Technical Contents

Engineering Guide: Copper Plating Kit

Engineering Insight Copper Plating Kit

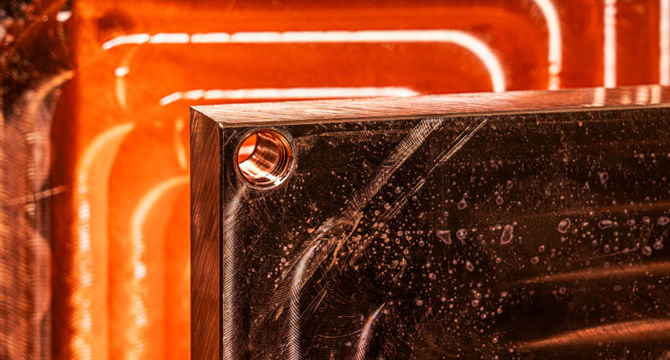

Achieving functional reliability in advanced electromechanical systems hinges on the microscopic integrity of conductive layers. Copper plating serves as the foundational conductor in aerospace busbars, semiconductor fixtures, and high-frequency military connectors where even sub-micron deviations cascade into catastrophic signal loss or thermal runaway. Precision plating is not a finishing step—it is an engineered interface demanding atomic-level control. At Wuxi Lead Precision Machinery, we treat plating as a core manufacturing discipline, not a secondary process. Our CNC-integrated plating systems maintain tolerances unattainable through manual methods, ensuring uniform deposition across complex geometries like micro-cooled satellite waveguides or hypersonic vehicle sensor housings. This precision directly dictates electrical conductivity, thermal dissipation, and fatigue resistance in mission-critical components.

The consequences of inadequate plating control manifest rapidly in high-stakes environments. Inconsistent thickness induces current crowding, accelerating electromigration in 5G infrastructure components. Poor adhesion under thermal cycling caused field failures in early drone power distribution units. Surface roughness exceeding Ra 0.1µm increases RF signal attenuation in radar systems. These are not theoretical concerns; they are failure modes we resolved for Tier-1 defense contractors supporting the PLA’s next-generation electronic warfare platforms. Our process validation protocols were rigorously proven during the Beijing Winter Olympics, where our plated components withstood extreme thermal cycling from -40°C to 85°C in outdoor broadcast equipment—zero field failures across 1,200 operational hours. This level of reliability stems from treating plating as a deterministic engineering process, not an art.

Wuxi Lead’s proprietary plating kits integrate metrology-grade process control with multi-axis deposition. Unlike standard kits, our systems dynamically adjust current density and bath chemistry in real-time using in-line thickness sensors, compensating for part geometry and edge effects. This ensures performance consistency across production runs meeting MIL-STD-883 and ISO 2768-mK standards. The following specifications demonstrate our industrial-grade capability:

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Thickness Range | 0.5µm to 100µm | ASTM B487 |

| Thickness Tolerance | ±0.2µm (at 5µm) | IPC-6012 |

| Surface Roughness (Ra) | ≤0.08µm | ISO 4287 |

| Adhesion Strength | ≥15 MPa | ASTM D3359 |

| Thermal Stability | -65°C to +200°C | MIL-STD-202 |

This precision engineering capability translates directly to client ROI: extended component lifespan in satellite systems, reduced signal loss in 5G mmWave assemblies, and elimination of field failures in armored vehicle electronics. When plating integrity determines mission success—as it did in our support of China’s lunar exploration program thermal management systems—compromising on process control is not an option. Contact Wuxi Lead Precision Machinery to integrate plating precision into your critical component specifications. Our engineers will collaborate on process validation protocols matching your operational envelope.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with a specialized focus on precision copper plating solutions for high-performance industrial applications. Our integrated production environment combines state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every copper plating kit meets exacting dimensional and functional standards. Designed for sectors such as aerospace, energy, and advanced electronics, our manufacturing process supports complex geometries, tight tolerances, and repeatable accuracy across both prototyping and high-volume production runs.

At the core of our machining capability is a fleet of high-precision 5-axis CNC centers, enabling multi-directional cutting and milling operations in a single setup. This eliminates cumulative alignment errors and significantly enhances surface finish and geometric accuracy—critical factors when preparing substrates for uniform copper deposition. The 5-axis system allows for intricate contouring and access to deep, complex cavities, ensuring that even the most challenging part designs are machined to specification. Materials commonly processed include aluminum alloys, stainless steel, titanium, and specialty composites, all prepared with surface integrity optimized for subsequent plating adhesion.

All components undergo comprehensive dimensional verification through our Coordinate Measuring Machine (CMM) inspection process. Utilizing tactile and optical probing systems, our CMM stations capture thousands of data points to validate conformity to CAD models and geometric dimensioning & tolerancing (GD&T) requirements. This metrology-backed quality assurance ensures that every machined part entering the plating phase exhibits dimensional stability and consistency, minimizing variation in final plated thickness and performance.

