Technical Contents

Engineering Guide: Cnc Montréal

Engineering Insight: Precision as Montreal’s Industrial Imperative

In Montreal’s advanced manufacturing ecosystem—anchored by aerospace giants, medical innovators, and defense contractors—precision CNC machining transcends technical specification; it defines product integrity, regulatory compliance, and market competitiveness. For industries where a micron-scale deviation can trigger catastrophic system failure or regulatory rejection, tolerances are non-negotiable. Montreal’s engineering teams demand partners who treat precision not as a target but as a foundational discipline, embedded in every spindle rotation and toolpath calculation. At Wuxi Lead Precision Machinery, we operationalize this rigor daily, delivering components where sub-micron repeatability is standard, not exceptional.

Our 18-year evolution in high-stakes sectors directly informs our approach to Montreal’s unique challenges. We engineered critical structural components for the Beijing 2008 Olympic Stadium, where thermal expansion tolerances of ±0.05mm across 300-meter spans dictated assembly success. Similarly, our work on classified military avionics systems demanded zero-defect certification under MIL-STD-810G, proving our capacity to merge extreme precision with uncompromising traceability. These experiences forged our methodology: precision begins with material science understanding, extends through vibration-damped machine calibration, and culminates in real-time in-process metrology. For Montreal’s aerospace suppliers facing AS9100 rev D audits or medical device firms navigating ISO 13485, this end-to-end control eliminates guesswork.

Consider the technical realities shaping Montreal’s precision landscape:

| Critical Parameter | Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.001 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.2 μm |

| Positional Repeatability | ±0.005 mm | ±0.0005 mm |

| Materials Complexity | Aluminum, Steel | Ti-6Al-4V, Inconel 718, CFRP |

This capability stems from our dedicated Swiss and German-machine cell, operating under ISO Class 7 cleanroom conditions for critical medical/aerospace runs. Crucially, we integrate Montreal’s design intent early—using your CATIA V5 or Siemens NX files to simulate thermal drift during machining, preempting field failures. When Pratt & Whitney Canada requires turbine blade fixtures holding ±0.002mm across 500mm, or Medtronic needs implant-grade titanium with 0.4μm Ra finishes, our process validation protocols ensure first-article approval on schedule.

Precision in Montreal isn’t merely about hitting numbers; it’s about engineering trust into every component. Wuxi Lead Precision Machinery delivers this through proven high-compliance manufacturing discipline—where Olympic and military heritage translates to your competitive advantage. Let us align our metrology-certified workflows with your next precision challenge.

Precision Specs & Tolerances

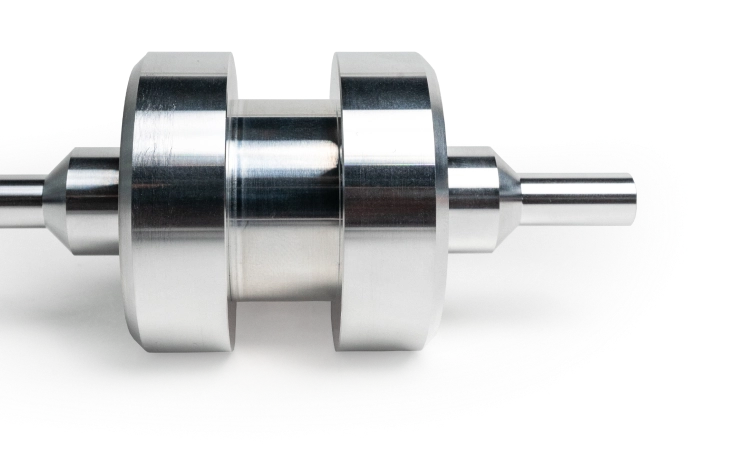

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored for high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across multiple planes, significantly reducing setup times and part handling while maintaining tight tolerances across intricate features.

Our machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software to ensure process stability and repeatability. This enables us to work efficiently with a broad range of materials including aluminum alloys, stainless steels, titanium, Inconel, and engineering plastics, meeting the demanding requirements of mission-critical applications. The integration of 5-axis technology not only enhances geometric flexibility but also improves tool reach and access, minimizing the need for secondary operations and custom fixtures.

To guarantee the highest level of quality and conformance, every production run is supported by comprehensive metrology and inspection protocols. We utilize a state-of-the-art Coordinate Measuring Machine (CMM) for first-article inspection and in-process quality control. The CMM system provides full 3D measurement validation, ensuring dimensional accuracy and compliance with GD&T (Geometric Dimensioning and Tolerancing) specifications. All inspection data is documented and traceable, supporting full quality reporting for audit and certification purposes.

Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and machining strategy. This collaborative approach reduces lead times, lowers production costs, and ensures that final components meet both functional and regulatory standards. With a focus on precision, consistency, and technical excellence, Wuxi Lead Precision Machinery is equipped to support low-volume prototypes through high-volume production runs with the same level of rigor and attention to detail.

