Technical Contents

Engineering Guide: Cnc Milling Company Georgia

Engineering Insight Precision as the Foundation for Georgia Manufacturers

For Georgia-based manufacturers operating in aerospace, medical device production, and advanced industrial sectors, precision CNC milling is not merely a service specification; it is the absolute cornerstone of product performance, regulatory compliance, and market competitiveness. In environments where tolerances measured in microns dictate safety, functionality, and longevity, the margin for error vanishes. A single micron deviation in a critical aerospace bracket or a medical implant component can cascade into catastrophic failure or regulatory rejection. Georgia companies demand partners whose engineering rigor transcends standard industry practices, ensuring every machined feature meets or exceeds the most stringent design intent. This level of consistency is non-negotiable when lives, brand reputation, and multi-million dollar programs are at stake.

Wuxi Lead Precision Machinery possesses deep, proven expertise in delivering this tier of precision under the most demanding global requirements. Our engineering team has consistently met the exacting standards required for components used in Olympic timing systems, where split-second accuracy is paramount, and in critical military applications where failure is not an option. These projects demanded not only achieving micron-level tolerances but also maintaining sub-micron repeatability across complex geometries in challenging materials like titanium alloys, Inconel, and high-performance composites. This experience translates directly to the needs of Georgia manufacturers who require absolute confidence in every part shipped – confidence built on documented processes, rigorous in-process inspection, and a culture where precision is engineered into every step, not merely inspected at the end.

Our capability to deliver this level of precision is anchored in advanced technology and disciplined methodology. We utilize state-of-the-art multi-axis CNC milling centers equipped with high-resolution probing systems and thermal compensation, operating within strictly controlled environmental conditions. This technical foundation, combined with our engineers’ deep understanding of material behavior and GD&T, allows us to consistently achieve specifications that push the boundaries of conventional machining. The table below outlines our core precision capabilities relevant to high-stakes Georgia manufacturing applications.

| Specification Category | Capability Range | Relevance to Georgia Manufacturing |

|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) standard | Critical for aerospace seals, medical implants |

| Geometric Tolerance (GD&T) | Achievable to ISO 2768-f / ASME Y14.5 | Ensures functional fit in complex assemblies |

| Surface Finish (Ra) | Down to 0.4 µm (16 µin) achievable | Vital for hydraulic components, optical mounts |

| Material Range | Titanium, Inconel, Stainless, Aluminum, Plastics | Supports diverse Georgia industry needs |

| Maximum Work Envelope (mm) | 1000 x 600 x 500 | Accommodates substantial aerospace structures |

Partnering with a CNC milling company capable of this demonstrable precision is a strategic imperative for Georgia manufacturers targeting high-reliability markets. It mitigates risk, accelerates time-to-market by reducing rework and scrap, and provides the tangible evidence of quality demanded by OEMs and regulatory bodies. Wuxi Lead Precision Machinery brings this validated, mission-critical precision capability – forged in Olympic and military programs – directly to your Georgia operations, ensuring your components perform flawlessly in the field. Precision isn’t just what we measure; it’s the engineering standard we deliver.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

Wuxi Lead Precision Machinery delivers world-class precision CNC machining services tailored for high-performance industries including aerospace, medical, robotics, and advanced automation. As a leading CNC milling company in Georgia’s global supply chain network, our facility in Wuxi, China, is engineered for maximum accuracy, repeatability, and efficiency. Our core strength lies in multi-axis machining, advanced quality control, and strict adherence to international manufacturing standards.

