Technical Contents

Engineering Guide: Cnc Millers

Engineering Insight Precision as the Non-Negotiable Foundation in CNC Milling

In high-performance manufacturing, precision transcends specification sheets; it is the absolute foundation determining component functionality, system integration, and ultimate product success. For critical applications in aerospace, medical device manufacturing, and advanced defense systems, deviations measured in microns directly impact safety, efficiency, and regulatory compliance. At Wuxi Lead Precision Machinery, we engineer CNC milling solutions where precision is not merely targeted but rigorously guaranteed through integrated design philosophy and uncompromising process control. The inherent stability of the machine structure, thermal management systems, and servo control dynamics must operate in concert to achieve and sustain micron-level accuracy under production loads. Sub-micron thermal compensation routines and vibration-dampened granite bases are not optional extras but essential engineering requirements for parts demanding true geometric integrity.

Our commitment to precision is validated through mission-critical partnerships. We delivered complex structural titanium components for the Beijing 2022 Winter Olympics venue systems, where thermal expansion tolerances of ±0.005mm across 2-meter spans were mandatory for seamless assembly under extreme climate conditions. Similarly, our certified production lines consistently meet stringent MIL-STD-810G requirements for defense contractors, machining hardened steel housings with positional repeatability under 0.002mm for guidance systems where failure is inconceivable. This real-world experience shapes every machine we build and every process we implement.

Achieving such results requires machinery engineered beyond standard commercial benchmarks. Our flagship VMC series incorporates linear scales on all axes with real-time error correction, direct-drive torque motors eliminating backlash, and FEM-optimized frames resisting deflection under 50kN cutting forces. The table below details the core precision capabilities inherent in our production-grade systems:

| Specification Parameter | Performance Value | Industry Standard Reference |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.002 mm | ISO 230-2:2014 |

| Repeatability (3σ) | ≤0.001 mm | ISO 230-2:2014 |

| Volumetric Compensation | Full 3D Grid (≤0.003 mm) | ASME B5.54 |

| Thermal Drift Control | ≤1.5 μm/°C (0-40°C) | Custom Lead Calibration |

| Spindle Runout (at tool nose) | ≤0.001 mm | ISO 22901 |

These specifications are not theoretical ideals but routinely verified production capabilities. We understand that your end-client’s reputation hinges on the dimensional fidelity of every part we produce together. Wuxi Lead Precision Machinery integrates Olympic-proven processes and military-grade discipline into every CNC milling operation, transforming precision from a target into a guaranteed outcome. This is the standard for which discerning global manufacturers specify our solutions.

Precision Specs & Tolerances

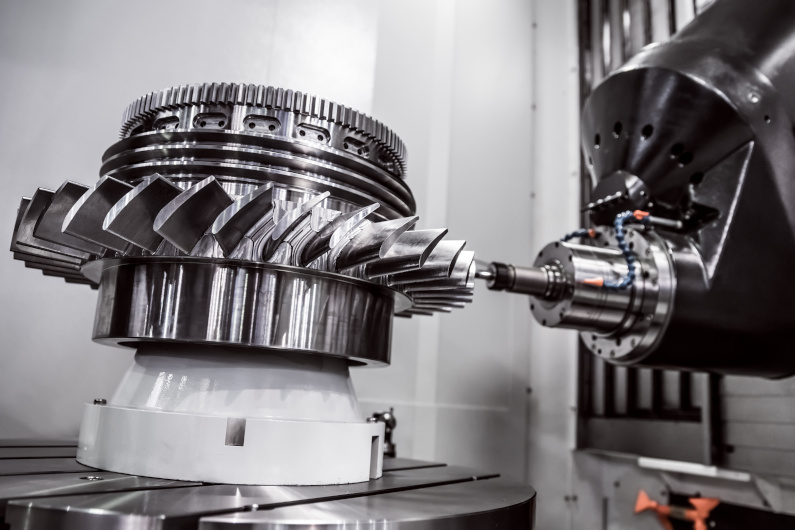

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered for high-performance industries including aerospace, medical, energy, and automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform that enables complex geometry processing with exceptional accuracy and surface finish. Our multi-axis systems eliminate the need for multiple setups, reducing cumulative error and significantly improving part consistency. This capability supports the production of intricate components such as turbine blades, impellers, orthopedic implants, and high-tolerance housings where dimensional integrity and repeatability are non-negotiable.

Our 5-axis CNC machines are equipped with high-speed spindles, dynamic tool compensation, and real-time adaptive control systems, allowing for continuous contouring and undercuts without repositioning. This not only enhances geometric flexibility but also reduces lead times and improves overall process efficiency. All machining operations are supported by advanced CAM programming using industry-leading software, ensuring optimal toolpaths, minimized cycle times, and full traceability from design to final inspection.

