CNC Turned Parts Supplier in China

CNC turned parts are an excellent choice for both standard and high-precision applications.

These components are reliable and cost-effective, making them a great option for many industries.

Whether you need a custom prototype or a mass-produced part, CNC turning is a versatile process that you should consider.

Characteristics of CNC Turned Parts

The standard profile of a CNC turned part is symmetrical because it is rotated during shaping.

This makes this machining process well-suited for round or cylindrical parts.

However, some features can be asymmetrical depending on available machinery and cutting tools.

CNC turned components are formed from tubes or solid bars but parts with very large or very small diameters may not be compatible.

Operations for Producing CNC Turned Parts

Different turning operations can be used on the workpiece depending on your design. This requires the use of different tools. Common turning operations include:

CNC turning allows you to combine multiple operations to produce parts with complicated features. With live tooling capabilities, even more operations can be performed on the workpiece without moving it. This is important if you need a precision turned part.

The workpiece is rotated while a single-point cutting tool moving parallel to it removes material from the side. This operation is used to produce features such as steps and chamfers.

The cutting tool removes a very thin layer of material to create a smooth surface finish.

A drill bit is used to cut a hole along the axis of the workpiece.

A boring tool is used to enlarge drilled holes or add features such as steps and chamfers inside them.

A single-point cutting tool is used to form threads on the outer surface of the workpiece.

A tool called a tap is used to cut internal threads in the workpiece.

Material Options For CNC Turned Parts

You can get CNC turned parts made from a wide range of materials including metals such as stainless steel, brass, and titanium, and non-metals such as PTFE, nylon, and acrylic.

To pick the right material for your precision turned part, you’ll need to consider its properties and cost.

Some materials are more challenging to machine and this can affect cost and lead times.

For example, brass turned parts cost less than titanium parts and can be machined faster.

CNC Turned Parts For Different Industries

CNC turned parts have proven their worth in many applications. They can be used for simple consumer goods such as tool handles and door knobs or in high-precision machines. Common applications for these parts in different industries include:

Automotive: Parts with cylindrical profiles such as pulleys, camshafts, and pins.

Medical: Dental implants, spinal implants, and high-precision parts for diagnostic and surgical instruments.

Oil and Gas: Valves, couplings, and fittings for hydraulic machinery.

Energy Generation: Shafts, rotors, and generator components.

Heavy industry: Gears, pulleys, and flanges.

CNC precision turning is also used to make parts for aerospace, robotics, and other industries on the bleeding edge. It can achieve the accuracies you need in such applications and can also form parts from high-performance materials.

Lead Precision Machinery’s Capabilities

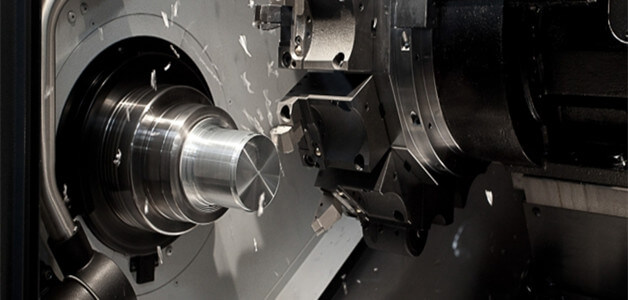

At Lead Precision Machinery, we are uniquely positioned to provide you with CNC turned parts of exceptional quality at competitive prices. We use advanced machinery including Okuma Twin Spindle Lathes and Mazak Quick CNC Lathes so you can enjoy benefits such as:

Exceptional roundness and concentricity – up to ±0.005mm tolerances

Superior surface finishes – up to Ra0.4

Wide size range – 1mm to 300mm workpiece diameter

Diverse material options including brass, stainless steel, titanium, Teflon, polycarbonate, and ABS.

Contact us for a free quote today and see why we should be your number one CNC turned parts supplier.

What are CNC Turned Parts?

CNC turned parts are produced by a process called CNC turning.

In this machining process, the workpiece is held and rotated in a lathe while being shaped by a cutting tool.

The process is controlled by instructions generated by a computer hence the name, Computer Numerical Control (CNC) turning.

This method of control allows the production of parts with tighter tolerances and unmatched consistency.

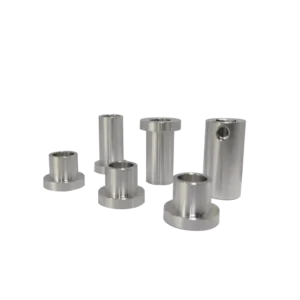

Some common CNC turned components you’ll see are bushings, pins, shafts, and lead screws.