Technical Contents

Engineering Guide: Cnc Mill/Turn Machining Services

Engineering Insight: CNC Mill/Turn Machining Services

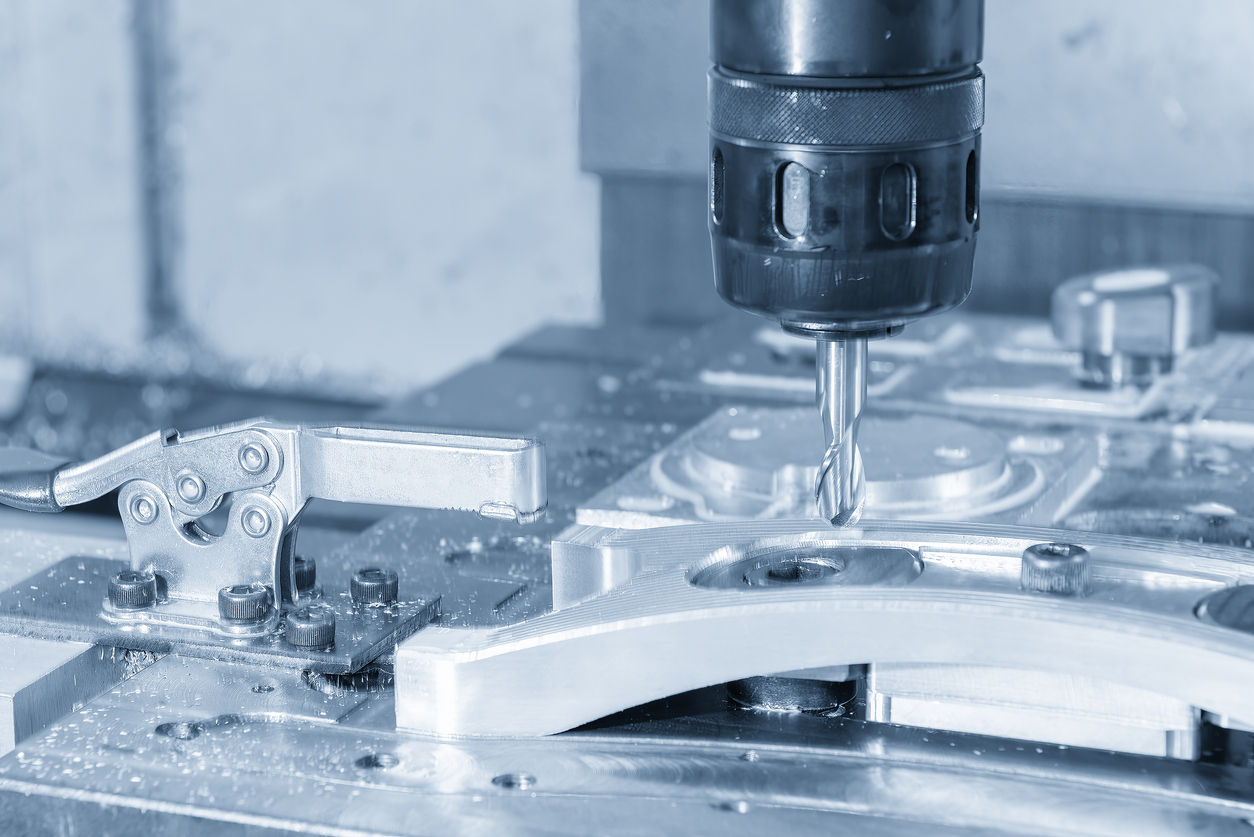

In high-performance manufacturing, the integration of CNC milling and turning operations is not merely a matter of efficiency—it is a fundamental requirement for achieving uncompromising precision, repeatability, and geometric complexity. At Wuxi Lead Precision Machinery, we define our expertise in CNC mill/turn machining services through decades of refinement, serving industries where tolerances are measured in microns and failure is not an option. Our engineering philosophy centers on the synchronization of advanced multi-axis technology with rigorous process control, ensuring every component meets the highest standards of dimensional accuracy and surface integrity.

