Technical Contents

Engineering Guide: Cnc Water Jet Cutting Georgia

Engineering Insight: CNC Water Jet Cutting in Georgia’s Advanced Manufacturing Sector

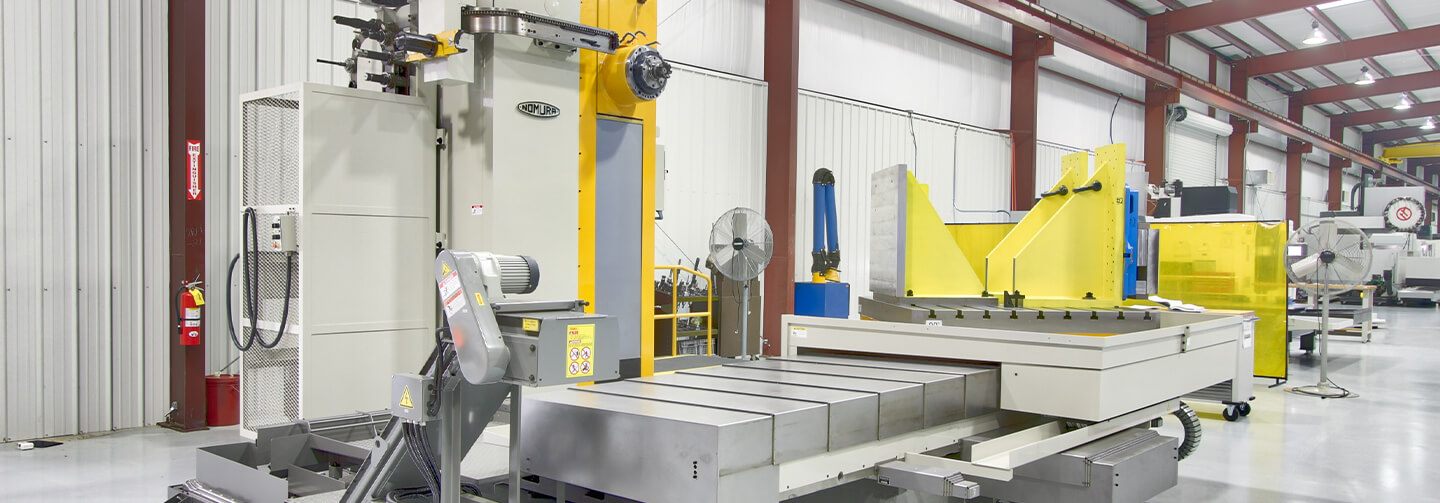

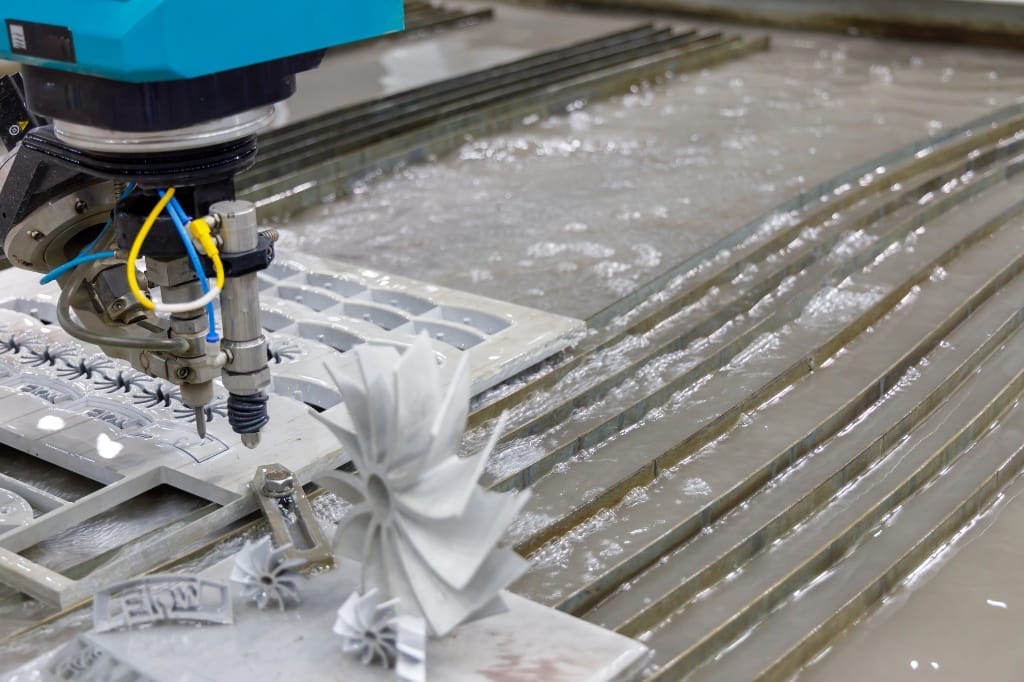

In the evolving landscape of precision manufacturing, CNC water jet cutting has emerged as a cornerstone technology—especially in high-stakes industries such as aerospace, defense, and energy. In Georgia, where advanced manufacturing hubs continue to expand, the demand for materials processed with micron-level accuracy has never been higher. CNC water jet cutting delivers this precision without the thermal distortion associated with laser or plasma methods, making it ideal for heat-sensitive materials like titanium, composites, and specialty alloys.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a specification—it is a standard. With over 15 years of experience serving Tier-1 defense contractors and Olympic-grade sports equipment manufacturers, our engineering team has developed water jet systems that consistently achieve tolerances within ±0.005 inches. This level of accuracy ensures seamless integration of components in mission-critical applications, where even the smallest deviation can compromise structural integrity or performance.

Our CNC water jet platforms are engineered for dynamic performance under continuous industrial operation. Utilizing 5-axis cutting heads and advanced abrasive delivery systems, our machines deliver clean, taper-free cuts across materials up to 200 mm thick. This capability is particularly valuable for Georgia-based fabricators working on complex geometries in defense vehicle components or energy sector tooling.

What sets Lead Precision apart is our integration of intelligent motion control and real-time pressure modulation. Our systems use closed-loop feedback to adjust water pressure (up to 90,000 psi) and abrasive flow rate based on material density and thickness variations. This adaptive control minimizes material waste and maximizes edge quality—critical factors in high-value production environments.

We have deployed our water jet solutions across North America, including key installations in Georgia’s manufacturing corridor, where clients rely on our technology for rapid prototyping and high-volume production. Our machines are built to meet MIL-STD-810 for durability and ISO 13399 for tooling compatibility, ensuring seamless integration into existing production workflows.

The future of manufacturing in Georgia depends on technologies that combine precision, versatility, and reliability. CNC water jet cutting, as advanced by Wuxi Lead Precision Machinery, represents the intersection of these qualities—enabling local industries to compete on a global scale.

| Specification | Lead Precision CNC Water Jet Model LP-WJ800 |

|---|---|