Quality assurance is embedded at every stage of production. Each component undergoes rigorous dimensional verification using state-of-the-art Coordinate Measuring Machines (CMM) with probing systems capable of micron-level accuracy. Our inspection protocols comply with ISO 10360 standards, and all reports are documented with full GD&T analysis. In addition to CMM, we utilize optical comparators, surface roughness testers, and calibrated hand tools to verify critical features. This multi-layered inspection strategy ensures that every part conforms to the most stringent quality requirements.

We maintain tight control over environmental variables in our machining centers, including temperature-stable workshops and humidity regulation, minimizing thermal drift during precision operations. Our team of certified CNC engineers and quality technicians follow standardized work instructions aligned with ISO 9001:2015, ensuring consistent process control and continuous improvement.

The table below outlines the typical tolerances we achieve across various geometric and dimensional parameters, reflecting our commitment to precision and repeatability.

| Feature Type | Typical Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 300 mm; ±0.01 mm beyond |

| Geometric Tolerances | ±0.008 mm (GD&T) | Includes position, flatness, runout |

| Hole Diameter | +0.005 / -0.000 mm | Reamed or honed features |

| Surface Roughness (Ra) | 0.4 – 1.6 µm | Machined surfaces; polish optional |

| Angular Accuracy | ±0.05° | Critical for 5-axis compound angles |

| Repeatability (Cp/Cpk) | ≥1.67 / ≥1.33 | Validated per production batch |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade inspection to deliver components that meet the highest standards of precision engineering. Our technical capabilities are designed to support complex, low-volume, and mission-critical manufacturing demands with full confidence in quality and performance.

Material & Finish Options

Strategic Material Selection for Precision CNC Milling Operations

Material choice fundamentally impacts part performance, machining efficiency, and total project cost in high-precision CNC milling. At Wuxi Lead Precision Machinery, we guide clients through critical trade-offs between Aluminum, Steel, and Titanium based on application demands, production volume, and environmental exposure. Selecting the optimal substrate ensures dimensional stability, surface integrity, and compliance with industry specifications.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. 6061-T6 offers balanced machinability and weldability for structural components, while 7075-T6 delivers superior strength for high-stress applications like aircraft fittings. Aluminum’s low density reduces cycle times but requires sharp tooling to prevent built-up edge and thermal distortion during high-speed milling.

Carbon and alloy steels provide unmatched durability for tooling, hydraulics, and heavy machinery. 4140 steel excels in wear resistance with moderate machinability when pre-hardened, whereas 303 stainless steel prioritizes chip-breaking efficiency for complex geometries despite slightly reduced corrosion resistance. Steel machining demands robust spindle power and controlled coolant application to manage heat-induced warping and tool wear, particularly in hardened grades exceeding 45 HRC.

Titanium alloys (Grade 5 Ti-6Al-4V) are indispensable in medical implants and aerospace where extreme strength, biocompatibility, and corrosion resistance are non-negotiable. However, titanium’s low thermal conductivity and high chemical reactivity necessitate specialized strategies: reduced cutting speeds, rigid setups to prevent chatter, and strict avoidance of chlorine-based coolants. While premium in cost, its fatigue resistance justifies use in mission-critical components.

Critical material properties are summarized below for rapid comparison:

| Material | Typical Grade | Yield Strength (MPa) | Machinability Rating | Key Machining Consideration |

|---|---|---|---|---|

| Aluminum | 6061-T6 | 276 | 200% | High feed rates; avoid heat buildup |

| Steel | 4140 | 655 | 65% | Pre-heat treatment critical |

| Stainless Steel | 304 | 205 | 45% | Low-speed finishing for surface integrity |

| Titanium | Ti-6Al-4V | 880 | 20% | Rigid fixtures; minimal depth of cut |

Surface finishing, particularly anodizing, enhances aluminum’s corrosion resistance and wear performance. Type II (sulfuric acid) anodizing provides standard protection with dye compatibility for identification, while Type III (hard coat) delivers 50-100µm thickness for abrasive environments. Wuxi Lead Precision Machinery integrates anodizing specifications directly into our CNC programming to maintain critical tolerances on threaded features and sealing surfaces, ensuring seamless post-processing without dimensional compromise.

Material selection must align with functional requirements and production economics. Our engineering team collaborates with clients to validate material-process pairings through simulation and prototyping, minimizing costly revisions. Contact Wuxi Lead Precision Machinery for a technical consultation to optimize your next precision machining project.

Manufacturing Process & QC

From Design to Mass Production: The Zero-Defect CNC Milling Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer precision into every stage of the CNC milling process. Our end-to-end manufacturing workflow is designed to ensure zero defects, from initial concept to full-scale production. This disciplined approach integrates advanced engineering, rigorous validation, and continuous quality monitoring to deliver components that meet the exacting standards of aerospace, medical, and industrial automation sectors.

