Technical Contents

Engineering Guide: Cnc Part Machine

Engineering Insight: The Critical Role of Precision in CNC Part Machining

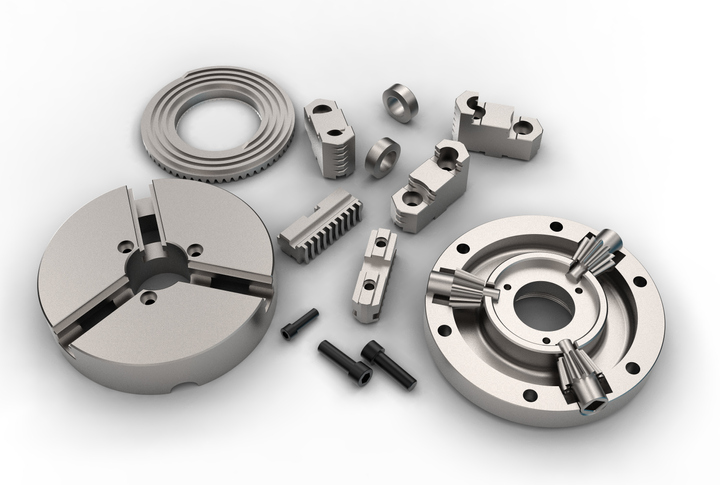

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we understand that the performance of any high-end mechanical system is directly tied to the accuracy and consistency of its individual CNC-machined components. Whether serving aerospace, defense, or high-performance industrial sectors, the margin for error in critical applications is effectively zero. This uncompromising demand drives our engineering philosophy and operational excellence.

