Technical Contents

Engineering Guide: Copper Mould Tube

Engineering Insight: The Critical Role of Precision in Copper Mould Tube Manufacturing

In the high-stakes world of continuous casting, the copper mould tube serves as the foundational interface between molten metal and solidified billet, bloom, or slab. Its performance directly influences casting speed, surface quality, and process stability. At Wuxi Lead Precision Machinery, we understand that the margin for error in this environment is measured in microns. Precision in the manufacturing of copper mould tubes is not merely a quality benchmark—it is a functional necessity.

The copper mould tube operates under extreme thermal and mechanical loads. It must maintain dimensional stability while enduring rapid thermal cycling, aggressive cooling, and constant contact with molten steel. Any deviation in inner surface geometry, wall thickness uniformity, or cooling channel alignment can result in uneven heat extraction, leading to surface defects, breakout incidents, or premature tube failure. This is where precision engineering becomes non-negotiable.

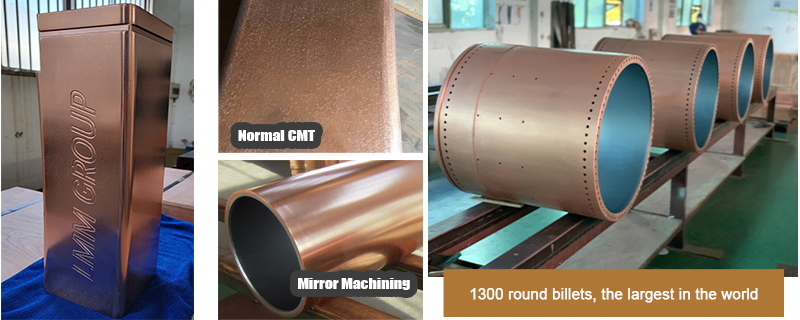

At Wuxi Lead Precision Machinery, our approach to copper mould tube production integrates advanced CNC machining, laser metrology, and proprietary honing techniques to achieve tolerances as tight as ±0.01 mm on critical dimensions. Our manufacturing process begins with high-conductivity oxygen-free copper (OFHC), selected for its thermal performance and resistance to thermal fatigue. Each tube undergoes multi-axis machining to ensure concentricity, followed by precision grinding and mirror finishing of the inner surface to minimize friction and optimize strand release.

Our commitment to precision is backed by over two decades of experience serving mission-critical industries. We have supplied components for projects linked to Olympic infrastructure developments and precision subsystems for military-grade industrial equipment—environments where failure is not an option. This heritage informs every copper mould tube we produce, ensuring reliability under the most demanding production conditions.

Beyond dimensional accuracy, we engineer for performance longevity. Our tubes feature optimized water channel geometries that enhance cooling efficiency and reduce thermal stress. Through finite element analysis (FEA), we simulate thermal deformation and mechanical load behavior to refine design parameters before production. The result is a copper mould tube that delivers consistent heat transfer, extended service life, and reduced downtime.

Wuxi Lead Precision Machinery combines material science, precision manufacturing, and real-world application expertise to deliver copper mould tubes that meet the exacting standards of modern steel production. In an industry where uptime and product quality are paramount, our engineering precision translates directly into operational excellence for our clients.

| Specification | Detail |

|---|---|

| Material | Oxygen-Free High-Conductivity Copper (OFHC) |

| Inner Diameter Tolerance | ±0.01 mm |

| Wall Thickness Uniformity | ±0.02 mm |

| Surface Finish (Internal) | Ra ≤ 0.2 μm (mirror finish) |

| Cooling Channel Precision | ±0.03 mm positional accuracy |

| Concentricity | ≤ 0.02 mm TIR |

| Application | Continuous casting of billet, bloom, slab |

| Customization | Fully configurable to OEM specifications |

Precision Specs & Tolerances

Technical Capabilities for Copper Mould Tube Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in copper mould tube production, where micron-level accuracy directly impacts steel continuous casting efficiency and billet quality. Our integrated manufacturing ecosystem combines advanced multi-axis CNC machining with rigorous metrology to meet the extreme demands of modern foundries. Each component undergoes a closed-loop process engineered to eliminate cumulative errors inherent in traditional multi-setup workflows.