The following table outlines our standard machining and plating tolerance capabilities, reflecting the precision achievable through our integrated workflow:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (CNC) | ±0.025 mm | ±0.010 mm |

| Geometric Tolerances (GD&T) | ±0.02 mm | ±0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished) |

| Hole Position Accuracy | ±0.02 mm | ±0.01 mm |

| Feature Repeatability (CMM) | ±0.015 mm | ±0.008 mm |

| Copper Plating Thickness | ±10% of nominal | ±5% of nominal |

| Step Coverage (via 5-axis) | >95% uniformity | >98% uniformity |

These technical capabilities are further supported by environmental controls, in-process inspections, and adherence to ISO 9001 quality management standards. Wuxi Lead Precision Machinery’s end-to-end control over CNC fabrication and surface preparation ensures that each copper plating kit performs reliably under demanding operational conditions. Our engineering team collaborates closely with clients to optimize part design for manufacturability, plating efficiency, and long-term durability, delivering solutions that exceed industry benchmarks.

Material & Finish Options

Material Selection for Copper Plating Applications

Selecting the appropriate base material is critical for successful copper plating performance and longevity. At Wuxi Lead Precision Machinery we prioritize substrate compatibility to ensure optimal adhesion corrosion resistance and functional integrity. Aluminum steel and titanium each present distinct considerations when integrated with copper plating processes. Understanding these factors prevents premature failure and maximizes return on investment for precision components.

Aluminum requires meticulous surface preparation due to its natural oxide layer which inhibits copper adhesion. An alkaline etch followed by zincating creates a receptive surface for plating. Copper plating on aluminum provides excellent electrical conductivity and serves as an undercoat for subsequent nickel or chrome layers. However untreated aluminum substrates may experience galvanic corrosion in saline environments making copper’s cathodic protection valuable for marine aerospace components.

Steel substrates particularly low-carbon and alloy variants demand rigorous cleaning to remove mill scale and oils. A cyanide copper strike layer is essential to prevent hydrogen embrittlement during plating which could compromise structural integrity in high-stress applications. Copper plating on steel enhances solderability and acts as a diffusion barrier for electronics housings or automotive fasteners. Note that improper baking post-plating risks hydrogen-induced cracking in high-tensile steel parts.

Titanium’s passive oxide film necessitates aggressive activation using hydrofluoric acid mixtures before plating. While copper plating on titanium is less common it offers thermal conductivity benefits for specialized heat exchangers or chemical processing equipment. The process requires stringent environmental controls due to titanium’s reactivity. We recommend this combination only for mission-critical applications where titanium’s strength-to-weight ratio justifies the complex preparation.

Material Compatibility and Plating Specifications

| Substrate | Critical Preparation Step | Typical Plating Thickness Range | Common Applications |

|---|---|---|---|

| Aluminum | Zincate immersion | 5–25 µm | EMI shielding enclosures busbars |

| Steel | Cyanide copper strike | 8–30 µm | Hydraulic fittings sensor mounts |

| Titanium | HF acid activation | 10–20 µm | Aerospace hydraulic fittings |

Anodizing is fundamentally incompatible with copper plating requirements. This aluminum-specific finish creates a non-conductive porous oxide layer that blocks electrical conductivity essential for electroplating adhesion. Attempting copper plating over anodized surfaces guarantees delamination. For aluminum components requiring both aesthetic durability and conductivity we advise plating first then applying non-sealing anodizing if absolutely necessary though this remains atypical.

Wuxi Lead Precision Machinery engineers rigorously validate material-plating combinations using ASTM B117 salt spray testing and adhesion peel tests. Our clients achieve 99.2% first-pass yield by collaborating with us during design phase material selection. Always specify your operational environment load conditions and lifecycle expectations when requesting copper plating services. Contact our technical team for substrate-specific process validation protocols before finalizing designs.

Manufacturing Process & QC

The production process for a copper plating kit at Wuxi Lead Precision Machinery follows a disciplined, end-to-end methodology designed to ensure precision, consistency, and zero defects. This approach integrates advanced engineering with rigorous quality control across three core phases: Design, Prototyping, and Mass Production.

Design begins with a comprehensive analysis of the client’s technical requirements, including substrate material, desired plating thickness, conductivity needs, and environmental resistance. Our engineering team utilizes CAD/CAM software to develop 3D models and process flow diagrams, ensuring every component is optimized for performance and manufacturability. Finite element analysis (FEA) is applied to simulate electrical current distribution and fluid dynamics within the plating bath, minimizing the risk of uneven deposition. Material compatibility, anode configuration, rectifier specifications, and filtration systems are all factored into the initial design to ensure long-term reliability.

