Technical Contents

Engineering Guide: Cnc Milling Machine Components

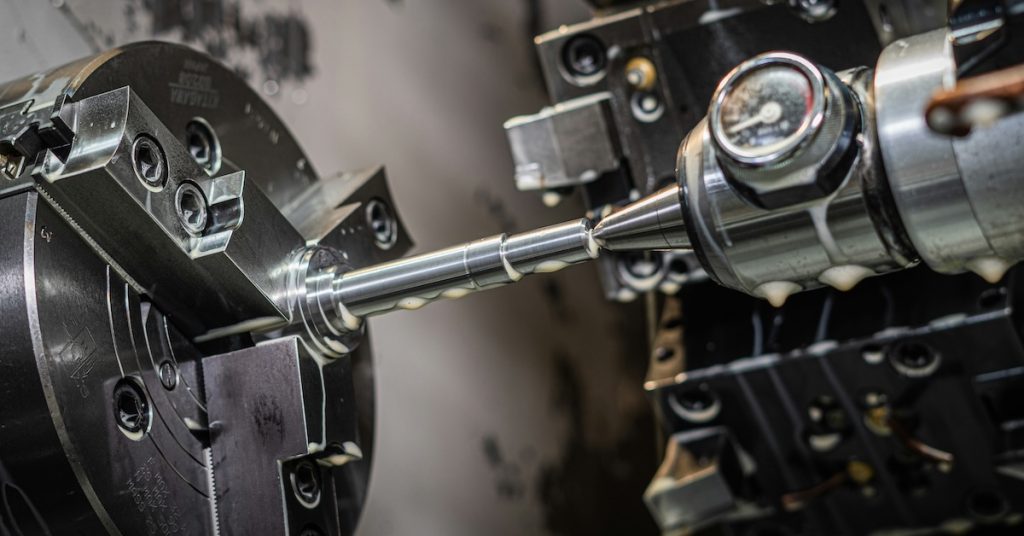

Engineering Insight Precision in CNC Milling Machine Components

Precision in CNC milling machine components is not merely a specification—it is the foundation of functional reliability and operational excellence. In high-stakes manufacturing sectors like aerospace defense and medical device production sub-micron deviations directly impact part integrity safety and lifecycle performance. Inferior spindle assemblies thermal instability in linear guides or inconsistent ball screw accuracy introduce cumulative errors that cascade through production. These flaws manifest as premature tool wear dimensional drift and catastrophic scrap rates costing enterprises millions annually. True precision engineering demands holistic component integration where every element operates within harmonized tolerances under real-world thermal and dynamic loads.

At Wuxi Lead Precision Machinery we engineer components to exceed ISO 230-2 and NAS979 standards through material science innovation and metrology-driven validation. Our spindle systems utilize aerospace-grade bearing preloads and liquid-cooled housings to maintain ±0.002mm runout stability across 8000 RPM operations. Linear motion components integrate hardened ground rails with anti-vibration damping polymers ensuring positioning repeatability remains unaffected by factory floor harmonics. Crucially precision cannot be isolated to individual parts—it emerges from the symbiotic calibration of spindles drives controls and structural frames. This systems-level approach prevents error propagation that plagues modular machine builds.

The following specifications reflect our production-proven component architecture validated across 500+ installations:

| Component | Specification | Industry Standard | Engineering Impact |

|---|---|---|---|

| Spindle Assembly | ±0.002mm runout @ 8000 RPM | ±0.005mm | Eliminates micro-vibrations in thin-wall machining |

| Linear Guides | ±0.0015mm/m positional accuracy | ±0.005mm/m | Ensures contour fidelity in 5-axis complex surfaces |

| Ball Screws | Preloaded C0 grade ±0.003mm/300mm | C3 grade ±0.01mm | Prevents backlash in micro-milling operations |

| Thermal Compensation | Real-time dual-sensor feedback | Single-point only | Maintains accuracy during 8-hour continuous shifts |

This technical rigor is not theoretical. Our components form the core of systems deployed in Olympic timing equipment where 0.01mm deviation invalidates world records and military avionics production where tolerances directly impact flight safety. These applications demand zero-failure operation under extreme environmental stress—a benchmark we meet through 100% component traceability and MIL-STD-810G vibration testing. When selecting CNC machinery scrutinize not just advertised tolerances but the engineering pedigree ensuring those tolerances persist across your production lifecycle. Precision is an investment in yield not a line-item cost. Partner with a manufacturer whose components prove their worth where failure is not an option.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the rigorous demands of aerospace, medical, automotive, and industrial equipment manufacturers. At the core of our production floor are state-of-the-art 5-axis CNC milling machines, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across X, Y, Z, A, and B axes, eliminating the need for multiple setups and significantly reducing cumulative error. This capability ensures that intricate components—such as turbine blades, surgical instrument housings, and high-performance transmission parts—are machined in a single operation, enhancing dimensional consistency and part integrity.

