Technical Contents

Engineering Guide: Cnc Steel Fabrication

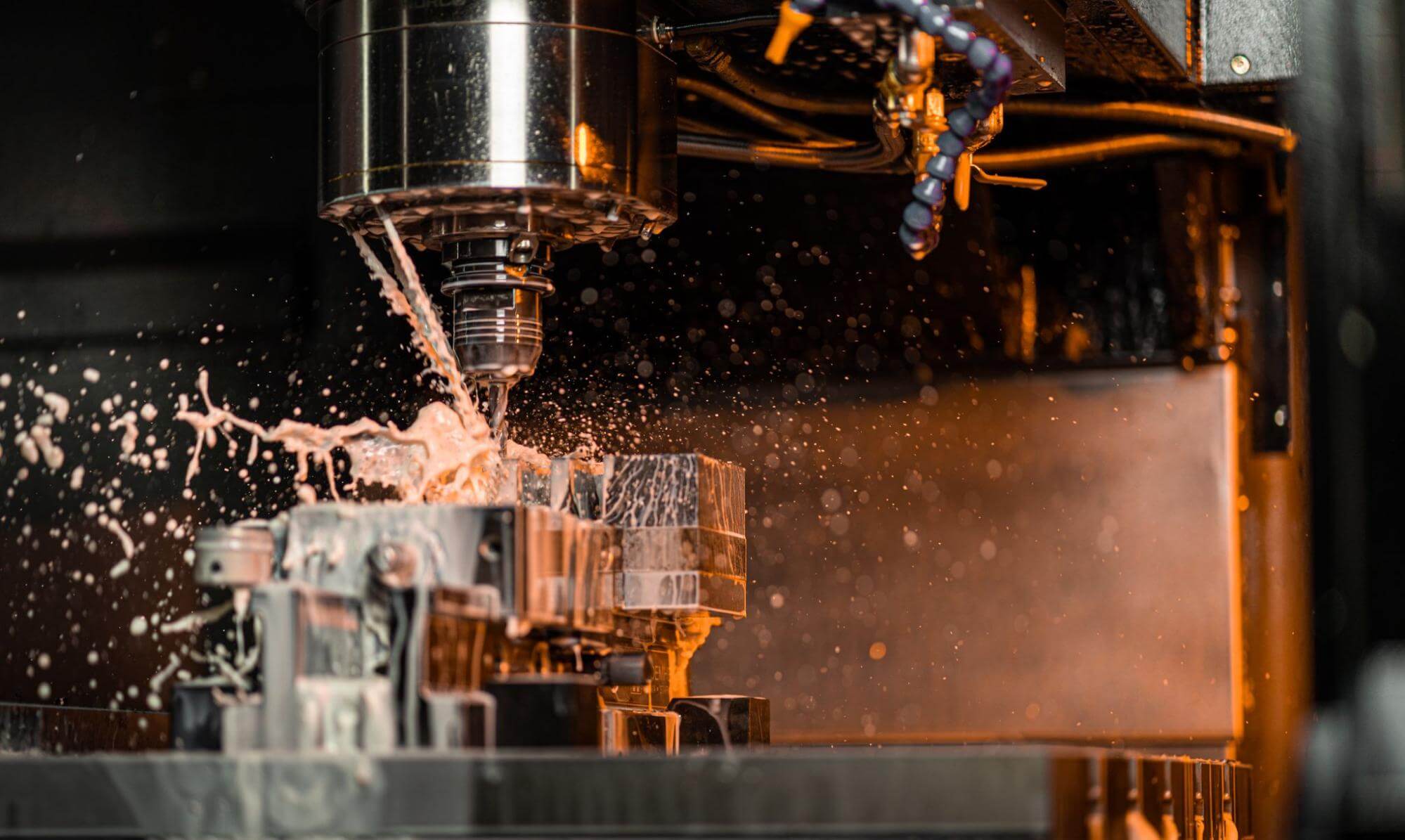

Engineering Insight: CNC Steel Fabrication – The Role of Precision in High-Performance Manufacturing

In the realm of advanced manufacturing, CNC steel fabrication stands as a cornerstone of modern industrial capability. The integration of computer numerical control (CNC) technology into steel processing has redefined the boundaries of accuracy, repeatability, and efficiency. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a technical specification—it is a foundational requirement for performance, safety, and reliability across critical industries.

