Technical Contents

Engineering Guide: Cnc Milling Shop

Engineering Insight: The Critical Role of Precision in Modern CNC Milling

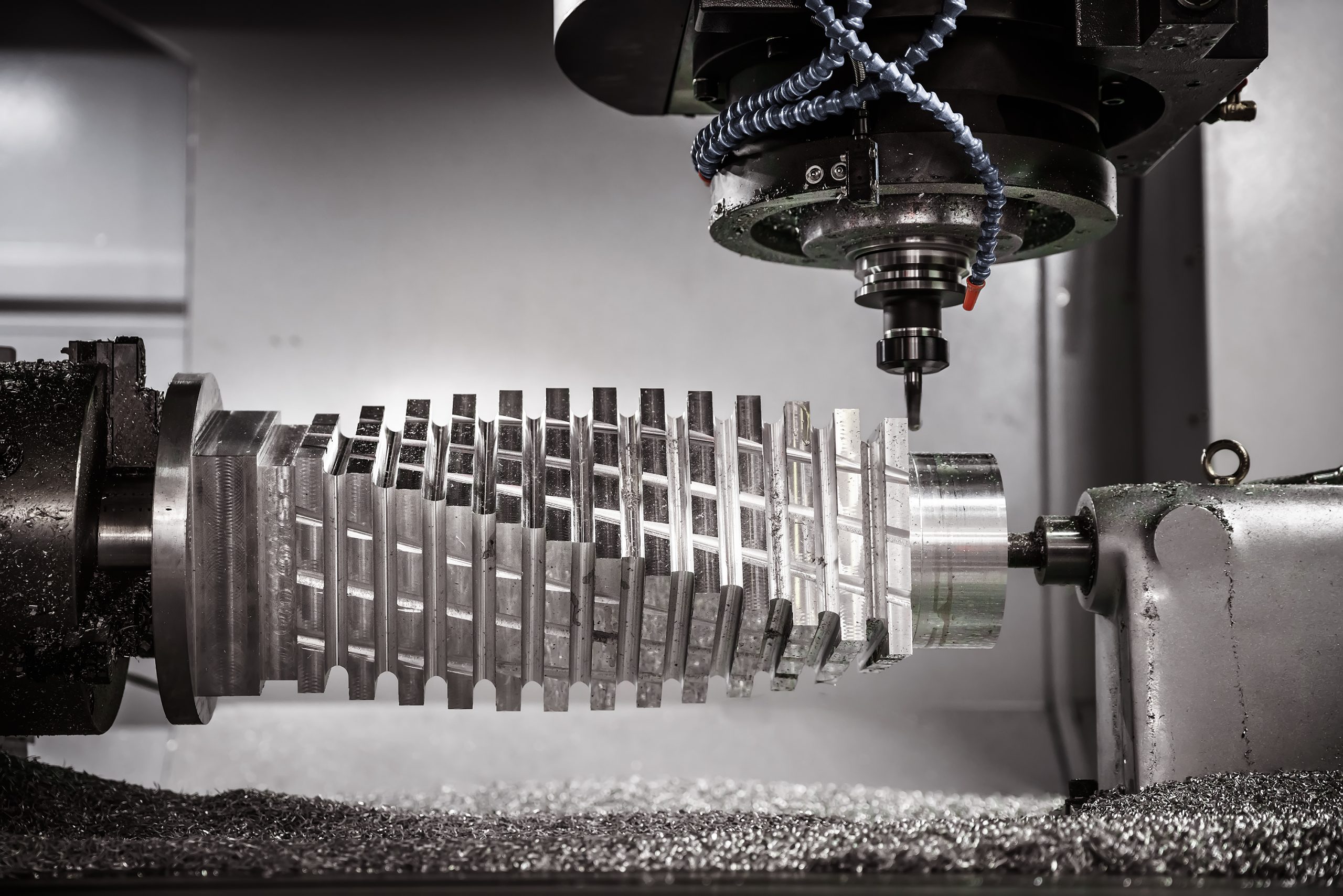

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we understand that in high-stakes industries such as aerospace, defense, and high-performance sports equipment, even micron-level deviations can lead to catastrophic outcomes. This understanding drives our engineering philosophy and operational excellence in every CNC milling operation we undertake.

