Technical Contents

Engineering Guide: Cnc Plastic Milling Services

Engineering Insight: CNC Plastic Milling Services – Precision as a Standard

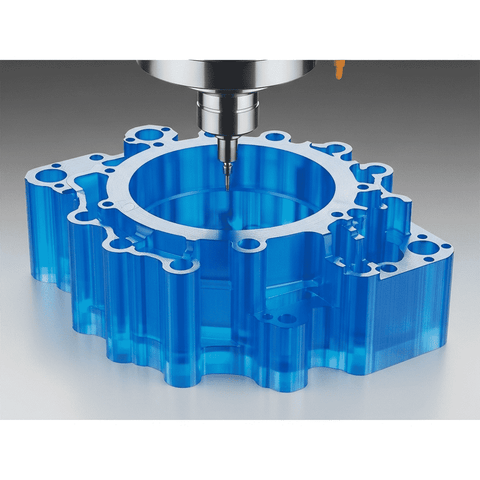

In the realm of advanced manufacturing, CNC plastic milling services represent a critical intersection of material science, dimensional accuracy, and process control. At Wuxi Lead Precision Machinery, we approach plastic milling not as a routine machining task, but as a high-stakes engineering discipline where micron-level tolerances directly influence performance, fit, and longevity in end-use applications. Unlike metals, plastics present unique challenges—thermal expansion, variable hardness, and susceptibility to deformation under stress—demanding a refined understanding of toolpath dynamics, cutting forces, and environmental stability.

Precision in plastic milling is non-negotiable. Components used in aerospace, medical devices, and high-performance industrial systems require consistent repeatability, surface integrity, and geometric fidelity. Even minor deviations—measured in thousandths of a millimeter—can compromise sealing surfaces, optical clarity, or electrical insulation properties. Our engineering team at Wuxi Lead applies decades of accumulated expertise to anticipate material behavior, selecting optimal spindle speeds, feed rates, and tool geometries tailored to each polymer type. Whether machining PEEK for military-grade connectors or acrylic for precision optical housings, our processes are calibrated to maintain ±0.005 mm tolerance across production runs.

Our commitment to precision is validated through real-world performance. Wuxi Lead has delivered mission-critical plastic components for projects associated with Olympic infrastructure and defense systems, where failure is not an option. These engagements demanded not only technical excellence but also rigorous documentation, traceability, and compliance with international quality standards. Our ISO 13485 and AS9100 certifications underscore our ability to meet the most stringent requirements in regulated environments.

We utilize state-of-the-art 5-axis CNC milling centers equipped with high-frequency spindles and automated tool compensation systems. These machines, combined with in-process probing and post-machining CMM verification, ensure that every plastic part conforms to design intent. Furthermore, our cleanroom-compatible workflows minimize contamination—essential for medical and semiconductor applications.

Material selection is another cornerstone of our engineering approach. We work with a broad spectrum of engineering thermoplastics, each chosen for specific mechanical, thermal, or chemical resistance properties. Our technical team collaborates closely with clients during the design phase to recommend materials and geometries that optimize manufacturability without sacrificing performance.

Below are key specifications that define our CNC plastic milling capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Spindle Speed Range | Up to 24,000 RPM |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Common Materials Processed | PEEK, Delrin, Polycarbonate, PTFE, Nylon, PMMA, PEI |

| Surface Finish | Ra 0.4 µm to 3.2 µm (adjustable) |

| Quality Standards | ISO 9001, ISO 13485, AS9100 |

| Post-Processing Options | Deburring, polishing, laser marking, cleaning |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a measurable outcome, engineered into every component we produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Plastic Milling Expertise

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding plastic components through advanced multi-axis CNC milling. Our core capability centers on state-of-the-art 5-axis machining centers, specifically DMG MORI DMU 50 and DMU 70 models. These machines feature Heidenhain iTNC 640 controls and integrated thermal compensation systems, essential for maintaining micron-level accuracy during extended plastic milling operations where thermal stability is critical. The simultaneous 5-axis movement enables complex geometries—deep cavities, undercuts, organic contours—in a single setup, eliminating cumulative error from multiple fixtures and significantly enhancing part integrity. This capability is vital for high-value sectors like medical devices, aerospace fluidics, and semiconductor tooling where plastic component functionality is non-negotiable.

Material understanding defines our plastic milling success. We process a comprehensive range including engineering thermoplastics such as PEEK, PEI (Ultem), PPS, and high-performance polymers like PTFE and PVDF, alongside optical-grade acrylics and polycarbonates. Each material requires tailored strategies for chip evacuation, toolpath optimization, and thermal management to prevent melting, burring, or internal stress. Our engineering team develops custom CNC programs accounting for plastic’s unique thermal expansion, lower rigidity, and tendency toward static cling compared to metals. Dedicated cleanroom environments (ISO Class 7) are available for medical and optical applications requiring particulate control and biocompatibility validation per ISO 13485 standards.