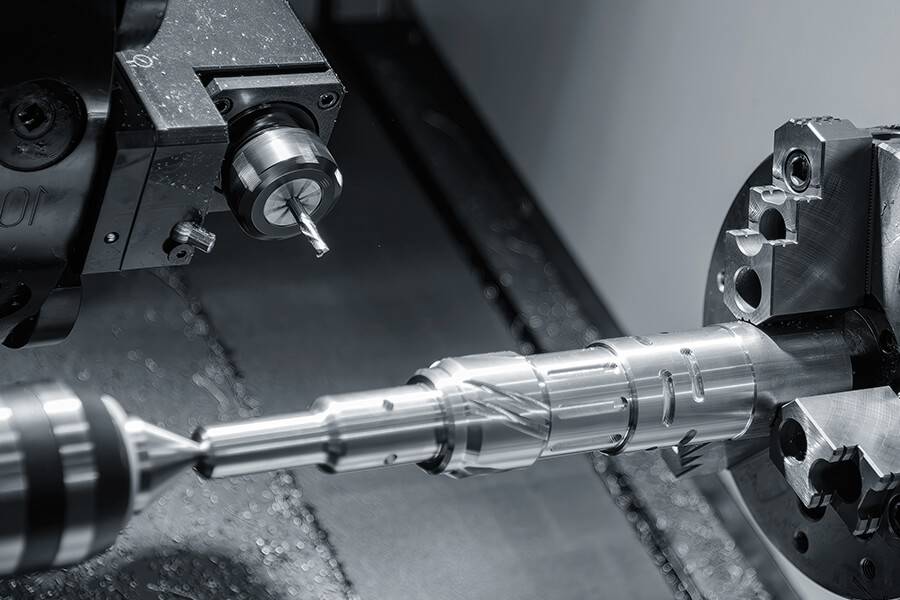

Precision in mill/turn machining stems from the seamless transition between rotating workpiece operations (turning) and multi-directional cutting (milling), all executed within a single setup on a hybrid CNC lathe. This consolidation eliminates cumulative errors introduced by part re-fixturing, significantly improving concentricity, positional accuracy, and overall part consistency. For mission-critical applications in aerospace, defense, and high-end industrial automation, such precision directly translates into enhanced performance, extended service life, and reduced system-level risk.

Our facility in Wuxi operates a fleet of advanced multi-axis mill/turn centers equipped with live tooling, Y-axis capabilities, and high-speed spindles. These machines enable the complete machining of complex geometries—such as eccentric features, radial holes, off-center milling, and intricate contours—without manual intervention. Coupled with in-process probing and automated tool compensation, our systems maintain tolerances as tight as ±0.002 mm, with surface finishes reaching Ra 0.4 µm or better, depending on material and design requirements.

Wuxi Lead Precision Machinery’s commitment to excellence is validated through our track record in supplying components for Olympic-grade timing systems and military-grade defense equipment. These projects demanded not only extreme precision but also full traceability, material certification, and adherence to international quality standards such as ISO 9001 and AS9100. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase, optimizing part geometry and material selection to ensure manufacturability without sacrificing performance.

The following table outlines the key technical specifications of our CNC mill/turn machining capabilities:

| Parameter | Specification |

|---|---|

| Machine Types | Multi-axis CNC turning centers with live tooling |

| Axis Configuration | Y-axis, C-axis, 3-axis and 4-axis mill/turn |

| Maximum Turning Diameter | 400 mm |

| Maximum Turning Length | 600 mm |

| Spindle Speed (Milling) | Up to 12,000 rpm |

| Tolerance Capability | ±0.002 mm |

| Surface Finish (Typical) | Ra 0.4 – 1.6 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Secondary Operations | Deburring, Cleaning, Precision Inspection, CMM |

In an era where component complexity continues to rise, Wuxi Lead Precision Machinery stands at the forefront of mill/turn innovation, delivering precision-engineered solutions that meet the most demanding global standards.

Precision Specs & Tolerances

Technical Capabilities: Precision Mill/Turn Machining at Scale

Wuxi Lead Precision Machinery delivers uncompromising precision for complex mill/turn components through integrated multi-axis technology and rigorous quality assurance. Our facility operates 28 advanced CNC machining centers, including 12 simultaneous 5-axis platforms from industry leaders Makino and DMG MORI. These systems feature high-torque spindles (up to 30,000 RPM), 1.2-meter travel envelopes, and dynamic tool changers supporting 60+ tool capacities. This infrastructure eliminates secondary operations by machining intricate geometries—such as turbine blades, hydraulic manifolds, and medical implants—in a single setup. The integration of Y-axis turning with 5-axis milling enables true mill/turn synergy, reducing part handling errors while achieving ±0.001 mm positional accuracy on features like off-center bores and compound angles.

