Technical Contents

Engineering Guide: Cnc Milling Service Online

Engineering Insight: The Critical Role of Precision in CNC Milling Services Online

In the world of high-performance manufacturing, precision is not merely a specification—it is the foundation of reliability, safety, and operational excellence. As industries from aerospace to medical technology demand tighter tolerances and more complex geometries, the need for advanced CNC milling services has never been greater. When sourcing CNC milling service online, engineers and procurement managers must prioritize not only cost and lead time but, more importantly, the proven capability to deliver micron-level accuracy consistently.

At Wuxi Lead Precision Machinery, precision is engineered into every process. With over 15 years of experience serving Tier-1 suppliers in defense, Olympic-grade sports equipment, and high-reliability industrial sectors, our facility has been trusted to produce components where failure is not an option. Our work on Olympic bobsled chassis and military-grade communication housings exemplifies the level of dimensional stability, surface finish control, and material integrity that defines true precision machining.

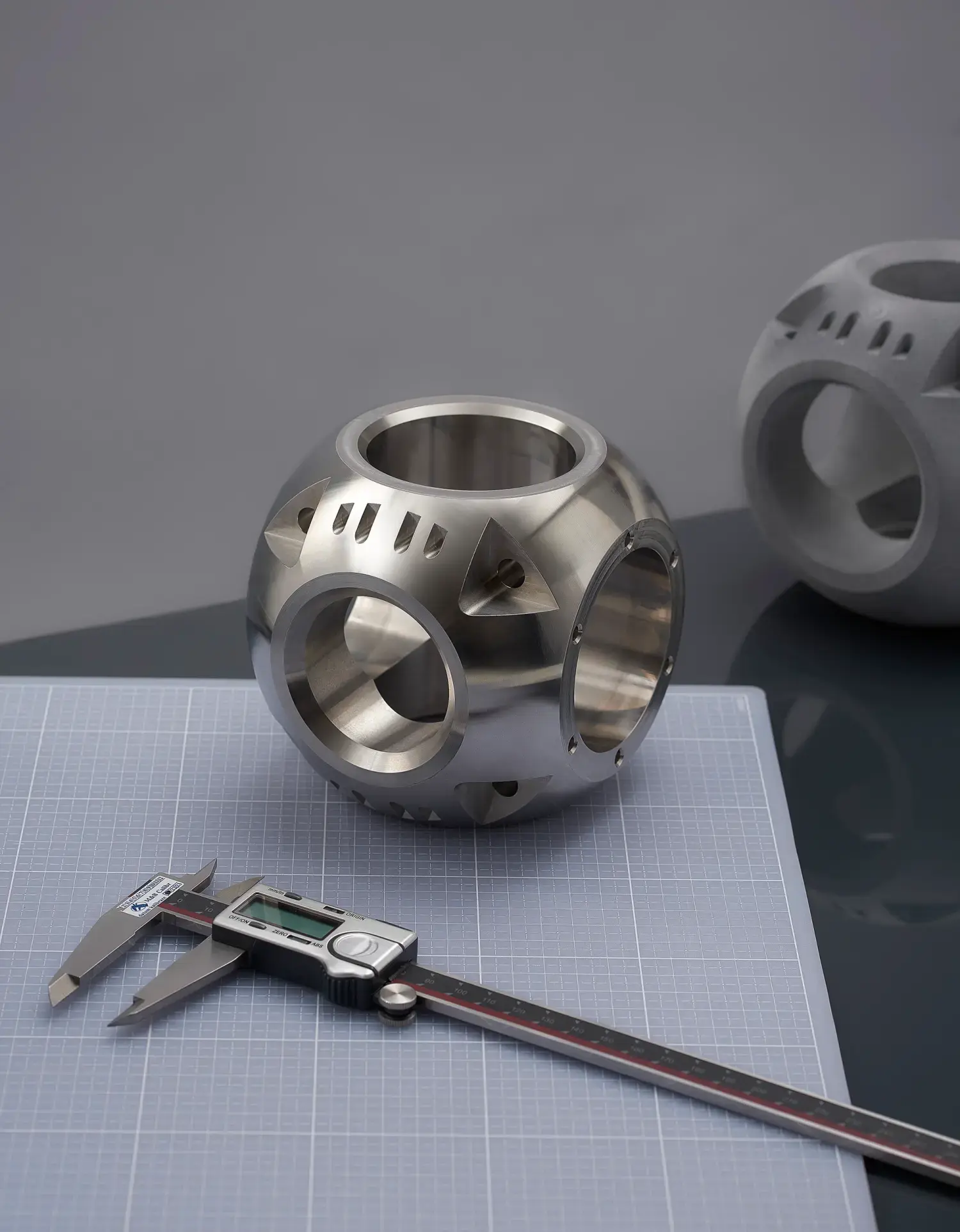

CNC milling, when executed at this level, transcends basic metal removal. It involves a holistic understanding of toolpath optimization, thermal compensation, vibration damping, and real-time process monitoring. At Lead Precision, we utilize high-rigidity 5-axis machining centers equipped with laser tool measurement and on-machine probing systems. These technologies ensure that each component adheres to tolerances as tight as ±0.002 mm, even in challenging materials such as titanium, Inconel, and high-strength aluminum alloys.

The shift toward online procurement of CNC services introduces both opportunity and risk. While digital platforms streamline quoting and order placement, they can obscure critical details about a supplier’s technical depth. A true precision partner must offer full traceability, first-article inspection reports (FAIR), and material certifications—all accessible through a secure customer portal. At Lead Precision, our online service integrates real-time production tracking with full documentation transparency, ensuring that every part shipped meets the same standards required by our most demanding clients.

Beyond equipment and data, precision is sustained through culture. Our engineering team includes veteran machinists and manufacturing engineers with decades of combined experience in high-stakes applications. This expertise allows us to perform Design for Manufacturability (DFM) reviews that anticipate potential issues before cutting begins—reducing scrap, improving yield, and accelerating time to market.

For industries where performance is non-negotiable, the CNC milling service online must be more than convenient—it must be trustworthy, technically superior, and rooted in real-world validation. At Wuxi Lead, our legacy in Olympic and military projects is not a marketing claim; it is proof of capability under extreme scrutiny.