| Cutting Accuracy | ±0.005 inches (±0.127 mm) |

| Maximum Pressure | 90,000 psi (6,205 bar) |

| Axis Configuration | 5-axis with tilt-cut capability |

| Material Thickness Capacity | Up to 200 mm (7.87 inches) |

| Abrasive Type | Garnet, 80-mesh standard |

| Motion Control System | Closed-loop servo with real-time feedback |

| Control Software | LeadCut Pro (ISO and G-code compatible) |

| Footprint | 4,000 mm × 2,500 mm × 1,800 mm |

| Compliance Standards | ISO 9001, MIL-STD-810, CE, ISO 13399 |

Wuxi Lead Precision Machinery continues to support Georgia’s industrial growth through innovation, precision engineering, and a commitment to exceeding the demands of modern fabrication.

Precision Specs & Tolerances

Technical Capabilities: Precision Water Jet Cutting for Georgia Manufacturers

Wuxi Lead Precision Machinery delivers advanced CNC water jet cutting solutions engineered to meet the stringent demands of Georgia’s aerospace, automotive, and heavy equipment sectors. While water jet technology inherently operates as a 3-axis process, our integrated manufacturing ecosystem leverages 5-axis CNC milling, turning, and laser systems to complement complex part production. This holistic approach ensures seamless transition from water jet profiling to secondary precision machining, eliminating supply chain fragmentation for Georgia-based clients requiring multi-process components. Our 90,000 PSI intensifier pumps cut materials up to 200mm thick with zero thermal distortion, accommodating titanium, Inconel, composites, and abrasion-resistant ceramics critical to Georgia’s industrial applications. Material flexibility extends across 500+ certified alloys and non-metals, with digital nesting software optimizing yield for high-value stock.

Precision is non-negotiable in mission-critical Georgia manufacturing. Our water jet systems achieve geometric accuracy through rigid gantry structures, dynamic pressure control, and proprietary taper compensation algorithms. Tolerances are rigorously maintained across material thickness variations, as quantified below:

| Material Thickness | Linear Tolerance | Angular Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| 0–25 mm | ±0.05 mm | ±0.25° | 3.2–6.3 µm |

| 26–75 mm | ±0.08 mm | ±0.35° | 6.3–12.5 µm |

| 76–200 mm | ±0.15 mm | ±0.50° | 12.5–25.0 µm |

All tolerances are validated against ASTM E303-93 standards using calibrated ruby-tipped probes. Critical features undergo 100% post-cut verification via Zeiss CONTURA CMM systems, with inspection reports traceable to NIST standards. Our Georgia clients receive full dimensional analysis packages, including first-article inspection (FAI) per AS9102 requirements for aerospace projects. Material certifications (e.g., EN 10204 3.1) and process capability studies (Cp/Cpk ≥1.67) are standard, ensuring compliance with Georgia’s defense and energy sector regulations.

