Technical Contents

Engineering Guide: Cnc Prototype Service

Engineering Insight Precision in CNC Prototype Services

Precision is non-negotiable in CNC prototyping. Early-stage prototypes validate design integrity, material behavior, and functional performance under real-world conditions. A tolerance deviation of ±0.005 mm can cascade into catastrophic failures in final production—especially in aerospace, medical, or defense applications where safety and compliance are paramount. At Wuxi Lead Precision Machinery, we treat every prototype as a mission-critical component, not merely a proof-of-concept. Our engineering philosophy centers on eliminating the “prototype gap”—the discrepancy between initial models and production-ready parts. This requires marrying advanced metrology with deep process expertise to ensure dimensional accuracy, surface finish consistency, and material properties align with end-use requirements from day one.

Our commitment to precision is forged in high-stakes environments. We have delivered zero-defect prototypes for Olympic-caliber sporting equipment, where micron-level tolerances directly impact athlete performance and safety. Similarly, our work with military subcontractors demands adherence to MIL-STD-883 and AS9100 standards, where failure is not an option. These projects validate our ability to manage thermal drift, tool deflection, and material anisotropy—factors often overlooked by standard service providers. By simulating production-scale stresses during prototyping, we de-risk your path to volume manufacturing, reducing costly redesigns and accelerating time-to-market.

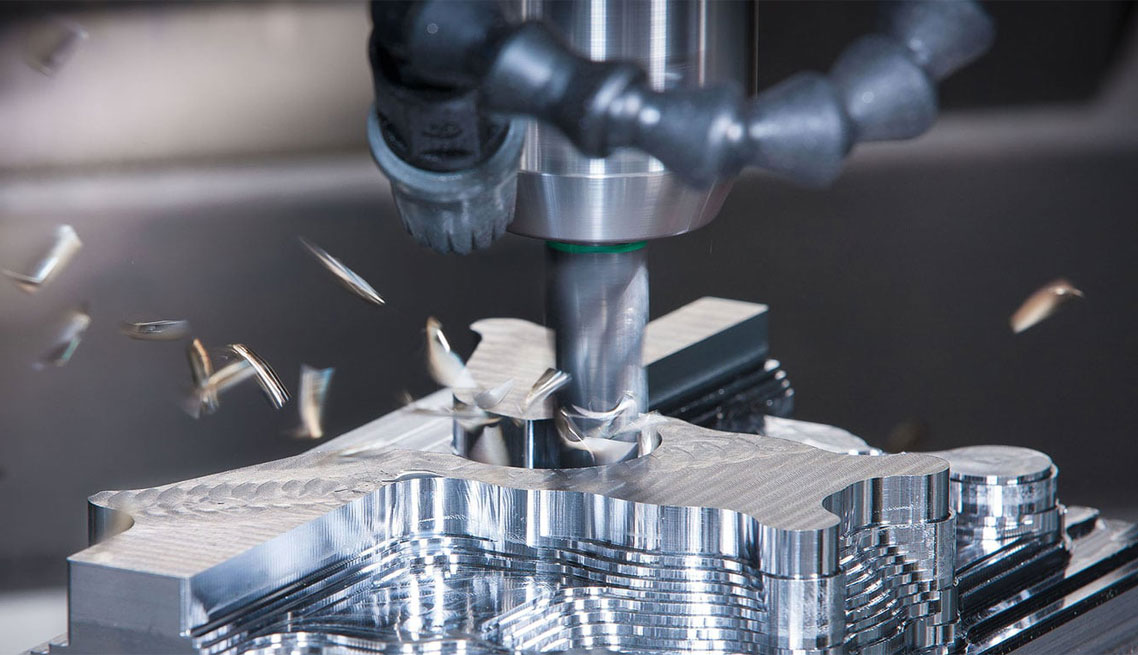

Wuxi Lead’s technical infrastructure enables this rigor. Our facility integrates 5-axis milling, Swiss-type turning, and multi-spindle machining centers with real-time in-process gauging. All equipment operates within ISO Class 7 cleanrooms, and our QA team employs Zeiss CMMs, optical comparators, and surface roughness testers calibrated to NIST standards. Below are core capabilities defining our prototype service:

| Specification | Capability | Application Impact |

|---|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm | Ensures fit/function in high-complexity assemblies |

| Material Range | Titanium, Inconel, PEEK, 7075-T6 Aluminum, Medical-Grade Stainless | Validates material performance under operational loads |

| Max Work Envelope | 1,200 x 800 x 650 mm | Supports large-scale structural prototypes |

| Surface Finish | Ra 0.4 µm to Ra 0.8 µm (as-machined) | Meets aerospace and medical biocompatibility requirements |

| Lead Time | 5–10 business days (complex geometries) | Accelerates design iteration cycles |

Precision prototyping transcends technical execution—it demands anticipatory engineering. We collaborate with clients during DFM analysis to identify potential manufacturability pitfalls before metal is cut, leveraging 30+ years of cross-industry insights. When your prototype performs identically to the production part, you eliminate guesswork and inject confidence into every development phase. For Wuxi Lead, precision isn’t a metric; it’s the foundation of trust. Contact our engineering team to discuss how Olympic and military-grade rigor can secure your next innovation.