Key Precision Capabilities at Wuxi Lead Precision Machinery

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless Steel 316L, PEEK |

| Surface Finish (Ra) | As low as 0.4 µm |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace-ready) |

| Inspection Equipment | CMM, Optical Comparator, Laser Micrometers |

When selecting a CNC milling service online, precision must be measurable, verifiable, and backed by experience. At Wuxi Lead Precision Machinery, it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers advanced CNC milling solutions engineered to meet the stringent requirements of aerospace, medical, energy, and high-tech industrial sectors. Our core strength lies in integrating cutting-edge multi-axis technology with rigorous quality assurance protocols, ensuring every component adheres to exacting specifications. We specialize in transforming complex 3D CAD models into high-integrity metal and engineered polymer parts, handling projects from rapid prototyping to high-volume production runs with equal proficiency. Our facility operates as a certified ISO 9001:2015 manufacturing environment, providing the foundational structure for consistent, repeatable precision.

Our technical foundation is built upon a strategically deployed fleet of 5-axis CNC machining centers, primarily featuring DMG MORI and MAZAK platforms. These machines, equipped with high-torque spindles (up to 24,000 RPM) and dynamic linear motor drives, enable the complete machining of intricate geometries in a single setup. This eliminates cumulative fixture errors inherent in multi-setup 3-axis processes, significantly enhancing part accuracy and surface finish while reducing lead times. Capabilities include continuous 5-axis contouring for organic shapes, precise deep cavity milling, and the efficient production of complex impellers, turbine blades, and structural brackets. Integrated probing systems perform on-machine verification, ensuring dimensional integrity before part removal and enabling adaptive machining strategies for critical features.

Quality control is not a final checkpoint but an embedded process throughout production. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs), including Zeiss and Hexagon GLOBAL systems with sub-micron accuracy. Our certified metrology technicians execute comprehensive inspection plans aligned with client drawings and ASME Y14.5 standards. Full first-article inspection reports (FAIRs) with detailed dimensional data, including GD&T analysis, are standard deliverables. In-process inspections at defined stages, coupled with SPC data collection on key characteristics, guarantee process stability and prevent non-conformances before final assembly. Material certifications and traceability documentation are meticulously maintained for full supply chain transparency.

