Technical Contents

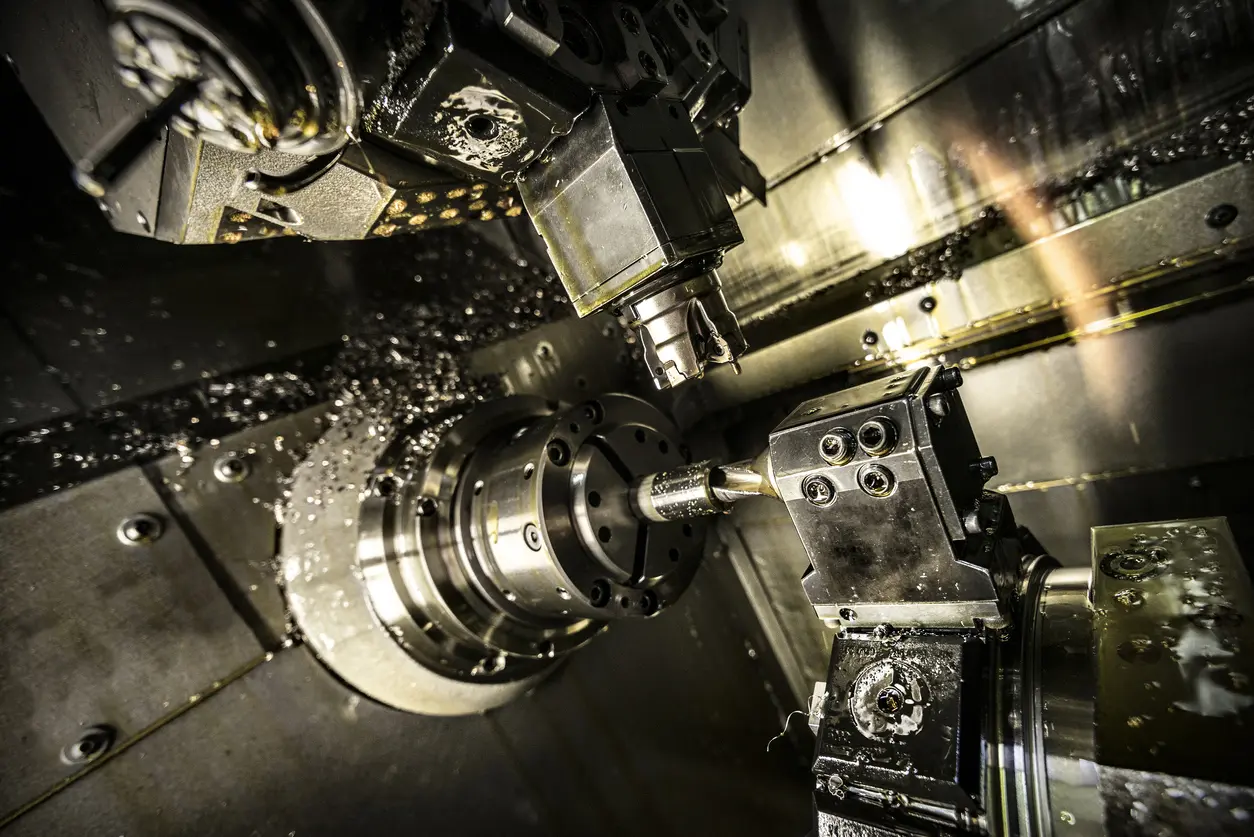

Engineering Guide: Cnc Mill Service

Engineering Insight: The Critical Role of Precision in CNC Mill Services

In high-performance manufacturing, precision is not merely a target—it is a necessity. The reliability, functionality, and longevity of engineered components depend on exact dimensional accuracy, tight tolerances, and superior surface finishes. At Wuxi Lead Precision Machinery, we understand that in sectors such as aerospace, defense, medical, and advanced automation, even a deviation of a few microns can compromise system integrity. Our CNC mill services are engineered to meet and exceed these exacting standards, ensuring every component performs as designed, every time.

