Technical Contents

Engineering Guide: Cnc Milling Machines For Custom Parts

Engineering Insight Precision as the Non-Negotiable Foundation for Custom CNC Milling Parts

In the demanding realm of custom precision components, CNC milling machines are not merely tools; they are the critical enablers of geometric integrity, functional performance, and ultimate client success. For applications spanning aerospace, medical devices, semiconductor tooling, and high-performance automotive systems, the margin for error is effectively zero. Sub-micron tolerances are often the baseline requirement, not the exception. Achieving this level of precision consistently across diverse materials and complex geometries demands far more than a standard machine tool. It requires an engineered system where thermal stability, structural rigidity, motion control accuracy, and process repeatability are meticulously calibrated and rigorously maintained. Compromised precision directly translates to increased scrap rates, costly rework, assembly failures, and ultimately, compromised product lifespan or safety – risks no discerning OEM can afford in mission-critical applications.

The path to guaranteed precision begins with the machine’s fundamental architecture. High-end CNC milling centers for custom parts must incorporate massive, vibration-damped cast iron or polymer concrete bases, precision-ground linear guideways with preloaded ball screws, and spindles engineered for minimal runout and exceptional thermal management. Advanced linear scale feedback systems operating directly on the machine axes, rather than the drive screws, are essential to eliminate backlash and compensate for thermal growth in real-time. Crucially, precision is not solely a machine specification; it is a holistic process outcome. It hinges on rigorous environmental control within the manufacturing cell, continuous machine calibration protocols like laser interferometry, and the deep expertise of engineers who understand how material properties, cutting strategies, and fixturing interact at the micron level. This integrated approach transforms theoretical machine capability into tangible, certified part accuracy.

Wuxi Lead Precision Machinery has honed this integrated precision philosophy through decades of delivering components where failure is not an option. Our engineering team possesses extensive experience meeting the exacting standards demanded by Olympic-level sporting equipment manufacturers requiring flawless aerodynamic surfaces and by defense contractors needing components validated for extreme environmental resilience and absolute dimensional conformity. This experience is embedded in our machine selection, process design, and quality assurance systems. The following table outlines the core precision specifications consistently achieved across our dedicated custom milling production lines:

| Specification | Performance Level | Significance for Custom Parts |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±0.002 mm | Ensures critical feature locations meet blueprint |

| Repeatability (X/Y/Z) | ≤ 0.001 mm | Guarantees batch-to-batch consistency |

| Spindle Runout (at nose) | ≤ 0.001 mm | Critical for fine surface finishes & tight bores |

| Thermal Drift Compensation | Active System | Maintains accuracy during extended production runs |

| Linear Scale Resolution | 0.0001 mm | Enables true micron-level feature control |

This commitment to demonstrable precision, forged in the crucible of Olympic and military-grade projects, defines Wuxi Lead Precision Machinery’s approach. We understand that your custom part is not just a component; it is the embodiment of your product’s performance promise. Partnering with a manufacturer whose engineering insight and proven capability deliver certified accuracy on every run is the essential foundation for your success in high-stakes markets. Precision is not a feature we offer; it is the absolute standard we operate under.

