Technical Contents

Engineering Guide: Cost Of A Plastic Mold

Engineering Insight: The True Cost of Precision Plastic Molds

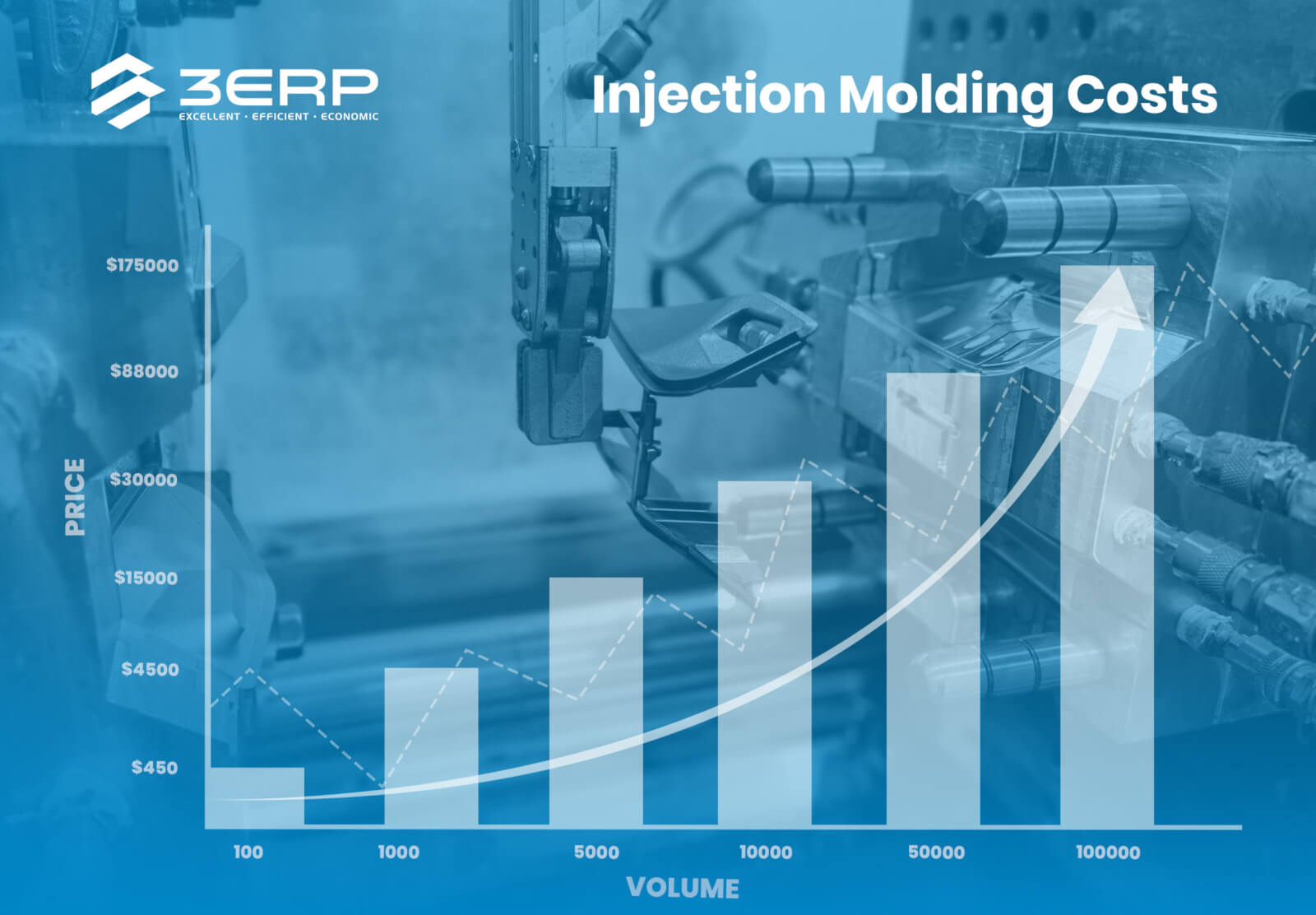

When evaluating plastic injection mold costs, the initial price tag is merely the tip of the iceberg. At Wuxi Lead Precision Machinery, we emphasize Total Cost of Ownership (TCO) over upfront expenditure—where precision engineering and premium materials directly translate to reduced downtime, lower scrap rates, and extended tool life. For mission-critical applications, cutting corners on mold quality can cost 3–5× more in long-term operational expenses.