The achievable precision of our processes is demonstrable across diverse part features. The following table outlines typical tolerance capabilities under controlled production conditions, recognizing that final achievable tolerances depend on specific material properties, part geometry complexity, and feature location.

| Feature Type | Standard Capability | Tight Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Up to 300mm; tighter achievable on smaller features |

| Angular Dimensions | ±0.05° | ±0.02° | Verified via CMM vector measurement |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | Relative to primary datums |

| Profile of a Surface | 0.020 mm | 0.010 mm | Full surface deviation from nominal CAD |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined finish; post-process options available |

These capabilities, combined with our engineering support team available for Design for Manufacturability (DFM) feedback, ensure Wuxi Lead transforms challenging designs into reliably precise, functionally superior components. We guarantee dimensional accuracy that meets or exceeds industry benchmarks for critical applications.

Material & Finish Options

Material Selection for High-Precision CNC Milling Services

Selecting the appropriate material is a critical step in the design and manufacturing of precision CNC-machined components. At Wuxi Lead Precision Machinery, we specialize in machining high-performance materials such as aluminum, steel, and titanium—each offering distinct mechanical properties, weight characteristics, and environmental resistance. The choice of material directly influences part functionality, durability, and cost-efficiency, making it essential to align material selection with application requirements.

Aluminum is widely favored in aerospace, automotive, and consumer electronics due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. The most commonly used grade, 6061-T6, provides good corrosion resistance and weldability, making it ideal for structural components and prototypes. For more demanding applications, 7075-T6 offers higher strength, though at a premium cost and reduced corrosion resistance.

Steel remains the material of choice for parts requiring high tensile strength, wear resistance, and dimensional stability under load. We offer precision machining of alloy steels such as 4140 and 4340, which are commonly used in tooling, shafts, and industrial machinery. Stainless steel grades like 304 and 316 are selected when corrosion resistance and hygiene are paramount, such as in medical devices and food processing equipment.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. It is frequently specified in aerospace, defense, and medical implant applications. While more challenging to machine due to its low thermal conductivity and tendency to work-harden, our advanced CNC platforms and tooling strategies ensure tight tolerances and superior surface integrity.

Surface finishing further enhances performance and longevity. Anodizing is a key post-processing option for aluminum components. This electrochemical process grows a durable oxide layer on the surface, significantly improving wear and corrosion resistance. Type II (sulfuric acid) anodizing allows for color dyeing and moderate protection, while Type III (hardcoat anodizing) produces a thicker, harder layer suitable for high-wear environments. All anodizing processes are performed in-house with strict adherence to MIL-A-8625 standards.

The following table outlines key mechanical properties and typical applications for the most commonly machined materials:

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | 2.7 | Enclosures, brackets, prototypes |

| Aluminum 7075-T6 | 572 | 150 | 2.8 | Aerospace, high-stress parts |

| Steel 4140 | 655 | 197 | 7.85 | Shafts, tooling, machinery |

| Stainless 316 | 580 | 160 | 8.0 | Medical, marine, chemical |

| Titanium Ti-6Al-4V | 900 | 360 | 4.43 | Aerospace, implants, racing |

At Wuxi Lead, we support material certification, lot traceability, and full inspection reporting. Our engineering team collaborates closely with clients to ensure optimal material and finish selection—maximizing performance while minimizing lead time and cost.

Manufacturing Process & QC

Precision CNC Milling Production Process: From Concept to Flawless Delivery

Wuxi Lead Precision Machinery executes a rigorously controlled production sequence for every CNC milling service online order, ensuring exceptional part fidelity and zero defects from initial concept through final shipment. Our integrated workflow eliminates quality gaps common in fragmented manufacturing approaches, delivering production-ready components meeting the most stringent aerospace, medical, and industrial specifications.

Design Phase

Engineering collaboration begins immediately upon receipt of your CAD model. Our team performs comprehensive Design for Manufacturability (DFM) analysis, identifying potential machining constraints, material optimization opportunities, and geometric dimensioning and tolerancing (GD&T) validation. We utilize Siemens NX and Mastercam software to simulate toolpaths, prevent collisions, and confirm feasibility against your technical drawings. This proactive review reduces iteration cycles by up to 40% and establishes the foundation for defect prevention. All design approvals require documented sign-off, ensuring absolute alignment before material procurement.

