Technical Contents

Engineering Guide: Complete Sheet Metal

Engineering Insight: The Non-Negotiable Imperative of Precision in Complete Sheet Metal Fabrication

In high-stakes sheet metal fabrication, precision transcends mere specification; it is the foundational element determining product performance, assembly integrity, and ultimate lifecycle cost. Tolerance stack-up during assembly, thermal distortion in welding, or minute deviations in bending radii cascade into catastrophic field failures for aerospace components, medical enclosures, or critical infrastructure housings. The cost of rework or scrap at the prototype stage pales against the liability of failure in operational environments. True precision engineering demands holistic control across the entire fabrication sequence – from raw material verification through laser cutting, CNC bending, welding, surface treatment, and final inspection. It requires understanding how material grain direction impacts bend allowance, how laser power density affects edge squareness on reflective alloys, and how fixturing strategy mitigates part distortion during multi-stage processing. This level of dimensional integrity separates functional prototypes from reliably mass-produced components.

Wuxi Lead Precision Machinery has honed this comprehensive precision capability through rigorous engagement with sectors where failure is not an option. Our processes and quality systems have been validated through the production of mission-critical components for major international defense sector programs and precision structural elements deployed within Olympic-standard sporting infrastructure. These projects demanded adherence to extreme tolerances under intense scrutiny, forging our methodology for managing the complete sheet metal workflow as an integrated system, not a series of isolated operations.

Achieving this standard necessitates advanced equipment calibrated to micron-level accuracy, coupled with deep metallurgical process knowledge. Our integrated manufacturing cell ensures data continuity from CAD model to finished part, eliminating translation errors. Real-time in-process metrology on critical features and statistical process control (SPC) monitoring of key parameters like laser assist gas pressure or bending tonnage are non-negotiables. The table below reflects the core precision capabilities underpinning our complete sheet metal solutions for demanding applications.

| Process | Typical Tolerance | Material Range | Max Thickness |

|---|---|---|---|

| Fiber Laser Cutting | ±0.05 mm | Mild Steel, SS, Al, Cu | 25 mm |

| CNC Precision Bending | ±0.1° / ±0.1 mm | Mild Steel, SS, Al | 6 mm |

| Robotic MIG Welding | ±0.2 mm distortion | Mild Steel, SS, Al | 4 mm |

Precision in complete sheet metal is not solely about hitting a dimension on a drawing. It is the engineered certainty that every part, across every batch, possesses the geometric fidelity and material consistency required for flawless integration and reliable performance in the final assembly. This commitment to dimensional truth, proven in the most demanding global projects, defines Wuxi Lead Precision Machinery’s value proposition. We deliver not just fabricated metal, but guaranteed engineering outcomes.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication capabilities engineered for high-precision industrial applications. Our technical infrastructure is built around state-of-the-art 5-axis CNC machining systems, enabling complex geometries and tight tolerances that meet the demands of aerospace, medical, and high-end automation sectors. The integration of multi-axis technology allows for simultaneous machining from multiple angles, reducing setup time and improving part accuracy. This capability ensures that even the most intricate sheet metal components are produced with consistency, surface integrity, and dimensional stability.

Our manufacturing workflow is supported by a fully integrated quality control system, anchored by Coordinate Measuring Machine (CMM) inspection. Every critical component undergoes rigorous metrological validation to ensure compliance with international standards. The CMM system provides non-contact and tactile measurement precision down to ±0.001 mm, capturing detailed data on form, position, and surface characteristics. This level of inspection guarantees that all fabricated parts adhere to design specifications and perform reliably in final assembly environments.

Material versatility is a cornerstone of our technical offering. We process a wide range of sheet metals including stainless steel, aluminum alloys, carbon steel, and specialty alloys such as titanium and inconel. Sheet thicknesses from 0.5 mm to 12 mm are routinely handled, with adaptive tooling and fixturing strategies optimized for each material type. Our CNC systems are equipped with high-speed spindles and automatic tool changers, enabling rapid transition between operations such as cutting, milling, drilling, and tapping—all within a single setup.

All fabrication processes are programmed using advanced CAM software, ensuring optimal toolpaths, minimal material waste, and repeatable accuracy. Our engineering team collaborates directly with clients during the design-for-manufacturability phase, offering feedback on feature feasibility, tolerance stack-ups, and cost-efficient production methods. This proactive approach reduces lead times and prevents downstream issues in assembly or performance.

