Technical Contents

Engineering Guide: Cnc Precision Machining Company Georgia

Engineering Insight: The Critical Role of Precision in Modern CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. For industries operating in high-stakes environments such as aerospace, defense, medical technology, and competitive sports engineering, even micrometer-level deviations can lead to catastrophic system failures or suboptimal performance. This uncompromising demand for accuracy defines the core mission of leading CNC precision machining companies, including Wuxi Lead Precision Machinery, a globally recognized manufacturer headquartered in China.

While the search for a “CNC precision machining company Georgia” may lead many to consider local U.S. providers, global capabilities must not be overlooked. Wuxi Lead Precision Machinery exemplifies how international engineering excellence can meet and exceed the standards expected by American and European industrial leaders. With over 15 years of experience in high-tolerance CNC machining, the company has developed a reputation for delivering mission-critical components where failure is not an option.

One of the most compelling validations of Wuxi Lead’s precision engineering capabilities came through its contribution to Olympic-level sports equipment. Components manufactured for high-performance athletic systems required not only repeatable accuracy but also advanced material handling and surface finish control. These parts underwent rigorous third-party metrology validation, consistently achieving tolerances within ±0.002 mm—performance levels on par with, or exceeding, those of top-tier U.S. machine shops.

Equally significant is the company’s work in military-grade applications. Collaborations with defense contractors have involved the production of ruggedized housings, actuation components, and sensor mounts designed for extreme environmental conditions. These projects demanded compliance with MIL-STD specifications, including thermal stability, vibration resistance, and long-term durability. Wuxi Lead’s ability to maintain strict process control across multi-axis CNC platforms—combined with full traceability and documentation—ensured seamless integration into mission-critical systems.

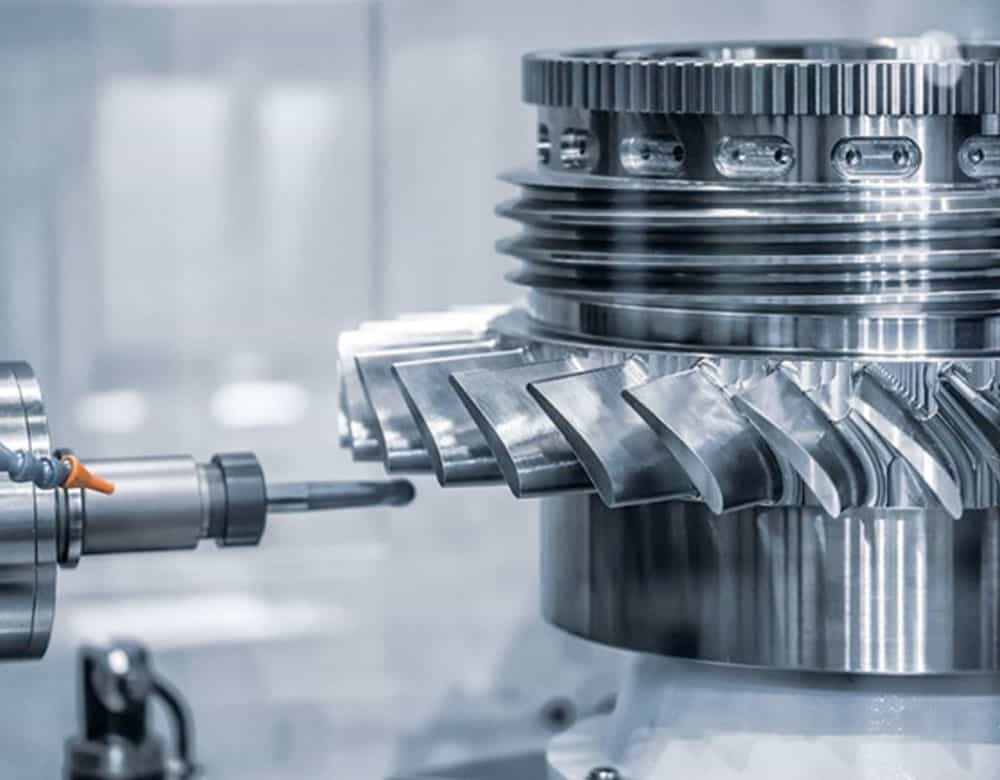

The technological backbone of this precision lies in Wuxi Lead’s advanced machining infrastructure. Utilizing state-of-the-art 5-axis CNC centers, Swiss-type lathes, and high-speed milling systems, the company supports complex geometries and tight-tolerance requirements across a broad range of materials—from aerospace-grade aluminum and titanium to high-performance polymers and hardened steels.