Steel, as a primary engineering material, offers exceptional strength, durability, and versatility. However, its full potential can only be realized when machined to exacting tolerances. In high-stakes applications such as aerospace, defense, and large-scale infrastructure, even micron-level deviations can lead to catastrophic failures. This is where CNC steel fabrication excels. By leveraging multi-axis machining centers, advanced toolpath algorithms, and real-time monitoring systems, CNC processes ensure that each component conforms precisely to design intent.

At Lead Precision, our expertise in CNC steel fabrication is backed by over a decade of delivering mission-critical components for Olympic-grade equipment and military-grade systems. These projects demand more than standard manufacturing capabilities—they require a culture of precision engineering, rigorous quality control, and deep material science understanding. Our work on Olympic timing and support systems demanded sub-micron repeatability, while our contributions to defense logistics required compliance with MIL-STD-810 and ISO 2768-2 standards. Each project reinforced our commitment to engineering excellence and zero-defect manufacturing.

Precision in CNC steel fabrication begins with material selection and extends through every phase: cutting, milling, turning, drilling, and finishing. Advanced CNC lathes and machining centers operate under tightly controlled environmental conditions to minimize thermal drift. In-process probing and post-process CMM (Coordinate Measuring Machine) verification ensure dimensional integrity. Surface finishes are optimized not only for aesthetics but for functional performance—reducing friction, enhancing fatigue resistance, and ensuring proper fit in high-load assemblies.

Our facility in Wuxi is equipped with state-of-the-art CNC systems capable of handling complex geometries and high-strength steel alloys, including 4140, 4340, and AISI 1045. With automated tool changers, high-pressure coolant systems, and real-time vibration analysis, we maintain consistent quality across both prototyping and high-volume production runs.

The following table outlines key capabilities of our CNC steel fabrication process:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 2000 mm × 1200 mm × 800 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 12,000 RPM |

| Tool Capacity | Up to 30 tools (automatic changer) |

| Materials Processed | Mild Steel, Alloy Steel, Tool Steel, Stainless Steel (300/400 series) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (adjustable) |

| Standards Complied | ISO 2768, MIL-STD-810, GB/T 1804 |

Precision is not an option—it is the standard. At Wuxi Lead Precision Machinery, we engineer every component with the understanding that performance, safety, and trust depend on it.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Steel Fabrication at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in steel fabrication through integrated advanced manufacturing systems. Our core competency lies in transforming high-grade steel alloys into mission-critical components where dimensional integrity directly impacts end-product performance and safety. This capability is anchored in a fully digital workflow, from CAD/CAM programming to final inspection, ensuring repeatability and traceability for aerospace, medical, and energy sector applications demanding the highest standards.

Our 5-axis CNC machining centers represent the pinnacle of multi-directional steel processing. Utilizing simultaneous 5-axis motion under German and Japanese control systems, we eliminate multiple setups and fixture-induced errors inherent in 3-axis processes. This enables the production of monolithic steel structures with intricate contours, deep cavities, undercuts, and compound angles in a single operation. We routinely machine hardened tool steels, stainless alloys, and carbon steels up to 3000mm in length with exceptional surface finishes. The integrated high-torque spindles and rigid bed designs ensure stability during heavy cuts, maintaining precision even in challenging materials and extended production runs. This capability significantly reduces lead times while enhancing geometric accuracy for complex assemblies.

Quality assurance is non-negotiable. Every critical steel component undergoes rigorous validation via our Zeiss and Hexagon Coordinate Measuring Machines (CMM). These metrology-grade systems perform full 3D dimensional analysis against the original CAD model, verifying not just linear dimensions but also complex form, position, and profile tolerances per ISO 1101. Our AS9100-certified inspection protocols include first-article inspection reports (FAIR), in-process checks, and final batch certification. Data from the CMM is directly fed back into our process control loop, enabling real-time adjustments and continuous improvement. This closed-loop system guarantees that every shipped part meets the stringent tolerance requirements specified, providing absolute confidence in fit and function.