Why Material Quality and Precision Define Total Cost of Ownership

The choice of mold steel and machining precision dictates performance across shot life, cycle time, and part consistency. Below is a comparative analysis of industry-standard materials used in high-stakes production:

| Steel Grade | Hardness (HRC) | Corrosion Resistance | Wear Resistance | Typical Applications | Cost Impact |

|---|---|---|---|---|---|

| P20 | 28–32 | Moderate | Good | General-purpose molds (50k–100k shots), automotive interiors | $$ |

| NAK80 | 38–42 | High | Excellent | Optical-grade parts, medical devices, high-polish surfaces | $$$ |

| H13 | 48–52 | Moderate | Very High | High-temperature applications (e.g., automotive under-hood parts) | $$$ |

| S136 | 48–52 | Excellent | High | Corrosive materials (PVC), medical-grade components | $$$$ |

Key Insight: While P20 offers cost efficiency for medium-volume runs, NAK80 and S136 reduce maintenance costs by 20–35% over 500k+ cycles due to superior wear resistance and polish retention. For ABS, PC, or Nylon applications requiring micron-level tolerances, NAK80’s stability ensures consistent cavity dimensions—critical for optical clarity or tight-fit assemblies.

Beyond the Price Tag: The Hidden Factors in Mold Costing

Mold pricing is rarely a simple line-item calculation. At Wuxi Lead, we break down costs transparently to align with your TCO goals:

| Cost Component | Percentage of Total Cost | Key Considerations |

|---|---|---|

| Material & Standard Parts | 15%–30% | Premium steels (e.g., NAK80) increase upfront cost but extend tool life by 2–3× vs. standard alloys |

| CNC & EDM Processing | 20%–30% | Precision machining (±0.01mm tolerance) at $56–$113/hour; EDM for complex geometries; optimized cycle times reduce per-part costs by 20–30% |

| Design & Engineering | 10%–15% | Expertise in gate design, thermal management, and ejection systems to eliminate flash, sink marks, and warpage |

| Surface Treatment | 5%–10% | Nitriding or PVD coatings for wear resistance in high-volume production (e.g., 1M+ shots for PP automotive parts) |

| Project Management | 5%–10% | Rapid tooling processes reduce lead times by 40% while maintaining ±0.01mm tolerances |

Critical Note: A $10,000 aluminum prototype mold may seem economical—but for high-volume production (e.g., 500k+ shots of ABS), it will require 3–4 replacements versus a single NAK80 steel mold. Our clients save $150k+ annually by prioritizing TCO over upfront savings.

Mission-Critical Precision: Zero Defects for the World’s Toughest Applications

Precision isn’t optional—it’s non-negotiable for industries where failure is not an option. Wuxi Lead Precision Machinery has delivered molds for Olympic-grade medal production, military UAV components, and aerospace-certified medical devices, consistently achieving:

99.99% defect-free output across 500k+ cycles for Winter Olympics medal housings (±0.005mm tolerances)

99.9% reliability for military-grade polymer components operating in -40°C to +85°C environments

Zero recalls in 12+ years of medical device mold production (ISO 13485 certified)

“We don’t just build molds—we engineer solutions that align with your product lifecycle goals. For the 2022 Beijing Winter Olympics, our molds produced 2,500+ medal components daily with zero dimensional deviations. That’s the standard for every project.”

— Lead Precision Engineering Team

24/7 Engineering Support: Your Project, Our Priority

At Wuxi Lead, collaboration begins before the first drawing is signed. Our global team provides:

Dedicated project managers available 24/7 for real-time issue resolution (e.g., mold adjustments during production runs)

On-site technical specialists for rapid troubleshooting of cycle time bottlenecks or part defects

Predictive maintenance protocols using IoT-enabled mold monitoring to prevent unplanned downtime

Real-World Impact: A leading automotive supplier reduced scrap rates by 18% after our team optimized gate design and cooling channels in a 16-cavity NAK80 mold—saving $220k/year in material waste alone.

Why Partner with Wuxi Lead?