Our 5-axis machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation, ensuring continuous precision across long production runs. The integration of advanced CNC controls and CAD/CAM software enables seamless translation of 3D models into precise toolpaths, supporting tight-tolerance machining of materials including aluminum alloys, titanium, stainless steel, and engineering plastics. This level of automation and control is critical for producing components where micron-level accuracy and repeatability are non-negotiable.

To maintain the highest standards of quality, every machined component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM systems provide full 3D metrology, verifying critical dimensions, geometric tolerances, and surface profiles against original CAD data. This inspection process is fully documented, delivering traceable quality reports for each production batch. In addition to CMM validation, we employ in-process probing, first-article inspection, and statistical process control (SPC) methodologies to monitor and correct deviations in real time, ensuring consistent output across high-volume orders.

The combination of advanced 5-axis technology and rigorous quality assurance enables Wuxi Lead to achieve industry-leading tolerances across a wide range of features. Our machining capabilities support both prototype development and high-mix, low-volume production, with rapid setup and minimal lead times. All processes are conducted in a climate-controlled environment to minimize thermal variation, further enhancing measurement stability and repeatability.

The following table outlines our typical tolerance performance under standard production conditions:

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.020 mm | ±0.008 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.025 mm | ±0.010 mm | CMM |

| Flatness | 0.020 mm | 0.005 mm | CMM, Optical Flats |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.01° | CMM, Optical Comparator |

These technical capabilities reflect Wuxi Lead Precision Machinery’s commitment to delivering precision-engineered components that meet and exceed global manufacturing standards.

Material & Finish Options

Material Selection for Precision CNC Milling Components

Material selection fundamentally impacts the performance, longevity, and cost-effectiveness of CNC milled components. At Wuxi Lead Precision Machinery, we emphasize matching the optimal material to the specific functional requirements, environmental conditions, and production constraints of your application. The dominant choices for high-precision parts are aluminum alloys, alloy steels, and titanium alloys, each offering distinct advantages.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are industry staples for components requiring an excellent strength-to-weight ratio, good machinability, and inherent corrosion resistance. Their lower density reduces inertia in moving parts, while high thermal conductivity aids in heat dissipation. Aluminum is ideal for aerospace brackets, drone frames, and electronic housings where weight savings are critical. However, pure aluminum lacks sufficient strength for structural loads, necessitating heat-treated alloys. Steel alloys, such as 4140, 4340, and 17-4 PH stainless, provide superior strength, hardness, and wear resistance compared to aluminum. They are essential for high-stress applications like hydraulic manifolds, tooling fixtures, and shafts demanding exceptional dimensional stability under load. While heavier and more challenging to machine than aluminum, steels offer broader temperature tolerance and higher ultimate strength. Titanium alloys, primarily Ti-6Al-4V (Grade 5), deliver an unparalleled combination of high strength, low density, and outstanding corrosion resistance, especially in harsh environments like saltwater or chemical exposure. They are vital for critical aerospace structural components, medical implants, and marine hardware. Titanium machining presents significant challenges due to its low thermal conductivity, high chemical reactivity, and tendency for work hardening, requiring specialized tooling, slower speeds, and rigid setups, impacting cost and lead time.

Surface finish selection is equally critical. Anodizing is the predominant finish for aluminum components, significantly enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a standard decorative and protective layer, while Type III (hard coat) anodizing delivers a much thicker, denser, and harder ceramic-like surface essential for high-wear applications. It is crucial to note that anodizing is specific to aluminum; steel components typically require plating (e.g., zinc, cadmium) or passivation, while titanium benefits from specialized treatments like chemical passivation or laser surface texturing, not anodizing.

The following table summarizes key comparative properties for common CNC milling materials:

| Material | Typical Alloys | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications | Key Limitation |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 – 2.8 | 310 – 570 | Excellent (A) | Aerospace brackets, enclosures, heat sinks | Lower strength vs steel |

| Alloy Steel | 4140, 4340, 17-4 PH | 7.8 – 7.9 | 655 – 1300+ | Moderate (C) | Hydraulic manifolds, tooling, shafts | Heavier, prone to rust |

| Titanium | Ti-6Al-4V (Grade 5) | 4.4 – 4.5 | 900 – 1000 | Poor (D) | Aerospace structures, medical implants | Very high cost, slow machining |

Selecting the right material and finish requires balancing performance needs with manufacturability and cost. Wuxi Lead Precision Machinery leverages decades of CNC milling expertise to guide clients through this critical decision, ensuring optimal part performance and value. Consult our engineering team early in your design phase for material-specific manufacturability analysis and finish recommendations tailored to your exact requirements.