The following table details our standard achievable tolerance classes for machined steel components under controlled production conditions. Actual tolerances for specific projects are determined during engineering review based on material, geometry, and functional requirements.

| Tolerance Class | Linear Dimensions (mm) | Angular Dimensions (°) | Surface Roughness (Ra µm) |

|---|---|---|---|

| Fine (f) | ±0.005 | ±0° 10′ | 0.4 – 0.8 |

| Medium (m) | ±0.025 | ±0° 30′ | 1.6 – 3.2 |

| Coarse (c) | ±0.100 | ±1° 00′ | 6.3 – 12.5 |

Wuxi Lead’s technical infrastructure ensures steel fabrication transcends basic machining. Our fusion of 5-axis capability, metrology-grade inspection, and process discipline delivers components where micron-level precision is standard, not exception. This commitment to technical excellence minimizes assembly issues, extends product lifecycles, and provides OEMs with a definitive competitive advantage through superior part quality and reliability. Partner with us for steel fabrication where theoretical tolerances become measurable reality.

Material & Finish Options

Material Selection in Precision CNC Steel Fabrication

Selecting the appropriate material is a critical step in precision CNC steel fabrication, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-tolerance CNC machining of advanced engineering materials, with a particular focus on aluminum, steel, and titanium. Each material offers distinct mechanical properties and is suited for specific industrial applications, from aerospace and automotive to medical and energy sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications where weight reduction is paramount without compromising structural integrity. Common grades such as 6061 and 7075 are routinely used in aerospace frames, electronic enclosures, and transportation components. Aluminum’s natural oxide layer provides inherent corrosion resistance, which can be further enhanced through surface treatments like anodizing.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, wear resistance, and versatility. Alloy steels like 4140 and tool steels such as A2 or D2 are commonly used in tooling, heavy machinery, and high-stress mechanical components. Stainless steel grades, particularly 304 and 316, offer superior corrosion resistance and are preferred in medical devices, food processing equipment, and marine environments. While steel is denser than aluminum, its mechanical robustness makes it indispensable in load-bearing applications.

Titanium, though more expensive and challenging to machine, delivers exceptional performance in extreme conditions. With a strength-to-density ratio surpassing both steel and aluminum, titanium is the material of choice for aerospace, defense, and high-performance automotive sectors. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy, offering excellent fatigue resistance and biocompatibility, making it suitable for surgical implants and jet engine components.

Surface Finishes: Enhancing Performance with Anodizing

Anodizing is a key post-processing technique applied primarily to aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving surface hardness, wear resistance, and corrosion protection. Decorative anodizing also allows for color coding and aesthetic customization, while hard anodizing (Type III) is used in high-wear applications such as hydraulic systems and aerospace fittings. At Wuxi Lead, we offer precision anodizing services tailored to international standards, ensuring consistent coating thickness and adherence.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Key Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | 6061, 7075, 5052 | Aerospace, electronics, transport | Anodizing, powder coating |

| Steel | 7.8 | 655 (4140) | 4140, 304, 316 | Machinery, tooling, structural parts | Zinc plating, passivation |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Gr2, Gr5 (Ti-6Al-4V) | Aerospace, medical, defense | Bead blasting, passivation |

At Wuxi Lead Precision Machinery, our engineering team collaborates with clients to select the optimal material and finish based on operational requirements, environmental exposure, and lifecycle expectations. This integrated approach ensures components meet the highest standards of precision, reliability, and performance.

Manufacturing Process & QC

Precision CNC Steel Fabrication: The Zero Defect Production Process

At Wuxi Lead Precision Machinery, our CNC steel fabrication process is engineered from inception to delivery for uncompromising quality and zero defects. This rigorous methodology ensures every component meets exacting aerospace, medical, and industrial specifications, transforming conceptual designs into flawless physical realities. The journey begins with meticulous digital design engineering, where our CAD/CAM specialists collaborate with clients to optimize geometries for manufacturability. Critical Design for Manufacturability (DFM) analysis identifies potential stress points, material constraints, and machining complexities early, preventing costly revisions. Material selection is validated against performance requirements, environmental factors, and regulatory standards, ensuring the chosen steel alloy—be it 304 stainless, 4140 chrome-moly, or custom tool steel—delivers the required strength, corrosion resistance, and thermal stability.

Prototyping is not a mere formality but a critical validation phase. We produce functional prototypes using the same CNC machining centers and tooling intended for full production. This allows exhaustive dimensional verification via CMM (Coordinate Measuring Machine) and surface finish analysis against blueprint tolerances. Any deviation triggers immediate root-cause analysis and process refinement. Client feedback is integrated iteratively, confirming fit, function, and assembly compatibility before committing to mass production. This stage eliminates assumptions, proving the design’s viability under real-world machining conditions and ensuring the production process blueprint is flawless.