Precision Specs & Tolerances

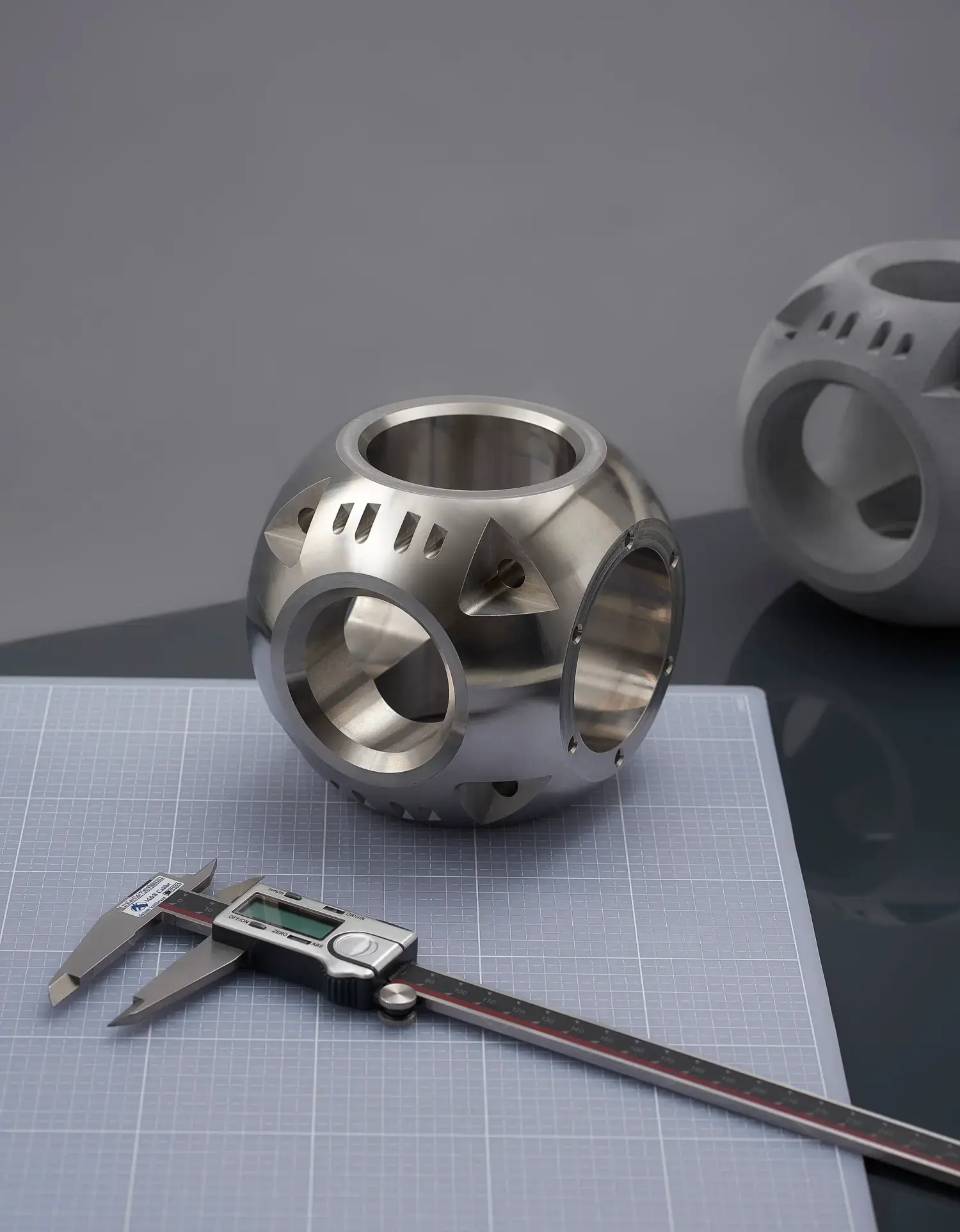

Wuxi Lead Precision Machinery delivers advanced CNC prototype services tailored for industries requiring extreme precision, rapid turnaround, and uncompromising quality. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with high accuracy and surface consistency. These multi-axis systems allow simultaneous cutting from five different directions, minimizing setup changes and ensuring tight tolerances across intricate features. This capability is particularly critical for aerospace, medical, and industrial automation components where design complexity and functional performance are tightly coupled.