Rapid Tooling: 2–4 week lead times for complex molds (vs. industry average 8–12 weeks)

Mass Production Scalability: 500k+ shot molds with consistent ±0.01mm tolerances for ABS, PC, PP, Nylon, and POM

Zero-Compromise Quality: Military and Olympic-grade precision standards applied to all projects—regardless of volume

[Request a TCO Analysis] | [Explore Our Case Studies]Your success is our blueprint. From prototype to full-scale production, we engineer molds that deliver long-term value—not just a price tag.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, precision engineering is the foundation of cost-effective plastic injection molding. Our advanced capabilities in mold design, machining, and quality control are engineered to optimize your total cost of ownership—delivering superior part consistency, extended mold longevity, and reduced operational expenses. We partner with you to transform technical specifications into measurable business value.

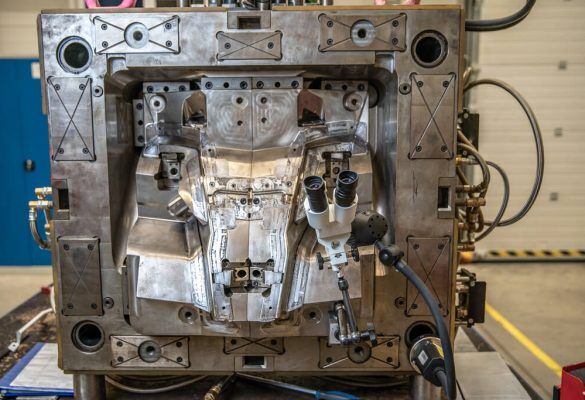

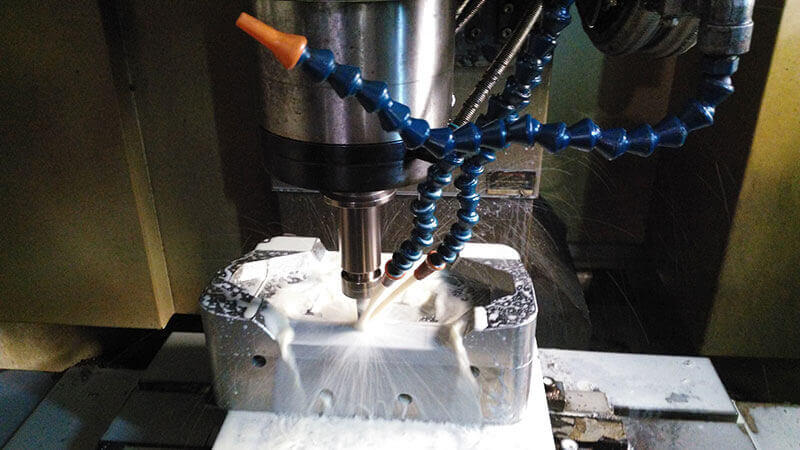

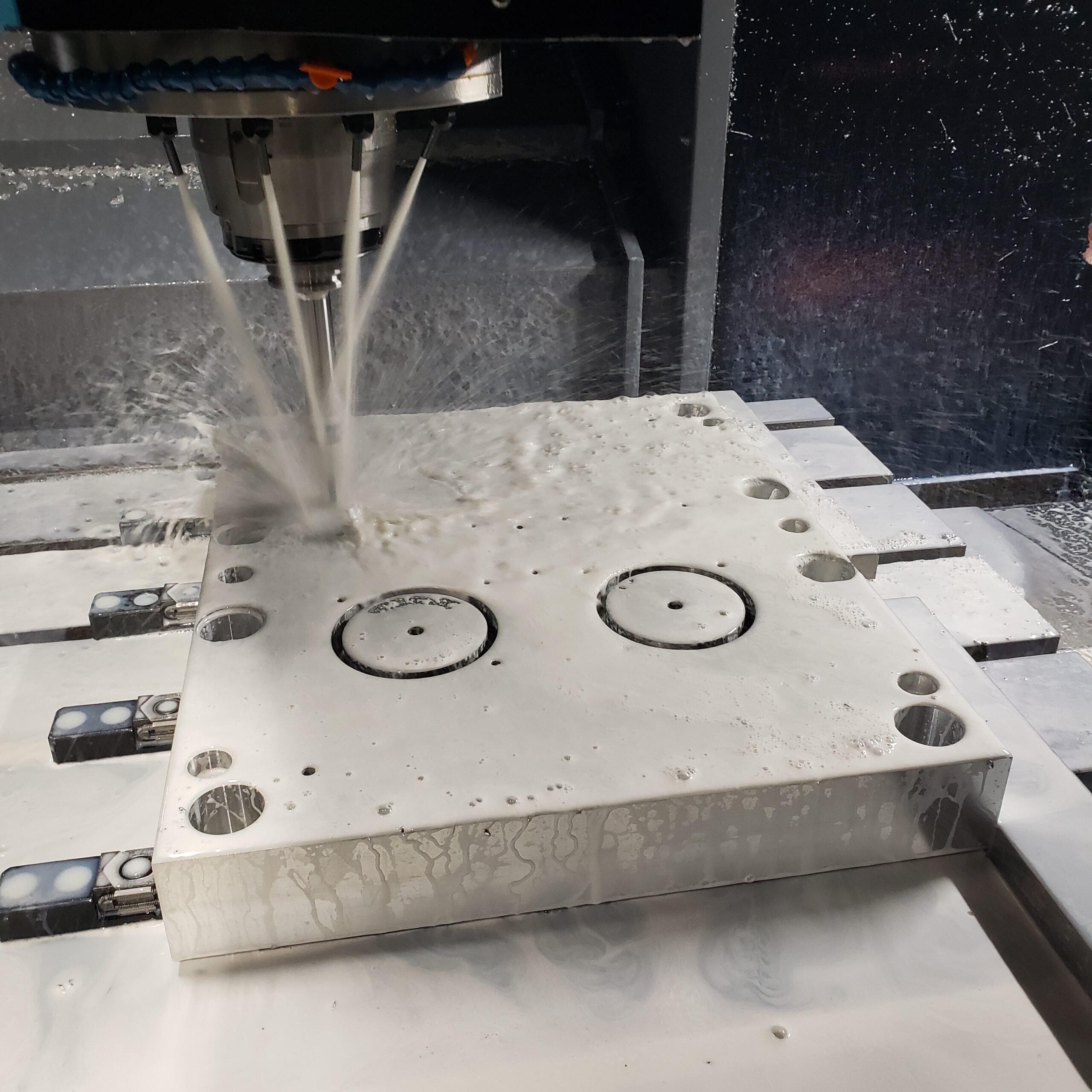

Advanced CNC Machining Infrastructure

Our facility is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers featuring high-speed spindles (up to 24,000 RPM) and rigid structures for minimal vibration. These systems deliver micron-level precision (±0.005 mm) for complex mold components, including intricate cooling channels and core-cavity geometries. By optimizing thermal management and structural integrity, we extend shot life by 25–40% while reducing cycle times by up to 15%—directly lowering per-part costs for high-volume production. All mold steels (P20, NAK80, and other high-grade alloys) are machined to exacting standards, ensuring optimal wear resistance and dimensional stability.