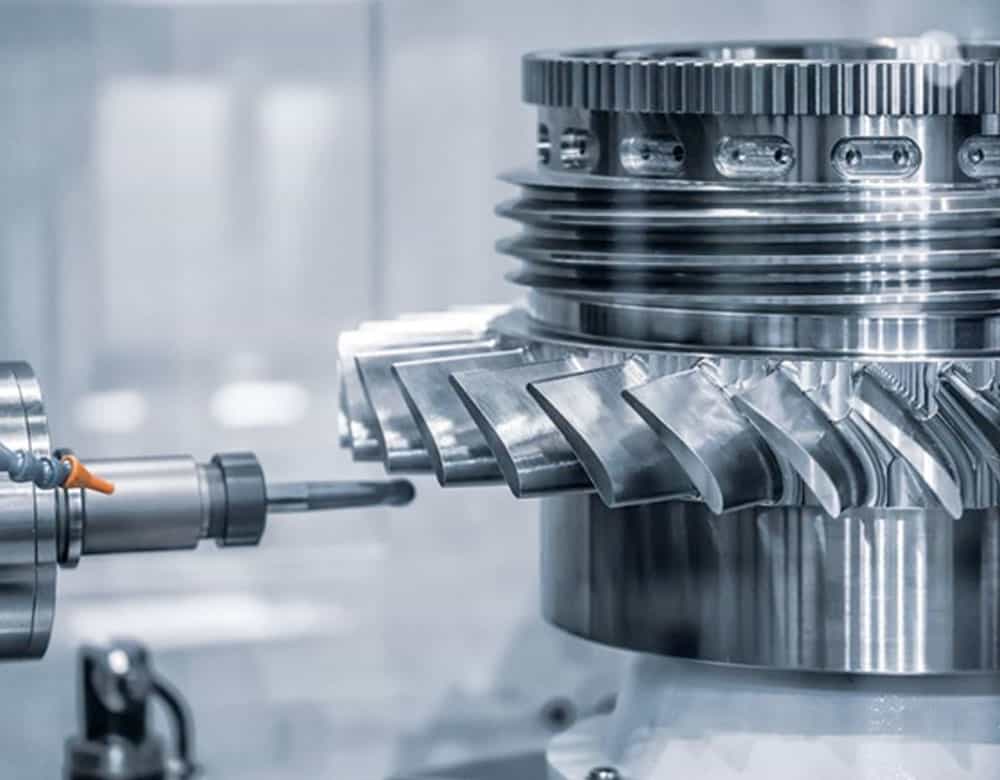

At the heart of our production floor are state-of-the-art 5-axis CNC machining centers, enabling complex geometry fabrication with exceptional surface finish and dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous cutting from five different angles, reducing setup times, minimizing human error, and maintaining tight tolerances across intricate part features. This capability is essential for manufacturing components with organic contours, undercuts, and internal channels—common in turbine blades, surgical instruments, and high-load structural elements.

Our machining fleet includes high-rigidity CNC systems from industry-leading brands, equipped with automatic tool changers, high-speed spindles, and real-time tool wear monitoring. These machines support a broad range of materials, including aerospace-grade aluminum alloys (e.g., 7075-T6), titanium (Grade 5), stainless steel (316L, 17-4 PH), engineering plastics (PEEK, PTFE), and exotic superalloys such as Inconel 718. Material versatility combined with 5-axis flexibility ensures that we meet the functional and environmental demands of the most challenging applications.

Quality assurance is integrated at every stage of production. Each component undergoes comprehensive dimensional verification using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), calibrated to ISO 10360 standards. The CMM provides micron-level accuracy in 3D geometry inspection, generating detailed reports with GD&T (Geometric Dimensioning and Tolerancing) analysis. Our quality technicians are certified to interpret ASME Y14.5 and ISO 1101 standards, ensuring full compliance with client engineering drawings and international specifications.

We maintain full traceability through batch numbering, material certifications (MTRs), and digital inspection records stored in our secure manufacturing execution system (MES). All processes are governed by ISO 9001:2015 and IATF 16949 standards, reinforcing our commitment to continuous improvement and defect prevention.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1,200 mm × 800 mm × 750 mm |

| Axis Configuration | 5-axis simultaneous milling |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (Machining) | ±0.010 mm per 100 mm |

| Angular Tolerance | ±0.02° |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Typical Lead Time | 7–15 days (depending on complexity) |

| Supported File Formats | STEP, IGES, X_T, DWG, PDF (with GD&T) |

Wuxi Lead Precision Machinery is equipped to handle low to mid-volume production runs with the agility and precision required by Georgia-based OEMs and high-tech innovators. Our technical capabilities ensure that every component meets the highest benchmarks in performance, reliability, and quality.