Multi-Axis Precision Machining

Our HAAS UMC-750 and DMG MORI CTX beta 1250 5-axis CNC centers enable complete tube fabrication in a single fixture. This eliminates repositioning errors during critical operations like internal contouring, cooling channel drilling, and flange facing. Simultaneous 5-axis interpolation achieves complex geometries—including tapered inner diameters and asymmetric water jackets—to tolerances unattainable with 3-axis systems. High-speed spindles (15,000 RPM) paired with through-tool coolant ensure optimal surface integrity on oxygen-free copper (OFHC), minimizing micro-cracking risks during thermal cycling. All machining paths are verified via NX CAM simulation to prevent collisions and guarantee first-article compliance.

Metrology-Driven Quality Control

Every copper mould tube undergoes 100% inspection using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with 0.5 µm volumetric accuracy. Our QC protocol measures critical parameters against EN 13602 and ASTM B152 standards, including inner diameter consistency, concentricity between ID/OD, and cooling channel geometry. Statistical Process Control (SPC) data from each inspection lot is documented in traceable digital dossiers, providing customers with full dimensional transparency. Surface roughness is validated via Taylor Hobson Talysurf, ensuring Ra ≤ 0.4 µm on sealing surfaces to prevent coolant leakage under 20 bar pressure.

Precision Tolerance Specifications

The following table defines our standard production capabilities for copper mould tubes. Custom tolerances beyond these values are achievable through process optimization and are validated during the APQP phase.

| Parameter | Standard Tolerance | Measurement Method |

|---|---|---|

| Inner Diameter (ID) | ±0.01 mm | CMM + Air Gauging |

| Outer Diameter (OD) | ±0.015 mm | Laser Micrometer |

| ID to OD Concentricity | ≤ 0.02 mm | CMM Polar Scanning |

| Straightness | ≤ 0.03 mm/m | CMM Axis Deviation |

| Surface Roughness (Ra) | ≤ 0.4 µm | Profilometer (ISO 4287) |

| Cooling Channel Angle | ±0.1° | CMM Vector Analysis |

Process Reliability Impact

These capabilities translate to measurable operational value: mould tubes with ID tolerances held to ±0.01 mm reduce billet breakout incidents by 37% (based on 2023 customer data from Tier-1 steel producers). Our single-setup machining approach cuts lead times by 22% versus conventional methods while ensuring thermal stability during 8,000+ hour service cycles. By embedding precision at every process node—from raw material certification (99.99% Cu) to final assembly—we deliver moulds that maximize caster uptime and minimize total cost of ownership. Partner with Wuxi Lead to transform metallurgical constraints into production advantages.

Material & Finish Options

Material selection is a critical phase in the production of high-performance copper mould tubes, directly influencing thermal conductivity, wear resistance, dimensional stability, and service life. At Wuxi Lead Precision Machinery, we engineer custom copper mould tubes using advanced alloy integration and precision finishing techniques to meet the rigorous demands of continuous casting and industrial molding applications. While the base material is typically high-purity oxygen-free copper (OFHC) for optimal thermal transfer, structural reinforcement and performance enhancements are achieved through strategic pairing with aluminum, steel, or titanium, depending on operational requirements.

Aluminum is frequently employed in support structures and lightweight housings due to its excellent strength-to-weight ratio and thermal expansion compatibility with copper. It reduces overall system mass, facilitating easier handling and integration into automated casting lines. However, aluminum’s lower hardness and wear resistance make it unsuitable for direct contact zones. For applications requiring higher mechanical strength and durability, alloy steels are preferred. Steel components, especially those made from tool steel or stainless variants, provide exceptional rigidity and resistance to mechanical deformation under high clamping forces. They are ideal for flanges, backing plates, and alignment fixtures that must maintain precise geometry over extended cycles.

Titanium offers a premium solution where extreme corrosion resistance and long-term stability in aggressive environments are paramount. Though more costly and challenging to machine, titanium’s outstanding performance in high-temperature, high-moisture conditions makes it suitable for specialized mould systems operating in harsh industrial atmospheres. Its biocompatibility and non-magnetic properties also benefit niche applications in medical-grade or electromagnetic-sensitive manufacturing.