A CNC milling shop is more than a collection of advanced machinery; it is a tightly integrated system of engineering expertise, process control, and material science. At Lead Precision, our facility is engineered to sustain tolerances as tight as ±0.002 mm, achieved through state-of-the-art 3-, 4-, and 5-axis CNC milling centers, real-time tool monitoring, and temperature-controlled environments. These capabilities are not theoretical—they are battle-tested through our contributions to Olympic-grade athletic equipment and mission-critical military components.

Our involvement in Olympic projects has demanded extreme repeatability and surface finish consistency, where the performance of an athlete can hinge on the precision of a machined bracket or aerodynamic housing. Similarly, our military-grade contracts require full compliance with stringent quality standards, including ISO 9001 and AS9100, ensuring traceability, material certification, and rigorous inspection protocols. These projects have reinforced a core truth: precision is not achieved through technology alone, but through a culture of continuous improvement and engineering accountability.

We utilize advanced metrology tools such as coordinate measuring machines (CMM), optical comparators, and laser interferometers to validate each component against design specifications. Our engineers work in close collaboration with clients during the design-for-manufacturability (DFM) phase, identifying potential risks and optimizing geometries to ensure both performance and producibility.

The table below outlines key technical capabilities of our CNC milling operations:

| Specification | Performance Metric |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Axis Configuration | 3, 4, and 5-axis simultaneous |

| Materials Processed | Aluminum Alloys, Titanium, Inconel, Stainless Steel, Engineering Plastics |

| Surface Finish (Ra) | As low as 0.2 µm |

Precision in CNC milling is not a feature—it is a commitment. At Wuxi Lead Precision Machinery, this commitment is validated through decades of delivering components where failure is not an option. Whether supporting elite athletic performance or national defense systems, our CNC milling shop stands as a benchmark in engineering integrity and technical mastery.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision and complexity management for the most challenging aerospace, medical, and energy sector components. Our core technical capability centers on advanced multi-axis machining, specifically leveraging state-of-the-art 5-axis CNC milling technology. This strategic investment enables the production of intricate geometries, deep cavities, and complex organic forms in a single setup, significantly reducing lead times, minimizing handling errors, and ensuring superior part integrity. We operate a dedicated fleet of high-torque, high-speed 5-axis machining centers from industry leaders including DMG MORI and Makino. These systems feature rotary tables with exceptional rigidity and sub-micron repeatability, capable of machining hard metals like Inconel 718, titanium alloys, and tool steels up to 1000 MPa tensile strength, alongside engineering plastics and composites. Our programming expertise utilizes Mastercam and Siemens NX CAM to optimize toolpaths for maximum efficiency, surface finish, and dimensional stability, even on thin-walled features.

Rigorous quality control is inseparable from our machining process. Every critical dimension and geometric feature undergoes verification using calibrated Coordinate Measuring Machines (CMMs). Our primary inspection platform is the Zeiss CONTURA series, renowned for its metrology-grade accuracy and thermal stability. All CMM operators are GD&T certified and follow AS9100D-compliant procedures, ensuring traceability to national standards. Inspection reports detail full first-article inspection (FAI) data, including comprehensive geometric dimensioning and tolerancing (GD&T) analysis, surface roughness measurements (Ra), and critical feature verification. This systematic approach guarantees that every component shipped meets or exceeds the stringent requirements of high-reliability industries, providing our clients with absolute confidence in part performance and regulatory compliance.

