every time.

The following table outlines typical countersink specifications for common steel grades processed at our facility:

| Parameter | Value Range | Tolerance | Applicable Steel Grades |

|---|---|---|---|

| Countersink Angle | 82°, 90°, 100°, 120° | ±0.5° | 4140, 4340, 17-4PH, A286 |

| Diameter (Pilot Hole) | 3.0 – 12.0 mm | ±0.02 mm | All structural steels |

| Surface Finish (Ra) | 0.8 – 1.6 µm | ±0.2 µm | Aerospace & Defense alloys |

| Depth Control | 2.0 – 15.0 mm | ±0.03 mm | High-strength low-alloy (HSLA) |

| Tool Material | Solid Carbide, TiAlN Coated | N/A | Universal |

Precision countersinking for steel is not a commodity process—it is an engineered solution. At Wuxi Lead Precision Machinery, we treat every countersink as a mission-critical feature, backed by our proven track record in elite industrial sectors.

Precision Specs & Tolerances

Technical Capabilities: Precision Countersinking for Steel Components

Wuxi Lead Precision Machinery delivers engineered countersink solutions for demanding steel applications, leveraging advanced 5-axis CNC machining to achieve micron-level accuracy and repeatability. Our focus on hardened and alloy steels—including 4140, 1045, and 304/316 stainless—ensures optimal performance in aerospace, automotive, and industrial assembly environments where hole preparation integrity is critical. Unlike conventional 3-axis methods, our integrated 5-axis platform executes complex countersink geometries in a single setup, eliminating cumulative errors from multiple operations and preserving critical concentricity between the countersink feature and the parent hole. This capability is essential for high-torque fastening systems requiring precise load distribution across the chamfered surface.

Material-specific toolpath strategies and rigid machine construction mitigate thermal deformation during high-speed steel machining. We utilize carbide and polycrystalline diamond (PCD) tooling optimized for steel’s abrasiveness, maintaining edge sharpness through adaptive feed-rate control and high-pressure coolant delivery. This approach prevents burr formation and surface micro-fractures that compromise fatigue resistance in safety-critical joints. All programs undergo virtual simulation to validate collision avoidance and surface finish targets before metal cutting begins, ensuring first-article success for low-volume, high-complexity orders.

Quality validation is non-negotiable. Every countersink feature undergoes 100% CMM inspection against ASME Y14.5 geometric dimensioning standards. Our Zeiss CONTURA CMM system measures angular deviation, diameter consistency, depth uniformity, and positional tolerance relative to datums, with results traceable to NIST standards. Statistical process control (SPC) data is provided with shipments, documenting capability indices (Cp/Cpk ≥ 1.67) for clients requiring PPAP documentation. This metrology-grade validation supports compliance with ISO 9001:2015 and IATF 16949 frameworks.

The following table outlines our standard and achievable tolerance capabilities for steel countersinks:

| Parameter | Standard Tolerance | Achievable Tight Tolerance | Measurement Method |

|---|---|---|---|

| Diameter (Ø) | ±0.05 mm | ±0.01 mm | CMM / Air Gage |

| Depth (Z) | ±0.05 mm | ±0.015 mm | CMM / Depth Gage |

| Included Angle | ±0.5° | ±0.1° | Optical Comparator |

| Concentricity | 0.05 mm | 0.02 mm | CMM |

Our end-to-end process—from material certification to final inspection report—reduces scrap rates by 40% compared to industry averages for precision steel countersinking. Clients benefit from accelerated time-to-assembly through guaranteed hole readiness, eliminating field rework. For mission-critical steel components where fastener integrity dictates system longevity, Wuxi Lead provides the convergence of machine capability, materials expertise, and uncompromising quality control demanded by Tier-1 manufacturers. Partner with us to transform your countersink specifications into validated, production-ready reality.

Material & Finish Options

Material Selection for Countersink Applications in High-Performance Steel Manufacturing

Selecting the appropriate base material and surface finish is critical when engineering precision countersink components for demanding industrial applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, delivering components that meet rigorous mechanical, thermal, and environmental requirements. For countersink operations in steel, understanding the interplay between material properties and finishing processes ensures optimal performance, durability, and cost-efficiency.