Material & Finish Options

Material Selection for Precision CNC Milling in Georgia’s Industrial Landscape

Material selection critically impacts part performance, manufacturability, and total cost for Georgia-based manufacturers. Choosing the optimal alloy and finish ensures components meet stringent aerospace, medical, defense, and industrial equipment requirements prevalent across the state. Wuxi Lead Precision Machinery leverages deep metallurgical expertise to guide clients through this complex decision, aligning material properties with functional demands and production efficiency.

Aluminum alloys dominate applications requiring high strength-to-weight ratios and excellent machinability. Series 6061-T6 offers versatile corrosion resistance and weldability, ideal for structural brackets, marine components, and general machinery frames common in Georgia’s manufacturing base. For higher strength demands, 7075-T6 is preferred in aerospace fixtures and high-stress automotive parts, though its lower corrosion resistance necessitates protective finishes. Aluminum’s thermal conductivity also benefits heat sink applications within Georgia’s growing electronics sector.

Steel selections prioritize strength, wear resistance, and hardness. 4140 chrome-moly steel provides exceptional toughness for shafts, gears, and tooling fixtures under heavy load. Stainless steels like 304 and 316 deliver critical corrosion resistance for medical instruments, food processing equipment, and marine hardware, with 316 offering superior chloride resistance vital for coastal Georgia operations. Tool steels such as A2 or D2 are essential for high-wear applications like molds and cutting tools, requiring precise heat treatment post-machining.

Titanium Ti-6Al-4V (Grade 5) is indispensable for aerospace components, medical implants, and high-performance automotive parts where extreme strength-to-weight ratio, biocompatibility, and corrosion resistance in harsh environments are non-negotiable. Its challenging machinability demands specialized tooling and processes, which Wuxi Lead executes with controlled parameters to prevent work hardening and ensure dimensional accuracy, directly supporting Georgia’s robust aerospace supply chain.

Anodizing is the premier surface treatment for aluminum, significantly enhancing corrosion and wear resistance while providing electrical insulation. Type II (Sulfuric Acid) anodizing offers a durable, dyeable finish for consumer and industrial parts. Type III (Hardcoat) anodizing produces a much thicker, harder ceramic layer essential for aerospace, military, and high-wear mechanical components, meeting stringent specifications like MIL-A-8625. Proper pre-treatment and process control are vital for adhesion and performance consistency.

Material property comparison for common CNC machining alloys:

| Material | Key Properties | Common Grades | Typical Georgia Applications |

|---|---|---|---|

| Aluminum | Lightweight, high conductivity, good machinability | 6061-T6, 7075-T6 | Aerospace brackets, heat sinks, marine hardware |

| Steel | High strength, wear resistance, magnetic | 4140, 304, 316, A2 | Shafts, medical tools, tooling, structural parts |

| Titanium | Exceptional strength-to-weight, corrosion resistant | Ti-6Al-4V (Gr5) | Aircraft components, medical implants, racing parts |

When Georgia manufacturers require precision-machined components where material integrity is paramount, Wuxi Lead Precision Machinery delivers certified materials, advanced CNC milling expertise, and controlled finishing processes. Our integrated approach ensures optimal material utilization, adherence to ASTM and AMS standards, and on-time delivery, solving complex supply chain challenges for Southern US industry. Partner with us for engineered material solutions that perform.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our CNC milling process in Georgia is engineered for uncompromising precision, efficiency, and zero-defect output. We serve high-demand industries including aerospace, medical, and advanced automation, where component reliability is non-negotiable. Our end-to-end production workflow integrates design validation, rapid prototyping, and scalable mass production—all governed by strict quality control protocols.

The process begins with design analysis, where our engineering team reviews client CAD models for manufacturability, tolerance feasibility, and material compatibility. Using advanced simulation software, we perform virtual machining trials to detect potential toolpath conflicts, material stress points, or geometric inaccuracies before any metal is cut. This proactive approach reduces downstream rework and accelerates time-to-market.

Once the design is optimized, we move to precision prototyping. Utilizing 3-, 4-, and 5-axis CNC milling centers, we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports are shared with the client for approval, ensuring alignment on form, fit, and function. This phase is critical for validating design integrity and securing stakeholder confidence prior to volume manufacturing.