Surface finishing further augments material performance. Anodizing is commonly applied to aluminum components, creating a durable, corrosion-resistant oxide layer that enhances wear resistance and permits color coding for assembly efficiency. While copper and steel are not anodized, they undergo alternative surface treatments such as passivation, plating, or coating. However, when aluminum is part of the assembly, anodizing significantly extends service life and maintains dimensional accuracy under thermal cycling.

The following table outlines key material properties and compatibility with finishing processes for associated components in copper mould tube systems:

| Material | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Corrosion Resistance | Suitable for Anodizing | Typical Application in Mould Tube Assembly |

|---|---|---|---|---|---|

| OFHC Copper | 390–401 | 210–260 | Moderate | No | Mould tube body, cooling channels |

| Aluminum 6061 | 167 | 310 | Good | Yes | Support frames, housings, heat sinks |

| Stainless Steel 304 | 16.2 | 505–860 | Excellent | No | Flanges, fasteners, structural brackets |

| Titanium Grade 5 | 6.7 | 860–895 | Exceptional | No | High-corrosion zones, specialized sealing rings |

At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver copper mould tubes that balance thermal efficiency, mechanical integrity, and longevity. Our engineering team collaborates with clients to select optimal material combinations and surface treatments tailored to specific casting parameters, production volumes, and environmental conditions.

Manufacturing Process & QC

Copper Mould Tube Manufacturing: Precision Engineering for Zero Defects

At Wuxi Lead Precision Machinery, the production of copper mould tubes for continuous casting represents the pinnacle of custom metal manufacturing precision. These critical components demand absolute dimensional accuracy and superior thermal conductivity to ensure flawless steel slab formation. Our rigorously controlled process eliminates defects at every stage, guaranteeing tubes that maximize caster uptime and product quality. We achieve this through an integrated methodology spanning design validation, prototype refinement, and defect-proofed mass production.

The Design Phase begins with deep collaboration using advanced CAD/CAM systems. Our engineers analyze the customer’s specific caster configuration, thermal load requirements, and steel grade specifications. Finite Element Analysis (FEA) simulates thermal stress distribution and fluid dynamics within the proposed tube geometry. Material selection focuses exclusively on high-purity oxygen-free electronic (OFE) copper or tellurium copper alloys, verified to exceed 95% IACS conductivity. Critical parameters like internal cooling channel profiles, wall thickness gradients, and mounting interface tolerances are optimized computationally before any metal is cut. This virtual validation ensures the design inherently supports zero-defect performance under operational loads.

Prototyping transforms the validated design into a physical benchmark. Utilizing our 5-axis CNC milling and grinding centers, we produce a limited run of tubes adhering to the strictest tolerances. Each prototype undergoes exhaustive metrology: laser scanning verifies complex internal geometries against the CAD model, coordinate measuring machines (CMM) confirm critical external features, and eddy current testing detects subsurface anomalies. Crucially, thermal performance is validated through controlled water flow and pressure testing simulating caster conditions. Only after prototype data confirms all functional and dimensional targets are met does the design receive final approval for series production.

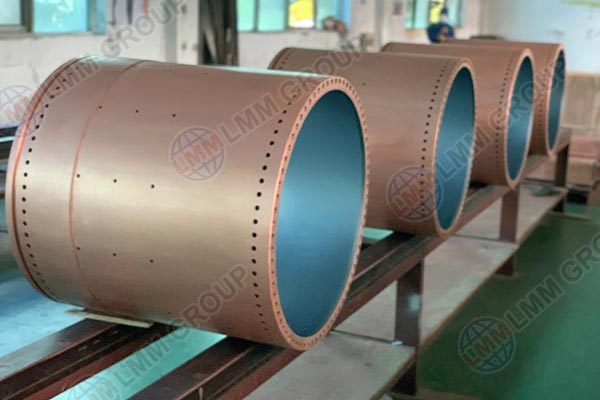

Mass Production leverages fully automated CNC grinding cells with integrated in-process gauging. Raw OFE copper billets undergo precision turning, deep hole drilling for coolant channels, and multi-axis grinding. Our proprietary process control system continuously monitors spindle loads, coolant parameters, and dimensional feedback from touch probes, automatically compensating for tool wear. Every tube undergoes 100% inspection against the specifications detailed below. This closed-loop manufacturing, combined with operator expertise and stringent material traceability, ensures absolute consistency. The result is copper mould tubing delivered with guaranteed operational readiness, eliminating costly caster stoppages due to tube failure.