Prototyping Phase

Critical for complex geometries and new production runs, our rapid prototyping leverages high-speed 5-axis milling centers to produce first-article parts within 72 hours. Each prototype undergoes full metrological validation using calibrated Zeiss CONTURA CMMs and optical comparators against the approved design. Dimensional reports, surface roughness measurements, and material certification documentation are provided for your verification. This phase confirms process capability and identifies micro-adjustments needed for series production. Below are standard capabilities for prototype and production runs:

| Material Category | Standard Tolerance (mm) | Max. Part Size (mm) | Surface Finish (Ra µm) | Lead Time (Prototype) |

|---|---|---|---|---|

| Aluminum Alloys | ±0.005 | 1200 x 800 x 600 | 0.8 – 3.2 | 2-3 Days |

| Stainless Steel | ±0.008 | 1000 x 700 x 500 | 0.4 – 1.6 | 3-4 Days |

| Titanium Alloys | ±0.010 | 800 x 600 x 400 | 0.8 – 2.5 | 4-5 Days |

| Engineering Plastics | ±0.020 | 1500 x 1000 x 700 | 1.6 – 6.3 | 1-2 Days |

Mass Production Phase

Upon prototype approval, we transition seamlessly to high-volume manufacturing using automated pallet systems and robotic loading on DMG MORI and Makino machining centers. Statistical Process Control (SPC) monitors critical dimensions in real-time, with automated data logging to our centralized quality management system. Every component undergoes 100% first-article inspection, in-process checks at defined intervals, and final batch validation per ISO 9001:2015 protocols. Our zero-defect mandate is enforced through multi-stage verification: automated vision systems for feature presence, CMM spot checks, and operator sign-off at each workflow handoff. Traceability is maintained via laser-etched part IDs linked to material certs and process parameters.

Zero Defects Commitment

Defect prevention is engineered into every stage, not inspected post-production. Our closed-loop corrective action system analyzes any non-conformance at the root cause level, implementing permanent process fixes. This methodology, combined with operator certification and calibrated equipment maintained to ISO 17025 standards, ensures consistent delivery of precision-machined components meeting your exact requirements—every time. Partner with Wuxi Lead for CNC milling services where perfection is the only acceptable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term manufacturing partnerships. As a leading provider of high-end CNC milling services in China, we specialize in producing complex, tight-tolerance components for industries where failure is not an option. From aerospace and medical devices to automation and energy systems, our machining solutions are engineered to meet the most demanding specifications.

Our commitment begins with advanced 3-, 4-, and 5-axis CNC milling technology, integrated with state-of-the-art quality control systems. Every component is manufactured under strict ISO 9001:2015 standards, ensuring repeatability, consistency, and full traceability. But what truly sets us apart is our engineering-first approach. We collaborate closely with your design and production teams to optimize manufacturability, reduce lead times, and lower total project costs—without compromising on precision.

Whether you require rapid prototyping, low-volume custom runs, or high-volume production, our facility in Wuxi is equipped to scale with your needs. Our skilled technicians and engineers bring decades of experience in materials ranging from aluminum and stainless steel to exotic alloys and engineered plastics. With in-house CAD/CAM support, real-time process monitoring, and a lean manufacturing environment, we ensure your parts are delivered on time, every time.

We understand that global procurement demands more than just technical capability—it requires trust, transparency, and responsive communication. That’s why every project is assigned a dedicated project manager who serves as your single point of contact, providing regular updates, inspection reports, and engineering feedback throughout the production cycle.

Choose a partner who speaks your language—both technically and commercially. At Lead Precision, we bridge the gap between Chinese manufacturing efficiency and Western engineering standards, offering a seamless online CNC milling service tailored to international clients.

To start your next project with confidence, contact us today. Send your drawings, specifications, and requirements to [email protected]. Our engineering team will respond within 12 hours with a detailed quote, DFM analysis, and timeline estimate. We support STEP, IGES, DWG, DXF, and PDF file formats, and welcome NDA-protected collaborations.

Let us become your trusted extension in precision manufacturing—where innovation meets accuracy, and partnerships drive results.

Key CNC Milling Specifications

| Specification | Capability |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, PEEK, Delrin, and more |

| Tolerances | As tight as ±0.001 mm |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.2 µm |

| Production Volume | Prototype to High Volume |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP available |

Begin your collaboration with Wuxi Lead Precision Machinery—engineer excellence with every cut. Contact [email protected] now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.