Precision Specs & Tolerances

Advanced 5-Axis CNC Milling for High-Precision Custom Parts

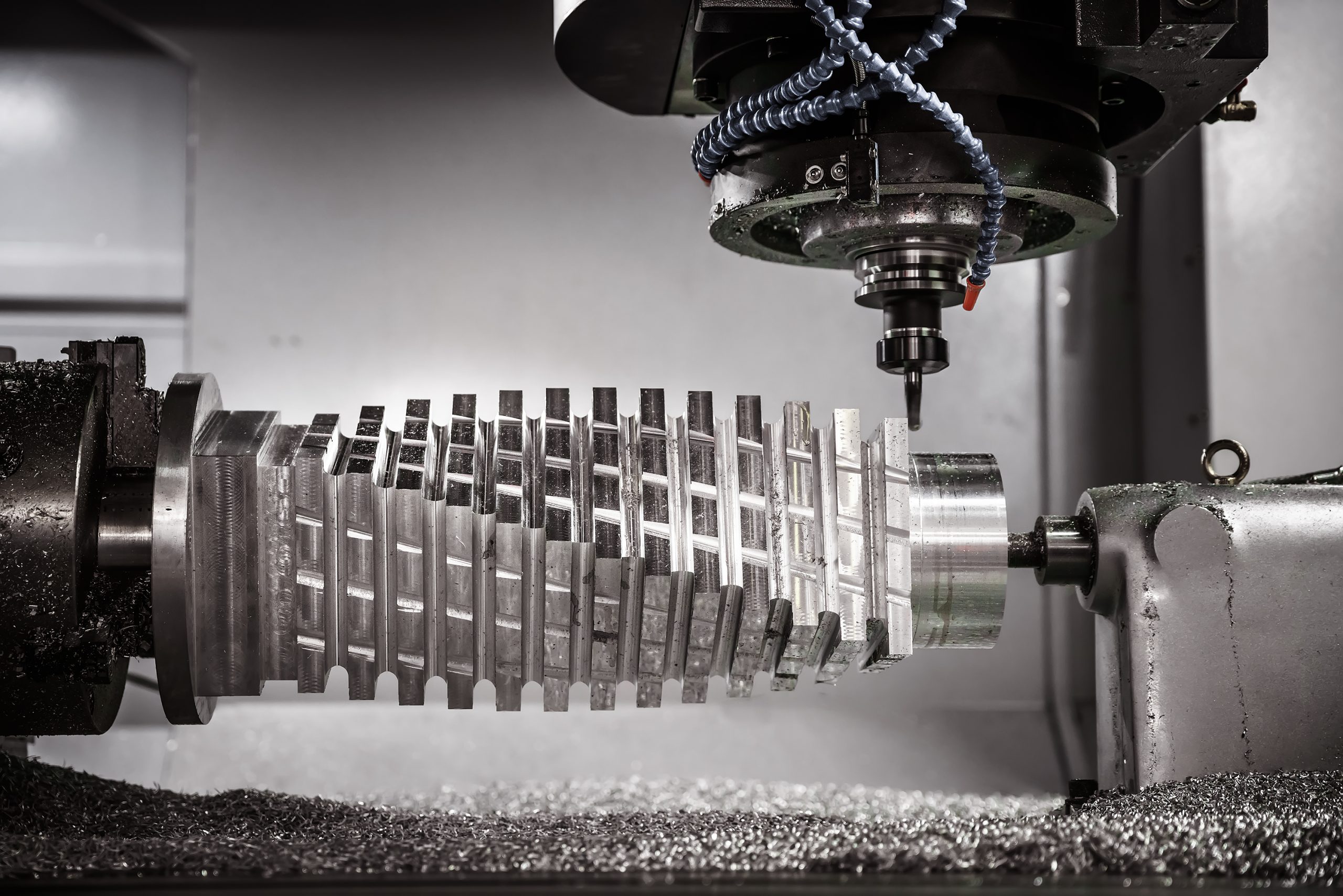

At Wuxi Lead Precision Machinery, our technical capabilities are built around advanced 5-axis CNC milling systems designed to deliver complex, high-accuracy components for demanding industries such as aerospace, medical, automotive, and industrial automation. Our 5-axis CNC machining centers enable simultaneous movement across X, Y, Z, and two rotary axes (A and B), allowing for uninterrupted tool access to complex geometries. This eliminates the need for multiple setups, reduces cumulative error, and ensures superior surface finish and dimensional consistency across intricate part designs.

Our machining fleet includes state-of-the-art multi-axis CNC platforms equipped with high-speed spindles, thermal compensation systems, and real-time tool monitoring. These features ensure micron-level precision and repeatability, even during extended production runs. The integration of adaptive machining strategies and high-resolution feedback loops allows us to maintain tight tolerances on challenging materials including titanium, Inconel, hardened steels, and engineering plastics.

Every custom part undergoes a rigorous quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems provide full 3D geometric verification, ensuring compliance with GD&T standards and customer-specific inspection requirements. All inspection data is documented and traceable, supporting full quality audits and compliance with ISO 9001 and AS9100 standards.

Our in-house technical team includes experienced CNC programmers and process engineers who utilize advanced CAM software such as Mastercam, Siemens NX, and PowerMill. This enables optimized toolpath generation, collision avoidance, and efficient material removal strategies tailored to each component’s geometry and material properties. We support both prototype development and high-volume production, with seamless scalability across project lifecycles.