Below are key performance specifications that define Wuxi Lead Precision Machinery’s engineering capabilities:

| Specification | Capability |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Standard Tolerances | ±0.005 mm (typical), down to ±0.002 mm (high-precision) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (3-axis), 600 x 500 x 400 mm (5-axis) |

| Surface Finish | Ra 0.2 µm (standard), down to Ra 0.05 µm (polished) |

| Materials Supported | Aluminum 6061/7075, Titanium Grade 5, Stainless Steel 316/17-4 PH, PEEK, Delrin, Inconel 718 |

| Quality Standards | ISO 9001:2015, Full CMM Inspection Reports, First Article Inspection (FAI) |

Precision is not achieved by equipment alone—it is engineered through process discipline, metrology integration, and a culture of continuous improvement. For global clients evaluating CNC precision machining partners, whether in Georgia or beyond, Wuxi Lead Precision Machinery stands as a proven leader in delivering components where accuracy defines success.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Georgian Industry Demands

Wuxi Lead Precision Machinery delivers advanced CNC machining solutions meeting the stringent requirements of Georgia’s aerospace, energy, and industrial equipment sectors. Our core strength lies in seamless integration of cutting-edge multi-axis machining with rigorous metrology, ensuring components perform flawlessly in critical applications. We specialize in transforming complex geometries from challenging materials into mission-critical parts, eliminating secondary operations through strategic process design.

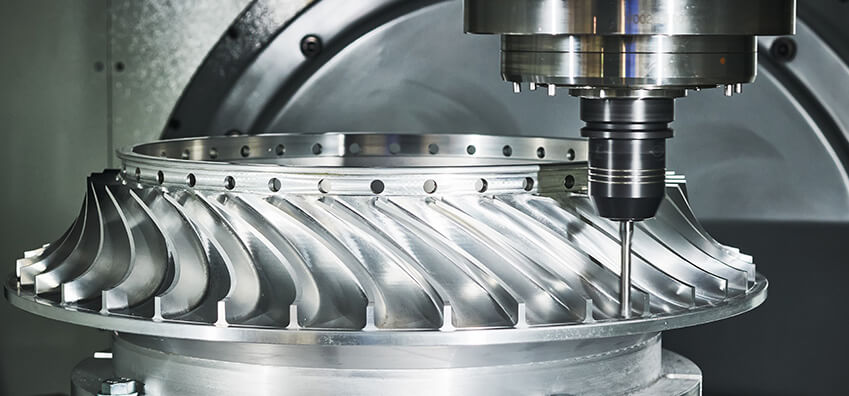

Our primary production platform features state-of-the-art 5-axis CNC machining centers, including DMG MORI and Makino models. This capability enables single-setup machining of intricate contours, deep cavities, and organic shapes impossible with 3-axis systems. The simultaneous movement of all five axes significantly reduces cycle times while enhancing part accuracy and surface integrity. This is essential for Georgian clients producing turbine components, hydraulic manifolds, or medical device housings where feature relationships and positional tolerances are non-negotiable. Material versatility spans aerospace-grade titanium and Inconel, high-strength steels, aluminum alloys, and engineered plastics, all processed under strict environmental controls to maintain dimensional stability.

Quality assurance is not a final step but an embedded process. Every critical feature undergoes validation using Zeiss and Hexagon Coordinate Measuring Machines (CMMs) operated by ASQ-certified technicians. Our ISO 17025 accredited metrology lab provides full first-article inspection reports (FAIRs) and production lot verification, traceable to NIST standards. Real-time SPC data monitoring occurs directly on the shop floor, allowing immediate process correction. Dimensional analysis is supplemented by surface roughness testers, optical comparators, and hardness verification, ensuring comprehensive conformance beyond basic dimensional checks. This systematic approach guarantees that parts shipped to Tbilisi, Batumi, or Rustavi meet or exceed ASME Y14.5 and ISO GPS specifications without exception.