Quality control is embedded at every process stage through our ISO 17025-accredited metrology lab. All critical dimensions undergo 100% verification via Zeiss CONTURA G3 CMMs equipped with REVO 5-axis scanning heads, enabling sub-micron measurement repeatability. Surface finishes are validated using Bruker white-light interferometers, while material certifications and heat treatment records are digitally traceable per AS9100 requirements. Statistical process control (SPC) monitors tool wear and machine performance in real time, ensuring batch consistency across volumes from 1 to 10,000+ units.

Our tolerance capabilities reflect aerospace and medical industry standards, validated through CMM inspection protocols. The table below details achievable specifications under controlled environmental conditions (20±0.5°C):

| Feature Type | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm | CMM with calibrated probes |

| Geometric Form | 0.015 mm | 0.003 mm | CMM scanning |

| Positional Accuracy | ±0.008 mm | ±0.0015 mm | CMM with iterative alignment |

| Surface Roughness | Ra 0.8 μm | Ra 0.2 μm | Interferometry |

| Thread Accuracy | 6H/6g | 4H/4g | Optical comparator |

This precision foundation supports rapid prototyping through full production runs for sectors demanding zero-defect outcomes. We machine all aerospace alloys (Inconel 718, Ti-6Al-4V), medical-grade stainless steels (316LVM, 17-4PH), and engineered polymers (PEEK, Torlon) with material-specific process parameters. Our engineering team collaborates pre-production to optimize part orientation, fixture design, and toolpath strategies—reducing cycle times by 22% on average while maintaining geometric integrity. All deliverables include full inspection reports with GD&T callouts per ASME Y14.5, ensuring seamless integration into your assembly workflows. Partner with Wuxi Lead to transform complex designs into certified, high-integrity components with documented process reliability.

Material & Finish Options

Material selection is a critical factor in the success of any precision CNC mill/turn machining project. At Wuxi Lead Precision Machinery, we understand that the right material not only ensures functional performance but also impacts manufacturability, cost-efficiency, and longevity of the final component. Among the most widely used materials in high-precision applications are aluminum, steel, and titanium—each offering distinct mechanical properties, corrosion resistance, and suitability for specific operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for aerospace, automotive, and electronics applications where lightweight and corrosion resistance are essential. The most commonly used grade, 6061-T6, provides good weldability and moderate strength, while 7075-T6 offers higher strength at the expense of reduced corrosion resistance. Aluminum’s low density and ease of machining make it ideal for complex geometries and high-volume production.

Steel, particularly alloy and stainless variants, delivers superior strength, durability, and wear resistance. 4140 alloy steel is widely used in high-stress mechanical applications such as shafts and tooling due to its excellent toughness and hardenability. Stainless steel 303 offers improved machinability for intricate parts, while 316 stainless provides outstanding corrosion resistance, especially in marine or chemical environments. Steel components are often chosen for industrial machinery, medical devices, and oil & gas equipment where long-term reliability under load is paramount.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace, defense, and medical implant manufacturing. Although more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s performance in demanding environments justifies its use where failure is not an option.

Surface finishing plays a vital role in enhancing both the functional and aesthetic qualities of machined parts. Anodizing, particularly Type II and Type III (hard coat), is a widely specified finish for aluminum components. It increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Type III anodizing provides a thicker, more durable coating suitable for aerospace and military-grade components. For steel and titanium, alternative finishes such as passivation, plating, or coating are typically recommended.

Below is a comparative overview of key material properties for common grades used in CNC mill/turn operations.

| Material | Grade | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 95 | 2.7 | Aerospace, Electronics, Automotive |

| Aluminum | 7075-T6 | 572 | 150 | 2.8 | High-stress Aerospace Components |

| Steel | 4140 | 655 | 197 | 7.85 | Shafts, Tooling, Industrial Parts |

| Stainless Steel | 316 | 580 | 155 | 8.0 | Marine, Medical, Chemical |

| Titanium | Ti-6Al-4V | 950 | 360 | 4.43 | Aerospace, Medical, Defense |

Selecting the optimal material and finish requires a deep understanding of both design intent and operational conditions. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through engineering consultation and advanced CNC manufacturing capabilities.

Manufacturing Process & QC

Design Collaboration and Engineering Validation

At Wuxi Lead Precision Machinery, the production process begins with intensive design collaboration. Our engineering team partners directly with clients to review CAD models, material specifications, and geometric dimensioning and tolerancing (GD&T) requirements. Finite element analysis (FEA) and manufacturability assessments are conducted to preemptively resolve structural or production challenges. This phase ensures designs align with both functional intent and CNC mill/turn machining capabilities, eliminating theoretical errors before physical work commences. Critical parameters including surface finishes, concentricity, and positional tolerances are formally signed off, establishing an unambiguous blueprint for zero-defect execution.

