Technical Contents

Engineering Guide: Cnc Mill Components

Engineering Insight Precision as the Non-Negotiable Foundation of CNC Mill Components

In high-performance manufacturing, the precision of individual CNC mill components dictates the ultimate functionality, reliability, and lifespan of the entire assembly. Tolerances measured in microns are not merely specifications; they are critical engineering mandates ensuring seamless integration, optimal load distribution, thermal stability, and resistance to fatigue. A seemingly minor deviation in a spindle housing bore, linear guide rail mounting surface, or torque transmission spline can cascade into catastrophic system failure—causing vibration, accelerated wear, positional inaccuracy, or complete mechanical breakdown under operational stress. The cost of imprecision extends far beyond component replacement, encompassing unplanned downtime, compromised product quality, and significant reputational damage for the end-user. Achieving and consistently maintaining these exacting standards demands far more than advanced machinery; it requires deep metallurgical understanding, rigorous process control, and an ingrained culture of precision engineering excellence.

The consequences of inadequate component precision are severe in demanding applications. In aerospace assemblies, a fraction of a micron variance in a turbine blade root slot can unbalance rotating masses, leading to destructive harmonic resonance. Within semiconductor manufacturing equipment, sub-micron inaccuracies in stage components directly translate to wafer misalignment and yield loss. Even in high-volume automotive production, inconsistent clutch housing dimensions result in transmission noise, vibration, and premature failure. Precision CNC milling is the cornerstone process for mitigating these risks, transforming raw material into geometrically perfect elements that perform predictably under extreme conditions. This necessitates mastery over every variable: cutting tool dynamics, thermal compensation, material stress relief, and real-time in-process measurement.

Wuxi Lead Precision Machinery operates at this uncompromising threshold of accuracy. Our decades of experience machining mission-critical components for Olympic infrastructure projects—where structural integrity and dimensional stability under dynamic loads are paramount—and classified military systems—requiring absolute reliability in harsh environments—forge our engineering philosophy. We understand that tolerances are not targets but absolute boundaries. Below are representative capability benchmarks demonstrating our commitment to exceeding standard industry precision:

| Parameter | Standard Commercial Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Dimensional | ±0.05 mm | ±0.003 mm |

| Geometric (Flatness) | 0.1 mm | 0.005 mm |

| Geometric (Concentricity) | 0.05 mm | 0.005 mm |

| Surface Finish (Ra) | 1.6 µm | 0.2 µm |

| Critical Feature Repeatability | ±0.02 mm | ±0.0015 mm |

This capability is institutionalized through our ISO 9001 and AS9100 certified processes, utilizing state-of-the-art multi-axis machining centers with sub-micron positioning accuracy, integrated CMM verification, and stringent environmental controls. Every component leaving our facility undergoes documented validation against the most demanding customer specifications. For engineers specifying CNC mill components where failure is not an option, partnering with a manufacturer whose precision pedigree is proven in Olympic venues and defense applications provides the essential assurance of performance and longevity. Precision is not our service; it is our fundamental engineering language.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Precision Mill Components

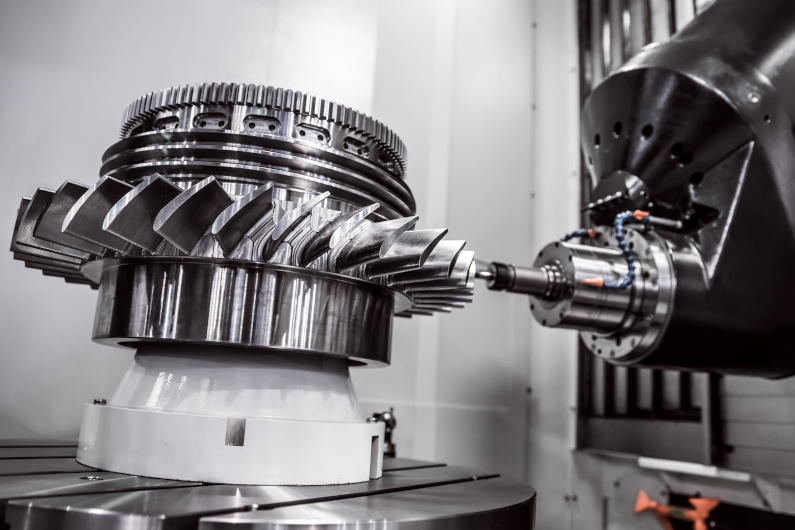

At Wuxi Lead Precision Machinery, our technical capabilities in precision CNC machining are anchored in state-of-the-art 5-axis CNC technology, enabling the production of highly complex and geometrically demanding mill components with exceptional accuracy and surface finish. Our 5-axis machining centers provide simultaneous movement across X, Y, Z, and two rotational axes (A and B), allowing for multi-faceted part processing in a single setup. This eliminates cumulative alignment errors, reduces cycle times, and enhances part consistency—critical for high-performance applications in aerospace, medical, energy, and advanced automation sectors.