The following table details our standard achievable tolerances, reflecting our commitment to precision for Georgia’s high-value manufacturing:

| Feature Category | Capability Range | Reference Standard |

|---|---|---|

| Linear Dimensions | ±0.005 mm (0.0002″) | ISO 2768-mK |

| Positional Tolerance | ±0.010 mm (0.0004″) | ASME Y14.5-2018 |

| Angular Tolerance | ±0.05 degrees | ISO 1101 |

| Surface Roughness (Ra) | 0.4 μm (16 μin) typical | ISO 1302 |

| Coaxiality/Circularity | 0.015 mm (0.0006″) | ISO 1101 |

These specifications are consistently maintained across production runs for components up to Ø600 mm in diameter and 1000 mm in height. Our engineering team collaborates directly with Georgian design departments during DFM analysis, proactively identifying opportunities to optimize part geometry for manufacturability without compromising functional intent. This partnership ensures your precision components arrive on schedule, fully qualified, and ready for immediate integration into your assembly lines. Wuxi Lead provides the technical depth and quality rigor Georgia’s advanced manufacturing sector requires.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. For high-performance industries such as aerospace, medical, and advanced robotics, choosing the right base material—alongside an appropriate surface finish—is essential to meeting stringent operational requirements. At Wuxi Lead Precision Machinery, our expertise in CNC precision machining enables us to support clients in selecting optimal materials and finishes tailored to application-specific demands.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is widely used in aerospace and automotive applications where weight reduction is critical. The most commonly used grades include 6061-T6 and 7075-T6, each offering distinct advantages. 6061-T6 provides good weldability and moderate strength, making it ideal for structural components. 7075-T6, while less weldable, delivers higher tensile strength, suitable for high-stress environments.

Steel remains the material of choice when maximum strength, wear resistance, and dimensional stability are required. In precision machining, alloy steels such as 4140 and 17-4 PH stainless steel are frequently specified. 4140 offers high fatigue strength and toughness, often used in shafts and tooling. 17-4 PH stainless steel combines corrosion resistance with high strength through precipitation hardening, making it ideal for aerospace and medical applications where sterilization and durability are paramount.

Titanium, particularly Grade 5 (Ti-6Al-4V), is favored in extreme environments due to its exceptional strength-to-density ratio and resistance to high temperatures and corrosion. It is commonly found in jet engines, medical implants, and marine systems. While more challenging to machine due to low thermal conductivity and high chemical reactivity, our advanced CNC toolpaths and cooling strategies ensure tight tolerances and superior surface integrity.

Anodizing is the preferred surface treatment for aluminum components, enhancing corrosion resistance, surface hardness, and aesthetic quality. Type II (sulfuric acid) anodizing provides a thin, decorative, and corrosion-resistant layer, often used in consumer-facing parts. Type III (hardcoat) anodizing produces a thicker, wear-resistant surface capable of withstanding harsh operational conditions. Both types allow for color dyeing, enabling brand-specific identification.

Below is a comparative overview of key material properties and finish capabilities:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Suitable Finishes |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Aerospace frames, enclosures | Type II/III Anodizing |

| Aluminum 7075-T6 | 570 | 2.8 | High-stress structural parts | Type III Anodizing |

| Steel 4140 | 950 | 7.85 | Shafts, tooling, fixtures | Zinc plating, passivation |

| 17-4 PH SS | 1000 | 7.75 | Medical devices, aerospace | Passivation, electropolishing |

| Titanium Ti-6Al-4V | 900 | 4.43 | Jet engines, implants | Anodizing, laser marking |

Selecting the correct material and finish requires a deep understanding of both mechanical requirements and environmental exposure. Wuxi Lead Precision Machinery combines technical expertise with advanced CNC capabilities to ensure every component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for CNC precision machining is engineered to eliminate defects before they occur. Serving Georgia manufacturers requiring aerospace, medical, and industrial components, we integrate rigorous engineering controls across three phases: Design Validation, Prototyping, and Mass Production. This closed-loop methodology ensures every part meets exacting specifications—consistently achieving tolerances down to ±0.0002″ (5µm).

Design begins with collaborative engineering analysis. Our team reviews CAD models for manufacturability, material suitability, and geometric feasibility using Siemens NX and Mastercam simulations. Critical to zero defects is identifying stress points, thermal deformation risks, and toolpath optimization early. We validate material certifications against ASTM/AMS standards and confirm fixture strategies to prevent micro-vibrations during machining. Only when simulations prove 100% conformance to GD&T requirements do we proceed.

