Technical Contents

Engineering Guide: Cnc Precision Machining Texas

Engineering Insight: The Critical Role of Precision in CNC Machining for Texas Manufacturing

In the high-stakes environment of industrial manufacturing, precision is not merely a performance metric—it is a foundational requirement. In sectors such as aerospace, defense, energy, and advanced automation, components must meet exacting tolerances to ensure operational safety, reliability, and compliance. This demand for precision is particularly acute in Texas, a state that serves as a hub for oil and gas, space exploration, and military technology. As such, the selection of a CNC machining partner capable of delivering micron-level accuracy is essential for any engineering team aiming to maintain a competitive edge.

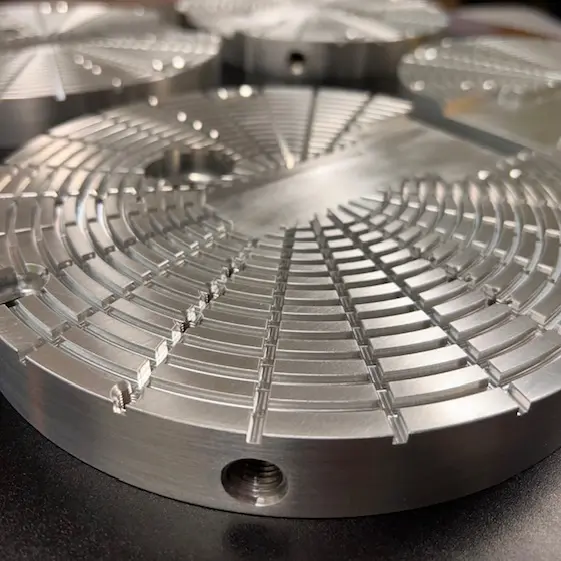

CNC precision machining in Texas must contend with increasingly complex geometries, stringent material specifications, and aggressive production timelines. The challenge lies not only in achieving tight tolerances—often within ±0.0002 inches—but in consistently reproducing those results across batches while maintaining surface integrity and dimensional stability. This level of consistency requires more than advanced equipment; it demands deep engineering expertise, rigorous quality control systems, and a culture of continuous process optimization.

At Wuxi Lead Precision Machinery, we bring over 15 years of experience in delivering mission-critical components to some of the world’s most demanding industries. Our work has supported Olympic-level sports technology, where marginal gains determine podium finishes, and military-grade defense systems, where failure is not an option. These projects have honed our ability to manage extreme precision under pressure, using multi-axis CNC machining, advanced metrology, and proprietary process validation protocols.

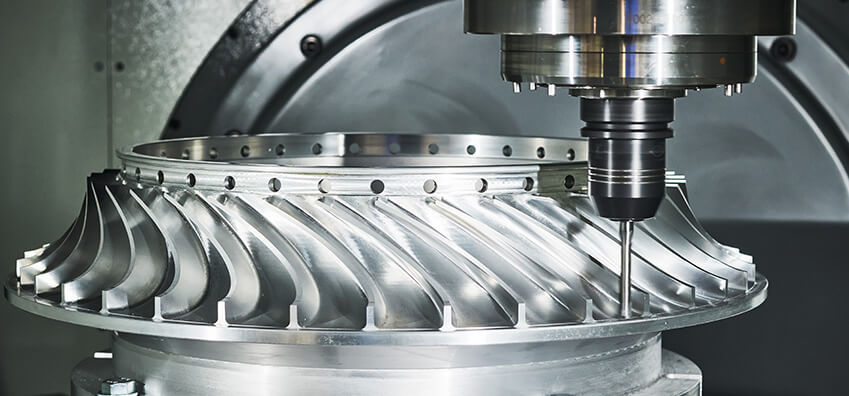

Our engineering team applies this same rigor to every project, whether producing turbine housings for Texas-based energy firms or structural components for aerospace platforms. We understand that in precision machining, variables such as tool deflection, thermal expansion, and material anisotropy must be actively managed through real-time monitoring and adaptive machining strategies. This systems-level approach ensures that every part meets or exceeds design intent.