The combination of 5-axis flexibility, precision tooling, and closed-loop quality control ensures that Wuxi Lead delivers custom-machined parts with exceptional accuracy, consistency, and reliability. Whether producing turbine blades, surgical instruments, or complex housings, our technical infrastructure is engineered to meet the most stringent performance criteria.

Standard Machining Tolerances and Capabilities

| Parameter | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm (standard), ±0.005 mm (precision) |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 µm (polished), typical 1.6–3.2 µm |

| Feature Repeatability | ±0.003 mm over multiple batches |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm (5-axis travel) |

| Minimum Feature Size | 0.3 mm radius (with micro-tooling) |

| CMM Measurement Accuracy | ±1.5 + L/300 µm (L in mm) |

These technical capabilities, combined with our disciplined process control and metrology-backed validation, position Wuxi Lead Precision Machinery as a trusted partner for mission-critical custom components requiring the highest levels of precision and reliability.

Material & Finish Options

Material Selection for Precision CNC Milling: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is fundamental to achieving performance, longevity, and cost-efficiency in custom CNC milled parts. At Wuxi Lead Precision Machinery, we leverage deep material science expertise to guide clients through this critical decision, ensuring the chosen alloy aligns perfectly with functional requirements, environmental exposure, and manufacturing feasibility. Aluminum, steel, and titanium represent the core structural metals for high-end applications, each offering distinct advantages.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate where weight reduction is paramount without sacrificing significant strength. Their excellent machinability allows for high feed rates, complex geometries, and fine surface finishes, reducing cycle times and costs. Aluminum excels in aerospace components, heat sinks, and consumer electronics housings. However, its lower hardness compared to steel necessitates careful design for high-wear interfaces. Steel, especially grades like 4140, 4340, and 17-4 PH stainless, delivers superior strength, hardness, and wear resistance. It is indispensable for high-stress structural elements, shafts, gears, and tooling. Machining steel requires robust tooling, precise coolant strategies, and optimized parameters to manage heat and prevent work hardening or tool deflection, impacting production speed. Titanium alloys, primarily Ti-6Al-4V, offer an exceptional strength-to-weight ratio and outstanding corrosion resistance, critical for aerospace, medical implants, and marine applications. Its low thermal conductivity and high chemical reactivity make it notoriously challenging to machine, demanding specialized tooling, lower speeds, rigid setups, and meticulous process control to avoid galling, excessive heat buildup, and poor surface integrity.

The following table summarizes key properties and machining considerations for these primary materials:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Machinability Rating | Key Machining Considerations | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (High) | High speeds/feeds; prone to galling; chip control | Aerospace brackets, enclosures, heat sinks |

| Steel 4140 | 7.85 | 655 | Good (Medium) | Requires rigid setup; manage heat/work hardening | Shafts, spindles, high-stress components |

| Titanium Ti-6Al-4V | 4.43 | 900 | Poor (Low) | Low speeds; high coolant pressure; sharp tools | Aircraft frames, medical implants, valves |

Anodizing is the essential post-machining finish for aluminum components. This electrochemical process significantly enhances surface hardness, wear resistance, and corrosion protection far beyond the base metal’s capabilities. It creates a durable, porous oxide layer that readily accepts dyes for cosmetic or identification purposes. Type II (Sulfuric Acid) anodizing is standard for general protection and coloring, while Type III (Hardcoat) anodizing delivers extreme wear resistance for demanding mechanical applications. Proper masking of critical dimensions and features is crucial during anodizing to maintain tight tolerances achieved through precision CNC milling. Wuxi Lead Precision Machinery integrates material expertise with advanced CNC milling capabilities and coordinated finishing processes, ensuring your custom parts meet the highest standards of performance and reliability from raw billet to finished component. We optimize cutting parameters and toolpaths specific to each material to maximize quality and efficiency.

Manufacturing Process & QC

The journey from concept to final product in precision CNC machining begins with a rigorous, structured production process designed to ensure zero defects and maximum repeatability. At Wuxi Lead Precision Machinery, we follow a three-phase methodology—Design, Prototyping, and Mass Production—that integrates advanced engineering with real-time quality assurance to deliver custom parts that meet the highest standards of accuracy and performance.

The Design phase is the foundation of our process. Our engineering team collaborates closely with clients to analyze part geometry, material specifications, tolerances, and functional requirements. Using advanced CAD/CAM software, we create detailed 3D models and generate optimized toolpaths that account for material behavior, tool wear, and machine dynamics. Each design is validated through simulation software to detect potential issues such as tool collisions or stress concentrations before any metal is cut. This digital-first approach minimizes errors and accelerates time-to-prototype.