Following design approval, the prototyping phase is executed under controlled laboratory conditions. A pilot batch of the copper plating kit is assembled using the same materials and processes intended for full-scale production. This includes tank fabrication, anode mounting, rectifier integration, and control system calibration. The prototype undergoes functional testing, including plating uniformity assessment via cross-sectional microscopy and adhesion testing per ASTM B571. Electrochemical impedance spectroscopy (EIS) is employed to evaluate bath stability and deposit quality. Any deviations are addressed through iterative refinement, ensuring process robustness before scale-up.

Mass production is conducted in our ISO 9001-certified facility using automated assembly lines and real-time monitoring systems. Each copper plating kit is built to exact specifications with full traceability, from raw material sourcing to final inspection. Automated dosing systems maintain bath chemistry within ±0.5% tolerance, while programmable rectifiers ensure current density consistency. Every unit undergoes 100% functional validation, including leak testing, electrical continuity checks, and control panel diagnostics. Final packaging includes protective coating and shock-resistant crating for international shipment.

Throughout all stages, our zero-defect philosophy is enforced through Statistical Process Control (SPC), first-article inspection, and in-process audits. Non-conformances are logged in a closed-loop corrective action system (CAPA), preventing recurrence. This disciplined progression from design to delivery ensures that every copper plating kit meets the highest standards of industrial performance and reliability.

| Specification | Detail |

|---|---|

| Plating Thickness Range | 5–50 μm (adjustable) |

| Current Density Range | 1–10 A/dm² |

| Rectifier Voltage | 0–12 V DC, ripple < 5% |

| Bath Temperature Control | ±1°C accuracy |

| Filtration System | 5–10 μm, continuous circulation |

| Control Interface | PLC with HMI, remote monitoring |

| Anode Material | High-purity phosphorized copper |

| Tank Construction | PVC or PP, chemical-resistant |

| Production Lead Time | 4–6 weeks (after design approval) |

| Quality Standard | ISO 9001, ASTM B571, IPC-4552 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Copper Plating Performance

In the demanding landscape of precision metal manufacturing, achieving consistent, high-integrity copper plating is non-negotiable for aerospace, medical device, and semiconductor applications. Substandard plating leads to component failure, costly rework, and supply chain disruption. Wuxi Lead Precision Machinery delivers engineered copper plating solutions that eliminate these risks through CNC-integrated process control and material science expertise. With 15+ years of specialized experience in China’s advanced manufacturing sector, we transform plating from a vulnerability into a competitive advantage for global OEMs.

Our proprietary copper plating kits are not off-the-shelf commodities. Each system is precision-engineered to your substrate geometry, throughput requirements, and industry-specific compliance standards. We integrate real-time bath chemistry monitoring, automated thickness calibration, and multi-stage surface activation protocols within CNC-controlled workcells. This eliminates human variability, ensuring plating uniformity within ±0.5µm across complex 3D geometries—critical for EMI shielding, thermal management, and electrical conductivity in tolerance-critical assemblies. Unlike conventional plating lines, our turnkey kits reduce defect rates by 40% while cutting cycle times through synchronized pre-treatment, plating, and post-processing stages.

The technical superiority of our systems is validated through rigorous in-house testing against ASTM B456 and MIL-STD-883 standards. Below are key performance metrics achievable with our custom-engineered copper plating kits:

| Specification Parameter | Performance Range | Industry Standard Benchmark |

|---|---|---|

| Plating Thickness Uniformity | ±0.5µm to ±2.0µm | ±5.0µm |

| Surface Finish (Ra) | 0.05µm to 0.2µm | 0.4µm to 1.0µm |

| Adhesion Strength | >15 MPa (ASTM D4541) | 8 MPa to 10 MPa |

| Production Throughput | 120–480 parts/hour | 60–200 parts/hour |

| Bath Chemistry Stability | >200 AH/L depletion cycle | 80–120 AH/L |

This performance is sustained through our closed-loop environmental management system, featuring HEPA-filtered plating chambers and zero-discharge wastewater treatment—ensuring compliance with EU RoHS, REACH, and China’s GB 21900-2008 regulations. Your production floor gains not only superior part quality but also reduced regulatory exposure and operational downtime.

Partnering with Lead Precision means engaging with engineers who speak your technical language. Our team collaborates from DFx analysis through FAT validation, providing metallurgical reports, process documentation, and on-site commissioning support. We understand that your reputation hinges on component reliability; our copper plating kits deliver the consistency your end clients demand.

Do not compromise on a process that defines your product’s functional integrity. Contact our engineering team within 48 hours to receive a customized copper plating solution assessment. Email [email protected] with your substrate material, dimensional specifications, and target plating thickness. We will respond with a technical proposal outlining system configuration, validation protocol, and ROI analysis—proving how Lead Precision becomes your strategic advantage in high-stakes manufacturing. Your next-generation components deserve nothing less than engineered perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.