To illustrate the capabilities required for high-end CNC work, the following table outlines key specifications that define precision machining performance:

| Specification | Capability | Industry Standard | Application Relevance |

|---|---|---|---|

| Positional Accuracy | ±0.0001 inches | ±0.001 inches | Critical for alignment in aerospace assemblies |

| Surface Finish (Ra) | 0.4 μm (16 μin) | 1.6–3.2 μm | Essential for hydraulic and sealing surfaces |

| Material Range | Aluminum to Inconel, Titanium, PEEK | Varies by shop | Supports diverse industrial needs |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Typically smaller | Enables large, complex components |

| Repeatability (CpK ≥ 1.67) | Achieved across 10+ batches | CpK ≥ 1.33 | Ensures long-term consistency |

Precision is not an isolated attribute—it is the result of integrated engineering excellence. For Texas manufacturers operating at the edge of performance, partnering with a globally proven provider like Wuxi Lead Precision Machinery ensures that every component meets the highest standards of quality, reliability, and technical sophistication.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Texas Industry Demands

Wuxi Lead Precision Machinery delivers advanced CNC machining solutions engineered to meet the rigorous demands of Texas aerospace, energy, and medical device manufacturers. Our core strength lies in high-precision 5-axis CNC milling and turning centers, enabling the production of complex geometries with exceptional accuracy and reduced lead times. These systems feature large work envelopes up to 1,200 x 800 x 600 mm and high-speed spindles (24,000 RPM), accommodating intricate components from single setups. This eliminates cumulative error from multiple fixturing stages, critical for Texas clients requiring monolithic structural parts or fluid-path components where alignment integrity is non-negotiable. Our Haas and DMG MORI platforms utilize adaptive control and thermal compensation systems, ensuring dimensional stability during extended production runs common in oilfield equipment and semiconductor tooling.

Quality assurance is integrated at every process stage, anchored by Zeiss CONTURA and GLOBAL S CMM systems operating in a climate-controlled 20°C metrology lab. Full first-article inspection (FAI) per AS9102 and PPAP Level 3 standards is standard practice, with real-time SPC monitoring during machining. Probe calibration adheres to ISO 10360-2, guaranteeing traceable measurement uncertainty of ±1.9 + L/350 µm. This rigorous protocol ensures compliance with Texas-based OEMs’ stringent requirements for safety-critical components, where deviations risk operational failure in high-pressure or high-vacuum environments.

Material versatility spans aerospace-grade titanium (Ti-6Al-4V), Inconel 718, 17-4 PH stainless steel, and engineered plastics like PEEK, all processed under controlled cleanroom conditions for medical applications. Secondary operations—including precision grinding, honing, and black oxide coating—are managed in-house to maintain process continuity and accountability. Our technical team collaborates directly with Texas engineering departments during DFM analysis, identifying cost-saving opportunities without compromising functional tolerances. This proactive approach reduces scrap rates by up to 30% compared to conventional suppliers, directly impacting clients’ bottom lines in competitive markets.

Standard Machining Tolerances

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Ultra-Precision Tolerance (mm) |

|——————–|————————-|————————–|——————————–|

| Linear Dimensions | ±0.05 | ±0.012 | ±0.005 |

| Hole Diameter | ±0.03 | ±0.008 | ±0.003 |

| Positional Accuracy| ±0.05 | ±0.015 | ±0.008 |

| Surface Finish (Ra)| 3.2 µm | 0.8 µm | 0.4 µm |

All tolerances conform to ASME Y14.5 standards and are validated through CMM reports with full point-cloud analysis. For Texas clients requiring sub-micron repeatability in hydraulic manifolds or turbine blades, our ultra-precision tier leverages air-bearing spindles and vibration-dampened foundations. This capability ensures seamless integration into Texas supply chains where dimensional fidelity directly impacts system performance and regulatory compliance. Contact our Texas liaison team to discuss how our certified processes and rapid prototyping capabilities can accelerate your next project.

