Technical Contents

Engineering Guide: Copper 3D Printing Service

Engineering Insight: Copper 3D Printing Service

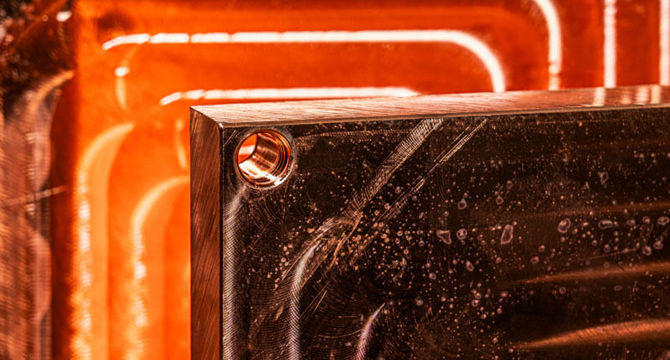

In high-performance manufacturing, copper 3D printing has emerged as a transformative capability, particularly in applications demanding superior thermal and electrical conductivity. Unlike traditional copper fabrication methods that involve complex assembly and material joining, additive manufacturing enables the production of fully dense, complex geometries in pure or oxygen-free copper—components that were previously impossible to manufacture using conventional techniques. At Wuxi Lead Precision Machinery, we recognize that the true value of copper 3D printing lies not just in design freedom, but in the precision and repeatability required to meet the exacting standards of industries such as aerospace, defense, and high-energy physics.

Precision in copper 3D printing is paramount due to the material’s high reflectivity and thermal conductivity, which pose significant challenges during the laser melting process. Standard laser systems often struggle to couple energy efficiently with copper surfaces, leading to inconsistent melt pools, porosity, and dimensional inaccuracies. At Lead Precision, we employ advanced fiber laser technology with optimized wavelength settings and dynamic beam shaping to ensure consistent energy absorption. This enables us to achieve layer-to-layer accuracy within ±0.02 mm and surface finishes as fine as Ra 4.5 μm, even on intricate internal channels and thin-walled structures.

Our expertise in precision copper manufacturing has been validated through mission-critical projects, including components used in Olympic-standard athletic equipment and thermal management systems for military-grade electronics. These applications demand not only material integrity but also geometric precision under thermal cycling and mechanical stress. Our in-house metrology suite, featuring coordinate measuring machines (CMM) and CT scanning, ensures every part meets stringent tolerance and quality benchmarks before delivery.

Copper 3D printing also allows for topology-optimized heat sinks, RF waveguides, and induction coils with internal conformal cooling—features that enhance performance while reducing weight and assembly complexity. By combining design innovation with process control, we deliver components that outperform traditionally machined counterparts in efficiency and reliability.

The following table outlines key technical specifications achievable with our copper 3D printing service:

| Parameter | Specification |

|---|---|

| Material | Oxygen-Free High-Conductivity Copper (OFHC), Cu-Custom Alloys |

| Build Volume | Up to 250 × 250 × 300 mm |

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 4.5–8.0 μm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Coating |

| Density | >99.95% |

| Conductivity (post-annealing) | ≥100% IACS |

At Wuxi Lead Precision Machinery, we combine deep metallurgical expertise with state-of-the-art additive systems to deliver copper components where precision is non-negotiable. Our proven track record in elite engineering environments underscores our commitment to performance, reliability, and technical excellence in every print.

Precision Specs & Tolerances

Technical Capabilities: Precision Copper Additive Manufacturing

Wuxi Lead Precision Machinery delivers advanced copper 3D printing services engineered for the demanding requirements of aerospace, power generation, and high-performance industrial applications. Our integrated manufacturing ecosystem combines state-of-the-art metal additive processes with precision subtractive capabilities and rigorous quality control, ensuring copper components meet exacting functional and dimensional standards. Pure copper and copper alloys like CuCrZr present unique challenges due to high thermal conductivity and reflectivity. We overcome these through specialized parameter development on our laser powder bed fusion systems, optimizing melt pool stability and density to achieve near-full density parts exceeding 99.95%. This foundational quality is essential for thermal management components, electrical contacts, and RF waveguides where material integrity is non-negotiable.

The true differentiator lies in our seamless integration of additive and subtractive manufacturing. While 3D printing enables complex internal cooling channels and organic geometries impossible with traditional methods, achieving critical feature tolerances and surface finishes often requires precision machining. Our dedicated 5-axis CNC machining centers are strategically deployed post-print for final feature definition, critical datum establishment, and interface surface preparation. This hybrid approach ensures geometric accuracy and surface integrity unattainable through printing alone. Complex contours, tight tolerance bores, and precision mating surfaces are machined in a single setup, eliminating cumulative errors and preserving the integrity of the printed copper structure.

Quality verification is embedded at every stage. Comprehensive first-article inspection reports are standard, utilizing our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM) with 0.5μm volumetric accuracy. This metrology backbone validates dimensional conformance against CAD models, including complex GD&T callouts on internal features accessed via specialized probes. Statistical process control data is maintained for high-volume production runs, providing traceability and assurance. Material certification and microstructure analysis are available upon request, confirming properties meet ASTM B111 or customer-specific copper alloy standards.