The following table outlines the key technical specifications and achievable tolerances across our sheet metal fabrication operations:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Sheet Thickness Range | 0.5 mm – 12 mm |

| Positional Tolerance | ±0.025 mm |

| Feature-to-Feature Tolerance | ±0.05 mm |

| Hole Diameter Tolerance | +0.03 mm / -0.01 mm |

| Angular Tolerance | ±0.1° |

| Surface Roughness (Ra) | As low as 0.8 μm |

| CMM Measurement Accuracy | ±0.001 mm |

| Materials Supported | Stainless Steel, Aluminum, Carbon Steel, Titanium, Inconel |

These capabilities are maintained under ISO 9001-certified quality management practices, ensuring full traceability, process control, and continuous improvement. Wuxi Lead Precision Machinery is committed to delivering technically superior sheet metal solutions where precision, reliability, and repeatability are non-negotiable.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material selection directly impacts component performance, lifecycle cost, and manufacturability in high-end sheet metal applications. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with functional requirements, environmental exposure, and finishing processes. This ensures optimal yield, precision, and long-term reliability in aerospace, medical, and industrial systems.

Aluminum alloys like 6061-T6 and 5052 dominate lightweight structural applications requiring corrosion resistance and weldability. 6061-T6 offers superior strength for chassis and brackets, while 5052 excels in marine environments due to its fatigue resistance. Steel remains indispensable: 304/316 stainless grades provide exceptional chemical resistance for medical enclosures and food processing equipment, whereas mild steel (A36/1018) delivers cost-effective strength for structural frames. Titanium Grade 2 is reserved for extreme scenarios—such as aerospace components—where its unmatched strength-to-weight ratio and biocompatibility justify higher costs. Critical trade-offs include aluminum’s lower wear resistance versus steel’s susceptibility to oxidation without treatment, and titanium’s challenging machinability requiring specialized CNC toolpaths.

Anodizing transforms aluminum surfaces into durable, non-conductive layers essential for electrical insulation and wear resistance. Type II (sulfuric acid) anodizing provides standard corrosion protection with dye compatibility for branding. Type III (hardcoat) anodizing achieves 50–70 μm thickness and 500+ HV hardness, critical for hydraulic pistons or military hardware exposed to abrasion. Note that anodizing requires precise voltage control to avoid dimensional shifts; our CNC processes account for this by holding tighter pre-plate tolerances (±0.05 mm). Steel alternatives include powder coating or electropolishing for stainless, but anodizing remains exclusive to aluminum.

Material performance must be validated against application-specific demands. For high-vibration aerospace assemblies, titanium’s fatigue strength outweighs cost concerns. In cost-sensitive industrial housings, 304 stainless with passivation often outperforms anodized aluminum in chemical resistance. Our engineering team collaborates with clients to simulate material behavior under load, temperature, and corrosion stress—ensuring your selection withstands real-world conditions.

Key Material Specifications

| Material | Key Grades | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 5052 | 290–310 | High (non-marine) | Enclosures, brackets, frames |

| Stainless Steel | 304, 316 | 515–620 | Excellent | Medical devices, valves |

| Mild Steel | A36, 1018 | 400–550 | Low (requires coating) | Structural supports |

| Titanium | Grade 2 | 345–450 | Exceptional | Aerospace, implants |

Wuxi Lead’s integrated approach—from material sourcing to precision CNC forming—guarantees dimensional stability through finishing. We avoid post-fabrication surprises by mapping material grain direction, thermal expansion, and finish adhesion during the design phase. Partner with us to transform material science into mission-critical advantage.

Manufacturing Process & QC

Design: The Foundation of Precision Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, the journey toward zero-defect sheet metal fabrication begins with meticulous design engineering. Our in-house design team collaborates closely with clients to translate conceptual requirements into manufacturable, high-precision technical drawings. Utilizing advanced CAD software such as SolidWorks and AutoCAD, we ensure every dimension, bend, and tolerance aligns with both functional demands and production feasibility. Design for Manufacturability (DFM) principles are applied rigorously to eliminate potential flaws before physical production begins. This proactive approach reduces rework, accelerates time-to-market, and ensures compatibility with downstream processes such as laser cutting, bending, and welding.