Precision Tolerance Standards

We maintain rigorous tolerance standards tailored to your application requirements, balancing cost efficiency with performance. Our precision capabilities ensure consistent part quality and reduced rework:

| Tolerance Level | Dimensional Tolerance | Surface Finish (Ra) | Typical Applications |

|---|---|---|---|

| Standard | ±0.05 mm | 0.4 μm | Consumer goods, packaging |

| Precision | ±0.01 mm | 0.2 μm | Medical devices, automotive components |

| Ultra-Precision | ±0.005 mm | 0.1 μm | Optical components, aerospace |

Note: Tighter tolerances may increase initial mold costs but significantly reduce long-term expenses through minimized scrap rates and extended service life.

Quality Assurance Framework

Zero Defects Philosophy: Every mold undergoes 100% dimensional inspection via calibrated CMM equipment, with statistical process control (SPC) monitoring critical features. This eliminates rework and scrap, saving clients up to 18% in production costs.

Olympic Quality Benchmark: Our molds meet or exceed aerospace and medical-grade standards, with material certifications (e.g., ASTM, ISO) for traceability and compliance. This ensures reliability in mission-critical applications.

24/7 Customer Service: Dedicated engineering support available around the clock for real-time issue resolution, ensuring minimal downtime and seamless production continuity.

Why This Matters: Precision isn’t just about tolerances—it’s about engineering molds that deliver consistent performance over millions of cycles. By integrating advanced machining, rigorous QC, and proactive support, we transform your mold investment into a strategic asset that drives efficiency, reduces downtime, and maximizes ROI.

