Technical Contents

Engineering Guide: Control Plan For Cnc Machining

Engineering Insight: Control Plan for CNC Machining – Ensuring Uncompromised Precision

In high-end precision CNC machining, consistency and repeatability are not merely objectives—they are requirements. A well-structured control plan is the backbone of this consistency, serving as a comprehensive roadmap that defines how every stage of the machining process is monitored, measured, and maintained. At Wuxi Lead Precision Machinery, we recognize that the margin for error in industries such as aerospace, defense, and high-performance sports equipment is effectively zero. This understanding drives our rigorous approach to control planning, ensuring every component meets exacting dimensional, material, and surface finish specifications.

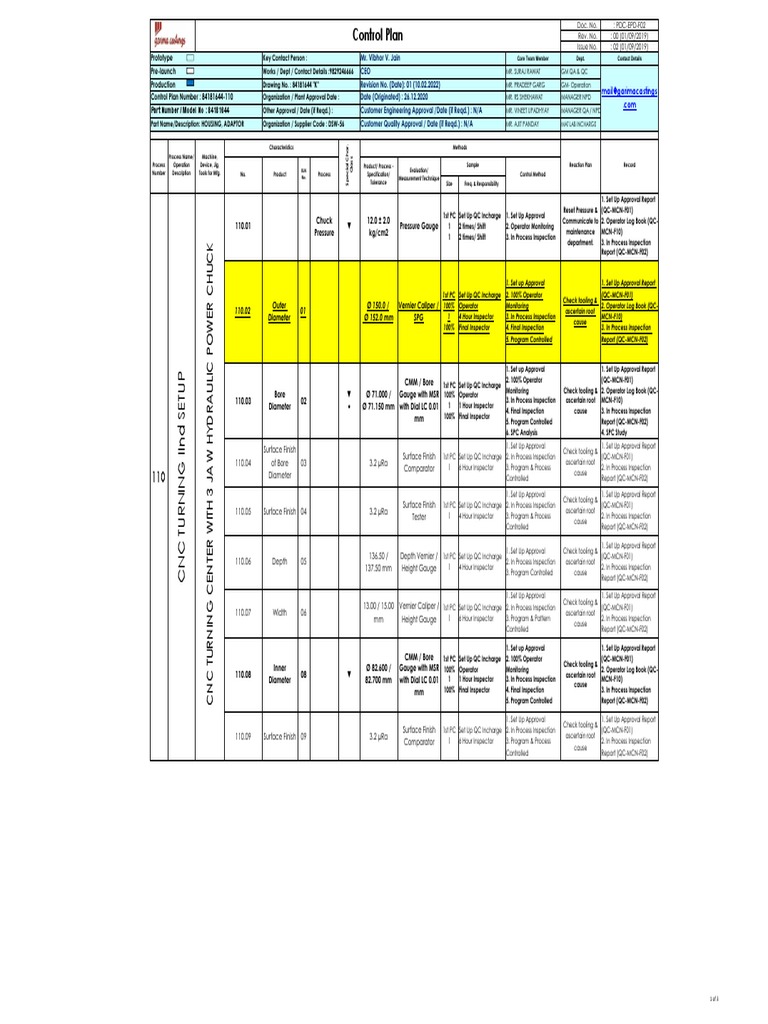

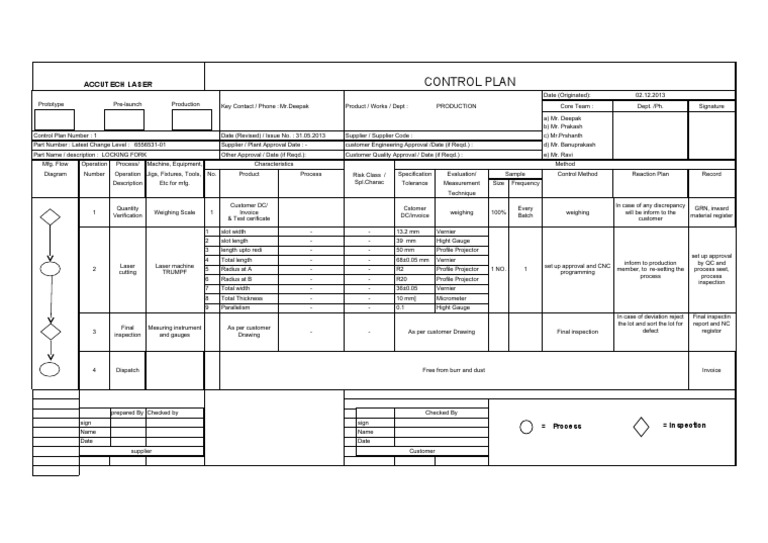

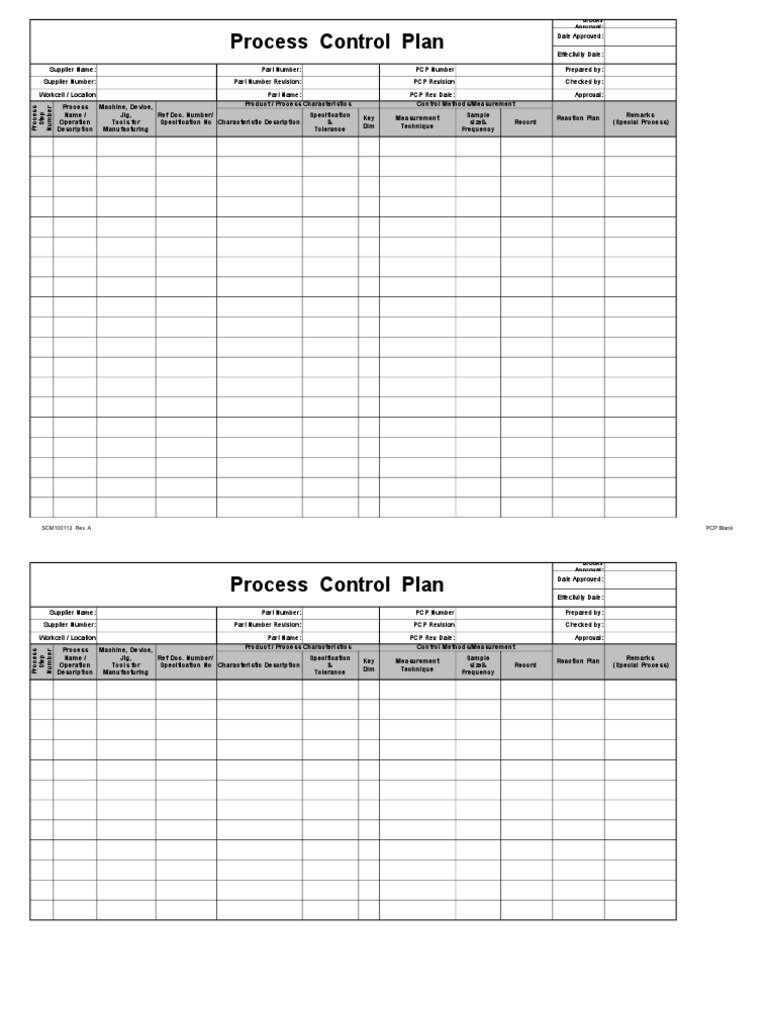

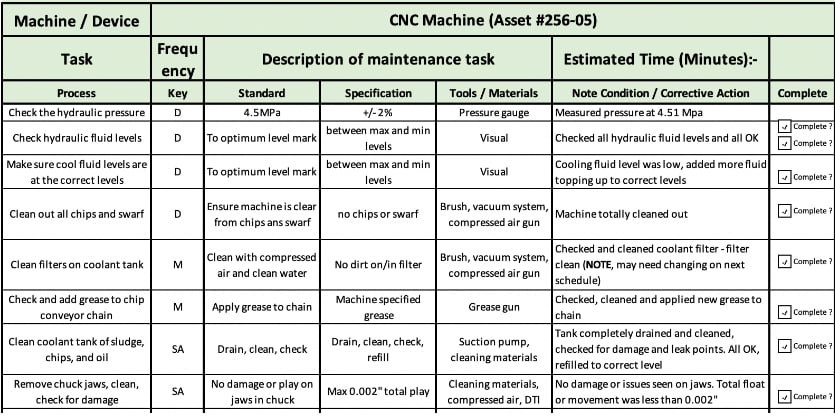

A control plan for CNC machining extends beyond a checklist. It integrates process flow diagrams, failure mode and effects analysis (FMEA), and detailed inspection protocols to mitigate risk before production begins. Each operation—from raw material inspection to final deburring and packaging—is documented with specific tolerances, measurement methods, and responsible personnel. This level of documentation ensures traceability, supports continuous improvement, and aligns with international quality standards such as ISO 9001 and AS9100.