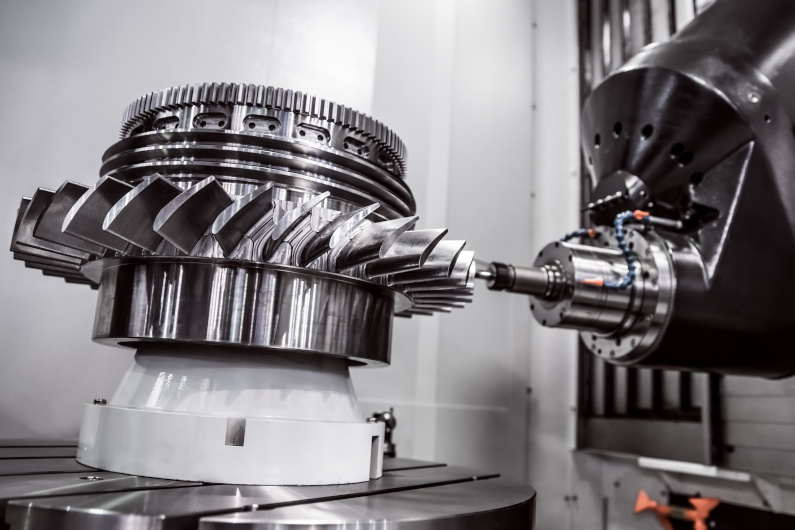

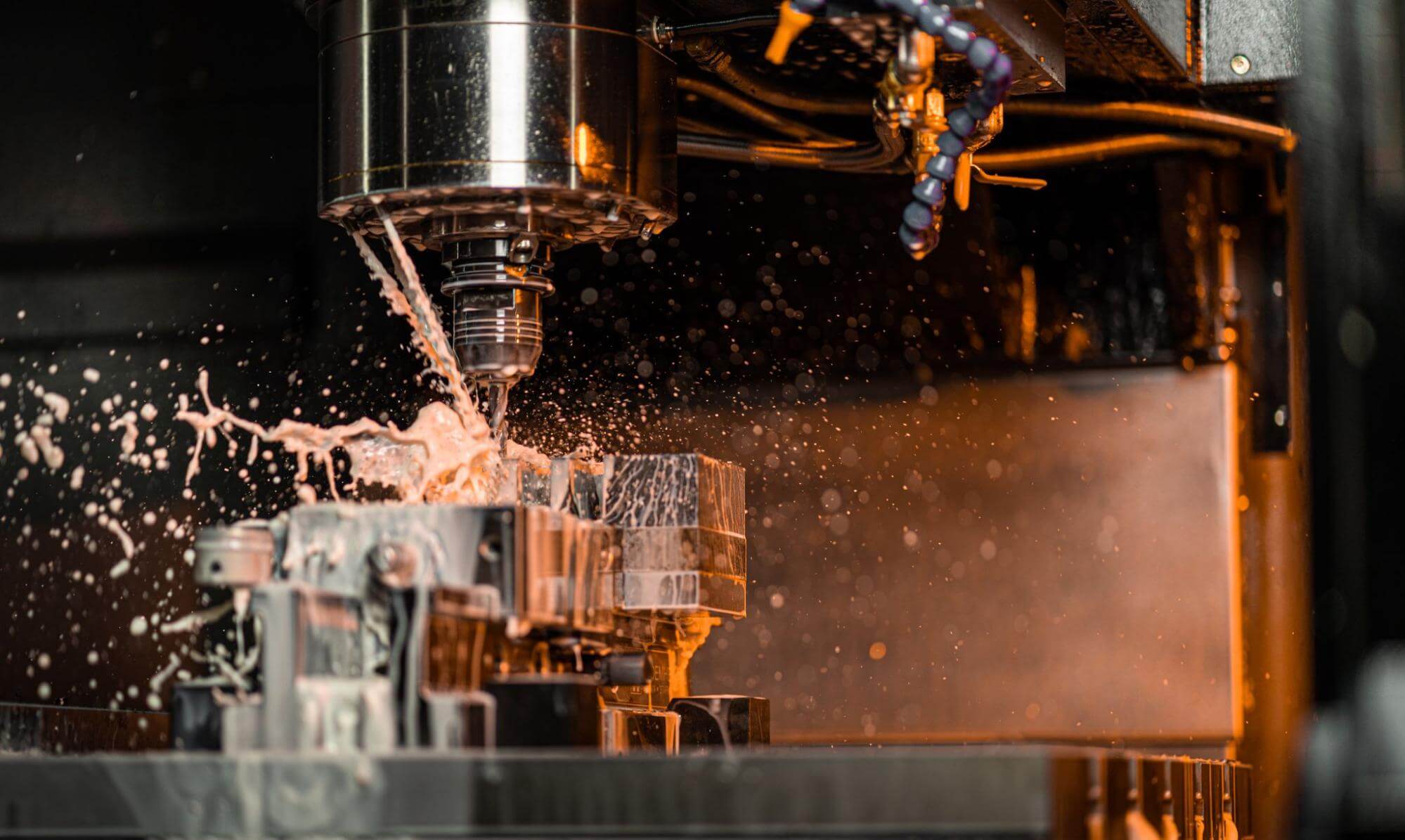

Precision in CNC part machining transcends dimensional accuracy. It encompasses repeatability, surface integrity, geometric conformity, and material consistency. Modern CNC part machines utilize multi-axis control, high-speed spindles, and real-time feedback systems to achieve tolerances within ±0.001 mm—a level of accuracy essential for components used in mission-critical environments. At Lead Precision, our investment in state-of-the-art CNC technology, combined with rigorous quality assurance protocols, ensures that every machined part meets or exceeds international standards.

Our expertise is validated not only through certifications but through real-world application in some of the most demanding environments. Wuxi Lead Precision Machinery has successfully delivered precision components for projects associated with Olympic-standard equipment and military-grade systems. These applications require absolute reliability under extreme conditions, where component failure is not an option. Our involvement in such high-profile, high-stakes projects underscores our capability to deliver precision on demand, backed by decades of engineering experience and continuous process optimization.

Material selection, tool path optimization, thermal compensation, and vibration damping are all engineered into our CNC machining workflows. We utilize advanced simulation software to predict and correct potential deviations before physical machining begins, minimizing waste and maximizing throughput. Furthermore, our in-house metrology lab, equipped with coordinate measuring machines (CMM) and optical inspection systems, ensures full traceability and compliance for every production batch.

The evolution of CNC part machines continues to push the boundaries of what is manufacturable. At Wuxi Lead, we remain at the forefront by integrating automation, Industry 4.0 connectivity, and predictive maintenance into our machining centers—ensuring not only precision today but sustained performance tomorrow.

Below are key technical specifications representative of our CNC machining capabilities:

| Specification | Performance Value |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Maximum Spindle Speed | 24,000 rpm |

| Axis Configuration | Up to 5-axis simultaneous |

| Work Envelope (Max) | 1200 x 800 x 600 mm |

| Surface Finish (Typical) | Ra 0.4 μm (can achieve Ra 0.1 μm with polishing) |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, engineering plastics |

Precision is not accidental—it is engineered. At Wuxi Lead Precision Machinery, it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mission-Critical Applications

At Wuxi Lead Precision Machinery, our technical foundation is built upon advanced multi-axis CNC machining and rigorous quality validation. We specialize in producing complex, high-integrity components for aerospace, medical, and energy sectors where dimensional stability and surface finish directly impact performance and safety. Our facility integrates 28 state-of-the-art CNC machining centers, including 12 DMG MORI CTX beta 2000 5-axis vertical machining systems with Siemens 840D controls. These platforms deliver simultaneous 5-axis contouring with 0.001mm linear resolution and 0.0005° rotary precision, enabling single-setup machining of organic geometries, deep cavities, and thin-walled structures that conventional 3-axis systems cannot achieve. Material versatility spans aerospace-grade titanium alloys (Ti-6Al-4V), Inconel 718, medical stainless steels (316LVM), and high-temp composites, processed under strictly controlled coolant and chip evacuation protocols to prevent thermal distortion.