Upon prototype approval, we transition seamlessly into mass production. Our Georgia facility leverages automated pallet systems, robotic part handling, and real-time tool monitoring to maintain continuous operation with minimal human intervention. Each production run follows a documented process plan that includes stage-specific quality checkpoints, first-article inspections, and in-process gaging. Statistical Process Control (SPC) is implemented to detect trends and correct deviations before defects occur.

Zero defects are achieved through a layered assurance model. Every component is traceable via our digital manufacturing execution system (MES), which logs machine parameters, inspection data, and operator inputs. Final inspection includes 100% critical dimension checks and batch sampling for non-critical features, all in compliance with ISO 9001 and IATF 16949 standards.

Our commitment to precision is reflected in the capabilities of our CNC milling systems. Below are key technical specifications:

| Specification | Detail |

|---|---|

| Axis Configurations | 3-axis, 4-axis, 5-axis |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Plastics (PEEK, Delrin) |

| Surface Finish | As low as Ra 0.4 µm (typical), down to Ra 0.1 µm (polished) |

| Tolerance Range | ±0.01 mm (standard), down to ±0.003 mm (tight-tolerance) |

From concept to volume delivery, Wuxi Lead Precision Machinery ensures every CNC milled part meets the highest standards of performance and reliability. Our Georgia operations combine Chinese manufacturing scale with Western engineering discipline, delivering zero-defect components on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic CNC Milling Partner for Georgia Manufacturing Excellence

When Georgia’s precision manufacturing sector demands uncompromising accuracy, repeatable quality, and agile responsiveness, Wuxi Lead Precision Machinery delivers engineered solutions that redefine reliability. As a globally certified ISO 9001:2015 and IATF 16949 facility with 15+ years of advanced CNC expertise, we bridge the gap between Georgia’s innovation-driven projects and world-class precision manufacturing. Our direct collaboration model eliminates intermediaries, ensuring your technical requirements are met with surgical precision—without the overhead of traditional offshore outsourcing.

Georgia’s aerospace, medical device, and industrial equipment manufacturers face unique challenges: complex geometries, stringent material certifications, and compressed timelines. Lead Precision tackles these with a dedicated engineering team fluent in AS9100 and FDA-compliant processes. We specialize in 3- to 5-axis milling of titanium, Inconel, aluminum alloys, and engineering plastics, achieving tolerances down to ±0.005mm. Our facility in Wuxi operates 24/7 across 30+ CNC centers—including DMG MORI, Haas, and Makino systems—guaranteeing scalability from prototype to high-volume production. Crucially, we synchronize with Georgia business hours through a U.S.-based technical liaison team, enabling real-time design validation and rapid iteration.

Technical Capabilities at a Glance

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005mm to ±0.025mm |

| Max Work Envelope | 1200 x 600 x 500 mm |

| Material Expertise | Titanium, Inconel, Stainless Steel, Aluminum, PEEK, Delrin |

| Surface Finish | Ra 0.4μm to Ra 1.6μm (as-machined) |

| Quality Documentation | FAIR, PPAP, Material Certs, CMM Reports |

Unlike regional Georgia shops constrained by capacity or equipment limitations, we offer tier-1 supply chain rigor at competitive landed costs. Our integrated metrology lab—featuring Zeiss CMMs and optical comparators—validates every critical dimension before shipment, ensuring zero non-conformance risk. For urgent Georgia projects, our air freight coordination delivers parts to Atlanta within 72 hours of final inspection. This operational synergy transforms offshore manufacturing into a strategic advantage: predictable lead times, cost transparency, and engineering partnership without geographical friction.

Initiate your precision workflow by contacting our Georgia-focused technical team. Email [email protected] with your CAD files and requirements for a guaranteed 4-hour response. We’ll provide a detailed manufacturability analysis, competitive quotation, and production timeline—no obligations. When Georgia’s next breakthrough project demands milling precision that matches its ambition, trust a partner engineered for excellence. Lead Precision doesn’t just machine components; we secure your competitive edge.

Contact [email protected] today to align your Georgia operation with global precision standards. Your project’s success begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.