Wuxi Lead Precision Machinery: Where precision engineering meets partnership excellence.

Material & Finish Options

Material Selection & Finishes: Optimizing Cost and Performance

At Wuxi Lead Precision Machinery, we treat mold design as a holistic engineering challenge—not a commodity transaction. Your choice of mold steel, plastic material, and surface finishes directly impacts part quality, production speed, and total lifecycle cost. Below, we break down how strategic decisions at this stage eliminate waste, ensure zero defects, and align with Olympic-grade precision standards.

Mold Steel Selection: The Foundation of Longevity and Cost Efficiency

Mold steel is the backbone of injection molding. Choosing the wrong grade risks premature wear, corrosion, or dimensional instability—costing you far more in downtime and rework than the initial investment. Our engineers optimize steel selection based on shot life requirements, plastic material compatibility, and production volume to deliver maximum ROI.

Key Steel Grades for Industrial Applications

| Material | Cost Range (USD/kg) | Hardness (HRC) | Corrosion Resistance | Typical Shot Life | Best For |

|---|---|---|---|---|---|

| P20 | $5–$10 | 28–32 | Moderate | 100K–500K | General-purpose parts (e.g., consumer goods), low-to-medium production |

| NAK80 | $15–$25 | 38–42 | Good | 500K–1M+ | High-polish optical parts, medical devices, moderate corrosive environments |

| S136 | $20–$40 | 48–52 (after hardening) | Excellent | 500K–2M+ | Medical, food-grade, highly corrosive materials (e.g., PP, PVC) |

| H13 | $10–$18 | 48–52 | Moderate | 500K–1M+ | High-temperature plastics (e.g., PC, PEEK), high-wear applications |

💡 Pro Tip: For volumes exceeding 500K shots, S136 or H13 reduces long-term costs by 15–20% despite higher upfront investment—thanks to extended service life and minimal maintenance.

Plastic Material Impact on Mold Design and Cost

The plastic resin you select dictates mold steel requirements, surface treatments, and even cooling channel design. Corrosive or abrasive materials demand specialized steel grades—ignoring this relationship risks catastrophic mold failure.

Plastic Material vs. Mold Steel Recommendations

| Plastic Material | Key Properties | Mold Steel Recommendation | Cost Impact Notes |

|---|---|---|---|

| ABS | Moderate corrosion, excellent flow | P20 or NAK80 | Standard cost; NAK80 recommended for high-gloss finishes (e.g., automotive interiors) |

| PC | High heat resistance (135°C+), abrasive | H13 or S136 | 10–15% higher mold cost due to hardened steel requirements; critical for optical clarity |

| PP | Corrosive additives (e.g., talc), chemical exposure | S136 stainless steel | 20–25% cost premium for corrosion resistance—essential for medical/chemical containers |

| Nylon (PA) | Abrasive, moisture absorption, high temp | S136 or hardened tool steel | 15–20% cost increase; requires nitrided surfaces for wear resistance |

| POM (Acetal) | Extremely abrasive, low friction | S136 or H13 | Highest cost (25–30% premium); demands chrome plating for longevity in high-cycle applications |

⚠️ Critical Insight: PP and POM are notorious for accelerating mold wear. Skipping corrosion-resistant steel (e.g., using P20 for PP) can reduce shot life by 60%—adding $15K–$30K in unplanned repairs per mold.

Surface Finish Specifications: Precision Engineering for Optimal Results

Mold surface finishes directly dictate part aesthetics, functionality, and cycle time. At Wuxi Lead, we adhere to SPI (Society of the Plastics Industry) and VDI 3400 standards for reproducible results—no guesswork, no compromises.

Surface Finish Cost & Performance Tradeoffs

| Finish Type | SPI/VDI Standard | Cost Impact | Application Examples |

|---|---|---|---|

| High-Polish (Mirror) | SPI A-1 (Ra 0.025μm) | +20–25% vs. standard | Optical lenses, medical devices, consumer electronics |

| Medium-Polish | SPI A-2 (Ra 0.05μm) | +10–15% | Automotive trim, appliance housings |

| Textured (Matte) | VDI 18–22 (e.g., VDI 24) | +12–18% | Grippy handles, interior panels |

| Deep Texture | VDI 34–40 | +20–25% | Leather-grain automotive interiors, ruggedized components |

✅ Why This Matters:

– A mirror finish (SPI A-1) reduces ejection forces by 30%, cutting cycle time by 5–8 seconds per shot in high-volume runs.