Wuxi Lead’s quality infrastructure integrates SPC monitoring at every workflow stage—from abrasive garnet analysis to final packaging. Real-time pressure and velocity sensors prevent stream deflection, while automated nozzle calibration maintains kerf consistency within 0.025mm. For Georgia manufacturers facing tight production windows, our 72-hour rapid prototyping service includes digital tolerance validation and material certification, with DDP shipping options to Savannah or Atlanta hubs. This technical rigor, combined with 15 years of ISO 9001:2015-certified production, positions Wuxi Lead as the strategic partner for Georgia enterprises demanding precision without process compromise.

Material & Finish Options

Material selection is a critical step in high-precision CNC water jet cutting, particularly when serving demanding industries such as aerospace, automotive, and industrial equipment manufacturing. At Wuxi Lead Precision Machinery, we specialize in delivering tight-tolerance water jet solutions tailored to the unique properties of aluminum, steel, and titanium—three of the most widely used engineering metals in advanced fabrication.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is commonly used in aerospace components, transportation systems, and electronic enclosures. When processed via CNC water jet cutting, aluminum maintains its structural integrity without heat-affected zones, preserving material properties. For enhanced durability and surface protection, anodizing is a preferred post-processing finish. Anodizing creates a durable oxide layer that improves wear resistance and allows for color coding or branding through dye integration.

Steel, particularly mild and stainless grades, offers superior strength, durability, and cost-effectiveness for heavy-duty applications. Its high density and toughness make it ideal for structural components, tooling, and machinery parts. Water jet cutting excels with steel by eliminating thermal distortion, ensuring clean edges and dimensional accuracy. Unlike laser or plasma cutting, water jet processing does not alter the metallurgical structure, which is essential for parts requiring subsequent welding or forming operations.

Titanium stands out for its exceptional strength-to-density ratio and resistance to extreme environments, including high temperatures and corrosive media. It is extensively used in aerospace, medical implants, and marine engineering. While more challenging to machine due to its low thermal conductivity and high chemical reactivity, titanium benefits significantly from cold-cutting methods like water jet technology. This approach prevents oxidation and micro-cracking, ensuring the integrity of critical components.

Post-cut finishing plays a pivotal role in final part performance. Anodizing, while primarily associated with aluminum, enhances surface hardness, dielectric strength, and aesthetic quality. Type II (sulfuric acid) anodizing is commonly applied for general-purpose protection, while Type III (hardcoat anodizing) delivers maximum wear resistance for industrial applications.

Understanding material behavior under high-pressure abrasion is essential for optimizing cut speed, edge quality, and overall throughput. The table below outlines key material specifications relevant to CNC water jet cutting:

| Material | Thickness Range (mm) | Abrasive Usage (g/min) | Typical Cut Speed (mm/min) | Surface Finish (Ra, µm) | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 1 – 150 | 300 – 500 | 100 – 1200 | 3.2 – 6.3 | Aerospace, Electronics |

| Stainless Steel | 1 – 100 | 400 – 600 | 40 – 500 | 3.2 – 8.0 | Medical, Food Processing |

| Titanium | 1 – 80 | 500 – 700 | 30 – 350 | 3.2 – 7.0 | Aviation, Defense, Medical |

At Wuxi Lead Precision Machinery, we integrate advanced nozzle technology, dynamic pressure control, and intelligent path optimization to ensure superior cutting performance across all material types. Our engineering team collaborates with clients to select the optimal parameters and finishing processes, ensuring every component meets stringent quality and performance standards.

Manufacturing Process & QC

Precision Water Jet Production Process: Design to Zero-Defect Delivery

Precision begins with rigorous process control. At Wuxi Lead Precision Machinery, our CNC water jet cutting workflow for Georgia manufacturers integrates advanced engineering with uncompromising quality protocols across three phases. This ensures dimensional accuracy, material integrity, and zero-defect outcomes for aerospace, automotive, and industrial clients across the Peach State.

The Design Phase starts with collaborative engineering. Our team reviews client CAD files against Georgia-specific material availability and application requirements—accounting for factors like Savannah’s coastal humidity affecting abrasive flow. We optimize nesting using Hypertherm ProNest software to maximize yield on Georgia-sourced aluminum, titanium, or composite sheets while validating kerf width and taper compensation. Material science input is critical; for instance, cutting carbon fiber for Atlanta aerospace suppliers requires adjusted pressure to prevent delamination. Only after full simulation and client sign-off do we proceed.

