Technical Contents

Engineering Guide: Cnc Millling

Engineering Insight: CNC Milling – The Foundation of Precision Manufacturing

In the realm of high-end manufacturing, CNC milling stands as a cornerstone technology, enabling the production of complex, high-tolerance components essential across aerospace, defense, medical, and advanced industrial sectors. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is a foundational requirement for reliability, safety, and innovation. Our engineering philosophy centers on delivering CNC-milled components that meet the most stringent specifications, where tolerances are measured in microns and consistency is non-negotiable.

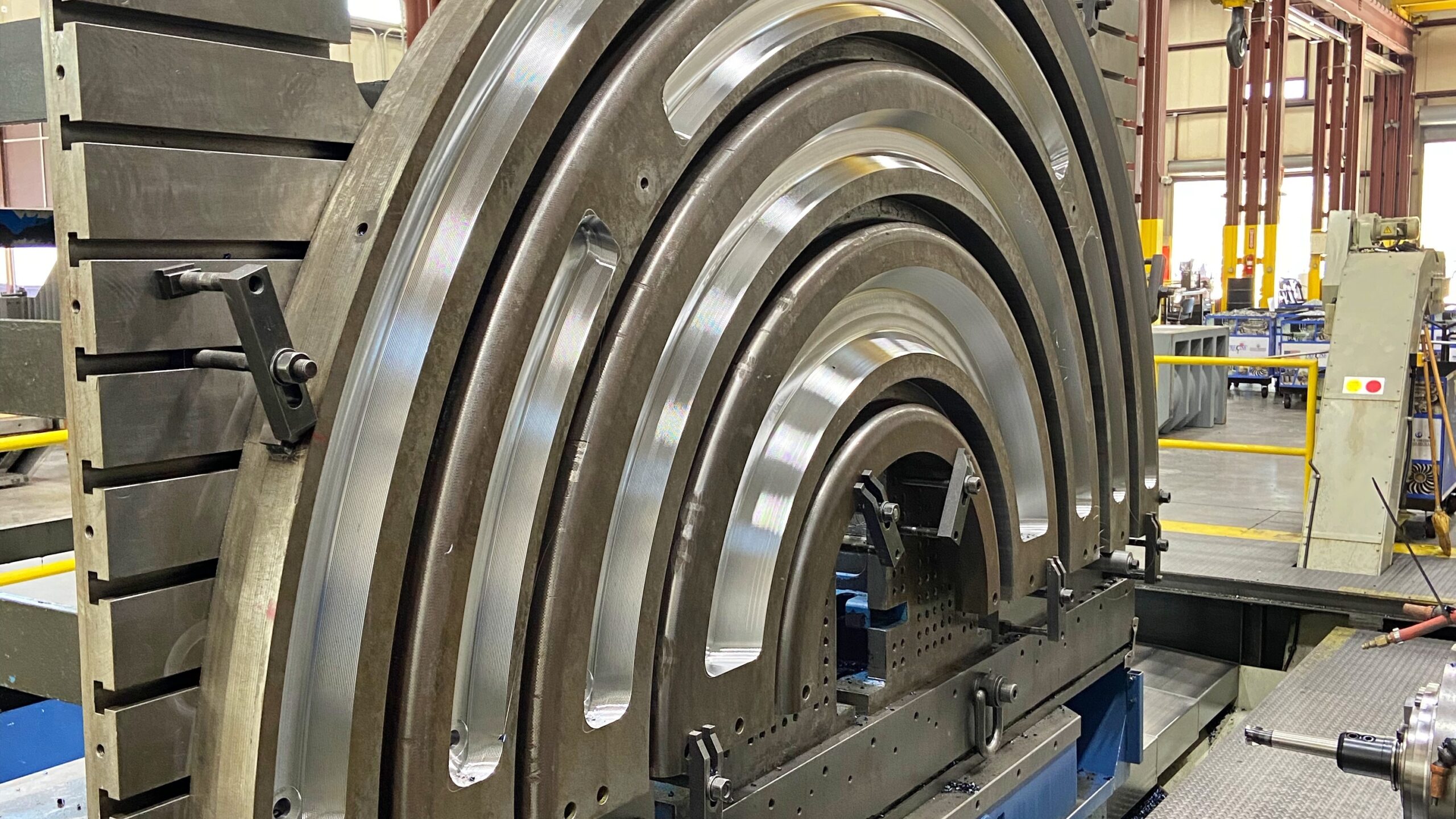

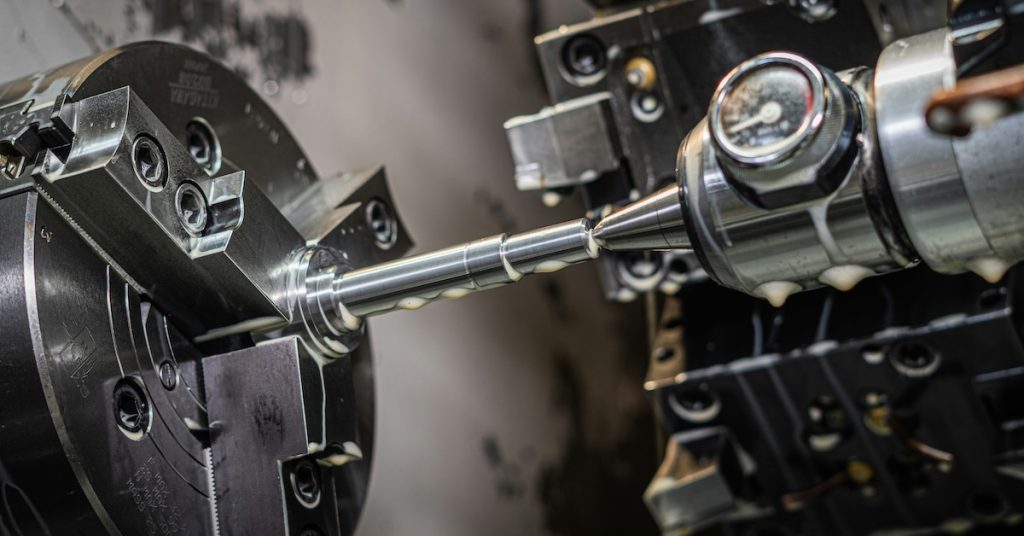

CNC milling involves the controlled removal of material using computer-guided rotating cutters, allowing for multi-axis machining of intricate geometries from metals, alloys, and advanced composites. What separates true precision milling from standard machining is the integration of high-rigidity machine platforms, thermal compensation systems, advanced toolpath algorithms, and continuous in-process inspection. At Lead Precision, our CNC milling operations leverage 3-, 4-, and 5-axis configurations, ensuring optimal tool access and minimal setup transitions—critical for maintaining dimensional accuracy across complex parts.

