Technical Contents

Engineering Guide: Cnc Prototype Services Georgia

Engineering Insight: CNC Prototype Services in Georgia – The Critical Role of Precision

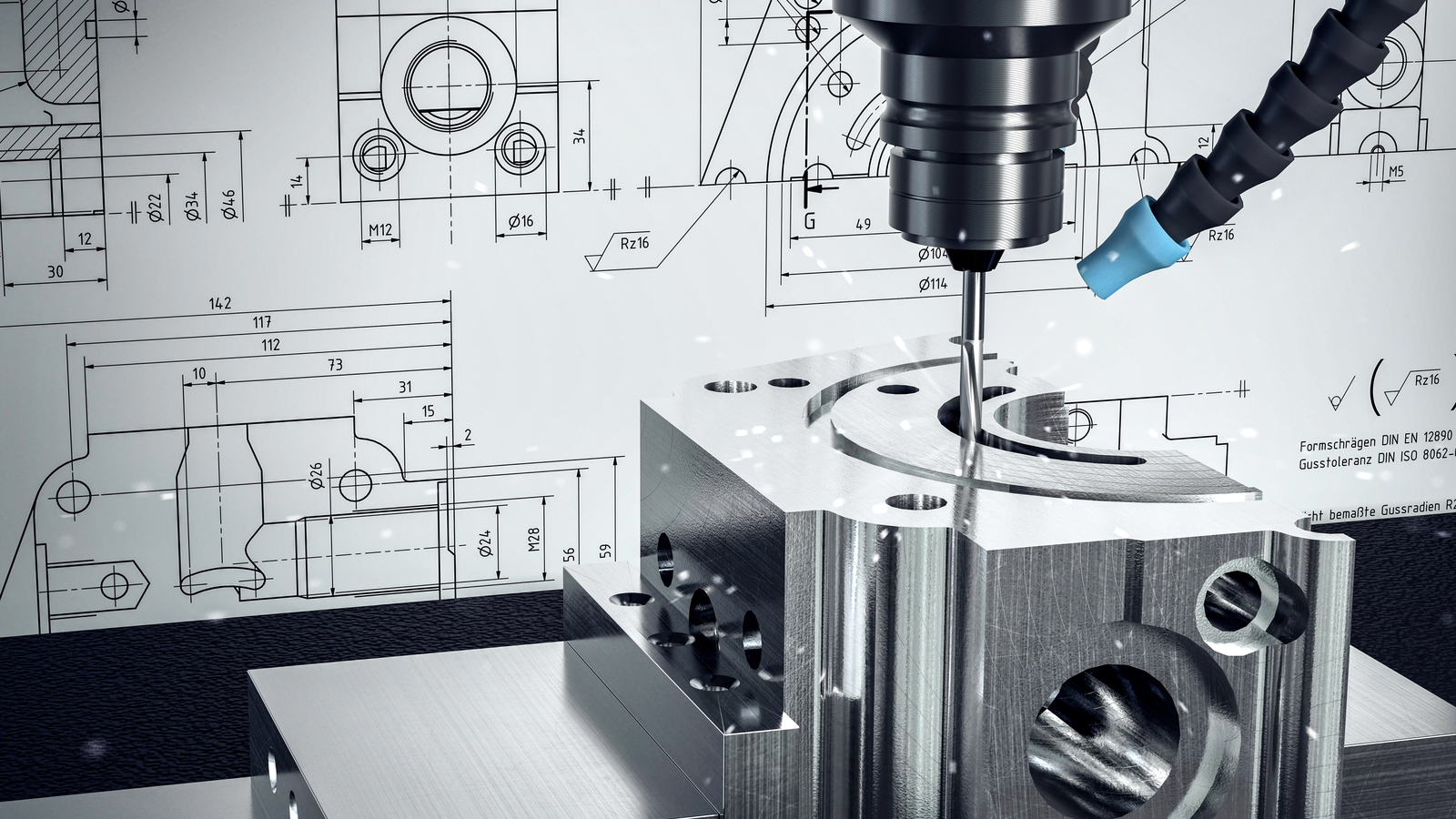

In the evolving landscape of advanced manufacturing, CNC prototype services in Georgia are increasingly sought after by industries demanding rapid development cycles and high-performance components. From aerospace and defense to medical device innovation, the state has become a strategic hub for companies requiring agile, precision-driven prototyping solutions. At the core of every successful prototype lies an uncompromising standard of accuracy—where tolerances measured in thousandths of an inch can determine the functionality, safety, and scalability of a final product.