Mass production leverages fully automated CNC machining centers operating under strict statistical process control (SPC). Each machine cell is monitored in real-time for tool wear, thermal drift, and vibration, with automated probes performing in-process gauging at defined intervals. Every component undergoes 100% critical feature inspection via CMM or optical comparators, with data logged for full traceability. Our integrated quality management system cross-references inspection results against the original CAD model, ensuring deviations are detected and corrected before subsequent operations. Final assembly and surface treatment—such as precision passivation or certified anodizing—are conducted in controlled environments to prevent contamination. The result is batch consistency where dimensional accuracy, material integrity, and surface quality consistently meet or exceed zero-defect targets.

The following table outlines core process specifications guaranteeing this outcome:

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (standard) | CMM, Laser Scanning |

| Surface Roughness | Ra 0.4 µm (critical surfaces) | Profilometer, Optical Comparison |

| Material Certification | Full Mill Test Reports (MTRs) | Document Audit, Spectro Analysis |

| Process Capability | Cp/Cpk ≥ 1.67 (all critical dims) | SPC Charting, Real-time Monitoring |

| Traceability | Lot/Batch to Individual Part ID | Barcoding, Digital Production Log |

This closed-loop production system, rigorously applied from initial design through to final shipment, is the foundation of Wuxi Lead’s zero-defect commitment. It transforms precision steel fabrication from a manufacturing task into a guaranteed outcome for the most demanding global industries.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Steel Fabrication

At Wuxi Lead Precision Machinery, we understand that in high-stakes industrial applications, precision, reliability, and consistency are non-negotiable. As a leading provider of precision CNC machining services in China, we specialize in delivering complex steel fabrication solutions tailored to the exacting demands of aerospace, automotive, energy, and advanced manufacturing sectors. Our commitment to engineering excellence and process integrity ensures that every component we produce meets the highest global standards.

When you partner with Lead Precision, you are not just outsourcing a machining task—you are gaining a strategic collaborator with deep technical expertise and a proven track record in solving complex manufacturing challenges. Our state-of-the-art facility in Wuxi is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, high-power fiber laser cutting systems, robotic welding cells, and automated bending lines. This integrated approach allows us to deliver end-to-end CNC steel fabrication—from raw material processing to final assembly—with minimal tolerance deviation and maximum repeatability.

We serve global OEMs and Tier-1 suppliers who demand more than just parts—they require precision-engineered components backed by rigorous quality assurance. Our ISO 9001:2015 and IATF 16949 certifications reflect our adherence to international quality management systems. Every production run undergoes comprehensive inspection using CMMs, laser trackers, and real-time process monitoring to guarantee dimensional accuracy and material integrity.

Our engineering team works closely with your design and R&D departments to optimize manufacturability, reduce lead times, and lower total production costs. Whether you require low-volume prototypes or high-volume serial production, our scalable infrastructure and lean manufacturing principles ensure agile, responsive delivery without compromising on quality.

Below are key technical capabilities that define our CNC steel fabrication services:

| Specification | Capability |

|---|---|

| Material Types | Carbon Steel, Stainless Steel, Alloy Steel, Tool Steel |

| Machining Tolerance | ±0.005 mm |

| Laser Cutting Thickness | Up to 30 mm (fiber laser) |

| CNC Bending Capacity | Up to 12 mm thickness, 3000 mm length |

| Welding Processes | MIG, TIG, Robotic Arc Welding (ISO 3834 certified) |

| Surface Treatments | Powder Coating, Zinc Plating, Passivation, Sandblasting |

| Quality Inspection | CMM, Hardness Testing, Ultrasonic Testing, Visual & Dimensional Reports |

We invite global manufacturers to experience the Lead Precision advantage—where advanced technology, skilled craftsmanship, and customer-centric service converge. Let us support your next project with precision-engineered steel components built to perform.

For technical consultations, quotations, or engineering support, contact us today at [email protected]. Our team responds within 12 business hours to all inquiries. Partner with Wuxi Lead Precision Machinery and elevate your manufacturing outcomes with confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.