Prototyping transforms validated designs into physical benchmarks. We produce 1–5 units on the same production-grade DMG MORI and MAZAK 5-axis platforms used for volume runs. Each prototype undergoes metrology-grade CMM inspection (Zeiss CONTURA), surface roughness testing (per ISO 1302), and first-article reporting (FAIR). Dimensional data is cross-referenced against simulation outputs; deviations trigger immediate process recalibration—not part rework. This phase confirms tooling stability, coolant efficacy, and thermal compensation algorithms, ensuring mass production starts with proven parameters.

Mass production executes with embedded quality assurance. Every machine runs under real-time SPC (Statistical Process Control) monitoring, tracking tool wear, spindle load, and positional accuracy via Renishaw probes. Components are serialized for full traceability; batch records include material lot numbers, machine IDs, and operator certifications. In-process inspections occur at predefined intervals using automated optical comparators, while final validation requires 100% dimensional verification against the FAIR baseline. Non-conformances halt the line instantly—no concessions to schedule pressure.

Our machine capabilities sustain this zero-defect standard across complex geometries and exotic alloys. Key specifications include:

| Capability | Specification Range | Materials Supported |

|---|---|---|

| Maximum Work Envelope | 1,200 x 800 x 650 mm (5-axis milling) | Titanium, Inconel, 17-4PH, PEEK |

| Positional Accuracy | ±0.0002″ (5µm) repeatability | Aluminum 7075-T6, Stainless 316L |

| Surface Finish | Ra 0.4 µm (micro-bore honing capable) | Tool Steels, Composites |

| Lead Time (Mass Production) | 2–4 weeks (including full QA dossier) | Ceramics, Magnesium Alloys |

This integrated process—where design integrity, prototype validation, and production controls operate as a single system—delivers uncompromised precision for Georgia’s high-stakes manufacturing sectors. We do not ship parts; we deliver certified performance. Contact Wuxi Lead to implement zero-defect machining for your critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Precision Machining Excellence

When your business demands components that meet the highest standards of accuracy, consistency, and material integrity, partnering with Wuxi Lead Precision Machinery ensures you’re working with a global leader in advanced CNC precision machining. Based in China but serving industries across North America, Europe, and Asia, we specialize in delivering mission-critical machined parts for aerospace, medical devices, automation, energy systems, and high-performance industrial equipment. Our precision engineering solutions are designed to support your most demanding applications—where tolerances are tight, materials are challenging, and reliability is non-negotiable.

At Wuxi Lead Precision Machinery, we understand that your supply chain depends on more than just parts—it depends on trust, responsiveness, and technical mastery. Our vertically integrated manufacturing facility combines state-of-the-art CNC machining centers with expert engineering oversight, enabling us to deliver complex components with tolerances as tight as ±0.0001 inches. From prototype development to high-volume production, our team collaborates closely with your engineers to ensure seamless integration, rapid turnaround, and full traceability across every batch.

Our commitment to quality is reinforced by ISO 9001:2015 certification, comprehensive in-process inspection protocols, and advanced metrology equipment including CMMs, optical comparators, and surface finish testers. Whether you’re working with titanium, stainless steel, aluminum, or exotic alloys like Inconel and Hastelloy, our precision machining processes are optimized for performance, durability, and repeatability.

We support a full range of CNC capabilities, including 3-axis, 4-axis, and 5-axis milling, turning, multi-tasking, and Swiss machining. Our facility is equipped to handle complex geometries, deep cavity milling, micro-machining, and tight-tolerance threading—all under strict environmental and quality controls.

Below is an overview of our core machining specifications:

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning, Swiss machining, multi-tasking |

| Tolerances | ±0.0001″ (2.5 µm) typical |

| Materials | Aluminum, stainless steel, titanium, brass, copper, plastics (PEEK, Delrin), Inconel, Hastelloy, tool steels |

| Max Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Surface Finish | As fine as 8 µin Ra |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, FAIR reporting |

| Lead Times | Prototype: 7–14 days; Production: 15–30 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a reliable, technically advanced manufacturing ally committed to your success. We bridge the gap between design intent and physical performance—delivering parts that perform under real-world conditions.

Contact us today to discuss your next precision machining project. Email us at [email protected] and let our engineering team provide a detailed quote, DFM analysis, and production timeline tailored to your specifications. With Lead Precision, precision isn’t just a goal—it’s our standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.