Precision is not merely a technical specification; it is an engineering philosophy. In prototyping, even minor deviations can propagate through design validation, testing, and eventual production, leading to costly redesigns or system failures. This is especially critical in sectors such as military systems and high-stakes industrial equipment, where performance under extreme conditions is non-negotiable. At Wuxi Lead Precision Machinery, we understand that precision is the foundation upon which trust is built. With over 15 years of specialization in CNC machining, our facility in China has delivered mission-critical components for Olympic-standard equipment and defense-grade systems—applications where failure is not an option.

Our experience in high-reliability environments has shaped a rigorous approach to CNC prototyping. Every process, from material selection to final inspection, is governed by ISO 9001-certified protocols and supported by state-of-the-art 3-, 4-, and 5-axis CNC machines. We utilize advanced metrology tools, including coordinate measuring machines (CMM) and optical comparators, to verify dimensional accuracy and surface integrity. This level of control ensures that prototypes not only meet but exceed the expectations of engineers and project managers in Georgia and beyond.

While local prototyping services offer logistical advantages, global partners like Wuxi Lead bring unparalleled expertise and capacity. By combining rapid turnaround times with deep technical insight, we support Georgia-based innovators in accelerating time-to-market without sacrificing quality. Whether machining titanium aerospace brackets or stainless steel medical housings, our commitment to precision ensures that every prototype performs as intended in real-world conditions.

The future of manufacturing in Georgia depends on access to reliable, high-precision prototyping partners who can scale with demand and uphold the highest engineering standards. Wuxi Lead Precision Machinery stands ready to deliver that capability—backed by proven performance in the world’s most demanding applications.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.005 mm (±0.0002″) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin |

| Max Work Envelope | 1200 x 600 x 500 mm (47 x 24 x 20″) |

| Axis Capabilities | 3-axis, 4-axis, 5-axis CNC milling and turning |

| Lead Times | As fast as 5–7 days for prototypes |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Georgia’s Demanding Prototypes

Wuxi Lead Precision Machinery delivers advanced CNC prototype services meeting the exacting standards required by Georgia’s aerospace, medical, and industrial sectors. Our facility operates at the forefront of precision manufacturing, utilizing integrated multi-axis technology and rigorous quality control to transform complex designs into functional, high-integrity prototypes. This capability is essential for Georgia engineers requiring rapid validation of form, fit, and function before committing to full production tooling.

Central to our service is a modern fleet of 5-axis CNC machining centers, primarily DMG MORI and MAZAK platforms. These systems provide unparalleled geometric complexity handling, enabling the production of intricate organic shapes, deep cavities, and compound angles in a single setup. Eliminating multiple fixturing operations significantly reduces cumulative error, accelerates lead times, and ensures superior surface finish critical for prototype evaluation. Our programming leverages Mastercam and hyperMILL software, optimizing toolpaths for material efficiency and part accuracy across diverse alloys including aluminum 7075-T6, stainless steel 17-4 PH, titanium Ti-6Al-4V, and engineering plastics like PEEK.

Quality assurance is non-negotiable. Every prototype undergoes comprehensive dimensional verification using state-of-the-art Coordinate Measuring Machines (CMMs), specifically Zeiss CONTURA and GLOBAL series units. Our AS9100-compliant inspection process, executed by certified technicians, validates critical features against CAD models with micron-level precision. Digital inspection reports, including full GD&T analysis and point-cloud comparisons, are provided with every shipment, offering Georgia clients complete transparency and confidence in dimensional integrity. This systematic approach ensures prototypes accurately represent final production intent, mitigating downstream design risks.