The following table details achievable geometric tolerances for copper components processed through our integrated workflow, reflecting realistic industrial capabilities for high-value applications:

| Feature | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 | ±0.02 |

| Angular Dimensions (°) | ±0.1 | ±0.05 |

| Positional Tolerance (mm) | ±0.08 | ±0.03 |

| Surface Roughness (Ra) | 1.6 μm (as-printed) | 0.8 μm (machined) |

| Flatness (mm per 100mm) | 0.05 | 0.02 |

This capability set enables Wuxi Lead to produce flight-certified heat exchangers, custom electrical busbars with integrated cooling, and high-frequency antenna components where thermal performance, electrical conductivity, and dimensional precision are interdependent critical factors. We partner with clients from design optimization through final inspection, transforming copper 3D printing from a prototyping tool into a validated production solution for mission-critical hardware.

Material & Finish Options

When selecting materials for high-performance copper 3D printing applications, understanding the complementary use of structural alloys and surface treatments is essential. While copper and its alloys serve as the core printing medium—offering superior thermal and electrical conductivity—the integration of materials such as aluminum, steel, and titanium in hybrid assemblies or support structures enhances mechanical performance. Additionally, post-processing techniques like anodizing play a critical role in improving durability and environmental resistance, especially when copper components interface with other metallic systems.

Aluminum alloys, particularly 6061 and 7075, are frequently used in conjunction with copper 3D printed parts due to their lightweight nature and excellent thermal conductivity. These alloys are ideal for heat exchangers, electronics enclosures, and aerospace components where minimizing weight without sacrificing thermal efficiency is crucial. When paired with copper printed elements such as internal cooling channels, the combined system achieves optimal heat dissipation. However, aluminum requires protective finishing to resist oxidation and wear, making anodizing a standard post-process.

Steel, especially stainless steel 316L and tool steel H13, offers high tensile strength, wear resistance, and dimensional stability. These properties make steel suitable for molds, tooling, and structural supports in high-load environments. In copper 3D printed systems such as induction coils or power transmission components, steel housings provide mechanical rigidity and protection. The galvanic compatibility between copper and steel must be carefully managed through insulation or coating to prevent corrosion in humid or conductive environments.

Titanium alloys, notably Ti6Al4V, deliver an exceptional strength-to-density ratio and outstanding corrosion resistance. They are commonly used in aerospace, medical, and marine applications where long-term reliability under extreme conditions is required. When integrated with copper 3D printed parts—such as in hybrid rocket nozzles or medical RF coils—titanium provides structural integrity while copper ensures efficient thermal management. Due to its high reactivity at elevated temperatures, titanium is typically joined to copper via brazing or mechanical fastening rather than direct printing.

Anodizing is a key surface treatment for aluminum components used in tandem with copper printed parts. This electrochemical process thickens the natural oxide layer, significantly improving corrosion resistance, surface hardness, and electrical insulation. Type II (sulfuric acid) and Type III (hard coat) anodizing are most common, with the latter offering enhanced durability for industrial equipment. While anodizing does not apply to copper or steel directly, it is critical for protecting aluminum subassemblies and preventing galvanic coupling with copper.

The following table summarizes key mechanical and thermal properties of commonly paired materials:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|

| Copper (Pure) | 210–250 | 398 | 8.96 | Heat exchangers, electrical components |

| Aluminum 6061 | 310 | 167 | 2.70 | Enclosures, lightweight structures |

| Stainless Steel 316L | 580 | 15 | 8.00 | Tooling, marine components |

| Titanium Ti6Al4V | 900 | 7.2 | 4.43 | Aerospace, medical devices |

Selecting the right material combination and surface treatment ensures long-term performance, especially in demanding industrial and high-tech environments. At Wuxi Lead Precision Machinery, we support comprehensive material integration and finishing services to optimize your copper 3D printed systems.

Manufacturing Process & QC

Production Process: Precision Copper 3D Printing from Concept to Volume

At Wuxi Lead Precision Machinery, our copper 3D printing service delivers mission-critical components through a rigorously controlled three-stage workflow designed for zero defects. This integrated approach ensures optimal thermal performance, structural integrity, and manufacturability for demanding industrial applications like heat exchangers, RF components, and electrical contacts.

Design Phase: Engineering for Additive Excellence

We initiate every project with collaborative Design for Additive Manufacturing (DfAM) analysis. Our engineering team works directly with your specifications to optimize geometry for copper’s unique thermal properties and the constraints of laser powder bed fusion. This phase focuses on minimizing thermal stress, ensuring proper support structures for overhangs, and validating fluid dynamics or electromagnetic performance through simulation. Critical features such as internal cooling channels or thin-walled conductors are refined to achieve target surface roughness and dimensional stability before any metal is melted. This upfront validation eliminates costly redesigns and ensures printability.