The following table outlines the key technical specifications and achievable tolerances across our 5-axis CNC machining processes:

| Parameter | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.003 mm (±0.0001 in) |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Maximum Work Envelope | 1,200 mm × 800 mm × 750 mm (47.2 in × 31.5 in × 29.5 in) |

| Spindle Speed | Up to 24,000 rpm |

| Tool-to-Part Interference Detection | Yes, via integrated probing and simulation |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Plastics |

| Inspection Equipment | Zeiss or equivalent CMM, Optical Comparators, Micrometers |

Through advanced equipment, rigorous quality control, and engineering expertise, Wuxi Lead Precision Machinery ensures that every component meets the exacting standards required by global manufacturers.

Material & Finish Options

Material Selection for Precision CNC Machining in Montreal’s Industrial Landscape

Material choice fundamentally impacts part performance, cost efficiency, and regulatory compliance in Montreal’s aerospace, medical, and industrial sectors. Selecting the optimal alloy requires balancing mechanical properties, machinability, environmental resistance, and end-use requirements. At Wuxi Lead Precision Machinery, we prioritize materials that align with stringent North American standards while optimizing for CNC manufacturability. Below we detail critical considerations for aluminum, steel, and titanium, followed by anodizing as a premier surface finish solution.

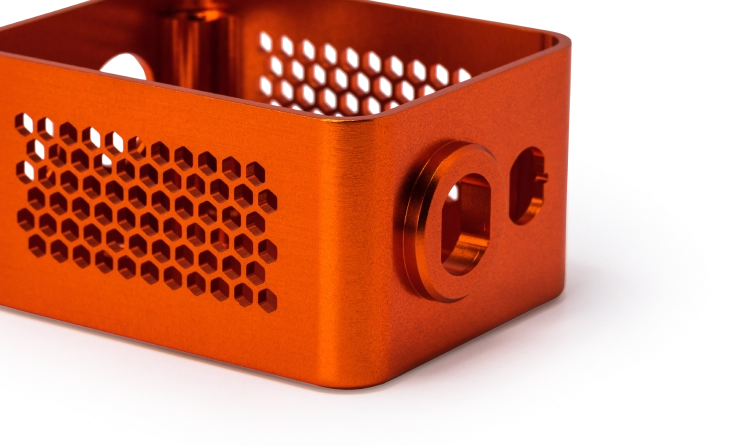

Aluminum alloys dominate lightweight applications demanding high strength-to-weight ratios. Grade 6061-T6 offers excellent weldability and moderate strength for structural components, while 7075-T6 provides superior strength for aerospace fittings. Aluminum’s low density reduces machining forces and cycle times, lowering production costs. However, its softness necessitates precise toolpath strategies to avoid burring or dimensional instability in thin-walled features common in Montreal’s drone and satellite manufacturing sectors.

Carbon and stainless steels deliver unmatched durability for high-stress environments. 4140 chrome-moly steel excels in shafts and gears requiring toughness, whereas 304 and 316 stainless grades are mandatory for medical implants and food processing equipment due to corrosion resistance and biocompatibility. Steel’s higher density increases tool wear and machining time versus aluminum, but its rigidity ensures dimensional stability in complex geometries. Montreal’s cold climate further validates steel for outdoor hydraulic components where thermal contraction must be minimized.

Titanium alloys like Grade 5 (Ti-6Al-4V) are indispensable for aerospace and medical applications demanding extreme strength, corrosion resistance, and biocompatibility. Despite its high cost and challenging machinability—requiring rigid setups, specialized tooling, and controlled feeds—titanium’s performance in critical load-bearing parts justifies its use. Montreal’s aerospace cluster frequently specifies titanium for landing gear and engine components where failure is not an option.

Anodizing remains the gold standard for aluminum surface enhancement. Type II (sulfuric acid) anodizing provides decorative finishes and moderate corrosion resistance, while Type III (hardcoat) anodizing delivers 50–100 µm thick wear-resistant layers essential for hydraulic pistons or marine hardware. Both processes improve adhesion for secondary coatings and meet MIL-A-8625 specifications demanded by Montreal’s defense contractors. Crucially, anodizing does not alter critical dimensions when controlled within tight tolerances.

Key material properties for CNC machining are summarized below:

| Material | Density (g/cm³) | Machinability Rating | Common Grades | Primary Montreal Applications |

|---|---|---|---|---|

| Aluminum | 2.7 | Excellent (100%) | 6061-T6, 7075-T6 | Aerospace brackets, drone frames |

| Steel | 7.8 | Good (65%) | 4140, 304, 316 | Medical implants, industrial gears |

| Titanium | 4.5 | Fair (20%) | Ti-6Al-4V (Gr 5) | Aircraft fittings, surgical tools |

Strategic material selection begins with understanding operational stresses, environmental exposure, and regulatory frameworks. For Montreal manufacturers targeting global markets, partnering with a precision CNC provider experienced in material science ensures components meet exacting performance criteria while controlling production costs. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to guide clients through this critical decision phase, guaranteeing optimal outcomes for every project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our CNC machining production process is engineered to deliver uncompromising precision, repeatability, and zero-defect performance for high-end industrial clients in markets such as aerospace, medical devices, and advanced automation. Our end-to-end workflow integrates three critical phases: Design, Prototyping, and Mass Production—each governed by strict quality protocols and advanced digital control systems.