At Lead Precision, our control plans are developed in tandem with our engineering and production teams, ensuring seamless translation from design intent to physical part. We utilize advanced statistical process control (SPC) to monitor critical dimensions in real time, allowing for immediate adjustments and minimizing process drift. Our investment in high-accuracy CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers enables us to validate conformance across every production batch.

Our experience in delivering mission-critical components for Olympic-level athletic equipment and military-grade hardware underscores our capability in high-stakes manufacturing environments. These applications demand not only micron-level tolerances but also full material certification and lot traceability—elements rigorously embedded within our control plans. Whether producing titanium structural components for defense systems or lightweight aluminum parts for competitive sports machinery, our control plans ensure every output is identical in performance and quality.

Below is a representative specification table reflecting the precision standards consistently upheld in our CNC control plans:

| Parameter | Standard Tolerance | Measurement Tool | Frequency |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM, Micrometer | Per batch |

| Geometric Tolerances (GD&T) | ±0.01 mm | CMM, Optical Comparator | First article & periodic |

| Surface Roughness (Ra) | Ra 0.8 µm | Surface Roughness Tester | Per operation |

| Material Certification | Mill Test Report | Documentation Review | Per lot |

| Thread Accuracy | 6g/6H Class | Thread Gages, Optical Comparator | 10% sample rate |

Precision in CNC machining is not achieved by chance. It is engineered through disciplined planning, executed with advanced technology, and verified through relentless inspection. At Wuxi Lead Precision Machinery, our control plans reflect over a decade of mastering the intersection of process control and high-performance manufacturing. For clients where failure is not an option, we deliver precision you can measure—and trust.

Precision Specs & Tolerances

Technical Capabilities: Precision Execution Within the Control Plan Framework

A robust control plan for CNC machining fundamentally relies on demonstrable technical capabilities that ensure consistent part conformance. At Wuxi Lead Precision Machinery, our control plans are engineered around core competencies in multi-axis machining and metrology, forming an inseparable system for quality assurance. This integration is non-negotiable for high-integrity components demanded in aerospace, medical, and advanced industrial applications.

Our foundation is a modern fleet of high-rigidity 5-axis CNC machining centers. These systems enable true simultaneous 5-axis contouring, critical for producing complex organic shapes, deep cavities, and intricate features in a single setup. This capability directly mitigates cumulative error inherent in multi-setup processes, a key risk factor addressed within our control plans. Advanced spindle technologies and thermal compensation systems maintain dimensional stability throughout extended production runs, ensuring the process remains centered within tolerance bands defined by the control plan. Material versatility spans aerospace alloys like Inconel and titanium, medical-grade stainless steels, and high-performance engineering plastics, all machined under strictly controlled environmental conditions.

Integral to our control plan execution is comprehensive, traceable metrology. Every critical feature defined in the plan undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs) operating under ISO/IEC 17025 accredited procedures. Our CMMs, equipped with high-precision probes and advanced software, perform full geometric dimensioning and tolerancing (GD&T) analysis. This provides objective, data-driven validation against the blueprint, moving beyond simple pass/fail checks to detailed process capability analysis. Real-time data from CMM inspections feeds directly back into the control plan, enabling immediate corrective actions and continuous process refinement, significantly reducing scrap and rework rates for our clients.