Our commitment to precision is validated by our proven track record in mission-critical applications. We have supplied components for infrastructure projects tied to Olympic venues, where structural integrity and dimensional consistency were paramount under extreme environmental loads. Additionally, our parts have been integrated into military-grade systems, where failure is not an option. These applications demand more than technical capability—they require a culture of precision embedded in every phase of production, from raw material sourcing to final inspection.

At the heart of our process is a quality assurance system aligned with ISO 9001 standards, supported by coordinate measuring machines (CMM), laser interferometry, and real-time tool wear monitoring. Every milled component undergoes rigorous dimensional and surface finish validation, ensuring compliance with GD&T (Geometric Dimensioning and Tolerancing) requirements.

The following table outlines the core specifications achievable through our precision CNC milling capabilities:

| Parameter | Capability |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Tolerance Range | ±0.01 mm (standard), ±0.005 mm (tight) |

| Surface Finish (Ra) | 0.4 – 3.2 µm (depending on material) |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| CNC Control Systems | Fanuc, Siemens, Heidenhain |

With over a decade of specialized experience, Wuxi Lead Precision Machinery continues to push the boundaries of what CNC milling can achieve. Our engineering team collaborates closely with clients to optimize part design for manufacturability, ensuring that precision is built in—not inspected in. In an industry where performance hinges on perfection, we deliver components you can trust—engineered to excel under the most demanding conditions.