The achievable precision for prototype components is demonstrable across standard materials. The following table outlines typical tolerance capabilities under controlled manufacturing conditions. Actual tolerances for specific features are determined during engineering review, considering geometry, material, and functional requirements.

| Material Category | Dimensional Tolerance (± mm) | Geometric Tolerance (± mm) | Surface Roughness (Ra µm) |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | 0.010 | 0.015 | 0.8 – 1.6 |

| Stainless Steel (e.g., 303, 17-4 PH) | 0.012 | 0.020 | 1.6 – 3.2 |

| Titanium Alloys (e.g., Ti-6Al-4V) | 0.015 | 0.025 | 1.6 – 3.2 |

| Engineering Plastics (e.g., PEEK, Delrin) | 0.025 | 0.050 | 3.2 – 6.3 |

Our technical infrastructure extends beyond core machining. We integrate high-speed milling for rapid material removal on large prototypes and Swiss-type turning for precision shaft components, ensuring comprehensive capability coverage. Dedicated metrology labs maintain environmental stability, critical for repeatable CMM measurements. This commitment to process control and technical excellence allows Georgia-based innovators to rely on Wuxi Lead for prototypes that perform as expected, accelerating their path from concept to market validation with zero compromise on precision.

Material & Finish Options

Material selection is a critical phase in CNC prototype development, directly influencing performance, durability, and cost-efficiency. For high-precision applications in industries such as aerospace, medical, and advanced manufacturing, understanding the mechanical properties and compatibility of materials like aluminum, steel, and titanium is essential. At Wuxi Lead Precision Machinery, we support clients across global markets—including engineering teams in Georgia seeking reliable CNC prototype services—with expert guidance in material and finish selection tailored to project specifications.

Aluminum is widely favored in prototyping due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly popular for functional prototypes and low-volume production parts, offering good corrosion resistance and weldability. It is ideal for applications where weight reduction is critical without sacrificing structural integrity. For enhanced surface protection and aesthetics, aluminum components are often finished with anodizing. Type II (sulfuric acid) anodizing provides a thin, corrosion-resistant layer with dyeing capability, while Type III (hardcoat) anodizing delivers a thicker, wear-resistant surface suitable for high-stress environments.

Steel, particularly alloy and stainless variants, offers superior strength, hardness, and temperature resistance. 4140 alloy steel is commonly selected for high-stress mechanical components due to its toughness and fatigue resistance, while 303 and 304 stainless steels are preferred in corrosive or sanitary environments such as medical devices or food processing equipment. Although heavier than aluminum, steel’s dimensional stability and durability make it suitable for long-life prototypes and end-use parts. Post-machining treatments such as passivation for stainless steel or black oxide coating enhance corrosion resistance and appearance.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for applications demanding extreme strength-to-density ratios and outstanding corrosion resistance. Common in aerospace and biomedical sectors, titanium is challenging to machine due to its low thermal conductivity and tendency to gall. However, with optimized CNC toolpaths and specialized tooling, Wuxi Lead achieves tight tolerances and superior surface finishes. Titanium does not support conventional anodizing for color, but alternative surface treatments like acid etching or laser marking are effective for identification and corrosion mitigation.

The following table summarizes key properties and applications for these materials:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Recommended Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, heat sinks, UAV components | Type II/III Anodizing, Bead Blast |

| Stainless Steel | 304 / 316 | 505–620 | 8.0 | Medical instruments, food-grade parts | Passivation, Electropolishing |

| Alloy Steel | 4140 | 655 | 7.85 | Shafts, gears, high-stress fixtures | Black Oxide, Zinc Plating |

| Titanium | Ti-6Al-4V (Gr 5) | 900 | 4.43 | Aerospace, implants, racing components | Laser Marking, Acid Etch, Bead Blast |

Selecting the right material and finish ensures your prototype meets functional requirements while streamlining the path to production. Wuxi Lead Precision Machinery combines advanced CNC capabilities with material science expertise to deliver prototypes that perform. For teams in Georgia and beyond, we offer seamless collaboration, rapid turnaround, and full documentation to support your innovation cycle.

Manufacturing Process & QC

Precision CNC Prototype Services: The Zero Defects Production Pathway

At Wuxi Lead Precision Machinery, our CNC prototype services for Georgia manufacturers are engineered around a single, non-negotiable principle: Zero Defects. This commitment begins at the earliest design stage and permeates every phase through to mass production, ensuring your final component meets exact specifications without compromise. We understand that precision failures in prototyping cascade into costly delays and quality issues downstream; our integrated process eliminates this risk.