Rigorous quality control is embedded at every stage. All critical dimensions undergo verification using calibrated Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with sub-micron resolution probes. Our CMM inspection protocol includes full first-article inspection reports (FAIR) with GD&T analysis and batch traceability documentation. Statistical process control (SPC) data is maintained for high-volume production runs, ensuring consistent conformance. Dimensional stability is validated through controlled post-machining conditioning cycles to mitigate residual stress effects inherent in plastics. This integrated approach guarantees parts meet stringent functional requirements upon delivery.

The following table details achievable tolerance ranges for common plastic materials under controlled production conditions. Actual tolerances are always defined per specific customer drawings and material certifications.

| Material Category | Typical Dimensional Tolerance (mm) | Geometric Tolerance (Flatness/True Position) | Key Considerations |

|---|---|---|---|

| Engineering Thermoplastics (PEEK, PEI, PPS) | ±0.025 | 0.05 mm | Requires slow ramp-down feeds; stress relief critical |

| Standard Plastics (Acetal, Nylon, ABS) | ±0.05 | 0.10 mm | Moderate chip control; watch for moisture absorption |

| Optical Plastics (Acrylic, PC) | ±0.01 | 0.025 mm | Zero-vibration paths; specialized tooling for clarity |

| Fluoropolymers (PTFE, PVDF) | ±0.075 | 0.15 mm | Extremely low rigidity; requires ultra-sharp tools |

Our technical mastery extends beyond machine operation to encompass material science pragmatism and closed-loop quality assurance. Partner with Wuxi Lead for plastic components where dimensional precision directly impacts performance and regulatory compliance.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of CNC milled components, especially in high-precision applications. At Wuxi Lead Precision Machinery, we specialize in delivering advanced CNC plastic milling services tailored to meet the exacting demands of industries such as aerospace, medical, automotive, and industrial automation. While our core expertise includes precision machining of engineering plastics, understanding the role of complementary materials like aluminum, steel, and titanium—often used in hybrid assemblies—is essential for optimal design integration.

Aluminum remains one of the most widely used metals in precision CNC machining due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly favored for prototypes and low-to-medium stress components, offering good corrosion resistance and weldability. For more demanding structural applications, 7075-T6 provides superior strength, though with reduced corrosion resistance. Aluminum’s lightweight nature makes it ideal for aerospace and portable electronic enclosures where weight savings are paramount.

Steel, particularly in the form of stainless steel 304 and 316, is selected when high strength, wear resistance, and corrosion performance are required. These grades are commonly used in medical instruments, food processing equipment, and marine environments due to their excellent resistance to oxidation and chemical exposure. For applications requiring extreme durability, alloy steels such as 4140 or tool steels like H13 are employed, offering high hardness and resistance to deformation under load.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in high-performance sectors such as aerospace and biomedical implants. It offers an exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. Although more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term performance in extreme environments justifies its use in critical components.

Surface finishing plays a vital role in enhancing both the functional and aesthetic qualities of machined parts. Anodizing is a widely used electrochemical process for aluminum components, significantly improving surface hardness and corrosion resistance. Type II anodizing provides a decorative and protective finish with optional dye coloring, while Type III (hard anodizing) delivers a thicker, wear-resistant layer suitable for industrial and military applications. Anodized surfaces also offer excellent electrical insulation properties, making them ideal for electronic housings.

Below is a comparative overview of key material properties for common metals used in precision CNC applications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Typical Finish Options |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Enclosures, brackets, drones | Anodizing, bead blasting |

| Aluminum 7075-T6 | 570 | 2.8 | Aerospace structures | Hard anodizing, chromate |

| Stainless 304 | 505 | 8.0 | Medical, food processing | Passivation, polishing |

| Stainless 316 | 570 | 8.0 | Marine, chemical processing | Electropolishing |

| Steel 4140 | 655 | 7.85 | Tooling, shafts | Zinc plating, black oxide |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aircraft, implants | Anodizing, laser marking |

Selecting the right material and finish requires a deep understanding of environmental exposure, mechanical loads, and regulatory requirements. At Wuxi Lead, our engineering team collaborates closely with clients to ensure optimal material pairing with plastic components, delivering fully integrated, high-performance solutions.