Precision Specs & Tolerances

Advanced 5-Axis CNC Milling Capabilities at Wuxi Lead Precision Machinery

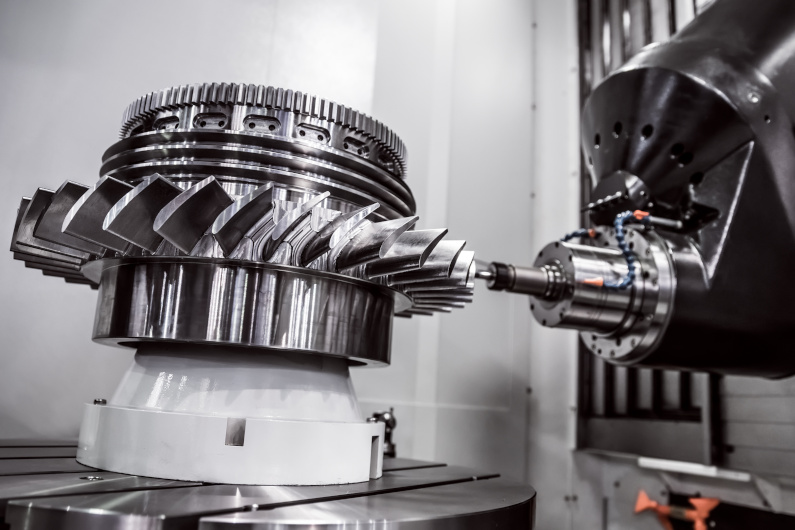

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding aerospace, medical, and energy sector components through our state-of-the-art 5-axis CNC milling platform. Our HAAS UMC-750 and DMG MORI CTX beta 1250 universal machining centers represent the pinnacle of multi-axis technology, enabling simultaneous five-axis interpolation for complex geometries unattainable with 3-axis systems. This capability eliminates the need for multiple setups, drastically reducing cumulative error and ensuring critical feature relationships are maintained within micron-level tolerances across intricate contours, deep cavities, and organic surfaces. We routinely machine high-value materials including Inconel 718, titanium alloys, hardened tool steels (up to 60 HRC), and advanced composites with exceptional surface integrity and dimensional stability.

The core strength of our 5-axis process lies in dynamic work envelope optimization. By continuously orienting the cutting tool normal to the part surface, we achieve superior surface finishes, extended tool life, and significantly reduced cycle times compared to indexed 3+2 axis approaches. This is critical for producing fluid dynamics components, turbine blades, orthopedic implants, and complex jigs/fixtures where geometric accuracy directly impacts functional performance. Our engineering team leverages Mastercam and Siemens NX CAM software to develop highly optimized toolpaths, rigorously simulating material removal to prevent collisions and ensure process reliability before any metal is cut. Material utilization is maximized through strategic fixturing and adaptive clearing strategies, minimizing waste on expensive stock.

Quality assurance is intrinsically woven into our manufacturing workflow, not an afterthought. Every critical dimension undergoes verification against the original CAD model using our Zeiss CONTURA G3 Coordinate Measuring Machine (CMM) equipped with VAST XT gold sensor technology. This metrology-grade system provides traceable, NIST-calibrated measurements with a volumetric accuracy of ±2.3 + L/300 µm, confirming positional tolerances, profile deviations, and complex form characteristics. Statistical Process Control (SPC) data is actively monitored during production runs, allowing for immediate process correction to maintain consistency. Final inspection reports detail all measured characteristics against specified tolerances, providing full transparency and auditability for our clients’ stringent quality management systems.