The process begins with Design, where our engineering team collaborates closely with client specifications using advanced CAD/CAM software. This stage includes full 3D modeling, tolerance analysis, material selection, and manufacturability evaluation. Finite element analysis (FEA) and design for manufacturability (DFM) reviews ensure that every component is optimized for both performance and production efficiency. All design files are version-controlled and digitally archived to maintain traceability throughout the production lifecycle.

Next, we move into Prototyping, a critical validation phase that bridges design intent with mass production readiness. Using high-precision 5-axis CNC machines, we produce functional prototypes from the actual production materials—such as aerospace-grade aluminum, titanium, or medical stainless steel. These prototypes undergo rigorous inspection via coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, fit, function, and thermal stability are verified against original specifications. Client feedback is incorporated at this stage, allowing for rapid iteration without impacting the production timeline.

Once prototype approval is confirmed, we transition seamlessly into Mass Production. Our fully automated CNC cells operate under real-time monitoring through integrated Manufacturing Execution Systems (MES), enabling live tracking of tool wear, spindle load, and dimensional drift. Each component is machined with micron-level precision, supported by in-process gauging and statistical process control (SPC). Every batch is subject to 100% first-article inspection and ongoing random sampling to ensure compliance with ISO 9001 and IATF 16949 standards. Our zero-defect philosophy is enforced through predictive maintenance, operator certification, and full documentation of every production parameter.

Throughout all stages, traceability is maintained via laser part marking and digital work orders, ensuring full accountability from raw material to final shipment. This disciplined, technology-driven approach allows Wuxi Lead to deliver consistent, high-integrity components at scale—meeting the exacting demands of global precision industries.

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness | Ra 0.4 µm (standard), down to Ra 0.1 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Supported | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, Brass, PEEK, Delrin |

| Quality Standards | ISO 9001, IATF 16949, ISO 13485 (medical) |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, Vision System |

| Production Capacity | 50,000+ units/month (depending on complexity) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Global CNC Machining Authority

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical CNC machining demands in Montréal’s high-stakes industrial landscape. We bridge the gap between ambitious design specifications and flawless physical execution, serving aerospace innovators, medical device pioneers, and automotive Tier 1 suppliers across Québec. Our facility operates under uncompromising ISO 9001:2015 and ISO 13485 standards, leveraging German and Japanese precision equipment to deliver components where sub-micron repeatability is non-negotiable. Forget the risks of fragmented supply chains; we provide end-to-end accountability from CAD file to certified shipment, ensuring your Montréal operations never face costly downtime due to dimensional drift or material non-conformance.

Our technical capabilities are engineered for Montréal’s most demanding applications. The table below details our core production parameters for immediate reference:

| Specification | Capability Range |

|---|---|

| Material Expertise | Titanium, Inconel, Hastelloy, 7075-T7, PEEK, 4140/4340 Steel |

| Tolerance Control | ±0.0001″ (2.5 µm) linear; ±0.00004″ (1 µm) positional |

| Max Work Envelope | 5-axis: 800 x 600 x 500 mm; Mill-Turn: Ø420 x 1,200 mm |

| Surface Finish | Ra 0.4 µm (standard); Ra 0.1 µm (optical-grade) |

| Lead Time (Prototype) | 12–18 business days from approved drawing |

What distinguishes Lead Precision is our engineer-to-engineer collaboration model. We deploy dedicated technical account managers fluent in both Montréal’s engineering lexicon and China’s manufacturing ecosystem. This eliminates translation delays and cultural friction, ensuring your Geometric Dimensioning and Tolerancing (GD&T) callouts are interpreted correctly on the first try. Our real-time quality reporting portal provides live CMM data access, while our Montreal-based logistics hub guarantees customs-cleared delivery within 72 hours of shipment from Shanghai. For Montréal firms facing compressed development cycles, our rapid prototyping cell reduces non-recurring engineering (NRE) costs by 30% compared to local alternatives, without sacrificing AS9100-compliant traceability.

Montréal’s precision manufacturing sector requires partners who understand the stakes of every micron. Whether you’re scaling production for Bombardier’s next-gen avionics or validating surgical robotics components, Lead Precision delivers the technical rigor and responsive partnership your projects demand. We don’t just meet specifications—we safeguard your reputation for excellence.

Initiate your precision machining partnership with zero procurement risk. Contact our Montréal technical team directly at [email protected] with your RFQ and engineering package. Specify “Montréal Priority” in the subject line to trigger our 4-hour response protocol. Let us demonstrate how global capability, local accountability, and uncompromised precision converge to accelerate your time-to-market. Your next breakthrough component starts with an engineer-to-engineer dialogue—reach out today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.