Steel remains the most widely used material for countersink applications due to its high tensile strength, wear resistance, and dimensional stability under load. Among steel variants, alloy steels such as 4140 and 4340 are preferred for aerospace and automotive fastening systems, where fatigue resistance and toughness are paramount. Stainless steels like 304 and 17-4 PH offer excellent corrosion resistance, making them ideal for marine, medical, and food-processing environments. When countersinking stainless steel, tool selection and feed rates must be carefully controlled to avoid work hardening and burr formation.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are frequently used in lightweight structural applications. While aluminum is softer and easier to machine than steel, its lower hardness requires precise countersink depth control to prevent thread stripping or fastener pull-through. Aluminum’s natural oxide layer provides some corrosion resistance, but for enhanced protection and surface durability, anodizing is highly recommended. Type II (sulfuric acid) anodizing increases wear resistance and allows for color coding, while Type III (hardcoat) anodizing delivers a thicker, more robust surface suitable for high-stress environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), is used in extreme-performance sectors such as aerospace and defense. Its high strength-to-density ratio and exceptional corrosion resistance make it ideal for critical fastening systems. However, titanium’s low thermal conductivity and chemical reactivity demand specialized tooling and cooling strategies during countersinking to prevent galling and tool wear. Due to its high cost, titanium is typically reserved for mission-critical components where weight savings and reliability are non-negotiable.

Surface finishing plays a pivotal role in the functional life of countersunk parts. Anodizing, while primarily associated with aluminum, enhances surface hardness, electrical insulation, and adhesion for paint or primers. For steel components, alternative finishes such as zinc plating, passivation, or black oxide are more appropriate to prevent oxidation and improve appearance.

The table below summarizes key material properties and finishing compatibility for common materials used in countersink manufacturing.

| Material | Tensile Strength (MPa) | Hardness (HB) | Corrosion Resistance | Recommended Finish | Machinability |

|---|---|---|---|---|---|

| Steel (4140) | 950–1200 | 250–300 | Moderate | Zinc Plating, Black Oxide | Good |

| Stainless (304) | 515–620 | 180–200 | High | Passivation | Fair |

| Aluminum (7075) | 500–570 | 150–160 | Low (without treatment) | Type II/III Anodizing | Excellent |

| Titanium (Ti-6Al-4V) | 900–1000 | 330–360 | Very High | None (native oxide) | Poor |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on application load, environment, and lifecycle requirements. Our engineering team ensures every countersink component meets international standards for precision and reliability.

Manufacturing Process & QC

Precision Countersink Production for Steel Components: A Zero-Defect Process

At Wuxi Lead Precision Machinery, manufacturing precision countersinks for hardened steel demands an uncompromising, integrated process. Steel’s inherent hardness and the critical function of countersinks—ensuring proper fastener seating, preventing stress concentrations, and enabling leak-tight assemblies—necessitate absolute dimensional accuracy and surface integrity. Our methodology rigorously follows Design, Prototyping, and Mass Production phases, each engineered to eliminate defects before parts reach your production line.

The Design phase begins with deep collaboration. Our engineering team analyzes your application specifics: steel grade (e.g., 4140, 4340, tool steels), required angle (typically 82°, 90°, 100°), depth tolerance, and functional interface requirements. We employ advanced CAD/CAM software and Finite Element Analysis (FEA) to simulate stress distribution and optimize geometry. Critical tolerances, surface finish parameters, and material-specific toolpath strategies are defined using Geometric Dimensioning and Tolerancing (GD&T) standards. This phase establishes the definitive blueprint where potential failure modes are identified and mitigated at the source, ensuring the design is inherently manufacturable to zero-defect standards.

Prototyping transforms the digital model into physical validation. Using the exact production-grade tooling and CNC machining centers intended for volume work, we produce initial samples under controlled conditions. Each prototype undergoes exhaustive metrology: Coordinate Measuring Machine (CMM) verification of angle, depth, and concentricity; surface roughness testing; and visual inspection for micro-chipping or burrs. We conduct functional fit tests with specified fasteners on representative steel substrates. This phase is not merely a formality; it is a critical stress test of the process. Any deviation triggers immediate root cause analysis and process refinement—tool geometry adjustment, spindle speed/feed optimization, or coolant strategy revision—before committing to mass production. Only prototypes meeting 100% of specifications are approved.