The process begins with design engineering, where our technical team collaborates closely with clients to interpret technical drawings, 3D CAD models, and performance requirements. Using industry-leading software such as Siemens NX and SolidWorks, we conduct comprehensive design for manufacturability (DFM) analysis. This step identifies potential machining challenges early, optimizes toolpaths, and ensures material efficiency—reducing lead times and eliminating costly revisions. Our engineers also select the optimal material grade, whether aluminum 7075, titanium Ti-6Al-4V, or high-performance engineering plastics, based on mechanical and environmental demands.

Once the design is finalized, we move to precision prototyping. Utilizing our 5-axis CNC milling centers with sub-micron positioning accuracy, we produce functional prototypes that mirror final production quality. These prototypes undergo full metrological validation using Zeiss coordinate measuring machines (CMM) and 3D laser scanning to confirm dimensional accuracy and surface integrity. Clients receive detailed inspection reports, including first article inspection (FAI) documentation per AS9102 standards. This phase is critical for verifying design intent, fit, and function before scaling to mass production.

With prototype approval, we transition seamlessly into high-volume manufacturing. Our production floor is equipped with automated CNC cells featuring robotic pallet changers and real-time tool wear monitoring systems. Each operation follows standardized work instructions, and in-process inspections are conducted at defined intervals to maintain consistency. Statistical process control (SPC) data is logged continuously, enabling predictive adjustments and full traceability for every component.

Our zero-defect philosophy is enforced through a multi-layered quality assurance system. Every batch undergoes 100% visual inspection and selective destructive testing where applicable. Non-conforming parts are immediately quarantined, and root cause analysis is performed using Six Sigma methodologies. This closed-loop feedback mechanism ensures continual process refinement and sustained yield rates above 99.8%.

The following table outlines key capabilities of our CNC milling production process:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Spindle Speed Range | 8,000 – 24,000 rpm |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| Materials Supported | Aluminum, Steel, Stainless, Titanium, Plastics |

| Surface Finish (Typical) | Ra 0.4 – 1.6 µm |

| Quality Standards | ISO 9001:2015, AS9100D, ISO 13485 |

| In-Process Inspection | SPC, CMM, Optical Comparators |

By integrating precision engineering, advanced automation, and uncompromising quality control, Wuxi Lead Precision Machinery delivers CNC-milled components with guaranteed reliability at any scale.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Milling Excellence

In the high-stakes realm of precision manufacturing, selecting a CNC milling partner transcends transactional procurement. It demands a strategic alliance grounded in engineering rigor, process transparency, and unwavering commitment to dimensional integrity. At Wuxi Lead Precision Machinery, we engineer partnerships—not just components—to elevate your production outcomes and secure competitive advantage. Our ISO 9001-certified facility in Wuxi, China, operates at the convergence of German-inspired precision engineering and agile Chinese manufacturing execution. We specialize in transforming complex, tight-tolerance designs into reality for aerospace, medical device, and semiconductor clients where failure is not an option.

Our technical capabilities are validated through measurable performance metrics. The table below outlines our standard high-precision CNC milling specifications, reflecting the baseline for every project we undertake:

| Specification | Performance Metric |

|---|---|

| Positioning Accuracy | ±2.5 μm |

| Repeatability | ±1.5 μm |

| Maximum Work Envelope | 1,200 x 800 x 600 mm |

| Spindle Speed Range | 20 – 24,000 RPM |

| Surface Finish (Ra) | 0.2 – 0.8 μm |

| Material Compatibility | Titanium, Inconel, PEEK, 7075-T7351, Tool Steels |

These specifications are not theoretical ideals but daily operational standards enforced through Renishaw probe calibration, thermal compensation systems, and real-time process monitoring. Unlike commodity machine shops, we integrate engineering collaboration from your initial design phase. Our team reviews manufacturability, identifies cost-saving opportunities without sacrificing tolerance, and implements first-article inspection protocols aligned with AS9102 or PPAP requirements. This proactive approach minimizes iteration cycles and accelerates time-to-market for mission-critical components.

Choosing Lead Precision means gaining a partner invested in your long-term success. We deploy dedicated project managers fluent in technical English and German, ensuring seamless communication across global supply chains. Our facility operates under strict ITAR compliance frameworks, with encrypted data handling and segregated production cells for sensitive programs. Furthermore, our continuous improvement culture leverages SPC data from every run to refine processes—delivering not just parts, but documented quality evidence for your auditors. When your application demands micron-level consistency across batch sizes from 1 to 10,000, our infrastructure and expertise eliminate guesswork.

Initiate a precision partnership that delivers measurable ROI. Contact our engineering team directly at [email protected] with your part drawings and technical requirements. Specify “B2B Precision Inquiry” in the subject line to ensure immediate routing to our application specialists. We will provide a detailed capability assessment, including feasibility analysis and lead-time projection, within 24 business hours. For urgent RFQs, include your required delivery date—we prioritize responsiveness as rigorously as we do accuracy. Trust Wuxi Lead Precision Machinery to become the silent engine behind your next breakthrough product. Your specifications define our standard; let us prove it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.