The journey starts with rigorous design validation. Our engineering team collaborates closely with your designers, utilizing advanced CAD/CAM software to conduct comprehensive manufacturability analysis. We scrutinize geometric complexity, material suitability, and tolerance feasibility before any metal is cut. This proactive review identifies potential stress points, tool access challenges, or tolerance stack-ups that could lead to defects, allowing for immediate design refinement. This critical step ensures the digital model is not just ideal, but perfectly executable on our machinery, forming the bedrock of Zero Defects.

Prototyping is not merely a formality in our process; it is the definitive validation stage. Leveraging our high-precision 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes using your specified production-grade materials. Each prototype undergoes stringent in-process and final inspection against the original CAD data using calibrated CMMs, optical comparators, and surface roughness testers. Dimensional integrity, material properties, and functional performance are verified. Crucially, any deviation triggers an immediate root cause analysis and corrective action loop – adjusting toolpaths, fixturing, or process parameters – before progression. This iterative, data-driven prototyping guarantees the design functions as intended in the real world and that the manufacturing process is inherently capable.

The transition to mass production is seamless because the process is already proven. The validated CNC programs, optimized tooling strategies, and refined inspection protocols developed during prototyping are directly deployed. Our production cells operate under strict ISO 9001:2015 quality management systems, with real-time process monitoring and SPC (Statistical Process Control) ensuring consistent output. Every component undergoes defined inspection points, with full traceability from raw material to finished part. This systematic approach, born from the prototype phase, locks in dimensional accuracy and surface quality, making Zero Defects an operational reality, not just a target.

Wuxi Lead Precision Capability Specifications

| Parameter | Capability Range | Typical Tolerance (mm) | Lead Time (Prototype) |

|---|---|---|---|

| Materials | Aluminum, Steel, Stainless, Titanium, Brass, Plastics | ±0.005 (Machining) | 5-10 Working Days |

| Max Work Envelope | 1200 x 800 x 600 mm | ±0.01 (Assembly) | |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (Machined) | ||

| Quality Standard | ISO 9001:2015 Certified, Full CMM Reporting |

This disciplined Design-Prototype-Production pathway, executed with uncompromising precision and backed by our global supply chain reliability, delivers Georgia manufacturers the confidence that their CNC prototypes and subsequent production runs meet the highest standards of quality and performance, defect-free.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Prototype Services from China to Georgia

When precision matters, global manufacturers in Georgia and across North America turn to Wuxi Lead Precision Machinery for high-performance CNC prototype services. As a trusted leader in advanced CNC machining, we specialize in delivering rapid, accurate, and scalable prototype solutions that accelerate product development cycles and reduce time-to-market. Our state-of-the-art facility in Wuxi, China, is equipped with advanced 3-, 4-, and 5-axis CNC machines, allowing us to produce complex geometries with micron-level accuracy. Whether you are an aerospace innovator, medical device developer, or industrial equipment manufacturer, our engineering team collaborates closely with yours to ensure prototypes meet exact design specifications and functional requirements.

At Lead Precision, we understand that prototyping is more than just part production—it’s a critical phase in validating design, testing performance, and securing stakeholder approval. That’s why we combine cutting-edge technology with rigorous quality control. Every prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers to guarantee compliance with ISO 9001:2015 standards. Our materials expertise spans aluminum, stainless steel, titanium, brass, and high-performance engineering plastics, enabling us to support a wide range of applications and industries.

Our global logistics network ensures seamless delivery from China to Georgia and beyond, with typical turnaround times as fast as 5–7 days for machined prototypes. We manage every detail—from DFM analysis and material sourcing to packaging and customs documentation—so you receive production-ready parts on schedule and within budget.

Below are key specifications that define our CNC prototype capabilities:

| Specification | Detail |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling, CNC Turning |

| Tolerances | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 600 x 500 mm (47 x 23.6 x 19.7 in) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr5), Brass, PEEK, Delrin |

| Finishes | As-Machined, Anodizing (Type II & III), Powder Coating, Passivation, Bead Blasting |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAIR) Reports |

| Lead Time | 5–10 business days (standard), expedited options available |

By partnering with Wuxi Lead Precision Machinery, Georgia-based manufacturers gain a strategic advantage through precision, speed, and cost efficiency. We don’t just deliver parts—we deliver confidence in your product’s performance.

Contact us today to begin your next prototype project. Email our engineering team at [email protected] for a fast response, free quote, and expert consultation. Let Lead Precision be your trusted partner in turning concepts into high-precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.