Our machining platforms integrate high-speed spindles, rigid tooling systems, and real-time tool monitoring to maintain dimensional stability across diverse materials, including aluminum alloys, stainless steels, titanium, Inconel, and engineered plastics. The ability to approach features from multiple angles ensures optimal tool engagement, minimizing deflection and enabling intricate contouring, deep cavity milling, and undercuts that are unattainable with conventional 3-axis systems. This level of precision supports the production of mission-critical components such as impellers, turbine housings, valve bodies, and structural brackets requiring tight tolerances and superior surface integrity.

Complementing our advanced machining infrastructure is a rigorous quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Every component undergoes comprehensive dimensional verification using Zeiss and Hexagon CMM systems, capable of sub-micron measurement resolution. These systems generate full GD&T (Geometric Dimensioning and Tolerancing) reports, ensuring compliance with ISO 1101 and ASME Y14.5 standards. In-process inspections, first-article validation, and batch traceability are standard procedures, providing full transparency and audit readiness for our clients.

Our engineering team leverages integrated CAD/CAM software—Siemens NX, Mastercam, and SolidWorks—to simulate toolpaths, optimize cutting strategies, and validate programs prior to machining. This digital-first approach reduces setup time, prevents collisions, and ensures seamless transition from design to production. Additionally, we maintain strict environmental controls in our machining zones to minimize thermal drift, further enhancing dimensional repeatability.

The following table outlines our standard machining tolerances and process capabilities:

| Parameter | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm (standard), ±0.005 mm (tight) |

| Geometric Tolerance (GD&T) | ±0.01 mm (flatness, concentricity) |

| Surface Roughness (Ra) | 0.4 μm to 1.6 μm (standard finish) |

| Minimum Feature Size | 0.5 mm (milled details) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Material Compatibility | Metals, alloys, engineering plastics |

| Inspection Accuracy (CMM) | ±0.0025 mm |

Wuxi Lead Precision Machinery is committed to delivering CNC mill components that meet the highest benchmarks in precision, reliability, and repeatability. Our technical capabilities are designed not only to meet specifications but to exceed the functional demands of advanced industrial applications.