Precision in CNC milling begins with machine rigidity, thermal stability, and advanced control systems. It extends into material selection, toolpath optimization, and real-time in-process inspection. At Lead Precision, our facility integrates state-of-the-art 3-, 4-, and 5-axis CNC milling centers equipped with high-resolution probing systems and automated tool compensation. These technologies enable consistent repeatability within ±0.002 mm, critical for complex geometries and multi-feature components.

Our commitment to precision is validated through rigorous quality assurance protocols. Every milling operation is supported by ISO 9001-certified processes, with full inspection reports using coordinate measuring machines (CMM) and optical comparators. This end-to-end traceability ensures compliance with international standards and customer-specific requirements.

Wuxi Lead Precision Machinery brings over 15 years of experience in mission-critical manufacturing. Our work has supported projects with Olympic-level precision timing systems and high-reliability military subsystems—applications where failure is not an option. These projects demanded more than technical capability; they required a culture of engineering excellence, disciplined process control, and unwavering attention to detail. We apply the same standards to every CNC mill service we provide, regardless of volume.

Whether producing single prototype components or managing long-run production batches, our team collaborates closely with engineers and design teams to optimize manufacturability, reduce cycle times, and enhance part performance. Our expertise spans aluminum, stainless steel, titanium, Inconel, and engineering plastics—materials chosen for their performance in extreme environments.

Below are key specifications that define our CNC milling capabilities:

| Specification | Capability |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Tolerance Range | ±0.005 mm to ±0.01 mm typical |

| Surface Finish | As low as Ra 0.4 μm (polished to Ra 0.1 μm) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, First Article Inspection (FAI) |

Precision is not achieved by machinery alone—it is the result of integrated engineering insight, disciplined process control, and a commitment to excellence. At Wuxi Lead Precision Machinery, we deliver CNC mill services built for performance, reliability, and absolute accuracy.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding CNC mill service requirements through our advanced 5-axis machining centers. Our core strength lies in simultaneous 5-axis milling, enabling the production of intricate geometries—organic contours, deep cavities, undercuts, and highly complex 3D surfaces—in a single, uninterrupted setup. This eliminates cumulative errors inherent in multi-setup processes, significantly improving part accuracy, surface finish, and overall component integrity. Utilizing industry-leading machines from manufacturers like DMG MORI and MAZAK, we achieve exceptional rigidity, thermal stability, and sub-micron positioning accuracy. Our integrated CAD/CAM systems, coupled with in-house programming expertise, ensure optimal toolpaths for challenging materials including titanium alloys, Inconel, hardened steels, and advanced composites, directly translating complex engineering designs into flawless physical components with minimal lead time.

Rigorous quality control is non-negotiable in precision manufacturing. Every critical dimension and feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Mitutoyo CMMs, operating within temperature-controlled metrology labs, provide traceable, high-accuracy measurement data fully compliant with ISO 17025 standards. This systematic inspection process, integrated directly into our production workflow, ensures dimensional conformity against the most stringent engineering drawings and GD&T specifications. Real-time CMM data feeds back into our process control systems, enabling immediate corrective actions and continuous process refinement. We provide detailed inspection reports, including full first-article inspection (FAI) documentation per AS9102 or client-specific formats, guaranteeing complete traceability and transparency from raw material to finished part shipment. This closed-loop quality system prevents non-conformances and delivers consistent, reliable results meeting aerospace, medical, and semiconductor industry benchmarks.

Our commitment to precision is quantified in the achievable tolerances across diverse part features, as demonstrated below. These capabilities represent our standard production excellence; tighter tolerances are achievable for critical features through specialized processes and enhanced inspection protocols.

| Feature Type | Standard Production Tolerance | Tight Capability (Special Process) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) | Up to 300 mm travel |

| Angular Features | ±0.001° | ±0.0005° | Verified via CMM |

| Positional Tolerance | ±0.008 mm (±0.0003″) | ±0.003 mm (±0.0001″) | True Position, MMC applicable |

| Surface Finish (Ra) | 0.8 µm (32 µin) | 0.2 µm (8 µin) | As-machined, material dependent |

| Profile of a Surface | 0.010 mm (0.0004″) | 0.005 mm (0.0002″) | Complex contours |

Wuxi Lead Precision Machinery’s integrated 5-axis CNC milling and metrology infrastructure forms the foundation for delivering mission-critical components where precision, reliability, and repeatability are paramount. We partner with engineering teams to transform ambitious designs into reality, ensuring every part meets the exacting demands of advanced manufacturing applications.