The precision achievable through this integrated approach is quantifiable. Our control plans explicitly define and guarantee the following tolerance capabilities, verified through routine CMM measurement:

| Parameter | Capability | Measurement Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | CMM, High-Precision Micrometers |

| Geometric Tolerances (Flatness, Roundness) | 0.003 mm (0.0001″) | CMM, Optical Flats, Roundness Testers |

| Surface Finish (Ra) | 0.4 µm (16 µin) | Profilometer |

| Positional Tolerances | ±0.010 mm (±0.0004″) | CMM (Full 3D Analysis) |

| Critical Feature Repeatability (CpK) | ≥ 1.67 | Statistical Process Control (SPC) Data |

This documented precision is not theoretical; it is the operational baseline embedded within every Wuxi Lead control plan. We translate stringent client specifications into actionable, monitored process parameters. The synergy between our 5-axis machining prowess and rigorous CMM validation ensures that the control plan functions as a dynamic quality shield, not merely a static document. This capability directly translates to reduced supply chain risk, accelerated time-to-market, and uncompromised part performance for our global partners. Trust in the component begins with trust in the process control.

Material & Finish Options

Material Selection in CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical step in developing an effective control plan for CNC machining. At Wuxi Lead Precision Machinery, we emphasize material compatibility with design intent, production efficiency, and end-use performance. Among the most widely used materials in precision CNC machining are aluminum, steel, and titanium—each offering distinct mechanical properties, machinability characteristics, and cost implications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is particularly suitable for aerospace, automotive, and consumer electronics applications where weight reduction is essential. Grades such as 6061 and 7075 are commonly machined due to their balance of strength and workability. Aluminum’s softness allows for high-speed machining, reducing tool wear and cycle times, which directly supports tighter process control and consistent output.

Steel, particularly alloy and stainless variants, is selected when higher strength, durability, and wear resistance are required. Materials like 4140 alloy steel or 304/316 stainless steel are used in industrial machinery, medical devices, and structural components. While steel is more challenging to machine than aluminum due to its hardness and tendency to generate heat, modern CNC systems with optimized toolpaths and coolant strategies can maintain tight tolerances. Steel also responds well to a range of heat treatments, enhancing its mechanical properties post-machining.

Titanium, notably Grade 5 (Ti-6Al-4V), is used in high-performance applications such as aerospace and medical implants. It offers exceptional strength-to-density ratio and outstanding corrosion resistance, especially in extreme environments. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools demand specialized machining parameters, including lower cutting speeds and rigid setups. These factors necessitate a robust control plan with real-time monitoring to prevent tool failure and maintain dimensional accuracy.

Surface finish selection further influences performance and longevity. Anodizing is a widely adopted post-processing technique for aluminum, enhancing surface hardness and corrosion resistance while allowing for color coding. Type II (sulfuric acid) and Type III (hardcoat) anodizing are common, with the latter providing thicker, more durable coatings suitable for high-wear environments.

Below is a comparative overview of key material properties and machining considerations.

| Material | Common Grades | Tensile Strength (MPa) | Machinability Rating | Typical Applications | Recommended Finish |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310–572 | Excellent | Aerospace, Electronics | Anodizing (Type II/III) |

| Steel | 4140, 304, 316 | 500–900 | Moderate to Good | Industrial, Medical | Passivation, Powder Coating |

| Titanium | Ti-6Al-4V (Gr 5) | 900–1000 | Fair | Aerospace, Medical Implants | Anodizing, Polishing |

Material selection directly impacts tool life, cycle time, inspection frequency, and final part quality. A well-structured control plan must account for these variables to ensure repeatability and compliance with industry standards. At Wuxi Lead Precision Machinery, we integrate material-specific protocols into every stage of production—from programming to post-processing—to deliver precision-engineered components with consistent reliability.

Manufacturing Process & QC

Control Plan Execution: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our CNC machining control plan is the backbone of defect-free manufacturing. We integrate precision engineering with rigorous process validation across three critical phases, ensuring every component meets aerospace and medical-grade tolerances. The journey begins with Design Phase Integration, where our engineers collaborate with clients to embed manufacturability into CAD models. We perform advanced DFM analysis to resolve geometric conflicts, optimize tool paths, and establish critical-to-quality (CTQ) characteristics. GD&T callouts are validated via simulation software, eliminating ambiguities that cause downstream errors. Material selection undergoes thermal and stress modeling to prevent warpage, while fixture design ensures 5µm positional repeatability during machining.