Mass Production executes the validated process with relentless quality control. Our CNC machining cells, equipped with high-rigidity spindles and in-process probing, run under strict Statistical Process Control (SPC). Every countersink operation is monitored in real-time for tool wear and dimensional drift. Crucially, we implement 100% post-machining inspection for critical features using automated optical comparators and calibrated gauges. Surface finish is verified per Ra specifications, and concentricity is checked against the primary datum. Material traceability is maintained throughout. This multi-layered inspection regime, combined with the rigor of the preceding phases, ensures every countersink shipped meets the exacting tolerances required for high-integrity steel assemblies, eliminating field failures and costly rework.

Critical Countersink Specifications for Steel Applications

| Parameter | Typical Tolerance | Measurement Method | Functional Impact |

|---|---|---|---|

| Included Angle | ±0.5° | Optical Comparator, CMM | Fastener head seating, stress distribution |

| Depth | ±0.05 mm | Digital Depth Gauge, CMM | Proper thread engagement, flush fit |

| Concentricity | ≤ 0.02 mm | CMM (Relative to Datum) | Uniform load distribution, sealing |

| Surface Roughness | Ra ≤ 0.8 µm | Surface Roughness Tester | Fatigue resistance, corrosion prevention |

| Edge Break | 0.05-0.10 mm CH | Visual/Magnification | Prevents micro-crack initiation |

This disciplined approach—grounded in proactive design, validated prototyping, and rigorously controlled mass production—guarantees countersinks that deliver flawless performance in demanding steel applications, safeguarding your assembly integrity and operational continuity.

Why Choose Wuxi Lead Precision

When precision matters, your choice of manufacturing partner defines the outcome. At Wuxi Lead Precision Machinery, we specialize in high-performance custom metal manufacturing solutions, with a focused expertise in countersink applications for steel components. Whether you’re producing aerospace fittings, automotive assemblies, or industrial machinery parts, achieving a flawless countersink is critical to structural integrity, fastener performance, and long-term durability.

Steel presents unique challenges in countersinking—its hardness, variability in alloy composition, and tendency toward work hardening demand precise tool geometry, optimal feed rates, and rigid CNC control. Off-the-shelf solutions often fall short. That’s where our engineering-led approach makes the difference. We don’t just manufacture parts—we engineer processes. Our team evaluates your steel grade, hole specifications, and application environment to design a countersinking solution that ensures consistent chamfer angles, burr-free finishes, and exact depth control.

Partnering with Wuxi Lead Precision means access to advanced CNC machining centers, in-house tooling development, and a quality management system certified to ISO 9001 standards. Every countersink operation is backed by rigorous material testing, real-time process monitoring, and first-article inspection reports. We work with carbon steel, stainless steel, and high-strength alloy steels, delivering repeatability within ±0.02 mm tolerance.

Our clients rely on us not only for precision but for collaboration. From prototyping to high-volume production, we integrate seamlessly into your supply chain, offering just-in-time delivery, full traceability, and responsive technical support. When your project demands tight tolerances, complex geometries, or mission-critical reliability, we become an extension of your engineering team.

Below are standard technical specifications for our countersink operations on steel. All parameters are customizable based on your design requirements.

| Parameter | Specification |

|---|---|

| Material Compatibility | Carbon Steel (e.g., AISI 1018, 1045), Stainless Steel (304, 316, 17-4 PH), Alloy Steels (4140, 4340) |

| Countersink Angle | 60°, 82°, 90°, 100°, 110°, 120° (custom angles available) |

| Diameter Range | 3 mm – 25 mm |

| Depth Tolerance | ±0.02 mm |

| Surface Finish | Ra ≤ 1.6 µm (standard), Ra ≤ 0.8 µm (fine finish option) |

| Tooling | Solid carbide or coated high-speed steel (TiN, TiAlN) |

| Equipment | 3-axis to 5-axis CNC machining centers |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP Level 3 available |

Your next project deserves more than a vendor—it needs a precision partner. Contact us today at [email protected] to discuss your countersink requirements for steel. Let Wuxi Lead Precision Machinery deliver the accuracy, consistency, and engineering support your application demands.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.