Material & Finish Options

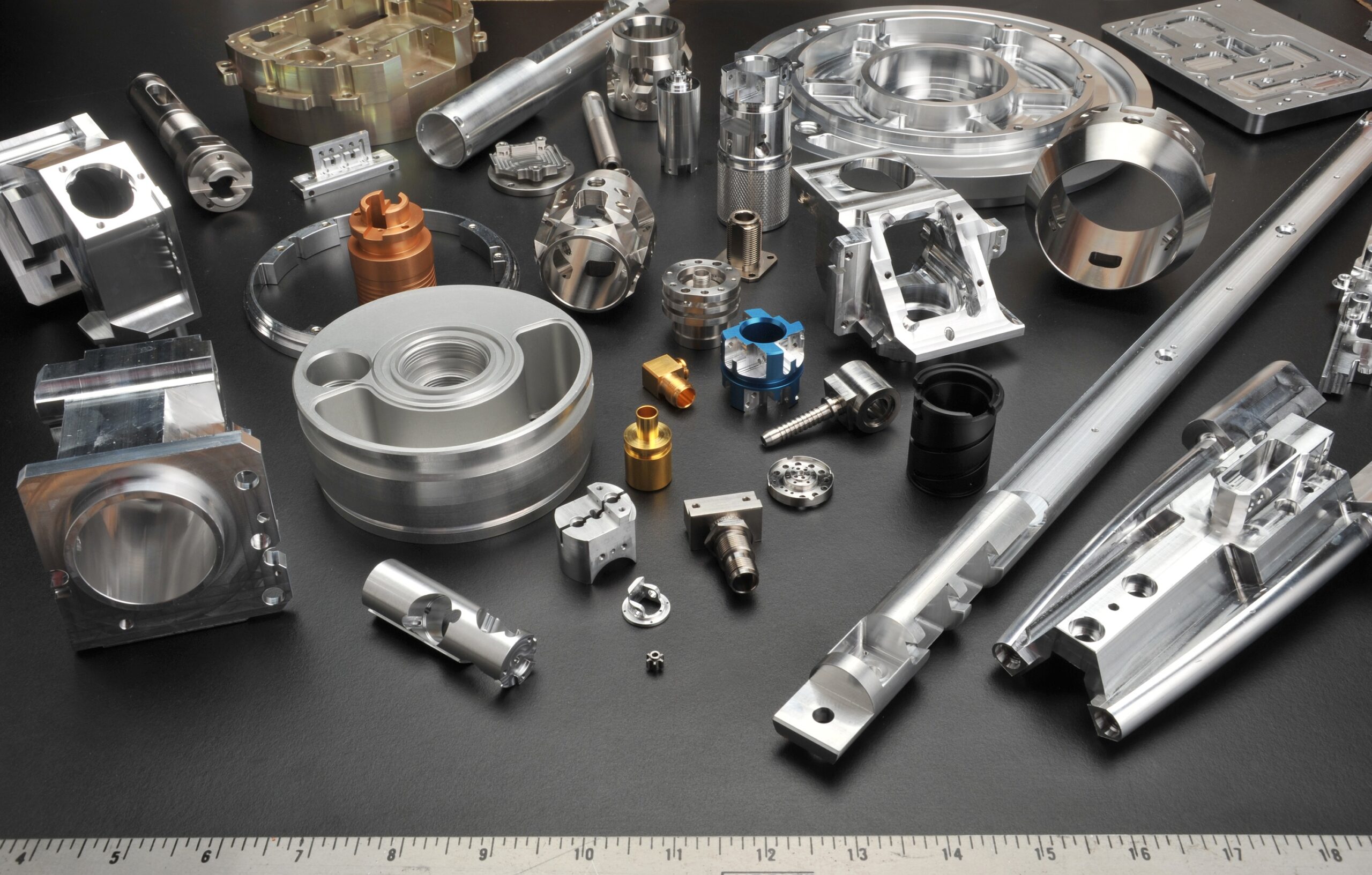

Material Selection for Precision CNC Mill Components

Material selection directly impacts component performance, longevity, and cost-efficiency in high-precision CNC milling. At Wuxi Lead Precision Machinery, we prioritize metallurgical compatibility with application demands, ensuring optimal machinability and end-use reliability. Below, we detail critical considerations for aluminum, steel, and titanium alloys, alongside anodizing finish specifications.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive sectors due to their exceptional strength-to-weight ratio and corrosion resistance. This grade offers excellent machinability, allowing for complex geometries with tight tolerances while minimizing tool wear. Its thermal conductivity suits heat-sensitive applications, though surface treatments like anodizing are essential for enhanced wear resistance in high-friction environments.

Steel variants such as 4140 and 17-4 PH provide superior hardness and fatigue strength for structural components in oil/gas or heavy machinery. 4140’s chromium-molybdenum composition enables deep hardening through heat treatment, critical for load-bearing parts. While machinability is moderate compared to aluminum, our optimized toolpaths and coolant strategies ensure micron-level accuracy without compromising edge integrity.

Titanium Ti-6Al-4V is indispensable in medical implants and aerospace where biocompatibility and extreme corrosion resistance are non-negotiable. Despite its low thermal conductivity and high reactivity—which challenge conventional milling—we leverage rigid machine setups and specialized carbide tooling to prevent galling and maintain surface integrity. Its density advantage over steel reduces weight in critical assemblies without sacrificing strength.

Anodizing remains the premier finish for aluminum components, transforming the surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing offers decorative and moderate wear protection with dye compatibility, while Type III (hard coat) delivers 50–100 μm thickness for severe abrasion resistance in hydraulic or marine applications. Both processes require stringent bath control and sealing—expertise we provide through certified finishing partners.

Material properties must align with functional requirements. The following table summarizes key specifications for common CNC mill substrates:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Machinability Rating | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 276–310 | 2.7 | 6061-T6, 7075-T6 | Excellent (A) | Enclosures, brackets |

| Alloy Steel | 655–1000 | 7.85 | 4140, 17-4 PH | Moderate (C) | Shafts, valves |