Quality assurance is non-negotiable. Every critical feature undergoes 100% inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with indexed rotary tables and VAST gold scanning technology. Our AS9100D-certified inspection workflow includes first-article validation per PPAP Level 3, in-process checks at defined operation milestones, and final certification with full GD&T analysis. All measurement data is traceable to NIST standards and stored digitally for client audit access. This closed-loop process ensures conformity to the most stringent engineering specifications, eliminating scrap and rework in downstream assembly.

Our documented capability to maintain extreme tolerances across production volumes is validated through continuous SPC monitoring. The following table reflects our standard production tolerances for critical features, achievable across all qualified materials and part sizes up to 800 x 600 x 500 mm:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.002 mm | CMM / High-Precision Micrometer |

| Positional Accuracy | ±0.015 mm | ±0.005 mm | CMM with Scanning Probe |

| Angular Tolerance | ±0.05° | ±0.01° | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| True Position (Ø) | 0.025 mm | 0.008 mm | CMM with Iterative Alignment |

This precision is sustained through environmental controls (20±1°C workshop), daily machine calibration per ISO 230-2, and operator certification requiring 5+ years of complex part experience. We do not merely meet drawings—we engineer repeatability. For clients requiring tolerances beyond industry standards, our engineering team collaborates from DFx stage to optimize manufacturability without compromising function. Contact us to discuss how our technical infrastructure delivers zero-defect components for your most demanding applications.

Material & Finish Options

Material selection is a foundational decision in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we guide our clients through informed choices based on application requirements, environmental exposure, mechanical loads, and finishing needs. Among the most widely used materials in high-performance industries such as aerospace, automotive, and medical devices are aluminum, steel, and titanium. Each offers distinct advantages and is paired with appropriate surface treatments to enhance functionality.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for applications requiring lightweight components without sacrificing structural integrity. The most common grades used in CNC machining are 6061 and 7075, with 6061 offering good weldability and corrosion resistance, while 7075 delivers higher strength, ideal for demanding structural roles. Aluminum naturally forms a passive oxide layer, but for enhanced surface protection and aesthetic finish, anodizing is recommended.

Steel, particularly stainless steel grades such as 304 and 316, provides superior strength, wear resistance, and corrosion resistance—especially in harsh environments. 316 stainless steel contains molybdenum, which improves resistance to chlorides and makes it ideal for marine and chemical processing applications. Carbon steels like 1018 and 4140 are chosen when high tensile strength and hardness are required, often in tooling or heavy machinery components. While steel does not anodize, it can be passivated, plated, or coated to improve surface durability.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in extreme performance applications. It offers an exceptional strength-to-density ratio, outstanding corrosion resistance, and the ability to maintain mechanical properties at elevated temperatures. Commonly used in aerospace and biomedical implants, titanium’s low thermal conductivity and chemical reactivity require specialized CNC machining techniques, which our facility is fully equipped to handle.

Surface finishing plays a critical role in both performance and appearance. Anodizing, primarily for aluminum, creates a durable, non-conductive oxide layer that enhances wear and corrosion resistance while allowing for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for most industrial applications, while Type III (hardcoat anodizing) provides thicker, harder layers for high-wear environments.

The following table summarizes key mechanical and finishing properties of commonly machined materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Suitable Finishes |

|---|---|---|---|---|

| Aluminum | 310 (6061) – 570 (7075) | 2.7 | 6061, 7075 | Anodizing (Type II/III), Powder Coating |

| Stainless Steel | 505 (304) – 580 (316) | 8.0 | 304, 316, 17-4PH | Passivation, Electropolishing |

| Carbon Steel | 440 (1018) – 970 (4140) | 7.85 | 1018, 4140 | Zinc Plating, Paint, Black Oxide |

| Titanium | 900 – 1,170 | 4.43 | Grade 2, Grade 5 | Anodizing (Tribological), Passivation |

At Wuxi Lead Precision Machinery, we combine material expertise with advanced CNC capabilities to deliver components that meet exacting industry standards. Our engineering team collaborates closely with clients to select optimal materials and finishes, ensuring reliability and performance in every application.

Manufacturing Process & QC

Precision CNC Production Process: From Design to Zero Defects Delivery

At Wuxi Lead Precision Machinery, our CNC part production process is engineered for uncompromising quality and repeatability, ensuring Zero Defects is not aspirational but our operational baseline. This rigor begins at the earliest design stage and permeates every subsequent phase.