Manufacturing Process & QC

From Concept to Completion: The Precision CNC Milling Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, the production of high-performance CNC milling machine components follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. This structured workflow ensures that every component meets exacting standards for precision, durability, and performance—delivering zero-defect outcomes for our global industrial clients.

The process begins with Design, where our engineering team collaborates closely with client specifications to develop detailed 3D CAD models. Utilizing advanced simulation software, we analyze stress points, thermal behavior, and dynamic loads to optimize geometry and material selection. This stage integrates design for manufacturability (DFM) principles to ensure that every feature can be consistently produced within tight tolerances. All designs undergo internal peer review and client validation before advancing to prototyping.

Next is Prototyping, a critical phase for verifying both functionality and manufacturability. Using high-speed CNC milling centers, we produce initial samples from the specified material—typically aerospace-grade aluminum, stainless steel, or hardened alloy steels. These prototypes undergo comprehensive metrology testing using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, geometric tolerances (GD&T), and surface finish are validated against ISO 2768 and client-specific standards. Feedback from this stage is used to refine toolpaths, fixturing, and inspection protocols, ensuring process readiness for scale.

Once prototype approval is confirmed, we transition to Mass Production under a fully documented quality management system compliant with ISO 9001:2015. Each production run is executed on multi-axis CNC milling machines equipped with automated tool measurement and in-process probing systems. These technologies enable real-time correction of dimensional drift, maintaining tolerances as tight as ±0.002 mm. Production batches are subject to first-article inspection (FAI), in-process checks, and final 100% visual and dimensional audits. Statistical process control (SPC) data is logged and analyzed to preempt deviations, supporting our zero-defect mandate.

Throughout all stages, traceability is maintained via laser-etched part IDs and digital process logs, ensuring full accountability from raw material to shipment. Our production floor operates under strict environmental controls to minimize thermal distortion, and all operators are certified to international machining standards.

The result is a seamless, scalable manufacturing process that delivers precision CNC milling components with unmatched consistency and reliability.

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 µm (adjustable) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Materials Supported | Aluminum 6061/7075, Stainless Steel 304/316, Tool Steel, Titanium, Brass |

| Tolerance Standards | ISO 2768, GD&T (ASME Y14.5) |

| Quality Certification | ISO 9001:2015, Full FAI & SPC Reporting |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical CNC Milling Components

In high-stakes manufacturing environments, component integrity directly dictates machine uptime, part fidelity, and operational profitability. Substandard spindles, ball screws, or structural elements introduce cumulative errors that compromise micron-level tolerances and accelerate system degradation. Wuxi Lead Precision Machinery engineers solutions where failure is not an option. Our ISO 9001-certified facility in Wuxi, China, leverages 15+ years of specialization in mission-critical CNC subsystems, serving aerospace, medical device, and semiconductor clients demanding uncompromised reliability. We transcend conventional component supply through integrated engineering collaboration—from material selection to dynamic load validation—ensuring every element performs identically under real-world thermal and mechanical stress.

Our manufacturing ecosystem combines German-sourced linear guideways, precision-ground HT300 cast iron beds, and proprietary thermal stability compensation algorithms. This foundation enables consistent achievement of 0.001mm positioning accuracy and 0.0005mm repeatability across 50,000+ operational hours. Unlike generic suppliers, we subject all components to rigorous in-house modal analysis and fatigue testing, simulating 3-shift production cycles before client delivery. The table below quantifies performance differentiators for core subsystems:

| Parameter | Lead Precision Standard | Industry Baseline | Impact on Production |

|---|---|---|---|

| Positioning Accuracy | ±0.001 mm | ±0.003 mm | Eliminates secondary finishing |

| Spindle Runout (ISO 26623) | ≤0.0008 mm | ≤0.002 mm | Extends tool life by 40% |

| Ball Screw Preload Life | 35,000 km | 20,000 km | Reduces unscheduled downtime |

| Bed Thermal Drift | ≤1.5 µm/°C | ≤4.0 µm/°C | Maintains tolerances in fluctuating environments |

| Vibration Damping | 92% reduction at 1.5 kHz | 75% reduction | Enables mirror-surface finishes |

This precision is engineered into every spindle housing, column assembly, and axis drive system we produce. Our technical team collaborates directly with your engineering staff during the design phase to address harmonic resonance risks, thermal expansion coefficients, and maintenance accessibility—transforming components from replaceable parts into performance assets. We provide full traceability via laser-etched serial numbers and digital twin documentation, ensuring seamless integration with your existing CNC infrastructure.

Initiate a technical consultation with our application engineers to validate your component requirements against our performance benchmarks. Forward your blueprint specifications or machine model details to [email protected]. Our team will respond within 4 business hours with a tailored analysis of how Lead Precision components can reduce your cost-per-part by 18–22% through extended tool life, minimized scrap rates, and unplanned downtime elimination. For mission-critical operations, component selection is not a cost center—it is your foundational advantage. Partner with the precision standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.