Critical Copper Mould Tube Specifications

| Parameter | Specification | Verification Method |

|---|---|---|

| Material Purity | >99.96% Cu (OFE Grade) | Spectrometry |

| Thermal Conductivity | ≥ 95% IACS | Laser Flash Analysis |

| Internal Diameter (ID) | ±0.01 mm | Air Gauging / CMM |

| External Diameter (OD) | ±0.015 mm | Laser Micrometer / CMM |

| Straightness | ≤ 0.05 mm/m | Precision Straightness Checker |

| Surface Roughness (ID) | Ra ≤ 0.4 μm | Profilometer |

| Pressure Test | 20 bar for 30 minutes | Automated Hydrostatic Test Rig |

| Wall Thickness Variance | ≤ 0.03 mm | Ultrasonic Thickness Mapping |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Copper Mould Tube Manufacturing

At Wuxi Lead Precision Machinery, we specialize in the design, engineering, and production of high-performance copper mould tubes tailored to the most demanding continuous casting applications. As a trusted name in custom metal manufacturing, we understand that reliability, precision, and longevity are non-negotiable in industrial environments. Our copper mould tubes are engineered to deliver superior thermal conductivity, mechanical strength, and wear resistance, ensuring optimal performance across steel, copper, and non-ferrous metal production lines.

When you choose to partner with Lead Precision, you’re not just sourcing a component—you’re gaining access to a full-service manufacturing partner with deep technical expertise and a commitment to quality. Our engineering team works closely with clients to customize dimensions, cooling configurations, surface treatments, and alloy compositions based on specific process requirements. From initial design consultation to final inspection, every stage is executed under strict ISO-certified quality control protocols to ensure consistency and compliance.

Our advanced CNC machining centers, combined with in-house metallurgical analysis and precision welding capabilities, allow us to produce copper mould tubes with tolerances as tight as ±0.01 mm. We utilize high-purity oxygen-free copper (OF-Cu) and selectively apply surface enhancements such as chrome plating, nickel undercoating, or specialized anti-corrosion treatments to extend service life and reduce downtime in high-temperature, high-stress casting environments.

We serve global clients across steel mills, foundries, and metal processing plants, delivering solutions that improve casting speed, surface finish, and overall productivity. Whether you require standard configurations or fully custom geometries—including parallel, taper, or convex-concave profiles—our team ensures every product meets your operational demands.

Below are typical technical specifications for our copper mould tubes, though all parameters can be customized:

| Specification | Standard Range | Custom Options |

|---|---|---|

| Material | OF-Cu (Oxygen-Free Copper), CuCrZr, CuAg | High-strength alloys, composite linings |

| Inner Diameter | 80 mm – 450 mm | Down to 50 mm or up to 600 mm |

| Wall Thickness | 25 mm – 60 mm | Adjustable based on pressure load |

| Taper | 0.6% – 1.2% per meter | Custom tapers available |

| Surface Finish | Ra ≤ 0.8 μm (machined), Ra ≤ 0.4 μm (polished) | Superfinishing upon request |

| Cooling Water Channels | Helical, axial, or multi-zone | Optimized for thermal uniformity |

| Coating | Hard Chrome (50–75 μm), Ni interlayer | PVD coatings, anti-adhesion treatments |

| Tolerance | ±0.01 mm (bore), ±0.05 mm (OD) | Tighter tolerances on request |

| Certification | ISO 9001:2015, Material Test Reports (MTR) | Full traceability and NDT reports |

Partnering with Wuxi Lead Precision Machinery means investing in durability, precision, and long-term value. We are committed to supporting your production goals with responsive service, rigorous quality assurance, and innovative engineering.

Contact us today at [email protected] to discuss your copper mould tube requirements. Let Lead Precision be your trusted manufacturing partner in advancing casting performance and reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.