Prototyping executes the first physical validation. A single-part trial run on our 90,000 PSI OMAX MAXIEM system verifies all design parameters. We measure edge squareness, surface roughness (Ra), and dimensional stability using Zeiss CMMs, comparing results against the digital twin. Any deviation—such as micro-chipping in thick stainless steel plates common in Macon fabrication—triggers immediate recalibration. This phase includes abrasive consumption analysis to minimize waste, a priority for Georgia facilities focused on sustainable operations. Client approval of the prototype is mandatory before scaling.

Mass Production deploys our zero-defect framework. Each run begins with automated calibration checks on pump pressure, nozzle alignment, and abrasive feed consistency. Real-time monitoring via LeadSmart IoT sensors tracks cutting speed deviations exceeding ±0.05 mm, halting production instantly if tolerances drift. For high-volume orders like Atlanta HVAC component batches, we implement sequential in-process inspections at 500-part intervals. All parts undergo final validation against ASME Y14.5 standards, with full traceability from raw material lot to finished piece. This closed-loop system eliminates scrap costs—a critical advantage for Georgia manufacturers facing tight project margins.

Critical Water Jet Specifications for Georgia Applications

| Parameter | Specification | Georgia Application Note |

|---|---|---|

| Max Material Thickness | 200 mm (8″) stainless steel | Ideal for Savannah shipbuilding structural cuts |

| Positioning Accuracy | ±0.05 mm | Meets Atlanta aerospace bracket tolerances |

| Surface Roughness (Ra) | 1.6–6.3 μm | Suitable for visible medical parts in Augusta |

| Abrasive Consumption | 0.5 kg/min (optimized) | Reduces operational costs for Dalton carpet tooling |

| Max Cutting Speed | 1,200 mm/min (thin materials) | Accelerates production for Columbus automotive molds |

Zero defects isn’t aspirational—it’s operational. By embedding quality at every stage, Wuxi Lead ensures Georgia manufacturers receive parts that fit, function, and comply on the first delivery. Contact our Atlanta technical team to integrate this process into your supply chain.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Water Jet Cutting Solutions

When it comes to high-precision CNC water jet cutting in Georgia and beyond, manufacturers demand reliability, accuracy, and speed. At Wuxi Lead Precision Machinery, we deliver advanced water jet cutting solutions engineered for performance in demanding industrial environments. Our systems combine cutting-edge technology with robust construction, enabling seamless integration into your production workflow—whether you’re processing aerospace-grade titanium, thick steel plates, or delicate composites.

Our CNC water jet cutting machines are designed with precision motion control, high-pressure pumping systems, and intelligent software interfaces that ensure micron-level accuracy across every cut. With decades of engineering expertise and a global footprint, we have become a trusted partner for manufacturers seeking to optimize throughput, reduce material waste, and maintain consistent quality.

We understand that every manufacturing operation has unique requirements. That’s why our team works closely with your engineers to tailor system configurations—adjusting cutting pressure, nozzle design, abrasive delivery, and motion parameters—to match your specific materials and production goals. From single-axis profiling to complex 3D contouring, our machines handle the full spectrum of industrial applications with ease.

Our commitment extends beyond equipment delivery. We provide comprehensive technical support, on-site installation guidance, operator training, and ongoing maintenance services to ensure your investment performs at peak efficiency for years to come. With localized support networks and responsive remote diagnostics, downtime is minimized and productivity maximized.

For companies in Georgia exploring next-generation water jet cutting technology, partnering with Wuxi Lead Precision Machinery means access to scalable, future-ready manufacturing solutions. We support job shops, heavy industry, and OEMs with systems that grow with your capacity needs and adapt to evolving market demands.

Explore the technical capabilities of our flagship CNC water jet cutting platform below.

| Specification | Detail |

|---|---|

| Maximum Cutting Pressure | 60,000 psi (4,137 bar) |

| Cutting Table Size (Standard) | 4 ft × 8 ft (1,220 × 2,440 mm) |

| Custom Table Options | Up to 16 ft × 32 ft (4,880 × 9,760 mm) |

| Positioning Accuracy | ±0.005 inches (±0.13 mm) |

| Repeatability | ±0.003 inches (±0.08 mm) |

| Material Thickness Capacity | Up to 12 inches (305 mm) |

| Compatible Materials | Steel, aluminum, composites, stone, glass, ceramics, rubber |

| Control System | Siemens or Delta CNC with intuitive HMI |

| Abrasive Delivery | Closed-loop metering for consistent flow |

| Pump Type | Direct Drive or Intensifier (user-selectable) |

To learn more about how Wuxi Lead Precision Machinery can elevate your manufacturing capabilities in Georgia, contact us today. Our engineering team is ready to discuss your project requirements, provide technical documentation, or arrange a virtual demonstration.

Email us at [email protected] to start the conversation. Let Lead Precision be your partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.