Material & Finish Options

When selecting materials for high-precision CNC machining in demanding industrial applications, three metals consistently stand out: aluminum, steel, and titanium. Each offers distinct mechanical properties, making them suitable for different operational environments. Understanding their characteristics is critical for optimizing performance, cost, and manufacturability—especially in sectors such as aerospace, medical devices, and high-performance automotive systems.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly common in structural and enclosure applications due to its weldability and moderate strength. For higher performance needs, 7075-T6 offers superior strength, often used in aerospace components. Aluminum’s low density reduces part weight significantly, a crucial factor in dynamic systems. However, its lower hardness compared to steel and titanium means it may not withstand extreme wear or high-temperature environments.

Steel, particularly alloy and stainless variants, provides high tensile strength, durability, and resistance to deformation under load. 4140 steel is a go-to for high-stress mechanical parts due to its toughness and hardenability. Stainless steel 303 offers improved machinability, while 316 excels in corrosive environments due to its molybdenum content. The primary trade-off with steel is weight—its high density can be a limiting factor in weight-sensitive designs. Additionally, stainless steels can be more challenging to machine due to work hardening tendencies, requiring precise toolpath strategies and rigid setups.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional combination of strength, corrosion resistance, and low density. It performs reliably in extreme temperatures and aggressive chemical environments, making it ideal for aerospace, defense, and medical implant applications. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools demand specialized CNC machining parameters, including lower cutting speeds and rigid tooling. This increases production time and cost, but the performance benefits often justify the investment.

For aluminum components, anodizing is the most effective finishing process to enhance surface durability. Anodizing creates a controlled oxide layer that improves wear and corrosion resistance while allowing for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for most industrial parts, while Type III (hardcoat anodizing) provides a thicker, harder surface for high-wear applications.

The following table summarizes key mechanical and machining properties of commonly used materials in precision CNC machining.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Hardness (HB) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | 95 | Enclosures, brackets | Excellent |

| Aluminum 7075-T6 | 570 | 2.8 | 150 | Aerospace structures | Good |

| Steel 4140 | 655 | 7.85 | 190 | Shafts, tooling | Moderate |

| Stainless 316 | 580 | 8.0 | 160 | Marine, medical | Moderate |

| Titanium Ti-6Al-4V | 900 | 4.4 | 360 | Aircraft, implants | Fair |

Material selection directly impacts part performance, production cost, and lead time. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal material and finish based on application requirements, ensuring precision, reliability, and value in every component.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero Defects Delivery for Texas Industry

At Wuxi Lead Precision Machinery, our CNC precision machining process for the Texas market is engineered for uncompromising quality and efficiency, directly supporting critical sectors like aerospace, energy, and medical device manufacturing. We implement a rigorously controlled workflow ensuring Zero Defects is not a goal, but a guaranteed outcome through systematic execution.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners with Texas clients during the initial design phase, utilizing advanced CAD/CAM simulation software to identify potential manufacturability issues, optimize toolpaths, and select the most suitable materials and processes. This proactive step prevents costly errors downstream, ensuring designs are not only functional but inherently producible to micron-level tolerances required by Texas aerospace suppliers and energy sector OEMs. Material certifications and traceability protocols are established at this stage, aligning with stringent AS9100 and ISO 13485 standards prevalent in these industries.

Prototyping transitions the validated design into tangible reality. We produce initial functional prototypes using the exact production-grade CNC equipment and materials intended for final manufacture. Every prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 standards, including full CMM metrology, surface finish verification, and material property validation. This phase is critical for Texas clients to verify form, fit, and function against specifications before committing to volume. Rigorous dimensional analysis and functional testing ensure the prototype meets all performance criteria, with any deviations triggering immediate design or process refinement. Client sign-off on the prototype is mandatory before progression.