Our machining centers are operated by seasoned CNC programmers and machinists who utilize advanced CAM software to optimize tool paths, reduce cycle times, and maintain dimensional stability. Each prototype is machined from a single block of material, ensuring structural integrity and eliminating assembly-related inaccuracies. We support a broad range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steel (303, 316), titanium, brass, and high-performance plastics such as PEEK and Delrin. This material versatility, combined with our 5-axis precision, allows us to meet the demanding requirements of functional prototypes and pre-production validation models.

Quality assurance is integrated at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM), providing traceable, high-resolution metrology data. Our CMM inspection process ensures compliance with GD&T standards and customer-specified tolerances. Additionally, first article inspection reports (FAIR) and full inspection documentation are available upon request, supporting regulatory compliance and design validation.

To maintain consistency and repeatability, our facility adheres to ISO 9001 standards, with calibrated equipment and controlled environmental conditions. From initial design review to final delivery, our engineering team collaborates closely with clients to resolve manufacturability issues and optimize part performance.

The following table outlines the standard tolerances we consistently achieve across various dimensional characteristics:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 300 mm |

| Hole Diameter | ±0.025 mm | ±0.01 mm | Reamed/bored |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | GD&T compliant |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm surface |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined/optional polish |

| Angular Features | ±0.1° | ±0.05° | 5-axis simultaneous |

These specifications reflect our commitment to precision and repeatability, ensuring that every prototype meets functional and aesthetic requirements. Wuxi Lead Precision Machinery is equipped to handle low-volume, high-mix production runs with the same rigor applied to individual prototypes, making us a trusted partner for engineering teams worldwide.

Material & Finish Options

Strategic Material Selection for High-Fidelity CNC Prototypes

Material choice fundamentally dictates prototype performance, manufacturability, and alignment with end-use requirements. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, mechanical properties, and cost efficiency for rapid iteration. Aluminum alloys dominate prototyping for their optimal strength-to-weight ratio, exceptional thermal conductivity, and swift machining cycles. Steel variants provide critical structural integrity for load-bearing applications, while titanium delivers unparalleled strength and corrosion resistance in extreme environments, albeit with extended lead times due to challenging work hardening characteristics. Surface finishes, particularly anodizing, further enhance functionality and aesthetics but are material-dependent. Below are key specifications guiding optimal selection.

| Material | Common Grades | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance | Typical Prototype Lead Time |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310-570 | Excellent (A) | Good | 3-5 days |

| Steel | 303, 4140, 1018 | 400-1000+ | Moderate (B-C) | Fair (varies) | 5-7 days |

| Titanium | Ti-6Al-4V (Grade 5) | 900-1000 | Poor (D) | Excellent | 7-10 days |

Aluminum 6061-T6 remains the prototyping industry standard for enclosures, brackets, and thermal components. Its low density accelerates machining, reduces tool wear, and supports tight tolerances down to ±0.005mm. Anodizing—specifically Type II (sulfuric acid) or Type III (hard coat)—is exclusively viable for aluminum, providing 15-25μm wear-resistant layers in custom colors while maintaining electrical insulation. Steel prototypes, often using free-machining 303 stainless, suit high-stress mechanical assemblies but require post-machining passivation to prevent rust. Avoid anodizing steel; electropolishing or powder coating are superior alternatives. Titanium excels in aerospace or medical prototypes demanding biocompatibility and 40% higher strength than steel at half the weight. However, its low thermal conductivity necessitates reduced cutting speeds, increasing costs by 2-3x versus aluminum. Anodizing titanium is impractical; plasma spray or laser marking are preferred for surface enhancement.

Critical considerations extend beyond raw properties. Aluminum’s thermal stability minimizes deformation during high-speed machining, ensuring dimensional accuracy in complex geometries. Steel’s magnetic properties may interfere with sensitive electronics testing, requiring non-magnetic alternatives like 316 stainless. Titanium’s reactivity mandates dedicated tooling to avoid contamination—a capability our multi-axis CNC systems rigorously maintain. Always validate material-process compatibility: anodizing requires uniform wall thickness to prevent current density variations, and titanium’s flammability demands strict chip evacuation protocols.

Material selection is not merely technical—it’s strategic. Choosing aluminum accelerates time-to-test by 30-50% versus steel, while titanium’s longevity justifies investment for mission-critical validation. Partner with Wuxi Lead to match your prototype’s functional demands with material science rigor, ensuring seamless transition from concept to production. Our engineers provide DFM analysis to optimize material utilization, minimizing waste without compromising fidelity.

Wuxi Lead Precision Machinery

Precision Engineered. Performance Validated.