Prototyping: Validating Design with Real-World Performance

Once the design is finalized, we move to the prototyping phase—a critical checkpoint in our zero-defect strategy. Using the same high-precision equipment employed in mass production, we fabricate initial samples under actual manufacturing conditions. This allows us to identify and resolve any material behavior anomalies, fitment issues, or assembly challenges. Prototypes undergo comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning technologies to verify dimensional accuracy within ±0.05 mm. Feedback from functional testing is integrated into final design adjustments, ensuring that only validated, performance-ready designs proceed to full-scale production.

Mass Production: Consistency, Control, and Quality Assurance

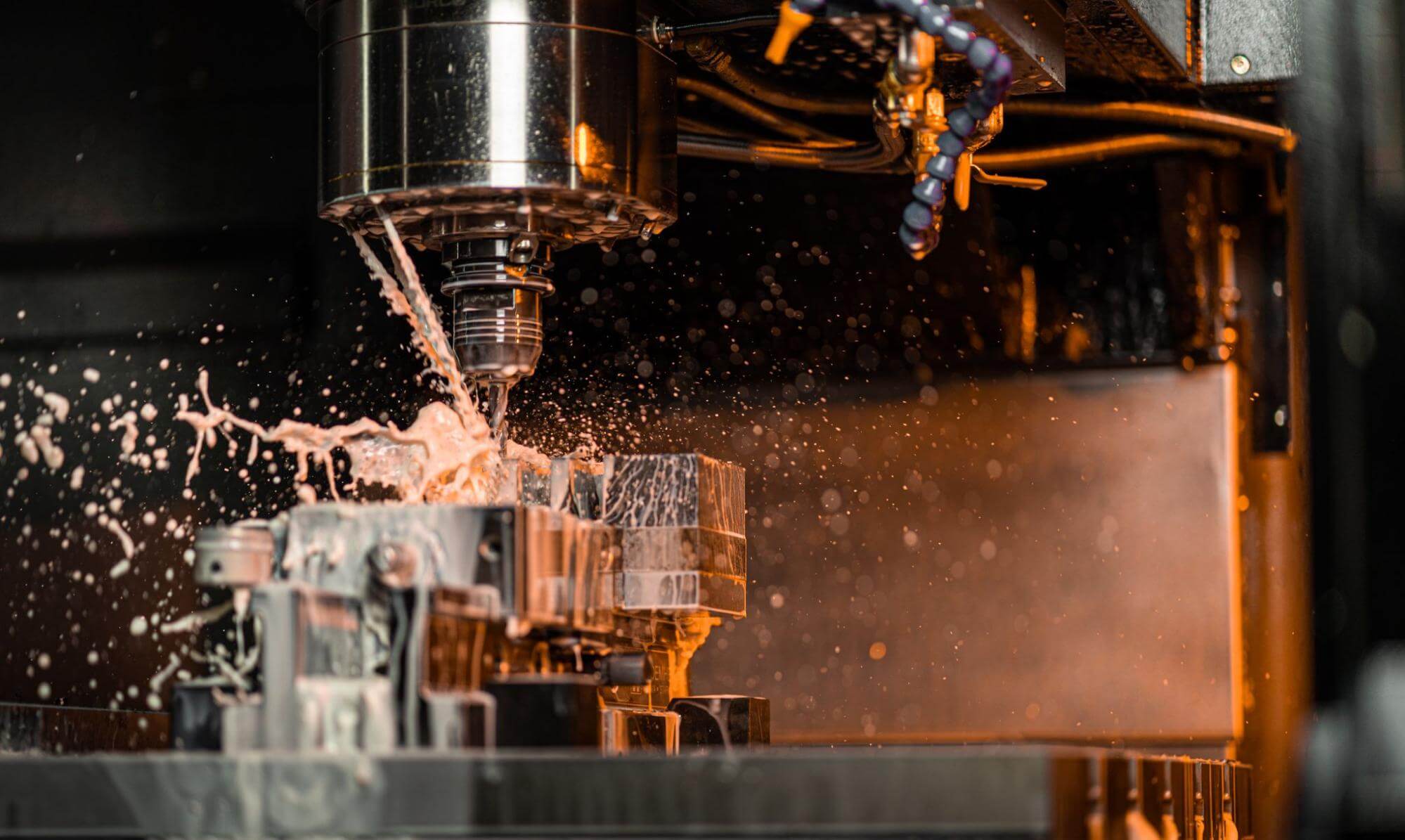

With approved prototypes, Wuxi Lead initiates mass production using fully automated and CNC-controlled systems. Our facility in Wuxi is equipped with state-of-the-art fiber laser cutting machines, automated bending cells, and robotic welding stations, all calibrated to maintain repeatability and precision across thousands of parts. Every production run follows standardized work instructions and is monitored through real-time quality control checkpoints. In-process inspections, first-article checks, and final audits are conducted to ensure compliance with ISO 9001 standards and customer-specific requirements.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Types | Cold-rolled steel, stainless steel, aluminum, galvanized steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2° / ±0.1 mm |