Mass Production leverages the perfected process under our Zero Defects Management System. Production runs are executed on state-of-the-art multi-axis CNC machining centers within climate-controlled environments, minimizing thermal drift. Real-time Statistical Process Control (SPC) monitors critical dimensions continuously, with automated data collection feeding into our quality management system. Every component undergoes 100% in-process inspection at defined checkpoints, not just final audit. Full material traceability from raw bar stock to finished part is maintained via laser marking and digital logs. Our closed-loop corrective action system ensures any potential non-conformance is identified instantly, contained, and eliminated at the source, preventing recurrence. This systematic approach guarantees consistent part conformance batch after batch, essential for Texas manufacturers demanding reliability in high-stakes applications.

The table below outlines core capabilities ensuring precision for Texas clients:

| Parameter | Capability | Industry Standard | Wuxi Lead Standard |

|---|---|---|---|

| Positional Tolerance | ±0.0002″ (5µm) | ±0.0005″ (13µm) | ±0.0001″ (2.5µm) |

| Surface Finish (Ra) | 0.8 µin (0.02 µm) | 3.2 µin (0.08 µm) | 0.4 µin (0.01 µm) |

| Material Range | Aluminum to Inconel | Standard Alloys | Full Aerospace/Exotic |

| Certifications | ISO 9001 | ISO 9001 | AS9100D, ISO 13485 |

This integrated Design-Prototype-Production methodology, underpinned by relentless process control and advanced metrology, delivers the defect-free precision Texas industry requires, strengthening your supply chain with globally certified, locally relevant manufacturing excellence.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched CNC Precision Machining Excellence

When sourcing high-precision CNC machined components for advanced industrial applications, global manufacturers demand more than just tolerances—they require reliability, consistency, and engineering partnership. At Wuxi Lead Precision Machinery, we deliver exactly that. Based in China but serving clients across North America—including key markets in Texas—we specialize in precision CNC machining for industries where performance is non-negotiable: aerospace, medical devices, energy, automation, and high-end industrial equipment.

Texas has emerged as a powerhouse in advanced manufacturing, with growing demand for domestic-grade precision components supported by agile, cost-competitive supply chains. While local CNC shops provide valuable services, partnering with an international leader like Wuxi Lead offers distinct advantages: scalable capacity, advanced multi-axis machining capabilities, and rigorous quality control—all at competitive pricing. Our ISO 9001:2015-certified facility integrates cutting-edge CNC equipment with expert process engineering to ensure every component meets exacting specifications.

We understand the challenges faced by Texas-based OEMs: supply chain volatility, lead time pressures, and the need for zero-defect components. That’s why we’ve built our operations around responsive collaboration. From initial design review to final inspection, our team works directly with your engineers to optimize manufacturability, reduce costs, and accelerate time to market. Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing systems adapt to your schedule—without compromising on precision.

Our technical capabilities are engineered for performance-critical applications. With CNC turning, milling, grinding, and multi-axis machining centers, we handle complex geometries in a wide range of materials, including aluminum alloys, stainless steel, titanium, and engineering plastics. All components are inspected using CMM, optical comparators, and surface roughness testers to ensure compliance with AS9100, ISO, or customer-specific standards.

Below is an overview of our core technical specifications:

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.001 mm (±0.00004 in) |

| Maximum Work Envelope | 1200 x 800 x 650 mm (47 x 31.5 x 25.6 in) |

| Axis Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning with live tooling |

| Materials | Aluminum, stainless steel, carbon steel, titanium, brass, PEEK, Delrin, and more |

| Surface Finish | As fine as Ra 0.2 µm (8 µin) |

| Quality Standards | ISO 9001:2015, full FAI and PPAP support, first-article inspection reports |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (based on complexity and volume) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic advantage in precision manufacturing. We bridge the gap between global efficiency and local performance requirements, offering Texas engineers and procurement teams a trusted offshore partner they can rely on.

For immediate support or to request a quote, contact us at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.