Our commitment to precision is quantified through rigorously maintained tolerance standards, consistently achieved across production batches:

| Tolerance Range | Primary Measurement Method | Typical Application Examples |

|---|---|---|

| ±0.005 mm (0.0002″) | CMM (Zeiss) | Aerospace hydraulic manifolds, medical implant interfaces |

| ±0.01 mm (0.0004″) | CMM / High-Precision CMM | Turbine blade root forms,精密 optical mounts |

| ±0.025 mm (0.001″) | CMM / Air Gaging | High-pressure seal surfaces,精密 bearing bores |

| ±0.05 mm (0.002″) | Calipers / Micrometers | Structural brackets, non-critical mating surfaces |

Wuxi Lead Precision Machinery operates at the intersection of cutting-edge technology and rigorous quality discipline. Our 5-axis milling capabilities, underpinned by certified metrology and deep process expertise, provide the foundation for manufacturing components where failure is not an option. We partner with global leaders who demand demonstrable precision, consistent repeatability, and complete process accountability in their critical metal components. Contact our engineering team to discuss your most challenging precision machining requirements.

Material & Finish Options

Material selection is a critical phase in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC milling services tailored to demanding industrial applications. Our expertise spans a range of engineering-grade materials, with aluminum, steel, and titanium being the most widely used due to their distinct mechanical properties and application suitability.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is commonly selected in aerospace, automotive, and electronics industries where lightweight components with high dimensional stability are required. The most frequently used alloy is 6061-T6, offering good weldability and corrosion resistance. For high-performance applications, 7075-T6 provides superior strength, though with reduced corrosion resistance compared to 6061.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, is chosen when high strength, wear resistance, and corrosion resistance are paramount. Stainless steel maintains integrity under extreme temperatures and harsh environments, making it ideal for medical devices, food processing equipment, and industrial tooling. While harder to machine than aluminum, modern CNC milling techniques enable precise and efficient steel part production with tight tolerances.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for mission-critical applications in aerospace, defense, and biomedical engineering. It offers an exceptional strength-to-density ratio and outstanding resistance to corrosion and high-temperature environments. Despite its challenging machinability—due to low thermal conductivity and high chemical reactivity—titanium components can be reliably produced using optimized cutting parameters and specialized tooling, which Wuxi Lead Precision Machinery routinely implements.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a widely used electrochemical process for aluminum components. It increases surface hardness, improves corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for general applications, while Type III (hardcoat anodizing) is used when enhanced wear resistance is required. It is important to note that anodizing is not applicable to steel or titanium in the same manner—these materials typically undergo passivation, plating, or coating processes instead.

Below is a comparative overview of key material properties relevant to CNC milling:

| Material | Typical Alloy | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics | Excellent |

| Aluminum | 7075-T6 | 572 | 2.8 | High-stress Structural Parts | Good |

| Stainless Steel | 304 / 17-4 PH | 515 / 1000 | 8.0 | Medical, Industrial Equipment | Moderate |

| Titanium | Ti-6Al-4V (Gr5) | 950 | 4.4 | Aerospace, Defense, Medical | Fair |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and production volume. Our engineering team ensures every CNC milled component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision CNC Milling Production Process: From Concept to Zero Defect Delivery

At Wuxi Lead Precision Machinery, our high-end CNC milling production process is engineered for uncompromising quality and repeatability, ensuring zero defects from initial concept to final shipment. This rigorously controlled three-phase workflow integrates advanced engineering with meticulous quality assurance, meeting the exacting demands of aerospace, medical, and semiconductor industries.

Design Phase: Engineering Flawless Foundations

The process begins with comprehensive design analysis and manufacturability review. Our engineering team collaborates closely with client CAD data, performing detailed DFM (Design for Manufacturability) assessments and advanced CAM simulation. Finite Element Analysis (FEA) validates structural integrity under operational loads, while thermal and stress simulations predict performance. Critical tolerances, material selection, and optimal toolpaths are defined during this stage, eliminating potential errors before metal is cut. This proactive engineering ensures the design is not only functional but inherently manufacturable to micron-level precision.