Our commitment to precision is quantifiable through consistently achieved tolerances, as demonstrated below. These capabilities represent standard production performance under controlled environmental conditions, not isolated best-case scenarios.

| Tolerance Type | Standard Capability | Advanced Capability | Units |

|---|---|---|---|

| Linear Dimension | ±0.010 | ±0.002 | mm |

| Geometric (Position) | ±0.015 | ±0.005 | mm |

| Geometric (Flatness) | 0.010 | 0.003 | mm |

| Surface Roughness (Ra) | 0.8 | 0.4 | µm |

| Hole Diameter (Reamed) | H7 | H6 | – |

| Linear Dimension | ±0.0004 | ±0.0001 | inch |

| Geometric (Position) | ±0.0006 | ±0.0002 | inch |

Material versatility spans aluminum alloys (2024, 7075), stainless steels (303, 304, 316, 17-4PH), titanium (Gr2, Gr5), nickel-based superalloys (Inconel 625, 718), brass, copper, and engineered plastics (PEEK, Delrin). Our integrated technical team collaborates closely with client engineering from the design-for-manufacturability (DFM) stage through final inspection, ensuring manufacturability and optimal performance. Wuxi Lead’s technical capabilities are engineered to transform complex designs into mission-critical components with unwavering precision and reliability.

Material & Finish Options

Material selection is a critical step in precision CNC milling, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance parts from advanced engineering materials, with aluminum, steel, and titanium being the most widely used in aerospace, medical, automotive, and industrial applications. Each material offers distinct mechanical properties, machinability characteristics, and compatibility with post-processing finishes such as anodizing.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly suitable for lightweight structural components and heat dissipation applications. The most common grades we machine include 6061-T6 and 7075-T6. 6061-T6 offers good weldability and moderate strength, ideal for prototypes and general-purpose parts. 7075-T6, with its higher strength, is preferred in aerospace and defense where performance under stress is critical. Aluminum is highly compatible with anodizing, especially Type II (sulfuric acid) and Type III (hard coat), which enhance surface hardness and wear resistance while allowing for color coding.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, provides superior strength, durability, and resistance to high temperatures and corrosion. 304 stainless steel is widely used in medical and food processing equipment due to its non-reactive surface and ease of sterilization. 17-4 PH, a precipitation-hardening stainless steel, delivers excellent mechanical properties after heat treatment, making it ideal for high-stress applications in aerospace and oil & gas. While steel is not anodized, it benefits from finishes such as passivation, electropolishing, and chrome plating to improve surface integrity and corrosion resistance.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments requiring high strength, low density, and exceptional resistance to corrosion and heat. It is extensively used in aerospace, medical implants, and marine applications. Although titanium is more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC milling capabilities ensure precise, burr-free results with tight tolerances. Titanium does not anodize in the conventional sense but can undergo specialized oxide coloring processes for identification and mild surface enhancement.

Below is a comparative overview of key material properties and finishing options:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 – 570 | 2.7 | Aerospace, Automotive | Anodizing (Type II/III), Powder Coat |

| Stainless Steel | 304, 17-4 PH | 505 – 1300 | 7.9 | Medical, Industrial | Passivation, Electropolishing |

| Titanium | Ti-6Al-4V (Gr5) | 900 – 1100 | 4.4 | Aerospace, Medical Implants | Oxide Coloring, Bead Blasting |

Selecting the right material and finish requires a balance of functional requirements, environmental exposure, and production efficiency. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through engineering consultation and prototyping services, ensuring optimal performance and cost-effectiveness across the product lifecycle.

Manufacturing Process & QC

Precision CNC Milling Production Process: Design to Zero Defects Manufacturing

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and efficiency, transforming client concepts into flawless precision components. We adhere strictly to a three-phase methodology—Design Validation, Rigorous Prototyping, and Scalable Mass Production—each phase fortified by our Zero Defects philosophy. This integrated approach eliminates costly errors, ensures first-time-right manufacturing, and delivers components meeting the most demanding aerospace, medical, and industrial specifications.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the design phase, scrutinizing CAD models for geometric feasibility, material suitability, and tolerance stack-up risks. We identify potential machining challenges—such as thin walls, complex undercuts, or micro-tolerances—before metal is cut. This proactive validation, leveraging advanced simulation software, optimizes toolpaths, selects optimal materials (including exotic alloys and engineered plastics), and establishes achievable GD&T callouts, preventing design-induced defects at the source.