Material & Finish Options

Material selection is a critical factor in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity components from aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding these materials enables engineers and procurement teams to make informed decisions aligned with functional requirements and environmental conditions.

Aluminum is widely favored in aerospace, automotive, and consumer electronics due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly used for structural components, while 7075-T6 offers higher strength for demanding applications. Aluminum’s natural corrosion resistance can be further enhanced through surface treatments such as anodizing, making it ideal for both functional and aesthetic parts.

Steel, particularly alloy and stainless variants, delivers superior strength, wear resistance, and dimensional stability. 4140 alloy steel is frequently selected for high-stress mechanical components such as shafts and gears, while 303 and 304 stainless steels are preferred in medical and food-processing equipment for their corrosion resistance and hygiene compliance. Although heavier than aluminum, steel’s robustness makes it suitable for industrial machinery and tooling applications where longevity under load is essential.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments such as aerospace, defense, and biomedical implants. Its exceptional strength-to-density ratio, combined with outstanding resistance to corrosion and high-temperature performance, justifies its higher cost and more challenging machinability. CNC milling titanium requires specialized tooling and precise process control—capabilities we have refined at Wuxi Lead through years of high-precision production.

Surface finishing plays a pivotal role in part performance and longevity. Anodizing is a widely used electrochemical process for aluminum, creating a durable, corrosion-resistant oxide layer. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hardcoat) anodizing delivers enhanced surface hardness and wear resistance. Our in-house anodizing services ensure tight control over coating thickness, color consistency, and adhesion, meeting ASTM and military specifications.

Below is a comparative overview of key material properties to guide selection:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, brackets, heat sinks | Excellent |

| 7075-T6 | 572 | 2.8 | Aerospace components, high-stress parts | Good | |

| Steel | 4140 | 655 | 7.85 | Shafts, gears, tooling | Moderate |

| 304 Stainless | 515 | 8.0 | Medical devices, food equipment | Fair | |

| Titanium | Ti-6Al-4V (Gr5) | 900 | 4.43 | Aircraft structures, implants | Poor (requires expertise) |

Selecting the right material and finish requires balancing performance, environment, and production efficiency. At Wuxi Lead Precision Machinery, we support clients with material consultation, prototyping, and full-scale CNC milling to ensure optimal outcomes for every project.