Prototyping Phase: Validation and Refinement

A limited prototype run follows design finalization, executed on the same production-grade 5-axis CNC mills used for full-scale manufacturing. Prototypes undergo exhaustive metrology using calibrated CMMs, optical comparators, and surface roughness testers against the original CAD model and specifications. Dimensional accuracy, surface finish, and material properties are verified. Any deviations trigger immediate root cause analysis and process refinement. This critical validation step confirms the manufacturing process capability and allows for micro-adjustments, ensuring the design intent is perfectly translated into physical form before committing to volume production.

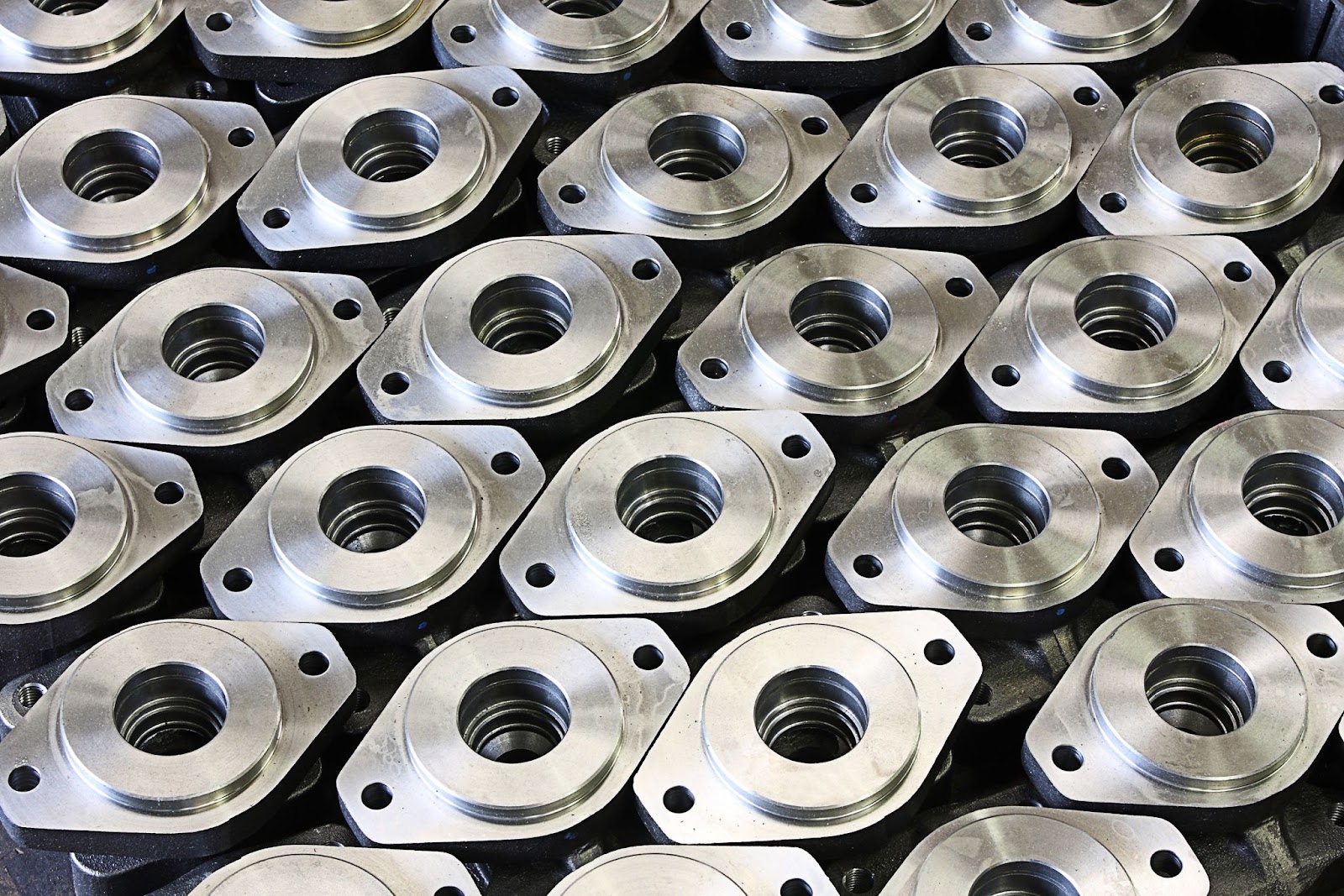

Mass Production Phase: Sustained Zero Defect Execution

Full-scale production leverages the validated process parameters under strict statistical process control (SPC). Every machine operates within tightly monitored environmental conditions, with real-time tool wear compensation and automated in-process gauging. Our integrated quality management system mandates 100% critical feature inspection on initial runs and continuous random sampling per AQL 0.65. Traceability is absolute, with full lot genealogy recorded for every component. This systematic approach, combined with operator certification and rigorous machine maintenance schedules, guarantees consistent output meeting the most stringent zero-defect requirements.

Key production capabilities enabling this zero-defect outcome are summarized below:

| Specification Category | Capability | Standard Compliance |

|---|---|---|

| Positional Tolerance | ±0.002 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.4 µm (typical) | ISO 1302 |

| Maximum Work Envelope | 1200 x 800 x 650 mm | Customizable |

| Material Range | Aluminum Alloys, Titanium, Inconel, Stainless Steels, Engineering Plastics | AMS, ASTM, ISO |

| Process Control | Real-time SPC, Cpk ≥ 1.67 | IATF 16949, ISO 9001 |

This integrated Design-Prototype-Production methodology, executed by Wuxi Lead’s certified engineers on state-of-the-art equipment, transforms complex designs into flawless precision components. Continuous verification at every stage is not a checkpoint but the core principle, delivering absolute confidence in every part shipped. Wuxi Lead Precision Machinery: Engineered Perfection, Guaranteed.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched CNC Milling Excellence