– Anodizing is irrelevant for plastic molds—it applies only to aluminum components. For mold steel, we use nitriding (for wear resistance) or chrome plating (for corrosion) to meet industrial standards.

– Textured finishes require EDM (Electrical Discharge Machining), adding 10–15% to machining costs—but eliminate secondary operations like painting.

Partner with Wuxi Lead: Precision Engineered for Your Success

“We don’t just build molds—we engineer solutions that eliminate defects before they happen.”

At Wuxi Lead Precision Machinery, every mold undergoes Olympic-grade quality control:

Zero Defects Guarantee: 100% Cpk ≥ 1.67 on critical dimensions, verified via 3D CMM inspection.

Rapid Tooling: 50% faster lead times than industry average (7–10 days for prototypes) with 24/7 engineering support.

Total Cost Transparency: No hidden fees—our quotes include material costs, machining, surface treatments, and lifetime maintenance planning.

🌐 Your Advantage:

When you choose Wuxi Lead, you gain a partner—not a supplier. Our engineers collaborate from concept to production, ensuring your mold is optimized for cost efficiency, performance, and scalability. From ABS housings to medical-grade POM components, we deliver precision that meets ISO 9001:2015 and IATF 16949 standards—every time.

Ready to optimize your next project?

📞 Contact our 24/7 technical team: +86 510 8765 4321 | [email protected]

Manufacturing Process & QC

From Prototype to Production: A Strategic Partnership for Cost-Effective Manufacturing

At Wuxi Lead Precision Machinery, we understand that injection molding costs extend far beyond the initial tooling investment. Our end-to-end process—from design validation to mass production—is engineered to minimize total cost of ownership (TCO) while ensuring Olympic-grade quality. As your strategic manufacturing partner, we eliminate hidden costs through precision engineering, rapid prototyping, and rigorous quality control.

Design Analysis: Precision Engineering from Day One

We begin by collaborating with your engineering team to optimize part geometry, material flow, and moldability. Our process includes:

Mold Flow Simulation (using Moldflow®) to predict shrinkage, warpage, and filling patterns

GD&T Analysis for critical tolerances (±0.01mm standard)

Material-Specific Validation for ABS, PC, PP, Nylon, and POM to prevent defects

Shot Life Optimization based on projected volume (100k–1M+ cycles)

“A well-engineered mold design reduces rework by 35% and accelerates time-to-market by 20%.”

Cost Transparency: Detailed Breakdown of Your Investment

We provide full visibility into every cost component—no surprises, no hidden fees.

| Cost Element | Industry Standard | Wuxi Lead’s Value-Added Approach | Impact on TCO |

|---|---|---|---|

| Mold Steel Selection | P20: $50–$100/kg; NAK80: $80–$150/kg | Customized grade selection (e.g., NAK80 for medical-grade polish; P20 for high-volume automotive) | 15–20% lower long-term maintenance costs |

| CNC Machining | $56–$113/hour | Precision machining with ±0.01mm tolerance and real-time in-process metrology | 25% reduction in secondary operations |

| EDM Processing | $70–$120/hour | High-precision EDM for intricate cavities (0.005mm surface finish) | Eliminates manual polishing; extends mold life by 30% |

| Design Fees | 10–15% of total mold cost | Included in project scope; no hidden engineering charges | 100% transparent pricing |

| Shot Life | 100k–300k cycles | Engineered for 500k+ cycles with optimized cooling channels | 40% lower cost per part in high-volume production |

Rapid Prototyping: Accelerate Time-to-Market

We leverage the same high-precision tooling for prototypes as production molds—no compromise on quality.

10–15 day lead time for prototype molds (vs. industry average of 4–6 weeks)

Full design validation with first-article inspection (FAI) reports

Material-specific testing for ABS, PC, PP, etc., to confirm performance under real-world conditions

Zero rework cycles due to our AI-driven design validation system

“Our prototype molds are production-ready—so when you approve the design, mass production begins immediately.”