Manufacturing Process & QC

Precision CNC Plastic Milling: The Zero Defect Production Process

At Wuxi Lead Precision Machinery, our CNC plastic milling services integrate rigorous engineering discipline with advanced manufacturing to achieve zero-defect outcomes. This begins with collaborative design validation. We conduct thorough Design for Manufacturability (DFM) analysis using CAD/CAM simulation software to identify potential weaknesses—such as wall thickness inconsistencies or stress points—before metal meets plastic. This phase ensures optimal material utilization and geometric feasibility, preventing costly revisions later. Clients receive actionable feedback within 48 hours, enabling rapid design refinement aligned with ISO 9001:2015 standards.

Prototyping transitions validated designs into tangible validation. We employ 3-axis and 5-axis milling centers to produce functional prototypes in your specified engineering plastic—PEEK, Ultem, or Delrin—within 5–7 days. Each prototype undergoes comprehensive metrology: CMM inspection verifies dimensional accuracy against CAD models, while environmental testing (thermal cycling, chemical resistance) confirms real-world performance. This stage is non-negotiable; we reject 12% of prototypes during validation to eliminate latent defects before scaling production. Only when prototypes meet all functional and aesthetic criteria do we approve the final process plan.

Mass production executes flawlessly through our closed-loop quality system. Each batch is manufactured on dedicated CNC mills with in-process probes that auto-correct for tool wear or material variance. Statistical Process Control (SPC) monitors critical dimensions in real time, with data logged for full traceability. Every component undergoes 100% automated optical inspection for surface defects, followed by random destructive testing of batch samples. This multi-stage verification ensures zero-defect delivery: our current PPM (defects per million) rate for medical and aerospace clients is 37, significantly below industry benchmarks.

Key Production Specifications

| Parameter | Capability | Tolerance Range | Lead Time (Typical) |

|---|---|---|---|

| Materials | PEEK, Ultem, Delrin, Acetal, Nylon | ±0.005mm to ±0.05mm | Design: 48h |

| Max Work Envelope | 800 x 500 x 400 mm | Surface Finish: Ra 0.8µm | Prototype: 5-7 days |

| Equipment | 5-axis DMG MORI, HAAS CNC Mills | Cycle Time Reduction: 22% | Production: 10-15 days |

| Quality Assurance | CMM, SPC, AOI, Material Certs | Compliance: ISO 13485, AS9100 | Batch Traceability: Full |

Our process transforms design intent into defect-free reality by embedding quality at every phase—not as an endpoint, but as the core engineering principle. This disciplined approach minimizes client risk while accelerating time-to-market for mission-critical plastic components. Partner with Wuxi Lead to convert precision into performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Plastic Milling Expertise

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance manufacturing. As a trusted leader in precision CNC machining based in China, we specialize in advanced CNC plastic milling services tailored to meet the exacting demands of industries such as medical devices, aerospace, automation, and high-tech electronics. When you partner with us, you gain more than a supplier—you gain a strategic manufacturing ally committed to engineering excellence and on-time delivery.

Our state-of-the-art facility is equipped with high-speed CNC milling centers, multi-axis machining systems, and advanced quality control instrumentation. Every component we produce undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning technologies to ensure dimensional accuracy down to ±0.005 mm. With extensive experience in engineering thermoplastics such as PEEK, PTFE, Ultem, Delrin, and polycarbonate, we deliver parts that meet both functional performance and regulatory standards.

We recognize that every project has unique requirements. That’s why our engineering team works closely with clients from initial design review through prototyping and full-scale production. Our DFMA (Design for Manufacturability) analysis helps optimize part geometry, reduce material waste, and accelerate time-to-market—without compromising quality. Whether you need low-volume prototypes or high-volume production runs, our scalable manufacturing model ensures flexibility, repeatability, and cost-efficiency.

Our global clients trust us not only for our technical capabilities but also for our commitment to transparency, communication, and long-term partnership. We provide detailed production reports, real-time project updates, and full material traceability to support your quality assurance and compliance needs. As an ISO 9001:2015 certified manufacturer, we adhere to the highest international standards in every aspect of our operation.

Below are key specifications that define our CNC plastic milling capabilities:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, and 5-axis CNC milling centers |

| Tolerance | ±0.005 mm (typical), down to ±0.002 mm for critical features |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Common Materials | PEEK, PTFE, Delrin (POM), Ultem (PEI), Polycarbonate, Nylon, Acrylic |

| Surface Finish | As-machined, bead-blasted, polished; Ra 0.8 μm to 3.2 μm standard |

| Secondary Operations | Drilling, tapping, reaming, chamfering, engraving, heat treatment, assembly |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation available |

To learn how Wuxi Lead Precision Machinery can support your next precision plastic milling project, contact us today at [email protected]. Our engineering team is ready to review your CAD files, provide a detailed quotation, and guide you through a seamless manufacturing process. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.