| Surface Finish Options | Mill finish, powder coating, anodizing, plating |

| Max Part Size | 3000 mm × 1500 mm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001, ISO 14001, RoHS compliant |

Throughout all stages, our digital traceability system records process parameters and inspection data for every batch, enabling full accountability and continuous improvement. By integrating design intelligence, prototype validation, and disciplined mass production, Wuxi Lead Precision Machinery delivers complete sheet metal solutions with uncompromising quality—zero defects is not a goal, it is our standard.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Production Through Strategic Partnership

In the demanding landscape of precision manufacturing, your sheet metal components require more than just fabrication; they demand a strategic partnership grounded in engineering excellence and operational reliability. Wuxi Lead Precision Machinery transcends the role of a conventional supplier. We function as your integrated engineering extension, committed to solving complex production challenges and ensuring your finished parts meet the most stringent functional and dimensional requirements. Our decades of specialized expertise in complete sheet metal solutions—from initial design analysis through to final assembly and finishing—provide the stability and innovation your supply chain needs. Partnering with Lead Precision means gaining a dedicated team focused solely on optimizing your component quality, reducing total cost of ownership, and guaranteeing on-time delivery for critical applications across aerospace, medical, energy, and advanced industrial sectors.

Our technical execution capabilities are engineered for uncompromising precision. We deploy a rigorously maintained fleet of advanced CNC equipment, including multi-axis laser cutters, high-tonnage press brakes with automatic tool changers, and sophisticated turret punch systems. This infrastructure, combined with our ISO 9001-certified quality management system and in-house metallurgical expertise, ensures consistent adherence to tight tolerances and complex geometries. Material integrity is paramount; we implement strict protocols for handling, processing, and traceability across a wide spectrum of metals, including stainless steel, aluminum alloys, carbon steel, and specialty materials. Every process step, from nesting optimization to deburring and surface treatment coordination, is meticulously controlled to eliminate waste and maximize yield for your specific components.

Core Technical Specifications

| Capability | Specification Range | Precision Standard |

|————|———————|——————-|

| Material Thickness | Laser Cutting: 0.5mm – 6mm | ±0.05mm |

| | CNC Punching: 0.5mm – 3mm | ±0.03mm |

| | CNC Bending: 0.5mm – 4mm | ±0.1° Angular |

| Max. Working Area | Laser: 3000mm x 1500mm | Full Nesting Optimization |

| | Punch: 2500mm x 1250mm | Dynamic Tool Selection |

| Tolerances | Forming: ±0.1mm per 100mm | ISO 2768-mK |

| | Hole Position: ±0.05mm | GD&T Capable |

| Production Capacity | 500+ Tonnes Monthly | Just-in-Time Scheduling |

This technical foundation enables us to manage projects of significant complexity and scale while maintaining the agility required for rapid prototyping and low-volume, high-mix production. We proactively engage during the Design for Manufacturability (DFM) stage, identifying potential cost savings and manufacturability improvements before tooling begins. Our engineering team collaborates directly with your designers to refine geometries, select optimal materials and processes, and mitigate risks, ensuring seamless transition from concept to certified production.

Initiate a technical dialogue with Wuxi Lead Precision Machinery to transform your sheet metal supply chain. Contact our Engineering Sales Team directly at [email protected]. Provide your specific component requirements, target volumes, and quality expectations. Our senior engineers will respond within 24 business hours to discuss feasibility, conduct a preliminary DFM review, and outline a tailored execution strategy. Do not settle for fragmented supplier relationships. Partner with a single-source precision manufacturer committed to your long-term operational success and product excellence. Let Lead Precision deliver the engineering certainty your critical sheet metal components demand. Reach out today to establish a partnership built on precision, partnership, and proven results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.