Design Phase

Our engineering team collaborates closely with clients during initial design review, applying deep expertise in manufacturability and GD&T. We utilize advanced CAD/CAM simulation software to identify potential geometric conflicts, tool access issues, and material stress points before metal is cut. This proactive analysis prevents costly revisions later, optimizes toolpaths for surface finish and dimensional stability, and ensures the design fully leverages the capabilities of our multi-axis machining centers. Material selection is validated for specific application requirements, including thermal properties and metallurgical integrity.

Prototyping Phase

Critical to our Zero Defects commitment is a rigorous rapid prototyping stage. Using identical 5-axis CNC machines and certified materials as planned for production, we manufacture functional prototypes. Every dimension, critical feature, and surface finish undergoes stringent first-article inspection against the approved drawing using calibrated CMMs, optical comparators, and surface roughness testers. Dimensional reports are shared transparently with the client for sign-off. This phase validates the entire process chain – fixturing, tooling, programming, and inspection methodology – eliminating theoretical risks and confirming the process is capable and stable before committing to volume.

Mass Production Phase

With design and process fully validated, we transition to high-volume production under strict SPC-driven protocols. Our state-of-the-art CNC machining centers operate within tightly controlled environmental conditions. Real-time in-process monitoring tracks critical parameters like tool wear, spindle load, and thermal drift. Every component undergoes 100% critical feature inspection via automated CMM routines at defined intervals, with full traceability to machine, operator, and material batch. Non-conforming parts are isolated immediately via our integrated MES, triggering root cause analysis and corrective action before any further processing occurs. This closed-loop system ensures consistent output meeting the most demanding aerospace, medical, and semiconductor tolerances.

Our commitment to Zero Defects is quantifiable through the precision capabilities consistently achieved across our production floor:

| Critical Specification | Wuxi Lead Precision Capability | Industry Standard Benchmark |

|---|---|---|

| Positional Tolerance | ±0.005 mm | ±0.012 mm |

| Surface Roughness (Ra) | 0.4 μm | 1.6 μm |

| Material Range | Aluminum to Inconel, Titanium | Primarily Aluminum, Steel |

| Critical Feature Inspection | 100% CMM Verification | Sampling Plans (AQL) |

| Process Capability (Cpk) | ≥1.67 | ≥1.33 |

This integrated process – from collaborative design validation through prototype verification to SPC-controlled mass production – is the foundation of Wuxi Lead’s reputation for delivering mission-critical CNC machined parts with absolute reliability. We transform complex engineering requirements into flawless physical components, batch after batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and speed are not just advantages—they are requirements. As a leading provider of precision CNC machining services in China, we specialize in delivering complex, high-tolerance components for industries where failure is not an option. From aerospace and medical devices to automotive and energy systems, our clients trust Lead Precision to meet and exceed the most demanding engineering specifications.

Our commitment begins with advanced 3-, 4-, and 5-axis CNC machining capabilities, supported by state-of-the-art equipment and a quality management system compliant with ISO 9001:2015 standards. Every component we produce undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers to ensure dimensional accuracy and repeatability. Whether you require low-volume prototypes or high-volume production runs, our scalable manufacturing solutions are engineered for consistency and performance.

What sets Lead Precision apart is our end-to-end engineering partnership. From initial design consultation to final delivery, our team of experienced CNC engineers collaborates closely with your technical staff to optimize part geometry, material selection, and manufacturability. We support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance plastics such as PEEK and PTFE. Our surface treatment options—including anodizing, passivation, plating, and powder coating—ensure your parts meet both functional and aesthetic requirements.

We operate on a foundation of transparency, responsiveness, and technical excellence. Our facility in Wuxi, Jiangsu Province, is equipped with real-time production monitoring and ERP integration, enabling us to provide accurate lead time tracking and full traceability for every order. With competitive pricing, fast turnaround times, and global shipping capabilities, we deliver value without compromise.

For mission-critical applications, the right manufacturing partner makes all the difference. Choose Lead Precision—where precision engineering meets industrial reliability.

Review our technical capabilities below:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; multi-axis Swiss machining |

| Tolerance | Up to ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Copper, PEEK, PTFE, Nylon |

| Max Work Envelope | 1200 x 800 x 600 mm (milling); Ø200 x 500 mm (turning) |

| Surface Finish | Ra 0.8 µm standard; down to Ra 0.2 µm with polishing |

| Quality Standards | ISO 9001:2015 certified, First Article Inspection (FAI), PPAP, FAIR reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

To begin your next precision machining project with confidence, contact us today at [email protected]. Our engineering team is ready to review your drawings, provide a competitive quote, and support your path to production excellence. Partner with Wuxi Lead Precision Machinery—your trusted source for high-precision CNC components from China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.