| Titanium | 900–950 | 4.43 | Ti-6Al-4V | Poor (E) | Implants, aircraft frames |

Selecting the right material-finish combination prevents premature failure and reduces lifecycle costs. Wuxi Lead Precision Machinery combines metallurgical analysis with decades of CNC milling experience to recommend solutions that balance performance, lead time, and budget. Partner with us to transform material science into precision-engineered reality.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful CNC mill component begins with meticulous design engineering. Our in-house team of mechanical engineers and CNC programming specialists collaborates closely with clients to translate technical concepts into manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, we develop 3D models and detailed technical drawings that define every geometric feature, tolerance, and surface finish requirement. During this phase, we conduct Design for Manufacturability (DFM) analysis to identify potential production challenges early, ensuring optimal material selection, toolpath efficiency, and cost-effectiveness. This proactive approach reduces risk and accelerates time-to-market while maintaining strict compliance with international standards including ISO 9001:2015 and AS9100 for aerospace-grade components.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to the prototyping stage—a critical checkpoint in our zero-defect strategy. Using high-precision 3-, 4-, and 5-axis CNC milling machines, we produce functional prototypes that mirror the final product in both form and function. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify dimensional accuracy and surface integrity. We also perform material verification and, when required, third-party testing for mechanical properties such as tensile strength and hardness. Client feedback is integrated at this stage, allowing for design refinement before committing to full-scale production. This iterative validation ensures that every specification is met and eliminates costly revisions downstream.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into mass production. Our automated CNC machining cells operate under strict process controls, with real-time monitoring of tool wear, spindle load, and environmental conditions to ensure consistency across batches. Statistical Process Control (SPC) is implemented throughout the production cycle, enabling early detection of variation and immediate corrective action. Each component is traceable through our digital manufacturing execution system (MES), recording machine parameters, inspection data, and operator logs. Final inspection includes 100% critical dimension checks and random sampling for non-critical features, all documented in a comprehensive First Article Inspection (FAI) report upon request.

CNC Milling Capabilities and Specifications

| Parameter | Specification |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm (custom down to Ra 0.2 µm) |

| Tolerance Range | ±0.01 mm (standard), down to ±0.003 mm (tight) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (PEEK, Delrin) |

| Production Capacity | 1 – 10,000+ units per order |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), AS9100 (aerospace) |

Our end-to-end process—from precision design to defect-free mass production—ensures that every CNC mill component delivered by Wuxi Lead Precision Machinery meets the highest standards of quality, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Mill Component Excellence

In the demanding landscape of precision manufacturing, your choice of machining partner directly impacts product performance, time-to-market, and operational reliability. Wuxi Lead Precision Machinery transcends the role of a standard supplier; we function as your strategic engineering ally, dedicated to solving complex production challenges through advanced CNC milling capabilities. With over 15 years of specialized expertise in high-tolerance components for aerospace, medical, and semiconductor sectors, we integrate rigorous process control with deep material science knowledge. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring every component meets the most stringent global requirements. When you partner with Lead Precision, you gain access to not just machinery, but a committed team focused on your success from prototype to high-volume production.

Our technical capabilities are engineered for mission-critical applications. The table below outlines core specifications achievable across our Haas and DMG MORI 5-axis milling platforms:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Tolerance Control | ±0.0002 inches (5 µm) | ASME Y14.5 |

| Surface Finish | Ra 0.4 µm to Ra 32 µm | ISO 21920-1 |

| Material Compatibility | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, PEEK, Tool Steels | ASTM/AMS |

| Max Work Envelope | 2000 x 1000 x 800 mm | |

| Repeatability (CpK) | ≥1.67 | ISO 22514-2 |

Beyond technical metrics, we address the operational pain points that disrupt your supply chain. Lead times are compressed through our dynamic scheduling system, reducing typical production cycles by 25% versus industry averages. Geometric Dimensioning and Tolerancing (GD&T) expertise is embedded in every engineering review, preventing costly misinterpretations of complex blueprints. Our in-house metrology lab, equipped with Zeiss coordinate measuring machines and optical comparators, provides full traceability with NIST-certified reports. For international clients, we manage seamless logistics including customs documentation and just-in-time delivery coordination to your assembly line.

The cost of component failure in high-stakes industries extends far beyond rework—it jeopardizes reputations and end-user safety. Wuxi Lead Precision Machinery eliminates this risk through proactive collaboration. Our engineers engage during your design phase to optimize manufacturability, reducing material waste and machining hours without compromising integrity. We implement real-time process monitoring with SPC data logging, providing transparency you can verify. This partnership model has enabled global clients to achieve 99.8% first-pass yield rates on components where failure is not an option.

Initiate a precision partnership that delivers measurable operational advantage. Contact our engineering team directly at [email protected] to discuss your specific component requirements. Include your project drawings or specifications for a tailored capability assessment within 24 business hours. Let Wuxi Lead Precision Machinery become the extension of your quality-focused manufacturing operation—where exacting standards meet unwavering execution. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.