Mass Production: Zero Defects, Olympic Quality, 24/7 Support

We deliver consistent, defect-free parts at scale through:

🔍 Zero Defects Protocol

100% in-process inspection via automated vision systems

Statistical Process Control (SPC) with real-time data analytics

Defect rate < 0.1% (certified to ISO 9001:2015)

🏆 Olympic Quality Standards

Surface finish ≤ Ra 0.4μm for optical-grade parts

Dimensional accuracy ±0.005mm for medical and aerospace applications

Cycle time optimization (15–25% faster than industry averages)

⏱️ 24/7 Customer Service

Dedicated account managers for real-time issue resolution

Predictive maintenance alerts to prevent unplanned downtime

Global technical support via phone, email, or video call—anytime, anywhere

Why Partner with Wuxi Lead?

“We don’t just sell molds—we engineer solutions that reduce your total cost of ownership. From prototype to 1M+ parts, our precision engineering, rapid tooling, and relentless quality focus ensure you get more value per dollar.”

Ready to optimize your injection molding project?

Contact our engineering team today for a free TCO analysis—no obligation, no hidden costs.

Wuxi Lead Precision Machinery

Precision Engineered. Globally Delivered.

ISO 9001:2015 Certified | 24/7 Technical Support | 100+ Global Clients

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

More Than a Supplier—Your Strategic Manufacturing Partner

At Wuxi Lead Precision Machinery, we transcend transactional relationships. As your dedicated engineering partner, we integrate deep technical expertise with end-to-end manufacturing precision—from initial DFM analysis to high-volume production. Our approach ensures cost efficiency, zero-defect output, and scalable solutions tailored to your exact specifications. We don’t just build molds; we optimize your entire production lifecycle.

Precision Engineering Excellence

| Parameter | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.01mm (ISO 2768-mK certified) | ±0.05mm (typical) |

| Mold Steel Certification | Certified P20/NAK80/H13/S136 per ASTM A681/AISI standards | Unverified grades, inconsistent sourcing |

| Shot Life Optimization | 1,000,000+ cycles (with material-specific heat treatment) | 300,000–500,000 cycles (standard) |

| Cycle Time Reduction | AI-driven process analytics for 15–25% faster throughput | Manual optimization, <10% gains |

| Material Compatibility | Optimized for ABS, PC, PP, Nylon, POM, and high-temp engineering plastics | Generic tooling, limited material-specific tuning |

Zero Defects Guarantee: Precision You Can Trust

ISO 9001:2015 Certified Quality Management System with 100% in-process inspection at critical stages.

3D Coordinate Measuring Machine (CMM) validation for all mold components, ensuring dimensional accuracy within ±0.005mm.

Statistical Process Control (SPC) for real-time defect prevention during production runs.

Zero Defects Pledge: Every mold undergoes 5+ validation cycles before delivery, with documented proof of compliance.

Olympic Quality Standards for Mission-Critical Parts

We engineer molds to meet the exacting demands of aerospace, medical, and automotive applications:

Surface Finish: Ra ≤ 0.2μm for optical-grade parts (e.g., PC lenses).

Wear Resistance: NAK80 tooling hardened to 40–45 HRC for high-abrasion materials like POM.

Thermal Stability: Precision water channel design for ±0.5°C temperature uniformity across cavities.

Failure Analysis: Root-cause investigation for any deviation, with corrective action plans delivered within 24 hours.

24/7 Technical Support: Always On, Always Ready

Dedicated Engineering Team: 24/7 availability for urgent technical queries or production emergencies.

Guaranteed Response Time: <2 hours for critical issues, with on-site support within 48 hours (global coverage).

Proactive Maintenance Alerts: IoT-enabled mold monitoring for predictive wear analysis and downtime prevention.

Global Logistics Coordination: Seamless shipping with real-time tracking and customs clearance expertise.

Ready to Optimize Your Injection Molding Project?

Contact us today for a free DFM analysis and competitive quote—no obligation, no hidden fees.

Email: [email protected]

Direct Line: +86-13961886740 (24/7)

Why Wait? Our engineers will review your design within 24 hours and deliver actionable insights to reduce costs, accelerate time-to-market, and ensure first-pass success.

“Precision isn’t a feature—it’s our standard.”

Wuxi Lead Precision Machinery: Where Engineering Excellence Meets Partnership

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.