In the fast-evolving world of precision manufacturing, selecting the right partner is critical to maintaining a competitive edge. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC milling solutions designed for industries where performance, reliability, and repeatability are non-negotiable. From aerospace components to medical devices and advanced industrial systems, our machining capabilities meet the most stringent global standards.

Our commitment begins with advanced 3-, 4-, and 5-axis CNC milling centers equipped with high-speed spindles, automated tool changers, and real-time monitoring systems. These machines are operated by a team of seasoned engineers and machinists who bring decades of collective experience in complex part production. We combine cutting-edge technology with rigorous quality control processes, ensuring every component meets exact dimensional tolerances and surface finish requirements.

What sets Wuxi Lead apart is not just our equipment, but our end-to-end engineering support. From initial design review and material selection to prototyping, production scaling, and final inspection, we work as an extension of your engineering team. Our facility is ISO 9001:2015 certified, and we utilize advanced metrology tools such as coordinate measuring machines (CMM), optical comparators, and surface roughness testers to validate every production run.

We understand that precision is more than just tight tolerances—it’s consistency across batches, traceability in materials, and responsiveness in delivery. Our lean manufacturing practices ensure rapid turnaround times without compromising quality. Whether you require low-volume prototypes or high-volume production runs, our scalable infrastructure adapts to your project’s unique demands.

Below are key specifications that define our CNC milling capabilities:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum alloys, stainless steel, titanium, brass, engineering plastics, and exotic alloys |

| Tolerances Achieved | ±0.01 mm typical, down to ±0.005 mm for critical features |

| Surface Finish | As low as Ra 0.4 µm |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation available |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (volume-dependent) |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered solutions that empower innovation. Our global client base trusts us to handle mission-critical components with the highest level of technical competence and service integrity.

Take the next step toward superior manufacturing performance. Contact us today at [email protected] to discuss your CNC milling requirements and discover how Wuxi Lead can become your strategic precision machining partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.