Prototyping and Iterative Refinement

Prototyping transforms validated designs into tangible precision components using identical CNC equipment deployed for mass production. Each prototype undergoes rigorous dimensional validation against the approved CAD model via coordinate measuring machines (CMM) and optical comparators. Material integrity tests, including hardness verification and microstructure analysis, confirm compliance with aerospace or medical-grade standards where applicable. Client feedback drives iterative adjustments—often within 72 hours—ensuring form, fit, and function meet exact specifications. This stage is non-negotiable for risk mitigation; it validates toolpaths, fixturing, and process stability while certifying that tolerances as tight as ±0.005 mm are consistently achievable.

Mass Production with Embedded Quality Assurance

Transition to volume production leverages the perfected prototype process under our Zero Defects framework. Every CNC mill/turn operation integrates real-time in-process inspections using touch-probe systems and laser tool setters. Statistical process control (SPC) monitors critical dimensions across batches, with automated alerts triggering immediate corrective action if deviations approach tolerance limits. Final inspection employs 100% first-article reporting and AQL 0.65 sampling for high-volume runs, cross-referenced against CMM datasets. All components ship with full traceability documentation, including material certificates and inspection reports, ensuring compliance with ISO 9001 and IATF 16949 standards.

Process Capability and Tolerance Specifications

| Phase | Tolerance Range | Key Verification Method | Output Standard |

|---|---|---|---|

| Design Validation | N/A (Theoretical) | FEA/GD&T Simulation | Approved CAD + Process Plan |

| Prototyping | ±0.005 mm to ±0.01 mm | CMM + Optical Comparator | 3D Deviation Report ≤ 0.002 mm |

| Mass Production | ±0.002 mm to ±0.008 mm | SPC + In-Process Probing | Cp/Cpk > 1.67 Certified |

This structured workflow—anchored in engineering rigor and closed-loop quality control—guarantees that every component from Wuxi Lead meets the uncompromising standards demanded by automotive, aerospace, and medical device industries. We transform complex designs into flawless production realities through systematic validation, not侥幸. Supply chain integrity begins with process perfection.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Mill/Turn Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a trusted leader in high-end CNC mill/turn machining services, we specialize in turning complex engineering designs into real-world, high-tolerance components for industries where performance cannot be compromised. From aerospace and medical devices to automation and energy systems, our machining solutions are engineered to meet the most demanding specifications.

Our advanced CNC mill/turn centers combine multi-axis milling and precision turning in a single setup, minimizing cycle times and eliminating cumulative errors from secondary operations. This integrated approach ensures superior geometric accuracy, exceptional surface finishes, and consistent repeatability—critical for mission-critical applications. With state-of-the-art equipment and a team of seasoned CNC engineers, we handle everything from rapid prototyping to high-volume production runs, all under strict ISO 9001:2015 quality standards.

What sets us apart is our end-to-end engineering collaboration. We don’t wait for you to finalize your design. Our technical team engages early, offering Design for Manufacturability (DFM) feedback to optimize part geometry, reduce material waste, and accelerate time-to-market. Whether you’re working with titanium, stainless steel, aluminum, or exotic alloys, we apply material-specific cutting strategies to ensure structural integrity and dimensional stability.

Our facility in Wuxi, China, is equipped with a full suite of precision tools, including Y-axis capable mill/turn machines, live tooling lathes, and high-speed 5-axis milling centers. Combined with in-process inspection using coordinate measuring machines (CMM) and optical comparators, we guarantee every component meets your exact tolerances—down to ±0.005 mm.

We understand that global supply chains demand more than just precision. They demand trust, transparency, and responsiveness. That’s why every project at Lead Precision is managed with real-time communication, scheduled progress updates, and full documentation traceability. When you partner with us, you’re not outsourcing—you’re gaining a manufacturing ally.

Below are key capabilities that define our CNC mill/turn machining services:

| Specification | Detail |

|---|---|

| Machine Types | CNC Mill/Turn Centers, Multi-Tasking Machines |

| Axis Capability | Up to 5-axis simultaneous machining |

| Maximum Work Envelope | Ø600 mm × 1,200 mm |

| Tolerance | As tight as ±0.005 mm |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Secondary Operations | Deburring, Anodizing, Passivation, Heat Treatment |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

Ready to elevate your manufacturing outcomes? Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery be the precision behind your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.