Manufacturing Process & QC

The journey from concept to final product at Wuxi Lead Precision Machinery follows a rigorously controlled production process designed to ensure zero defects and uncompromising quality in every component. Our approach integrates precision engineering with advanced manufacturing technologies across three key phases: Design, Prototyping, and Mass Production.

In the Design phase, our engineering team collaborates closely with clients to analyze technical drawings, 3D CAD models, and functional requirements. Utilizing advanced simulation software, we conduct manufacturability assessments (DFM) to optimize geometry, material selection, and tolerances. This proactive evaluation identifies potential production challenges early, minimizing risks and ensuring the design is both efficient and scalable. Every specification is validated for compliance with international standards, including ISO 2768 and GD&T protocols.

Prototyping is the critical validation stage where theoretical designs become tangible. Using state-of-the-art 3-, 4-, and 5-axis CNC machining centers, we produce high-precision prototypes in the actual production-grade materials—aluminum, stainless steel, titanium, or engineering plastics. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Functional testing is performed to verify fit, form, and performance under real-world conditions. Feedback from this stage drives any necessary design refinements before transitioning to full-scale production.

Mass Production is executed with the same precision as prototyping, leveraging automated CNC cells, in-process gauging, and real-time monitoring systems to maintain consistency. Our production floor operates under strict ISO 9001-certified quality management protocols, with full traceability on every batch. Statistical process control (SPC) is employed to detect and correct deviations instantly, ensuring zero defects. Components are packaged using industry-standard protective methods to prevent damage during transit.

Throughout all stages, communication remains transparent. Clients receive detailed inspection reports, first-article submissions (FAI), and production updates to ensure alignment with project goals. Our integrated workflow reduces time-to-market while guaranteeing that every part meets the highest standards of accuracy and reliability.

Below are the key technical specifications supported across our CNC prototype and production services:

| Parameter | Capability |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Spindle Speed | Up to 24,000 rpm |

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on geometry) |

| Surface Roughness | Ra 0.4 μm to Ra 3.2 μm (standard) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin |

| Finishes | As-machined, Anodizing (Type II & III), Plating, Passivation, Powder Coating |

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we deliver precision-engineered solutions built on a foundation of quality, consistency, and technical excellence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical CNC Prototyping

In the high-stakes arena of advanced product development, your prototype is not merely a model—it is the tangible validation of engineering intent. At Wuxi Lead Precision Machinery, we engineer CNC prototypes to the exacting standards demanded by aerospace, medical device, and semiconductor industries where failure is not an option. Our ISO 9001:2015-certified facility in Wuxi integrates 5-axis milling, precision turning, and Swiss-type machining with rigorous in-process metrology, ensuring every component meets your functional and dimensional requirements on the first iteration. We eliminate the guesswork inherent in conventional prototyping through closed-loop manufacturing processes that guarantee sub-micron repeatability and material integrity from aluminum 7075-T6 to Inconel 718 and PEEK.

Our engineering team collaborates with your design staff from DFM analysis through final inspection, identifying potential manufacturability risks before metal is cut. This proactive approach reduces revision cycles by up to 40% compared to standard service providers. We deploy calibrated CMMs, optical comparators, and surface roughness testers against your specifications, delivering full first-article inspection reports traceable to NIST standards. When your project requires tolerances tighter than ±0.0002″ or complex geometries with undercuts and micro-features, our Haas and DMG MORI platforms—paired with master machinists averaging 15+ years’ experience—deliver production-intent quality at prototype speed.

Technical Capabilities Summary

| Specification | Capability Range | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.0001″ (2.5µm) standard | Aerospace hydraulic components |

| Max Work Envelope | 2000 x 1000 x 800 mm | Medical imaging subsystems |

| Material Expertise | Titanium, Inconel, PEEK, 4140PH, BeCu | Semiconductor chamber parts |

| Lead Time | 5-10 business days (complex parts) | Accelerated product validation |

| Surface Finish | Ra 0.4µm (16µin) achievable | Fluid-critical sealing surfaces |

Choosing a prototype partner is a strategic decision that impacts time-to-market, regulatory compliance, and ultimate product performance. Wuxi Lead Precision Machinery operates as an extension of your engineering department—providing not just machining, but actionable insights that prevent downstream production issues. Our clients consistently achieve first-pass success in qualification testing because we treat prototypes as functional production units, not disposable models.

Do not compromise your innovation cycle with generic machining services. Contact our engineering team directly at [email protected] with your 3D CAD files and requirements. We will respond within 4 business hours with a detailed manufacturability assessment, timeline, and fixed-price quotation. Specify your target tolerance class and material certification needs to expedite the review. For urgent projects requiring 72-hour turnaround, reference code LEAD-URGENT in your subject line. Let us transform your design intent into a physically validated reality—engineered for performance, certified for confidence. Your breakthrough prototype awaits precise execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.