Manufacturing Process & QC

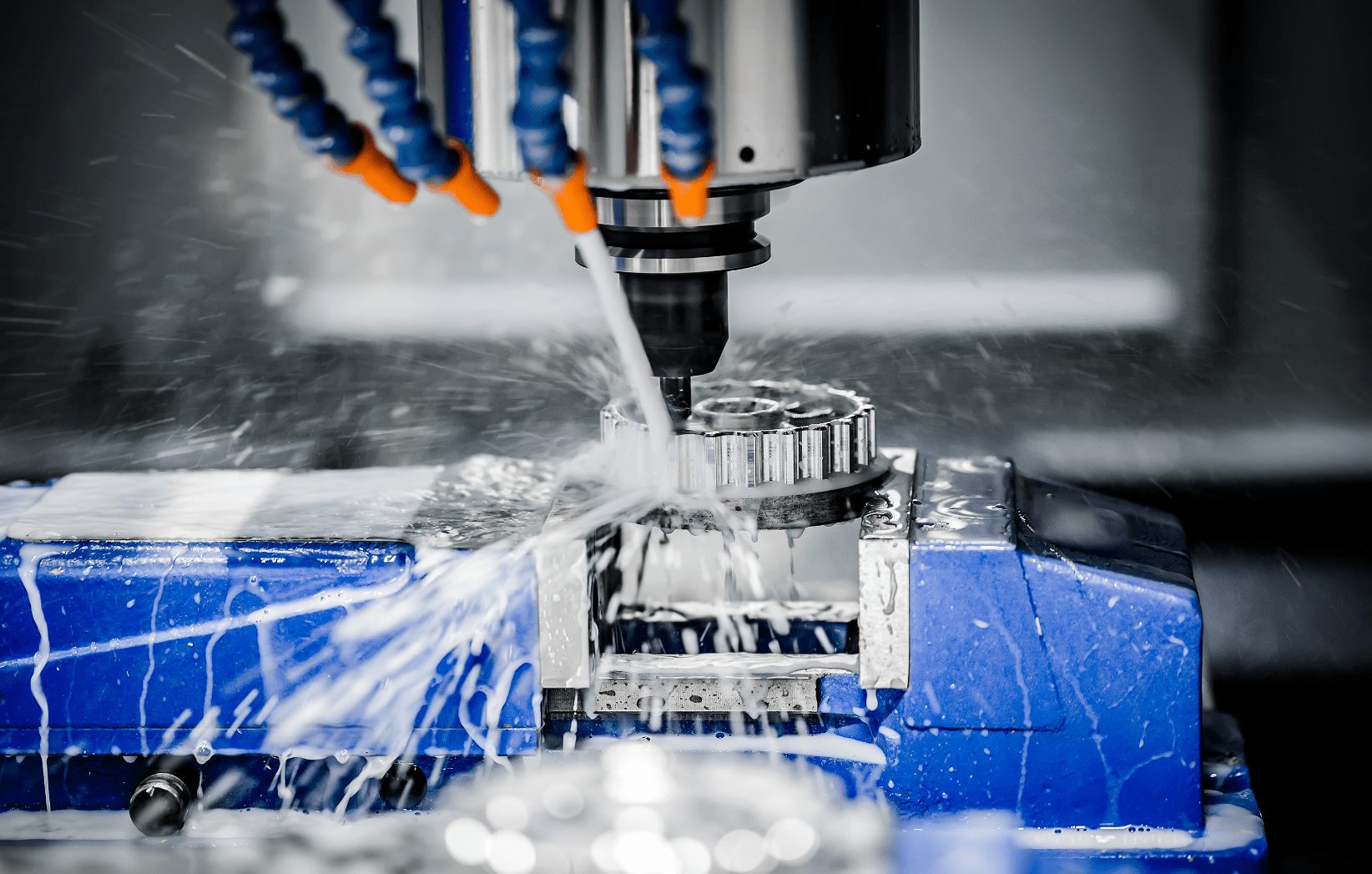

Precision CNC Milling Production Process: From Concept to Zero Defects Fulfillment

Precision manufacturing begins at conception. At Wuxi Lead Precision Machinery, our CNC mill service production process is engineered for absolute fidelity to your specifications, ensuring zero defects from initial design through high-volume delivery. This disciplined sequence is non-negotiable for mission-critical components in aerospace, medical, and semiconductor sectors.

The journey starts with rigorous design validation. Our engineering team collaborates deeply with your CAD data, performing comprehensive manufacturability analysis and GD&T callout verification. We identify potential tolerance stack-ups, tool access constraints, and material behavior risks before metal is cut. Advanced CAM simulation validates toolpaths, preventing collisions and ensuring optimal chip evacuation. This proactive scrutiny eliminates 90% of potential downstream errors, transforming your digital model into a fully de-risked manufacturing blueprint. We do not proceed until every geometric and functional requirement is achievable within our controlled parameters.

Prototyping is not merely a formality; it is the critical validation phase. Utilizing the exact production-grade CNC mills and tooling intended for volume runs, we produce functional prototypes under identical process conditions. Each prototype undergoes 100% dimensional inspection against your master CAD model using calibrated CMMs and optical comparators. Material properties and surface integrity are verified. This phase allows for iterative refinement based on empirical data – not assumptions – ensuring the final process window is robust and capable. Client sign-off on prototype conformance is mandatory before scaling.