Prototyping is not merely a formality; it is a critical quality gate. We produce functional prototypes using the exact production-grade CNC mills, tooling, and materials intended for volume runs. Each prototype undergoes comprehensive metrology on calibrated CMMs and surface profilers, validating dimensional accuracy, surface finish, and mechanical properties against the design intent. Any deviation triggers immediate root-cause analysis and process refinement. This iterative validation ensures the manufacturing process is statistically validated and fully capable before committing to mass production, eliminating the risk of scaling flawed methodologies.

Mass production leverages our fully documented, process-controlled workflow. Every component is machined on state-of-the-art 3-, 4-, and 5-axis CNC milling centers under strict environmental controls. Real-time in-process inspection via probe systems and post-process 100% critical feature verification guarantee adherence to specifications. Our integrated Quality Management System (ISO 9001:2015, IATF 16949 certified) mandates continuous SPC monitoring, with all process parameters and inspection data digitally archived for full traceability. Zero Defects is achieved through this closed-loop system where prevention, not detection, is paramount.

Key Production Specifications Achieved

| Parameter | Capability Range | Quality Assurance Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | CMM, Optical Comparator, Micrometers |

| Surface Roughness (Ra) | As low as 0.4 μm (16 μin) | Surface Profilometer |

| Geometric Tolerance | Positional: ±0.002 mm | CMM, Custom Gauges |

| Material Compliance | Aerospace Alloys, Medical SS, Titanium, Plastics | Material Certificates, Spectroscopy |

| Process Capability (Cpk) | ≥ 1.67 (Target) | Statistical Process Control (SPC) |

This disciplined progression from validated design through proven prototyping to rigorously controlled mass production ensures Wuxi Lead delivers components with absolute reliability. We transform precision requirements into tangible reality, eliminating rework costs and supply chain disruptions for our global partners. Partner with us for manufacturing where perfection is not an aspiration—it is the standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Excellence

When your business demands precision, reliability, and speed in CNC milling, partnering with Wuxi Lead Precision Machinery is the strategic advantage you need. As a leading CNC milling shop in China, we specialize in high-accuracy, tight-tolerance machining for industries where failure is not an option—medical, aerospace, automotive, and advanced industrial equipment. Our commitment to engineering excellence, combined with state-of-the-art technology and a customer-first approach, makes us the preferred partner for global OEMs and tier-one suppliers.

At Lead Precision, we understand that your supply chain is only as strong as its weakest link. That’s why we’ve built a vertically integrated manufacturing ecosystem designed to minimize lead times, reduce costs, and ensure total quality control. From prototype to full-scale production, our team of seasoned CNC engineers and machinists applies deep technical knowledge to every project. We operate 24/7 in a climate-controlled facility equipped with over 80 CNC machining centers, including 3-axis, 4-axis, and 5-axis milling systems, ensuring we can handle complex geometries with micron-level accuracy.

Our quality management system is ISO 9001:2015 certified, and we maintain strict adherence to international standards for metrology and process validation. Every component undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers, guaranteeing that what leaves our shop meets your exact specifications.

We don’t just manufacture parts—we deliver solutions. Whether you’re facing a challenging material like titanium, Inconel, or PEEK, or require rapid prototyping with quick turnaround, our team collaborates closely with your engineers to optimize designs for manufacturability, reduce waste, and accelerate time-to-market.

Below are key capabilities that define our CNC milling services:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Materials Processed | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (PEEK, Delrin, etc.) |

| Tolerances Achieved | As tight as ±0.003 mm |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Standard Certifications | ISO 9001:2015, RoHS compliant |

Our clients choose us not only for our technical capabilities but for our responsiveness and transparency. We assign a dedicated project manager to every order, ensuring seamless communication, real-time updates, and full traceability from raw material to final shipment.

If you’re looking for a CNC milling shop that combines precision engineering with operational agility, it’s time to partner with Lead Precision. Contact us today at [email protected] to discuss your next project. Let us help you turn design intent into manufacturing reality—with accuracy, consistency, and speed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.