Prototyping transforms validated designs into physical proof. We execute first-article inspection (FAI) using calibrated CMMs and optical comparators, measuring 100% of CTQ features against AS9102 standards. Each prototype undergoes functional testing under simulated operational loads, with data fed back to refine the control plan. Our proprietary thermal compensation algorithm adjusts for machine drift during extended runs, capturing dimensional stability across 8-hour cycles. This phase finalizes inspection frequency, tool-wear thresholds, and SPC control limits—never moving to production until Cpk ≥ 1.67 is sustained across 30 consecutive parts.

Mass production deploys closed-loop process control. Every CNC machine runs with real-time in-process gaging, automatically halting operations if tool wear exceeds 12µm or surface roughness deviates beyond Ra 0.8µm. Our MES platform monitors 50+ parameters per machine second, triggering corrective actions before defects occur. Operators perform hourly attribute checks on critical dimensions, while automated vision systems scan complex geometries at 0.5-second intervals. Crucially, we enforce tool-life management: inserts are replaced after 95% of predicted wear limits, preventing micro-burrs that cause assembly failures. This system reduces scrap rates to 12 PPM versus industry averages of 2,500 PPM.

The table below defines our non-negotiable control parameters:

| Process Phase | Key Control Parameter | Target Value | Measurement Method | Frequency |

|---|---|---|---|---|

| Design | GD&T Compliance | 100% adherence | CAD Simulation | Per model |

| Prototyping | Cpk for CTQ Features | ≥ 1.67 | CMM FAI Report | Per batch |

| Mass Production | Tool Wear Threshold | ≤ 12µm | Laser Micrometer | Per tool change |

| Mass Production | Surface Roughness | Ra ≤ 0.8µm | Profilometer | Hourly |

Wuxi Lead’s control plan transcends documentation—it is a living system where data drives action. By anchoring each phase in measurable physics rather than assumptions, we achieve true zero-defect outcomes. Our clients gain not just parts, but certified process stability for mission-critical applications. Contact our engineering team to implement this framework for your next high-precision project.

Why Choose Wuxi Lead Precision

When it comes to precision CNC machining, a robust control plan is not just a procedural document—it is the backbone of consistent quality, repeatability, and compliance with stringent industry standards. At Wuxi Lead Precision Machinery, we understand that your manufacturing success hinges on precision, reliability, and traceability. That’s why we integrate comprehensive control plans into every stage of our CNC machining process, ensuring that your components meet exact specifications and perform flawlessly in their intended applications.

Our control plans are developed using a systematic approach that aligns with APQP (Advanced Product Quality Planning) and PPAP (Production Part Approval Process) frameworks. From initial material inspection to final dimensional verification, each step is meticulously documented and monitored. We utilize advanced measurement technologies such as CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers to validate conformance to tolerances as tight as ±0.002 mm. Our in-house quality laboratory is ISO 9001:2015 certified, reflecting our unwavering commitment to excellence.

What sets Wuxi Lead apart is our ability to customize control plans based on your unique requirements—whether you’re producing low-volume prototypes or high-volume production runs. We work closely with engineering teams to define critical-to-quality (CTQ) characteristics, establish process capability (Cp/Cpk), and implement real-time SPC (Statistical Process Control) monitoring. This proactive approach minimizes variation, reduces scrap rates, and ensures long-term process stability.

We specialize in machining complex components from a wide range of materials, including aluminum alloys, stainless steel, titanium, and engineering plastics. Our multi-axis CNC machining centers, combined with skilled programming and setup, allow us to deliver parts with superior surface finish and geometric accuracy. Every production batch is supported by full inspection reports, material certifications, and first-article inspection documentation, providing complete transparency and audit readiness.

Partner with Wuxi Lead Precision Machinery to elevate your manufacturing outcomes through precision, accountability, and technical excellence. Let us help you build a control plan that not only meets but exceeds your quality expectations.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Machining Tolerance | Up to ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Supported Materials | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin |

| Quality Standards | ISO 9001:2015, PPAP, APQP, SPC, FAI |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, Calipers, Micrometers |

Contact us today at [email protected] to discuss your project and receive a tailored control plan for your CNC machining needs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.