Mass production leverages the validated process with uncompromising statistical process control. Every workpiece is tracked via our integrated MES, linking material certs, machine parameters, and operator logs to individual part IDs. In-process inspections at defined intervals monitor critical dimensions using automated gauging. Final inspection is exhaustive: 100% CMM verification of all GD&T features, surface roughness measurement, and visual inspection under controlled lighting. Our zero-defect commitment is enforced through real-time SPC charting; any parameter drift triggers immediate process correction, not just part rejection. This closed-loop system guarantees consistency batch after batch.

Our core machining capabilities consistently achieve the demanding tolerances and finishes required for zero-defect delivery, as demonstrated below:

| Parameter | Standard Capability | Premium Capability (Tight Tolerance) |

|---|---|---|

| Positional Tolerance | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) |

| Surface Roughness | Ra 0.8 µm (32 µin) | Ra 0.2 µm (8 µin) |

| Feature Size Range | 1 mm to 800 mm | 0.1 mm to 500 mm (micromachining) |

| Material Range | Aluminum, Steel, Titanium, Plastics | Inconel, Hastelloy, PEEK, Ceramics |

| Max Work Envelope | 1000 x 600 x 500 mm | 800 x 500 x 400 mm (5-axis) |

This end-to-end process, governed by ISO 9001:2015 and AS9100D standards, transforms design intent into flawless physical reality. Wuxi Lead delivers not just parts, but guaranteed performance and unwavering reliability through engineering discipline at every stage. Your zero-defect requirement is our operational mandate.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Mill Service Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a global leader in high-end CNC milling services, we specialize in transforming complex engineering concepts into flawless, production-ready components. Our advanced manufacturing capabilities, combined with decades of technical expertise, make us the preferred partner for industries where tolerances matter most—medical, aerospace, automation, and high-performance industrial equipment.

Our state-of-the-art facility in Wuxi, China, is equipped with a full range of 3-axis, 4-axis, and 5-axis CNC milling centers, enabling us to handle everything from rapid prototyping to high-volume production runs. Every process is governed by ISO 9001:2015 standards, ensuring consistent quality, traceability, and on-time delivery. Whether you’re developing a single prototype or scaling up to thousands of precision-machined components, our team provides end-to-end support—from design consultation and material selection to finishing and logistics.

We understand that your success depends on more than just tight tolerances. It depends on partnership. That’s why we assign a dedicated project engineer to every client, ensuring seamless communication, real-time updates, and rapid response to design changes or production challenges. Our customer-first approach extends beyond the shop floor—we integrate with your development cycle, offering Design for Manufacturability (DFM) feedback to reduce costs, improve performance, and accelerate time-to-market.

By choosing Wuxi Lead Precision Machinery, you gain access to a vertically integrated manufacturing ecosystem. We control every step in-house, from CNC milling and turning to surface treatments like anodizing, plating, and precision grinding. This integration eliminates third-party delays, enhances quality control, and gives you a single source of accountability.

Our technical capabilities are matched by our global service commitment. We ship precision-machined parts to clients across North America, Europe, and Asia with consistent lead times and full customs documentation support. Whether you’re an R&D team in California or a Tier-1 supplier in Germany, we are structured to meet your operational requirements.

Below are key specifications that define our CNC milling service performance:

| Specification | Capability |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis milling |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Material Compatibility | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin, and more |

| Typical Tolerances | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance) |

| Surface Finish | As low as Ra 0.4 µm (polished), standard Ra 3.2 µm |

| Production Volume | Prototypes to 100,000+ units annually |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, CMM reporting |

Your next breakthrough component starts with the right manufacturing partner. Contact us today at [email protected] to discuss your CNC milling requirements. Let Wuxi Lead Precision Machinery become an extension of your engineering team—driving precision, performance, and progress.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.