Prototyping Phase: Validation Under Real Conditions

Prototyping is not merely a shape verification step; it is a comprehensive functional validation. Using the exact production-grade oxygen-free copper (OFHC) powder and process parameters, we produce initial units subjected to stringent in-process monitoring and post-build metrology. Each prototype undergoes CT scanning for internal porosity detection, CMM verification against CAD tolerances, and application-specific testing—such as thermal conductivity measurement or pressure cycling. Laser power modulation and inert gas flow are dynamically adjusted based on real-time melt pool monitoring to guarantee 99.95%+ density. Only when all quality metrics, including surface finish and material homogeneity, meet our zero-defect standard do we approve the design for scale-up.

Mass Production Phase: Consistent, Certified Output

Volume production leverages the validated parameters within our climate-controlled manufacturing cells. Each build undergoes continuous in-situ monitoring with high-speed cameras and thermal sensors, with AI-driven systems detecting anomalies at micron-level deviations. Automated powder handling ensures material consistency, while HIP (Hot Isostatic Pressing) is applied where required for absolute density. Every component receives full traceability via laser marking and is inspected against the final acceptance criteria. Post-processing—including precision CNC machining of critical interfaces, stress relief annealing, and surface polishing—is performed in-house under the same quality management system. Final shipment includes full material certification, dimensional reports, and non-destructive test results.

This closed-loop methodology, from DfAM to certified delivery, ensures every copper part meets the exacting demands of aerospace, energy, and semiconductor industries. Our process guarantees repeatability, eliminating scrap and accelerating time-to-market for high-value applications.

| Parameter | Specification | Tolerance/Application |

|---|---|---|

| Material | Oxygen-Free Copper (OFHC), Cu-ETP | ASTM B152, >99.99% Cu |

| Layer Thickness | 20–50 µm | Adjustable per geometry |

| Build Volume | 250 x 250 x 300 mm | Optimized for part density |

| Density | ≥99.95% (as-built) | Verified via Archimedes’ test |

| Surface Roughness (Sa) | 8–15 µm (as-built) | <3 µm after polishing |

| Dimensional Accuracy | ±0.05 mm per 100 mm | Certified via CMM report |

| Thermal Conductivity | ≥390 W/m·K | Measured per ASTM E1461 |

| Lead Time (Prototype) | 7–10 working days | Includes full validation |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Copper 3D Printing Expertise

At Wuxi Lead Precision Machinery, we don’t just provide copper 3D printing services—we deliver precision-engineered solutions tailored to the most demanding industrial applications. As a leader in custom metal manufacturing, we specialize in additive manufacturing of high-conductivity copper components that meet exacting standards in aerospace, power electronics, automotive R&D, and advanced energy systems. When you partner with us, you gain access to cutting-edge technology, deep metallurgical expertise, and a commitment to quality that sets the benchmark in Chinese precision manufacturing.

Our copper 3D printing process leverages state-of-the-art laser powder bed fusion (LPBF) systems calibrated specifically for pure copper and copper alloys. These materials present unique challenges due to their high reflectivity and thermal conductivity, but our proprietary parameter optimization and in-situ monitoring ensure consistent density, fine microstructure, and superior mechanical and electrical performance. Whether you require complex heat exchangers, RF waveguides, or custom electrode designs, our engineering team works closely with yours from concept to certified production.

We understand that in high-end manufacturing, specifications are non-negotiable. That’s why every component undergoes rigorous post-processing and quality validation, including dimensional inspection, metallographic analysis, and conductivity testing. Our ISO 9001-certified facility supports full traceability, batch control, and NDT compliance, ensuring your parts meet international standards and perform reliably in mission-critical environments.

Our clients choose Lead Precision not only for our technical capabilities but for our collaborative approach. We act as an extension of your engineering department, offering design for additive manufacturing (DfAM) consultation, material selection guidance, and rapid prototyping cycles that accelerate time to market. With scalable production capacity and strict IP protection protocols, we support both low-volume innovation projects and high-mix, medium-volume production runs.

Below are key specifications for our copper 3D printing service:

| Parameter | Specification |

|---|---|

| Material Options | Pure Copper (C10100, >99.99% Cu), CuCrZr, CuNi, Bronze Alloys |

| Build Volume | Up to 250 × 250 × 300 mm (standard), custom chambers available |

| Layer Thickness | 20–60 μm (adjustable for resolution vs. speed) |

| Typical Density | ≥ 99.95% (as-built), near-theoretical density achievable |

| Surface Roughness (as-built) | Ra 10–15 μm (post-processing down to Ra 0.8 μm) |

| Tensile Strength (Pure Cu) | 220–250 MPa |

| Electrical Conductivity | ≥ 85% IACS (post-annealing) |

| Post-Processing | Stress relief, HIP, CNC finishing, polishing, coating options |

| Quality Standards | ISO 9001, full inspection reports, material certification |

Elevate your next project with a manufacturing partner that combines technical excellence with responsive, client-focused service. For inquiries, technical collaboration, or sample requests, contact us today at [email protected]. Let Wuxi Lead Precision Machinery bring your most challenging copper component designs to life—with precision, performance, and partnership at the core.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.