Once the design is finalized, we move to Prototyping. A small batch of parts is produced under full production conditions using our high-precision CNC milling machines. This phase serves both to verify the design and to validate the manufacturing process. Every prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, surface finish, and material integrity are cross-checked against client specifications. Feedback from this stage is used to fine-tune tooling, fixturing, and machining parameters, ensuring that the process is fully optimized before scaling.

Mass Production follows only after formal client approval of the prototype. At this stage, our automated CNC milling systems operate under strict process controls. Each machine is monitored in real time for vibration, temperature, and tool condition, with data logged for traceability. We implement Statistical Process Control (SPC) to detect deviations before they affect output quality. Every part is subject to in-process and final inspection, with critical dimensions verified at defined intervals. Our zero-defect policy is enforced through a combination of automated inspection systems and expert human oversight, ensuring 100% compliance with specifications.

Throughout all phases, documentation is maintained to support full traceability, including material certifications, inspection reports, and process logs. This disciplined approach enables us to deliver custom-machined components with consistent quality, on time and to the exacting standards demanded by industries such as aerospace, medical, and high-performance automotive.

Key CNC Milling Machine Specifications

| Parameter | Specification |

|---|---|

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Table Size (Max) | 1,200 x 600 mm |

| Tool Capacity | Up to 30 stations (automatic changer) |

| Control System | Fanuc / Siemens / Heidenhain |

| Axis Configuration | 3-axis, 4-axis, and 5-axis machining |

| Maximum Workpiece Weight | 800 kg |

| Coolant System | High-pressure through-spindle cooling |

| Compliance Standards | ISO 9001:2015, ISO 13485 (medical devices) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Milling Excellence

When sourcing mission-critical custom parts, your choice of manufacturing partner directly impacts product performance, reliability, and time-to-market. At Wuxi Lead Precision Machinery, we engineer CNC milling solutions for industries where precision is non-negotiable—medical devices, aerospace components, semiconductor tooling, and advanced industrial systems. Our commitment transcends standard production; we integrate deep engineering collaboration with advanced 3-5 axis milling capabilities to transform complex designs into flawless physical realities. This partnership model ensures your specifications are not merely met but exceeded through proactive problem-solving and technical rigor.

Our facility operates under strict ISO 9001:2015 and IATF 16949 standards, leveraging state-of-the-art equipment calibrated to sub-micron tolerances. The table below outlines core capabilities for custom part production:

| Specification | Capability | Relevance for Custom Parts |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | Ensures dimensional integrity for micro-features and tight assembly fits |

| Surface Finish | Ra 0.4 μm (achievable) | Critical for sealing surfaces, optical components, and fatigue resistance |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates complex, large-scale assemblies without segmentation |

| Material Range | Titanium, Inconel, PEEK, Aluminum Alloys, Tool Steels | Supports extreme environment and high-wear applications |

| On-Machine Probing | Full 3D GD&T verification | Eliminates post-process inspection delays and scrap |

Beyond technical specs, our value lies in engineering partnership. We conduct Design for Manufacturability (DFM) reviews at the quotation stage, identifying potential machining challenges and material optimization opportunities before a single chip is cut. This prevents costly redesigns and accelerates prototyping cycles. Our CNC programmers and tooling engineers collaborate directly with your R&D team, ensuring complex geometries—such as deep cavities, thin walls, or organic contours—are machined with optimal toolpaths and minimal thermal distortion.

Quality is embedded in every process layer. Real-time thermal compensation systems counteract environmental fluctuations, while in-process gauging validates critical features mid-operation. Each part undergoes full first-article inspection with certified CMM reports, and batch traceability is maintained via serialized material logs. This systematic approach delivers consistent repeatability, whether producing a single prototype or 10,000 units.

For projects demanding absolute precision and technical accountability, Wuxi Lead Precision Machinery provides the engineering depth and operational discipline your custom parts require. We do not simply fulfill orders; we safeguard your product’s performance and reputation. Initiate a technical dialogue with our application engineers to discuss your specific challenges, material requirements, and throughput needs. Contact us directly at [email protected] to receive a detailed capability assessment and DFM analysis within 24 hours. Let us prove how precision engineering partnership drives your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.